Automatic return gear for motor of intelligent electronic type contactless one-way rotary windscreen wiper

A one-way rotation, automatic return technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., to overcome the effect of heavy structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will now be described in further detail in conjunction with the accompanying drawings and preferred embodiments. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

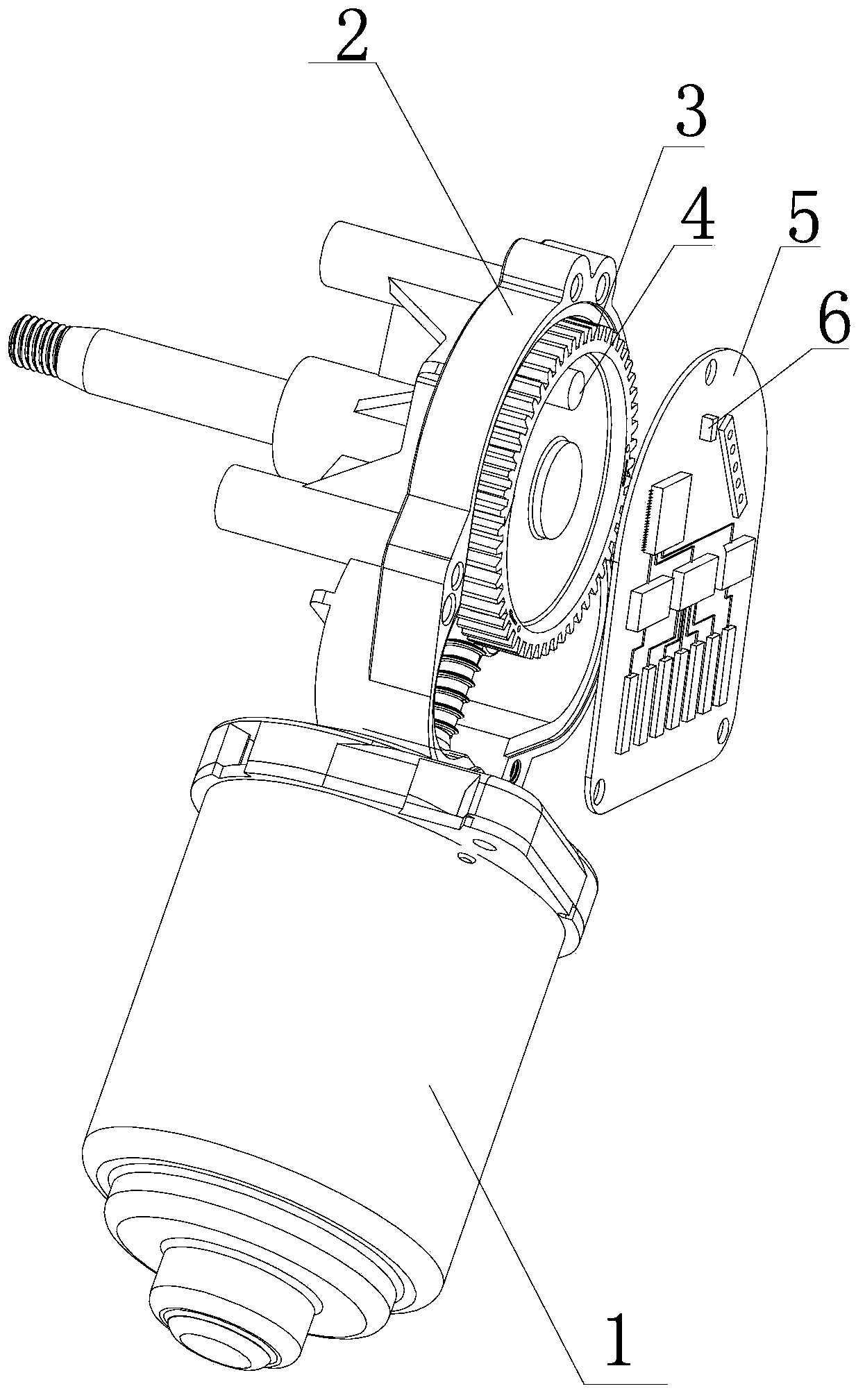

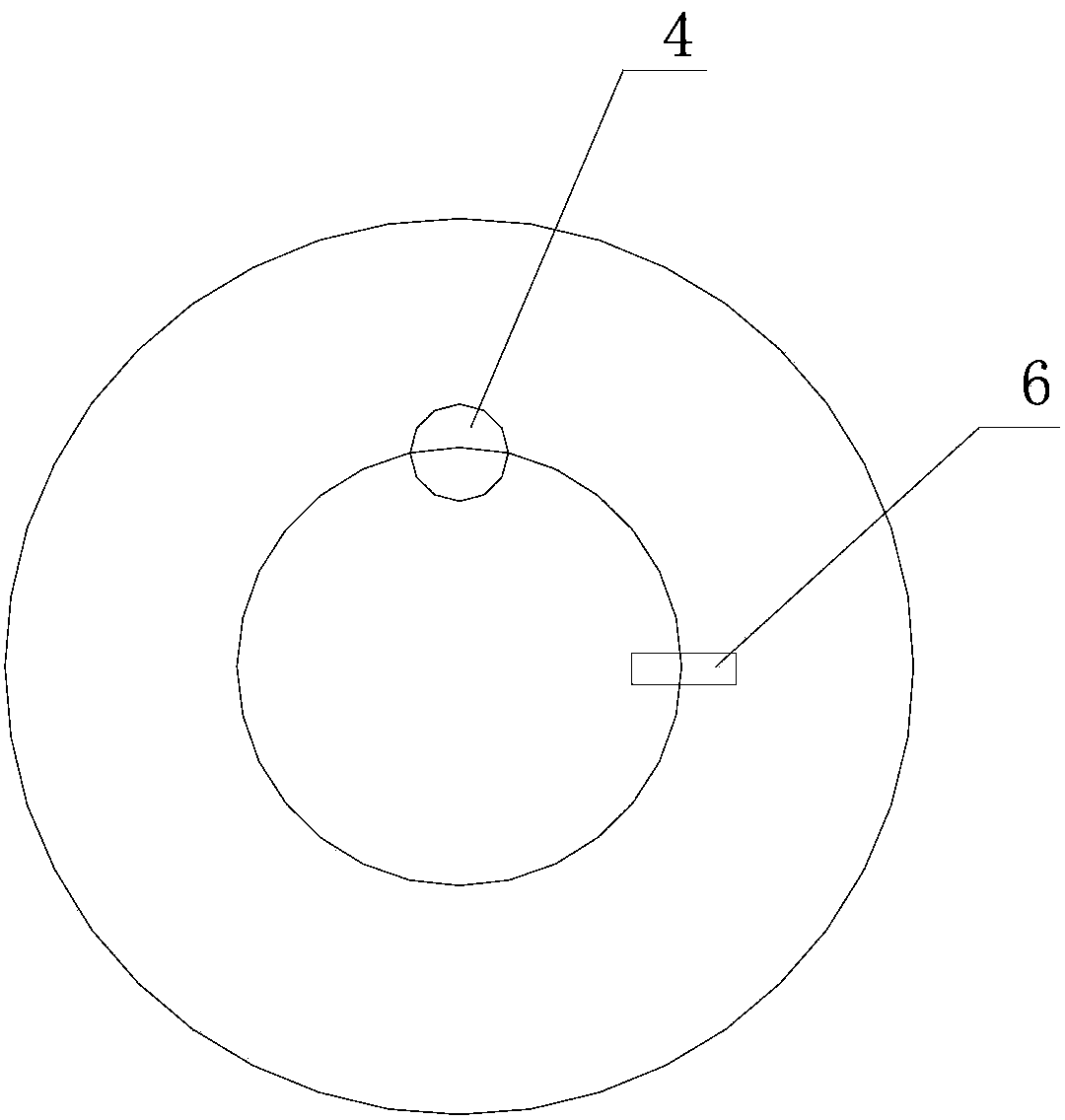

[0011] The present invention is an embodiment of an electronic non-contact one-way rotating intelligent wiper motor automatic return gear, the gear 3 is installed on the end cover 2 of the motor body 1, and the gear 3 is embedded with a A circular magnetic steel 4, a circuit board 5 is fixed above the gear 3 and there is a gap between the gear 3 and the circuit board 5, and a Hall switch 6 is arranged on the circuit board 5. The Hall switch 6 is installed on the opposite side of the circuit board 5 and the circular magnetic steel 4 circumferential line on the gear 3. When the gear 3 rotates with the motor, it passes directly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com