Plastic module chain assembly provided with dirt discharge groove

A plastic and component technology, applied in conveyors, shackles, packaging, etc., can solve the problems of low operation efficiency, accelerated wear of shaft pin holes, high cost, and achieve the effect of improving operation efficiency, reducing maintenance costs and extending service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

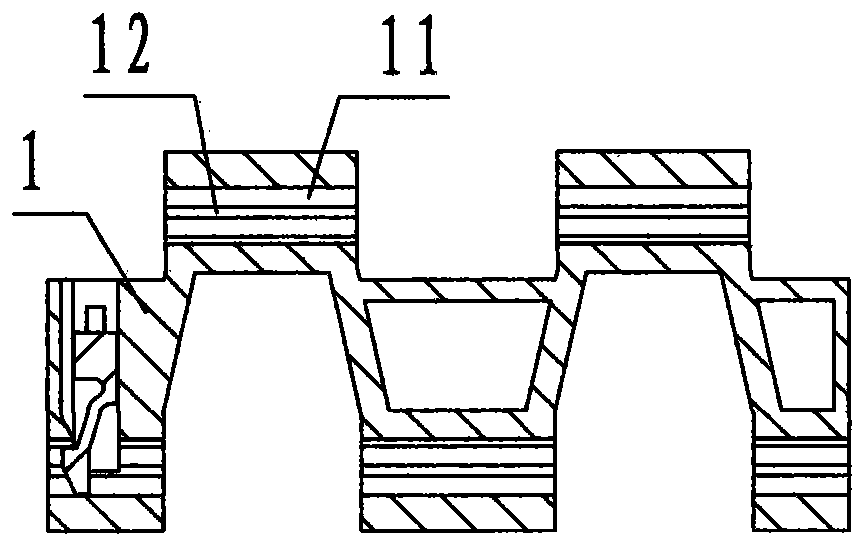

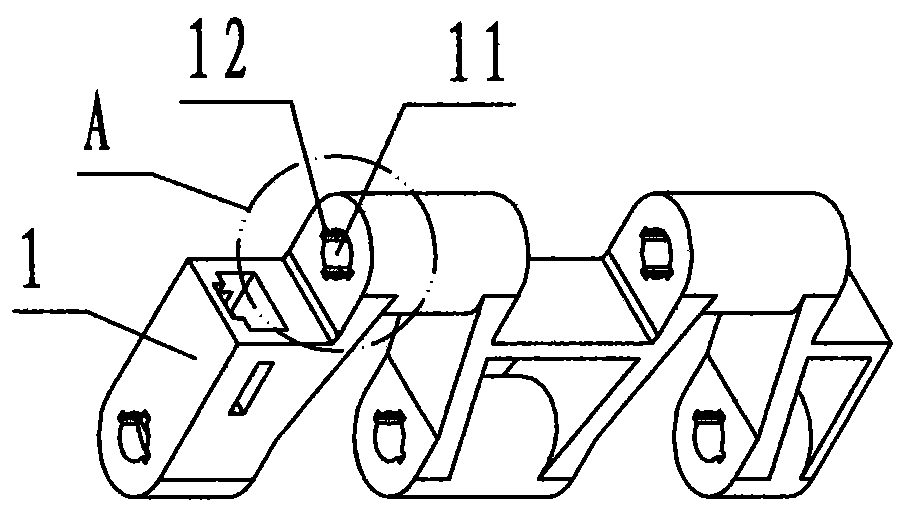

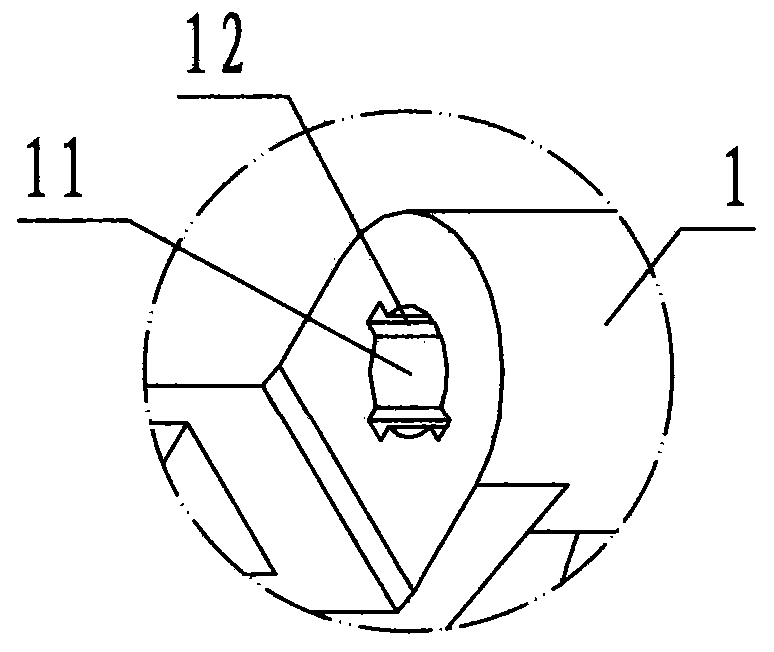

[0021] refer to Figure 1 to Figure 7 , a plastic modular chain assembly provided with a scale discharge tank of the present invention, comprising a D module chain 1 and a Z module chain 2, wherein: when the D module chain 1 is spliced to form a chain belt conveyor belt, it is used to close the conveyor belt The plastic quality module chain elements at the left and right ends, the shaft pin holes used for connection of the D module chain 1 are called D shaft pin holes 11, and the D shaft pin holes 11 are circular through holes in the left and right directions; the D shaft pins The front and back of the inner wall of the hole 11 and the side wall facing the D center are provided with a left-right direction and a rectangular cross-section through groove called D scale discharge tank 12, and the D-center is the center line facing the left and right direction of the D module chain 1 the direction of

[0022] The Z module chain 2 is a plastic module chain element used for splici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com