M-xylylenediamine type semi-aromatic polyamide and preparation method thereof

A m-xylylenediamine type and m-xylylenediamine technology, which is applied in the m-xylylenediamine type semi-aromatic polyamide and its preparation field, can solve the problems of increased nylon polymerization energy consumption, low production efficiency, environmental hazards, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

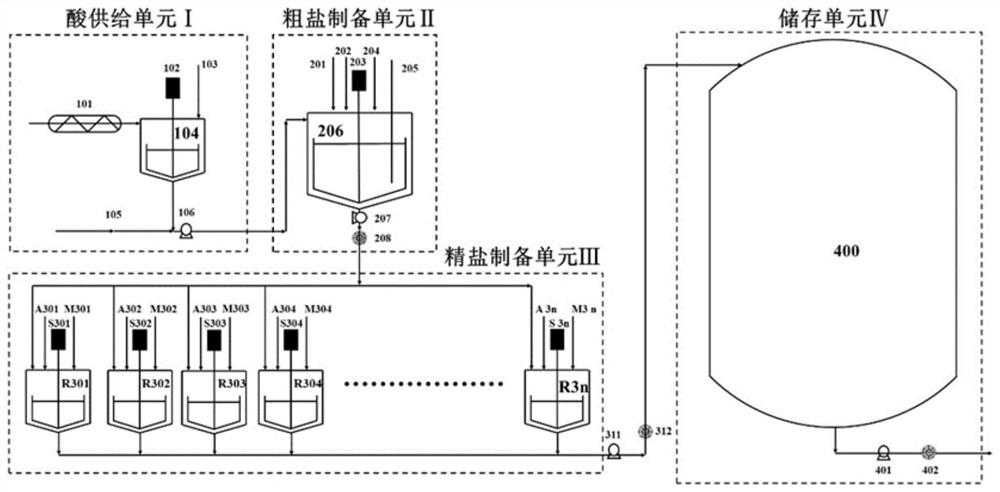

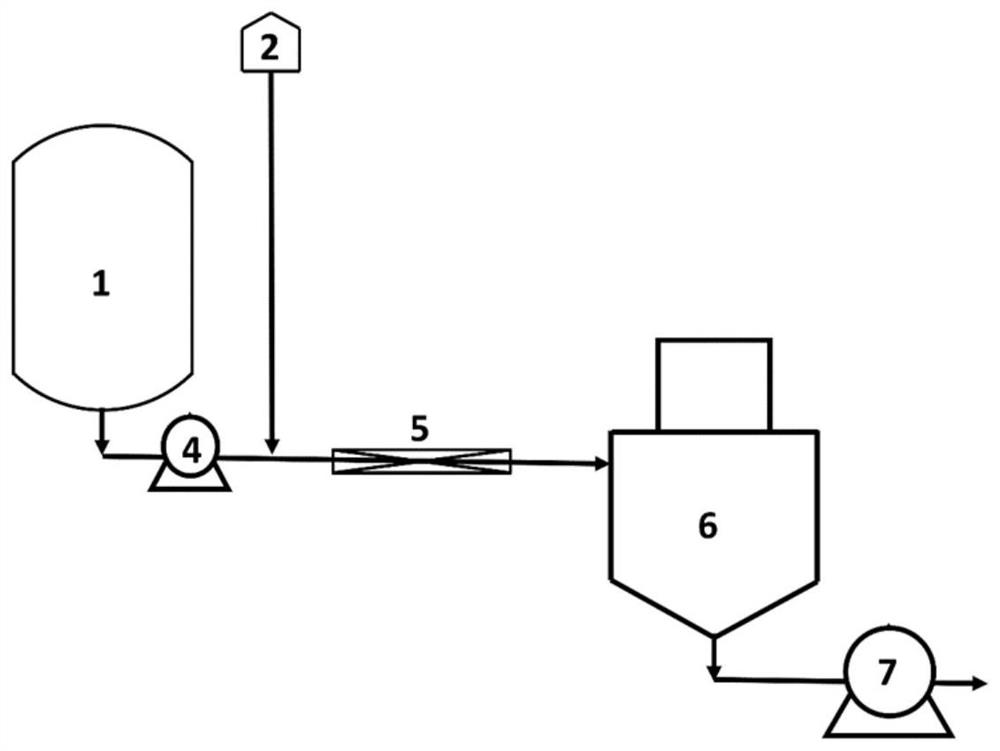

[0067] The method for preparing MX salt solution (salt-forming method for short) of the present invention mainly uses semi-aromatic diamine MXDA and one or more dibasic acid aqueous solutions to directly mix to prepare a stable semi-aromatic polyamide salt solution.

[0068] The salt-forming method of the present invention comprises performing a salt-forming reaction with one or more dibasic acid aqueous solutions and m-xylylenediamine to prepare MX salt solution.

[0069] In the present invention, the salt-forming reaction of the MX salt solution is carried out under the protection of stirring and inert gas (such as nitrogen).

[0070] In some embodiments, the salt-forming method of the present invention comprises the following steps:

[0071] (1) providing an aqueous dispersion of dibasic acid;

[0072] (2) mixing the aqueous dispersion of dibasic acid and MXDA to obtain m-xylylenediamine type semi-aromatic nylon coarse salt solution (referred to as coarse salt solution); ...

Embodiment 1

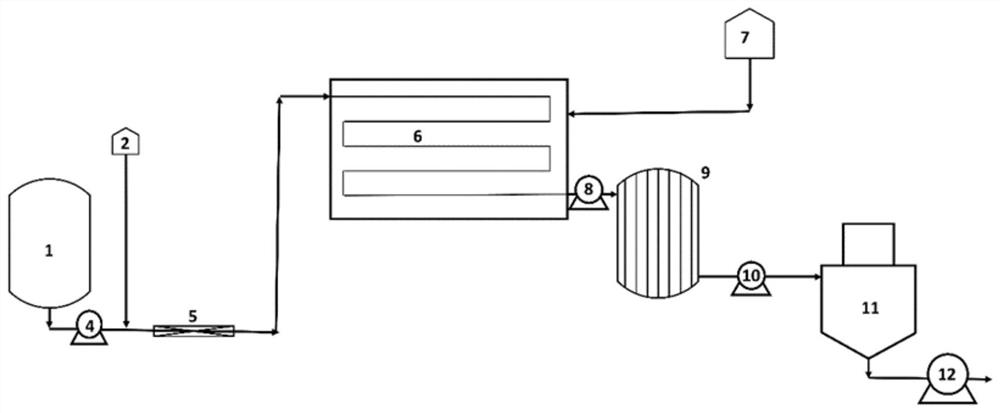

[0143] In this example, m-xylylenediamine and adipic acid were used as raw materials, and the salt-forming device of Equipment Example 1 and the continuous polymerization device of Equipment Example 2 were used to prepare MXD6 nylon by a continuous method.

[0144] First, each tank is evacuated with high-purity nitrogen, and 500 kg of adipic acid and 420 kg of desalted water are prepared in the acid supply unit I to form an aqueous dispersion of adipic acid. Transport to coarse salt preparation unit II through pump 106, and inject m-xylylenediamine into crude salt reactor 206 through m-xylylenediamine pipeline 201 in coarse salt preparation unit II, and control by pH detection device 205 and feedback adjustment system, the addition of m-xylylenediamine is controlled to form a crude salt solution with a pH of 4.5. At this time, the temperature in the crude salt reactor is 140° C., and the crude salt concentration is 64 wt%.

[0145] The crude salt solution is injected into the ...

Embodiment 2

[0150] In this example, m-xylylenediamine, adipic acid and sebacic acid were used as raw materials, and the salt-forming device of Equipment Example 1 and the continuous polymerization device of Equipment Example 2 were used to prepare MXD6-MXD10 copolymerized nylon by a continuous method.

[0151] First, each tank is evacuated with high-purity nitrogen, and 450kg of adipic acid, 50kg of sebacic acid and 500kg of desalinated water are prepared in the acid supply unit I to form a diacid aqueous dispersion. Transport to coarse salt preparation unit II through pump 106, and inject m-xylylenediamine into crude salt reactor 206 through m-xylylenediamine pipeline 201 in the coarse salt preparation unit, and pass pH detection device 205 and feedback adjustment control system , controlling the addition of m-xylylenediamine to form a crude salt solution with a pH of 4.9, at this time the temperature in the crude salt reactor was 130° C., and the crude salt concentration was 61 wt%.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com