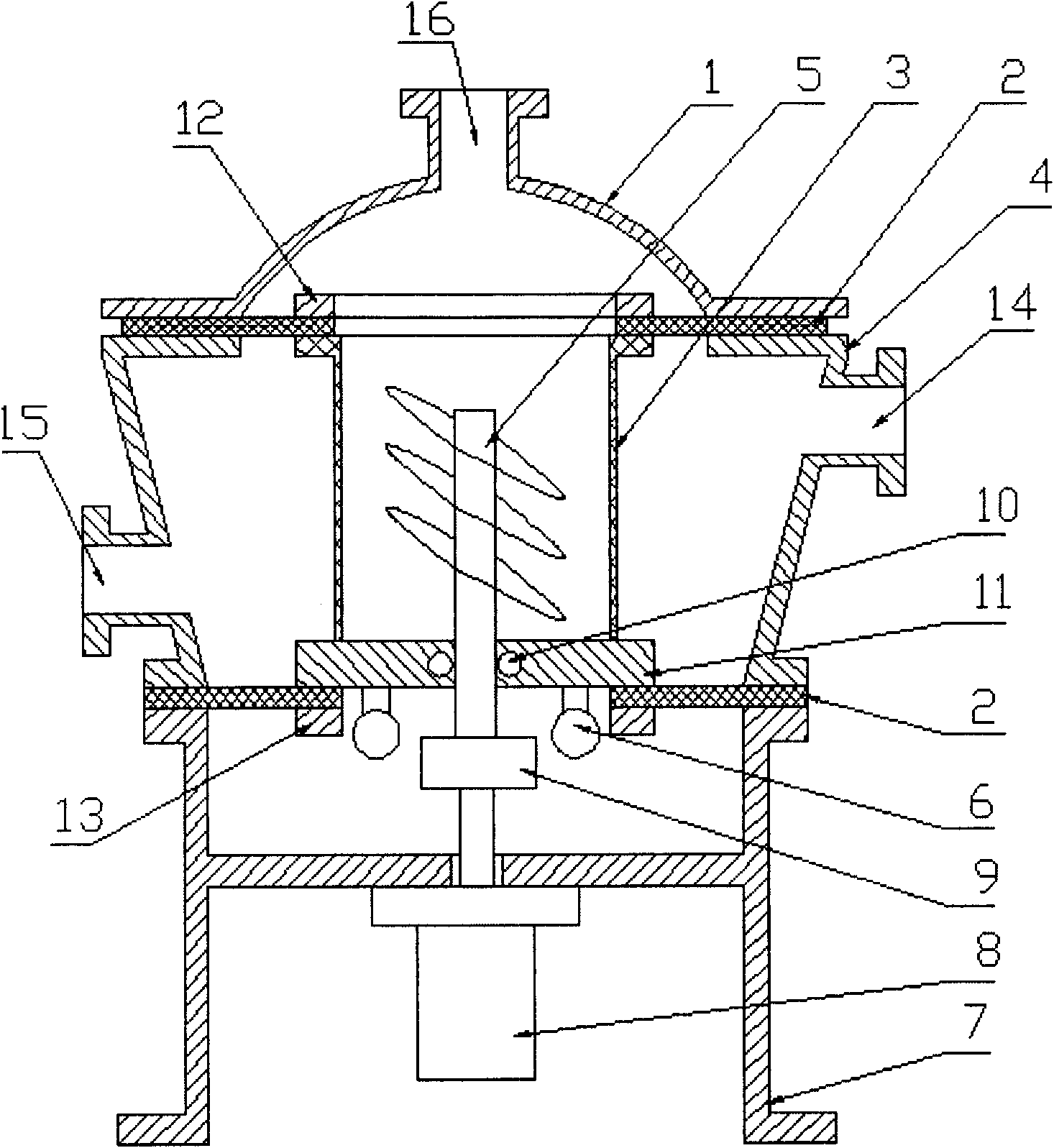

Liquid medium separation device

A separation device and liquid medium technology, applied in the direction of filtration separation, separation method, mobile filter element filter, etc., can solve the problems of complex manufacturing process, high failure rate and high installation accuracy requirements, and achieve the effect of overcoming complex manufacturing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The separation device has a cylindrical screen 3, and the cylindrical screen 3 is installed on the circular supporting plate 11, and the upper flange 12 and the lower flange 13 respectively install two elastic diaphragms 2 on the circular supporting plate 11. The bottom surface of the bottom surface and the upper mouth of the cylindrical screen 3, the spiral impeller shaft 5 is installed in the center of the cylindrical screen 3 through the circular support plate 11 and the upper flange 12, and the mechanical high-frequency vibration device 6 Installed at the bottom of the circular support plate 11, the above-mentioned components are installed in the center of the shell through the elastic diaphragm 2 above and below the cylindrical screen 3, and installed on the top of the base 7, and the motor 8 is installed and fixed at the center of the bottom of the base 7 On the shaft, the flexible coupling 9 is connected to the screw shaft 5 , and the upper cover 1 is fixed to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com