Aluminum modified acidic silica sol and preparation method thereof

An acid silica sol, aluminum modification technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve problems such as instability of silica sol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Preparation of sodium metaaluminate solution: 60 mg of sodium metaaluminate was weighed and dissolved in 60 L of pure water.

[0033] (2) getting particle diameter is 6~15nm, concentration is 30% alkaline silica sol 50kg, through 50kg cation exchange resin (001 * 7 type) reaction obtains acidic silica sol, pH is 2.3, is heated under the situation of stirring to 100°C, keep stirring, the stirring speed is 150rpm / min, add the sodium metaaluminate solution obtained in step (1) dropwise at a flow rate of 20L / h, the addition amount is 0.12wt%, the concentration is 0.10wt%, and the reaction is 24h to obtain aluminum-modified silicon Sol;

[0034] (3) Adjust the sol obtained in step (2) with 160 mL of acetic acid to a pH of 4.0 to obtain an aluminum-modified acidic silica sol.

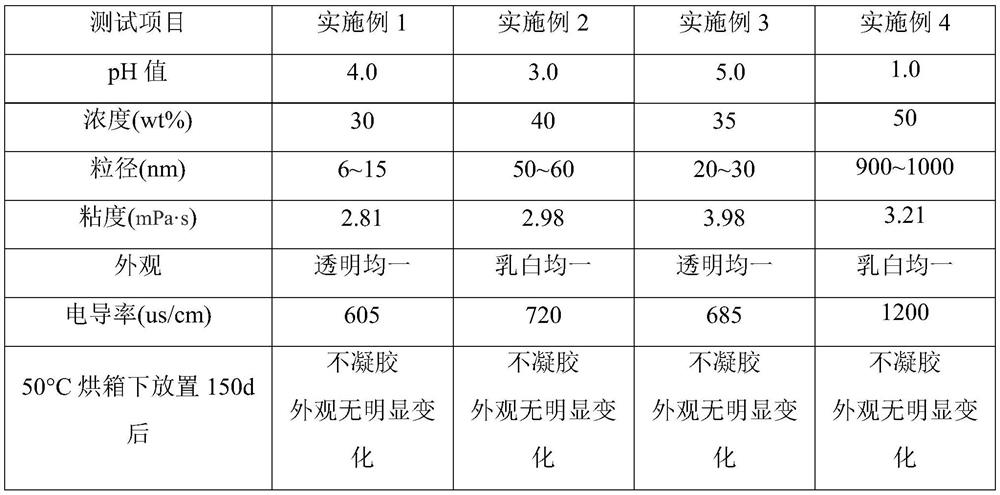

[0035] The test results of each parameter are shown in Table 1.

Embodiment 2

[0037] (1) Preparation of sodium metaaluminate solution: 80 mg of sodium metaaluminate was weighed and dissolved in 8 L of pure water.

[0038] (2) get particle diameter and be 50~60nm, concentration is 50kg of alkaline silica sol of 40%, react acidic silica sol through 35kg cation exchange resin (Lewatit-100 type), pH is 2.0, under the situation of stirring, be heated to 105°C, keep stirring, the stirring speed is 100rpm / min, add the sodium metaaluminate solution obtained in step (1) dropwise at a flow rate of 3L / h, the addition amount is 0.16wt%, the concentration is 1wt%, and the reaction is 6h to obtain aluminum-modified silica sol ;

[0039] (3) Adjust the sol obtained in step (2) with 280 mL of acetic acid to a pH of 3.0 to obtain an aluminum-modified acidic silica sol.

[0040] The test results of each parameter are shown in Table 1.

Embodiment 3

[0042] (1) Preparation of sodium metaaluminate solution: 25 mg of sodium metaaluminate was weighed and dissolved in 250 mL of pure water.

[0043] (2) Take 50kg of alkaline silica sol with a particle size of 20-30nm and a concentration of 35%, react with 50kg of cation exchange resin (PC003 type) to obtain acidic silica sol, pH is 2.2, and heat to 100°C while stirring , keep stirring, the stirring speed is 120rpm / min, dropwise add the sodium metaaluminate solution obtained in step (1) at a flow rate of 0.1L / h, the addition amount is 0.05wt%, the concentration is 10wt%, and the reaction is 3h to obtain aluminum-modified silica sol;

[0044] (3) Adjust the sol obtained in step (2) with 100 mL of acetic acid to a pH of 5.0 to obtain an aluminum-modified acidic silica sol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com