Novel friction clutch for walking tractor

A walking tractor, friction clutch technology, applied in the direction of friction clutch, mechanical drive clutch, clutch, etc., can solve the problems of high cost, inconvenient installation and maintenance, poor safety, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

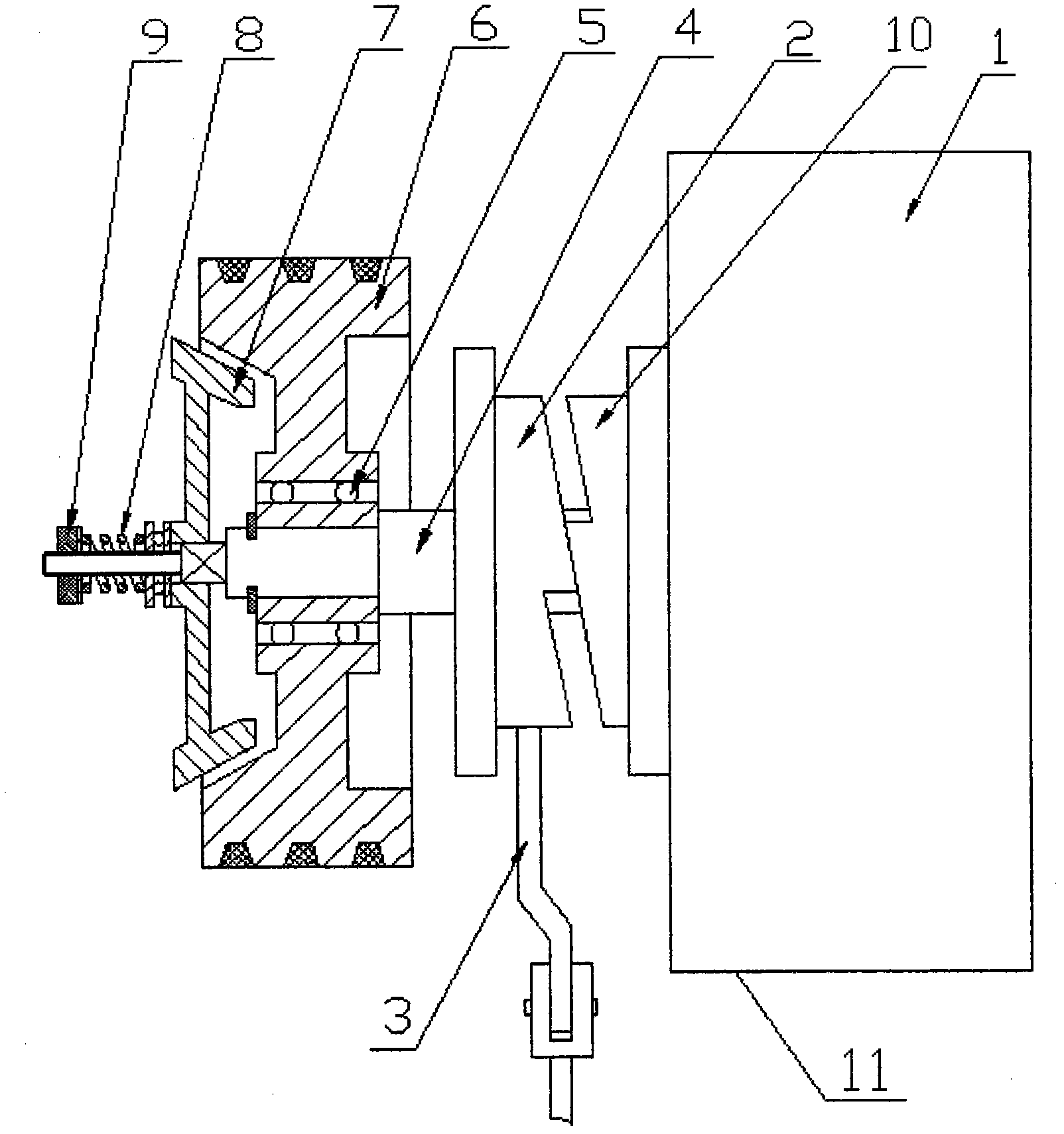

[0008] The cone-disc friction clutch has a fixed fitting slope 10, which is installed on the transmission shaft 4 on one side of the gearbox 1; the rotatable fitting slope 2 is installed on the transmission shaft 2 opposite to the fixed fitting slope 10 , the joystick 3 is connected with the rotatable fitting inclined surface 2; the flywheel 6 is installed on the drive shaft 4 outside the rotatable fitting inclined surface 2 through the bearing 5, and the outer side of the flywheel 6 has an inner cone made, and the driving disc 7 is a cone Its taper is the same as the inner cone surface on the inside of the flywheel 6, and the driving disc 7 is installed on the transmission shaft 4 outside the flywheel 6 through a spline; the compression spring 8 is installed on the transmission shaft 4 outside the driving disc 7, and the nut 9 will compress The spring 8 is installed on the transmission shaft 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com