A kind of pneumatic adjustment system of liquid phase deacidification equipment

A pneumatic adjustment and deacidification technology, which is applied to textiles and papermaking, papermaking, paper, etc., can solve the problems of low production efficiency, no real-time monitoring, and the impact of deacidification quality, so as to reduce work intensity, control pH value, and improve The effect of deacidification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

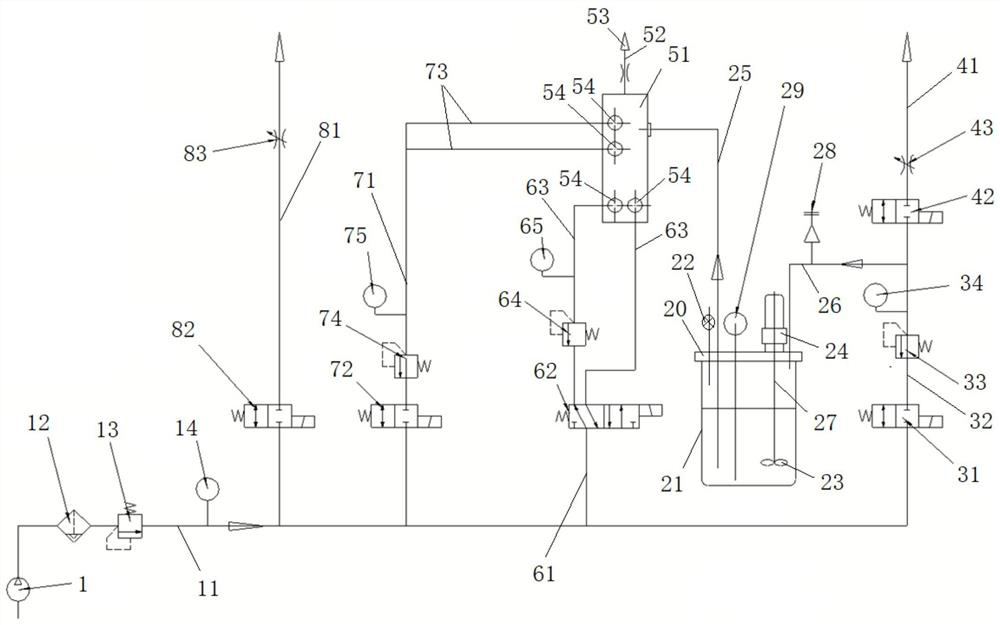

[0024] like figure 1 As shown, a pneumatic adjustment system of a liquid phase deacidification equipment includes an air source device 1, a first air pipe 11, a blowing device, a nozzle device, a nozzle atomization device, a nozzle opening and closing control device, a stirring tank device, and a stirring tank. Pressurizing device and mixing tank pressure relief device.

[0025] The air outlet of the air source device 1 is communicated with the air inlet end of the first air delivery pipe 11, and the air outlet end of the first air delivery pipe 11 is respectively connected to the blowing device, the spray nozzle atomization device, the nozzle opening and closing control device, and the stirring tank for pressurization. The device is connected, the nozzle device is respectively connected with the nozzle atomization device, the nozzle opening and closing control device and the stirring tank device, and the stirring tank pressurizing device and the stirring tank pressure relief ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com