Hydraulic adjusting frame structure of forging press

A technology for adjusting frames and forging presses, applied in forging/pressing/hammering machinery, forging/pressing/hammer devices, manufacturing tools, etc., can solve the problems of low adjustment accuracy, slow adjustment, complex structure, etc., and achieve fast adjustment speed , easy maintenance, overcome the effect of complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

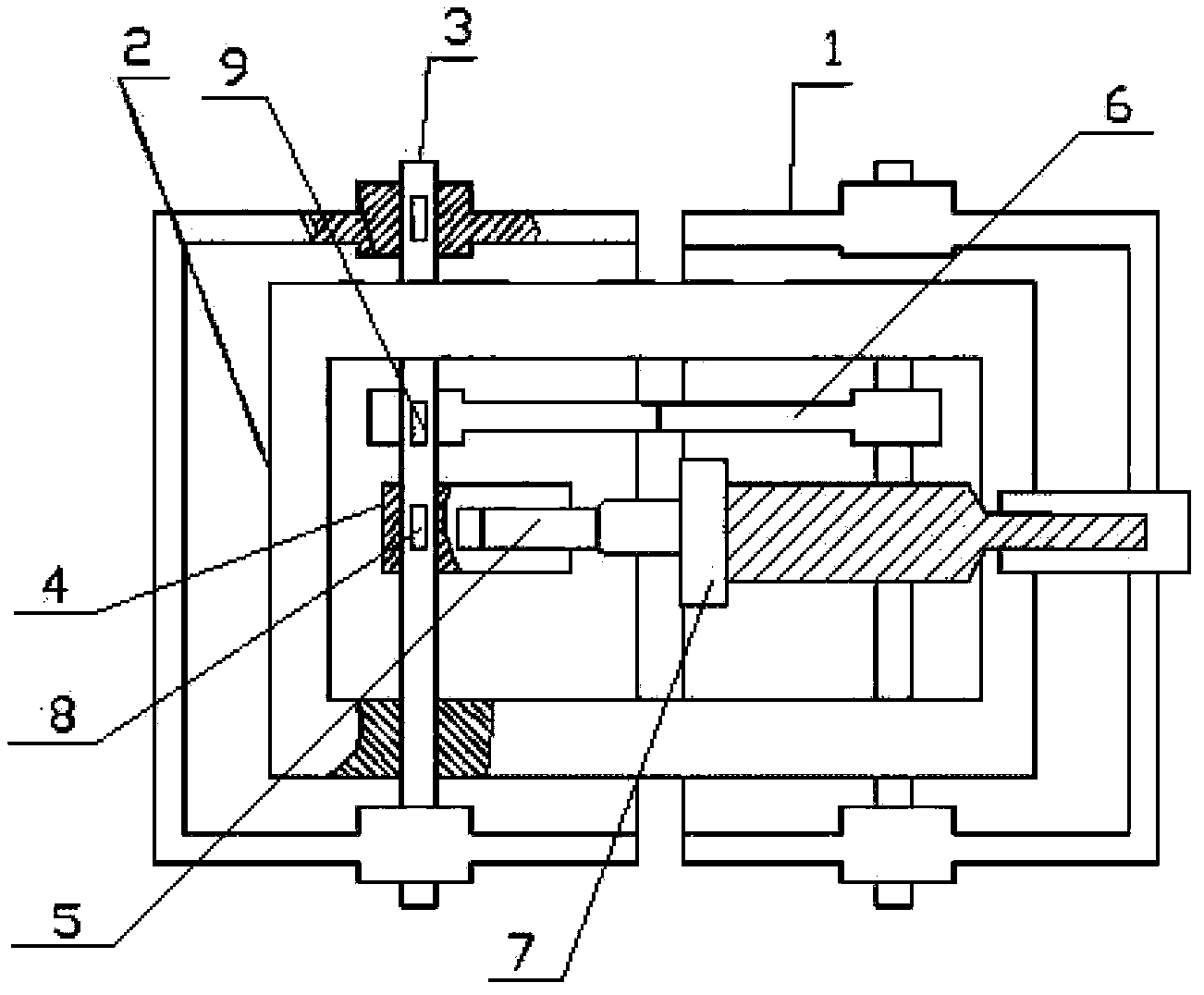

[0010] The structure of the hydraulic adjustment frame has a transmission frame (2), and a rotating arm (4) and a gear (6) are installed in the inner cavity of the transmission frame (2), and positioning devices are respectively arranged on the rotating arm (4) and the gear (6). Key (8) and gear positioning key (9), pass the rotating shaft (3) through each shaft hole of the mechanism body (1), transmission frame (2), rotating arm (4) and gear (6) in turn and the mechanism The other end of the body (1) is connected and fixed by the positioning key (8) and the gear positioning key (9), and the cylinder body of the hydraulic cylinder (7) is hinged to the rotating arm (4) with the pin shaft (5). , and the other end is connected with the mechanism body (1).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com