Patents

Literature

49results about How to "Reduce the chance of bonding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for eliminating dioxins in flue gas

InactiveCN101249378ASimple processNo equipment bottleneckDispersed particle separationUreaEnvironmental chemistry

The invention relates to a method used for eliminating dioxin in fume. The method has the following steps that water solution containing substance of hydrazine type is sprayed into the fume containing dioxin or potentially containing dioxin so that the fume fully touches and reacts with the water solution, and the water in the solution is completely evaporated at the temperature above 160 DEG C. In this way, dioxin in the fume is eliminated. The water solution with hydrazine type substance is fresh solution prepared based on 0.05 percent to 1 percent by weight before use, and is sprayed into the fume with the temperature ranging from 200 DEG C to 600 DEG C, or into the fume with the temperature ranging from 600 DEG C to 850 DEG C. At the temperature ranging from 600 DEG C to 850 DEG C, the water in the water solution containing hydrazine can adopt urea or ammonia. At the temperature ranging from 200 DEG C to 600 DEG C, the water to dissolve hydrazine can adopt alkaline solution or urea solution in combination with purification of other noxious gases such as SOx and NOx by using a prior or a late established purification device or system, so that NOx and acidic gases in the fume are eliminated, and toxicant content in fly ash is reduced. By adopting the method, dioxin in the fume is eliminated without production of noxious byproducts. Throughout the course, no waste water or waste solid is produced; the concentration of dioxin in fly ash is reduced; the treating process is simple, and the cost of disposal is low.

Owner:TONGJI UNIV

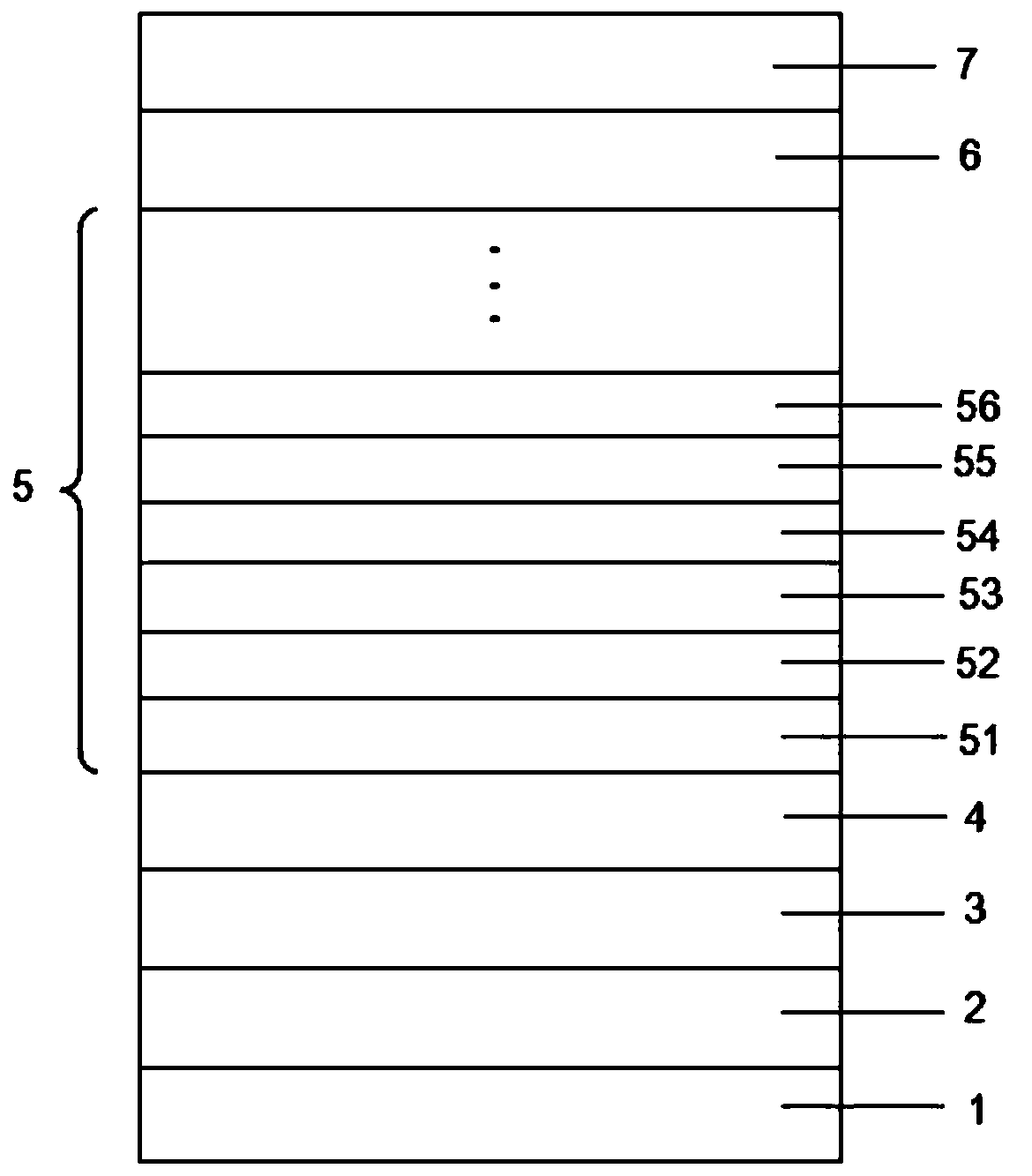

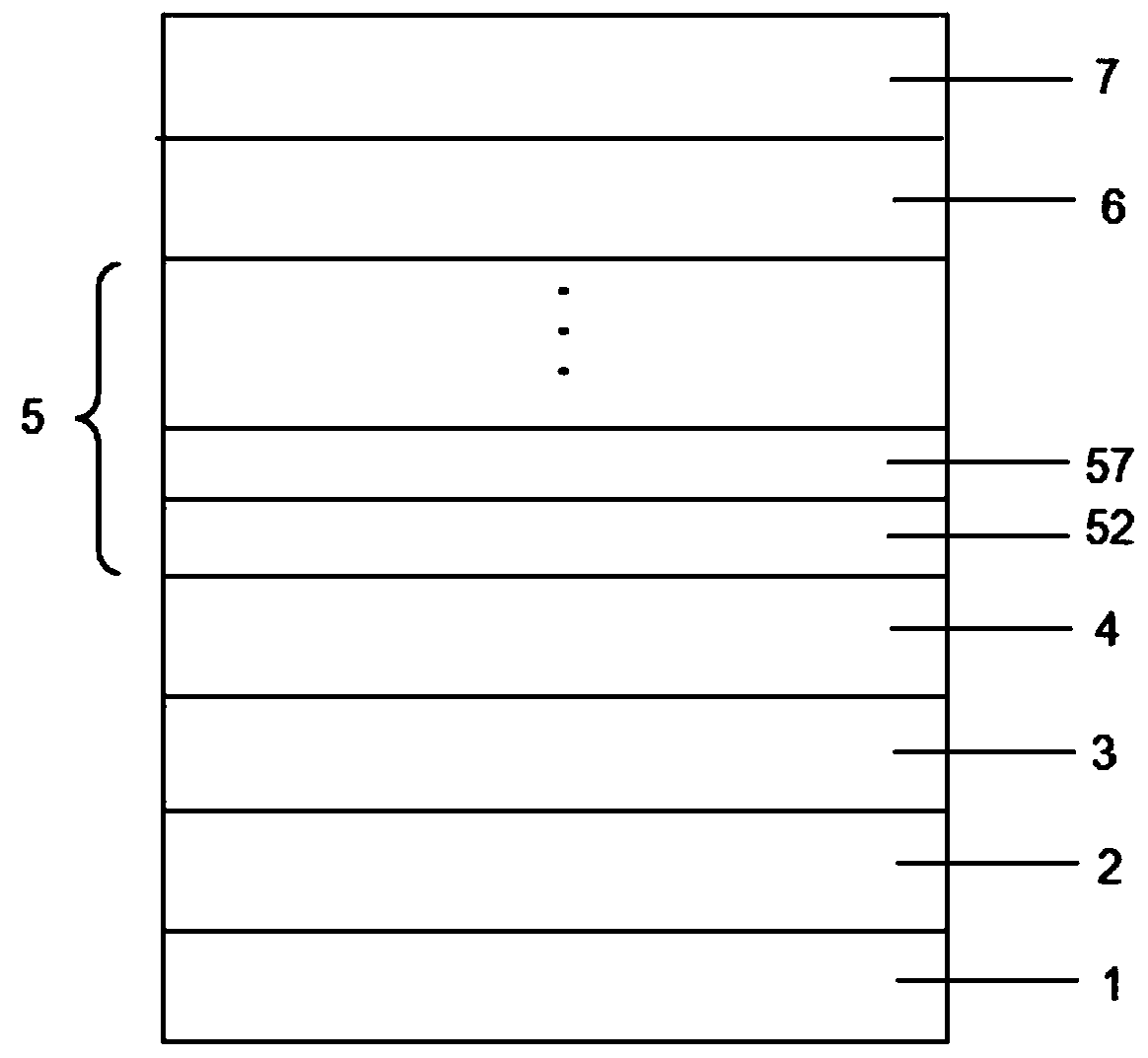

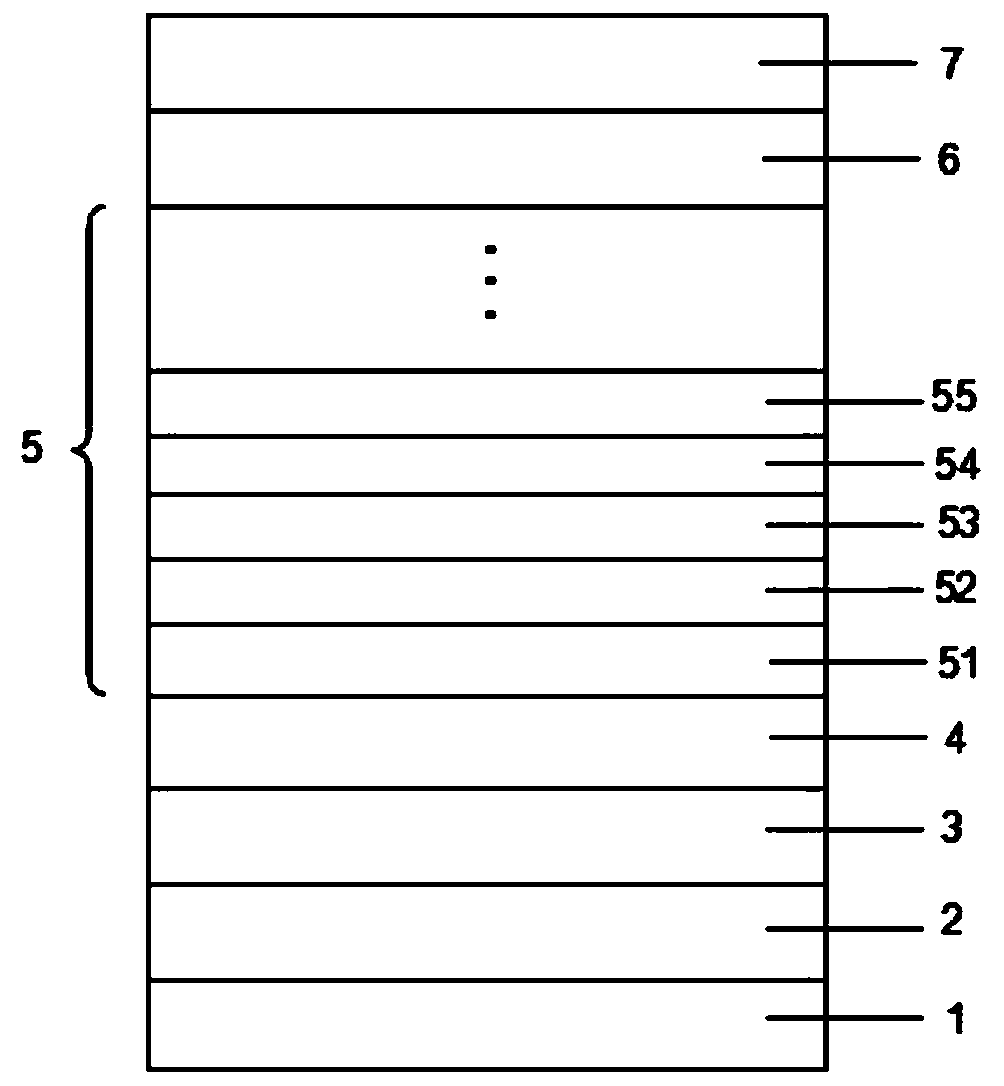

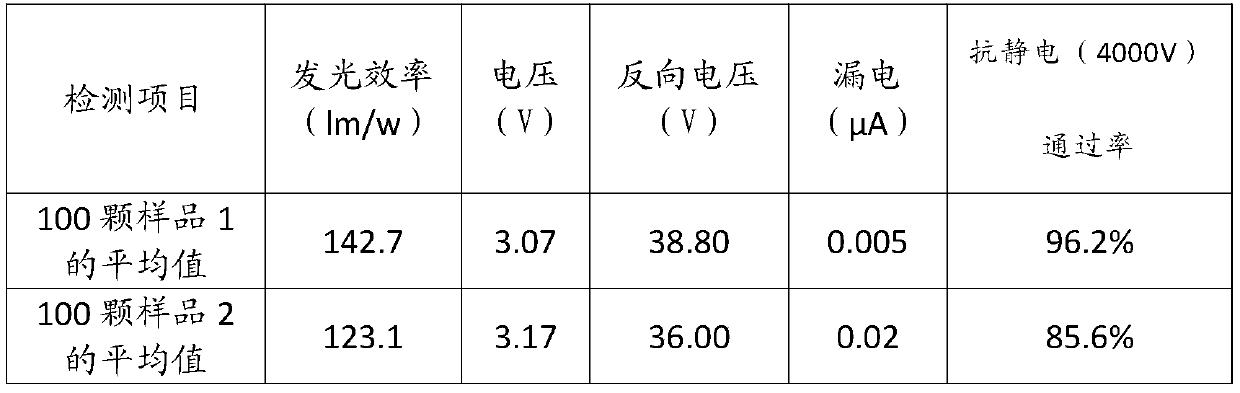

LED epitaxial growth method for improving radiation recombination efficiency

PendingCN111223764AImprove luminous efficiencyIncrease hole concentrationSemiconductor/solid-state device manufacturingChemical vapor deposition coatingElectron blocking layerMultiple quantum

The invention discloses an LED epitaxial growth method for improving radiation recombination efficiency. The method sequentially comprises the steps of processing a substrate, growing a low-temperature buffer layer GaN, growing an undoped GaN layer, growing a Si-doped N-type GaN layer, growing a multi-quantum well layer, growing an AlGaN electron blocking layer, growing a Mg-doped P-type GaN layerand cooling, wherein the step of growing the multi-quantum well layer sequentially comprises the sub-steps of growing an InGaN transition layer, growing an InGaN well layer, growing a doped gradientSiN layer, growing a doped gradient MgN layer, growing a GaN barrier layer doped with Mg in a linear gradient mode and growing an InAlN layer. According to the method, the problems of low quantum wellgrowth quality and low quantum well radiation recombination efficiency in the existing LED epitaxial growth method are solved, so that the luminous efficiency of the LED is improved.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

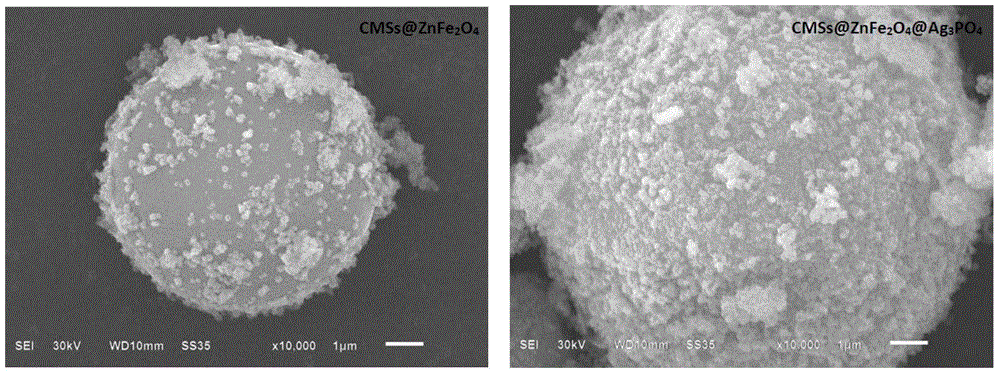

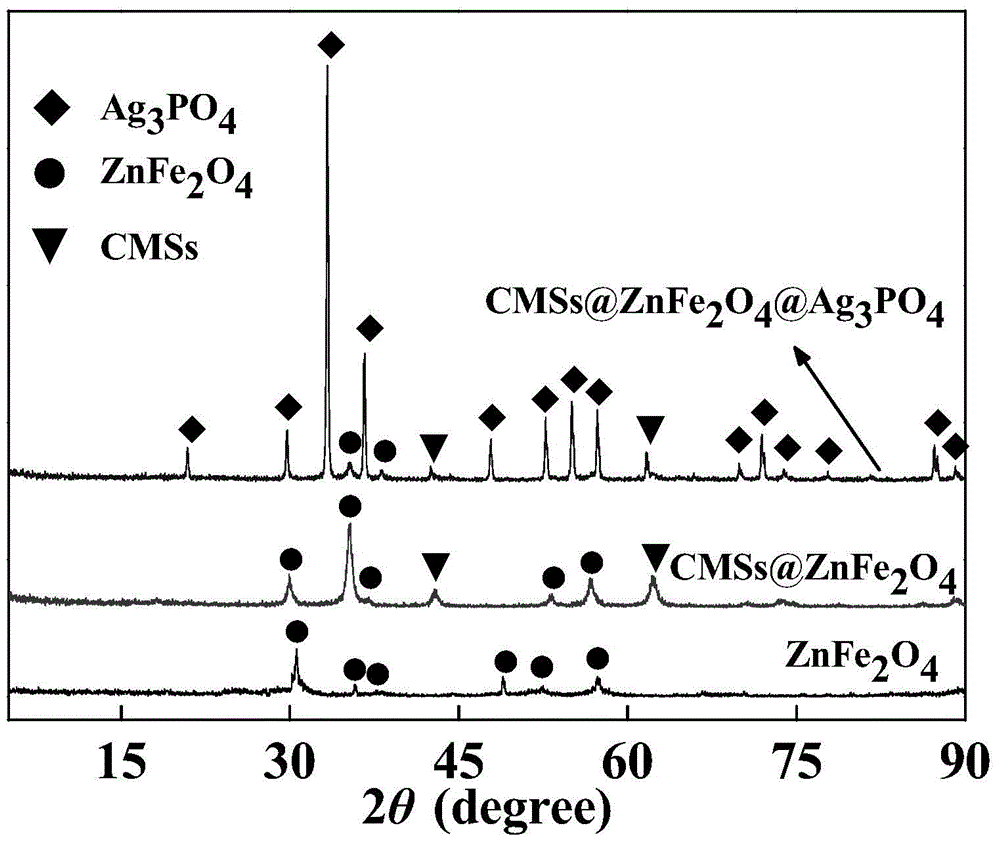

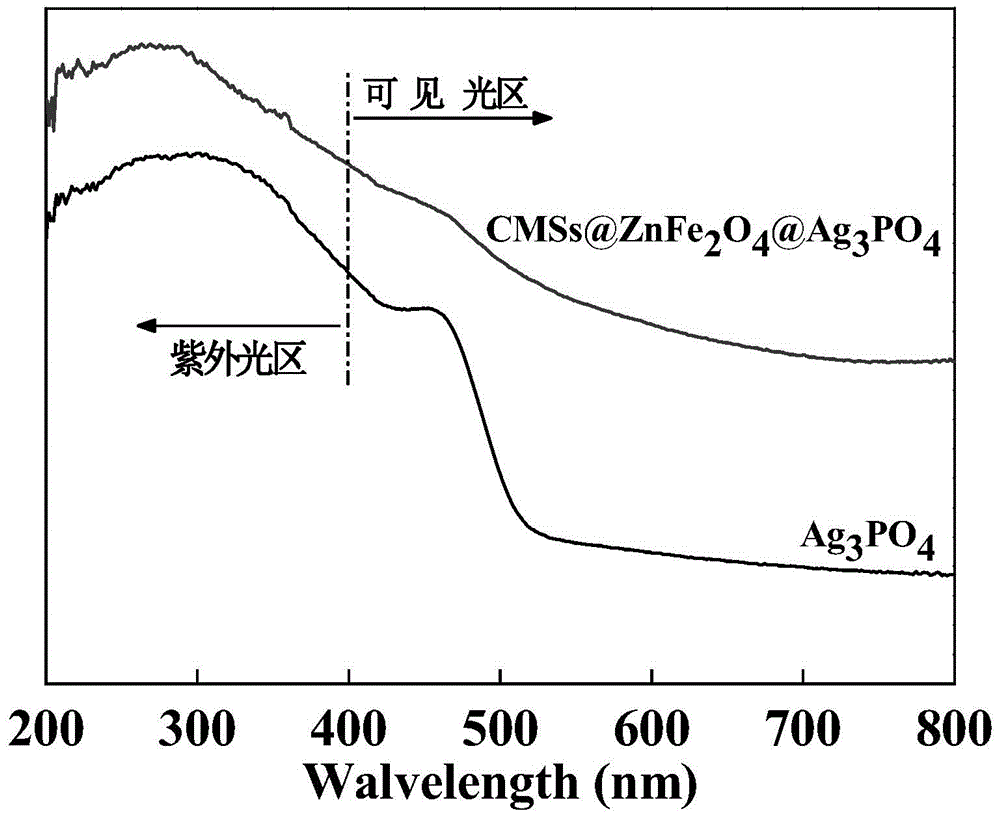

Visible-light responding type magnetic compound photocatalyst with core-shell structure and preparation method and application thereof

ActiveCN104437574AEasy to prepareEasy to operatePhysical/chemical process catalystsWater/sewage treatment by irradiationMicrosphereWastewater

The invention provides visible-light responding type magnetic compound photocatalyst carbon microspheres-zinc ferrite and silver phosphate (CMSs-ZnFe2O4 and Ag3PO4) with core-shell structures and a preparation method and application of the visible-light responding type magnetic compound photocatalyst carbon microspheres. The CMSs are used as cores, zinc ferrite and silver phosphate are sequentially loaded on the surface of the CMS by a solvothermal method and an in-situ precipitation method, therefore, the compound photocatalyst carbon microspheres-zinc ferrite and silver phosphate with the double core-shell structures is prepared. Compared with pure Ag3PO4, the prepared compound photocatalyst has the advantages of high visible light absorption strength, good magnetic separation property, strong photo corrosion resistance and the like, is applied to treatment of 2,4-dichlorophen non-biodegradable organic wastewater, has high removal rate of 96.56% for 20mg / L of 2,4-dichlorophen solution within 150min, and still has the removal rate up to 86.21% for the 2,4-dichlorophen solution after used repeatedly for four times.

Owner:XIANGTAN UNIV

Battery electrode paste composition

The invention relates to a battery electrode paste composition, containing a silane coupling agent-modified active substance, that contains a silane coupling agent-modified active substance, a conductive additive, an adhesive, and a maleimide additive. This composition may provide better battery safety and longer cycle life.

Owner:IND TECH RES INST

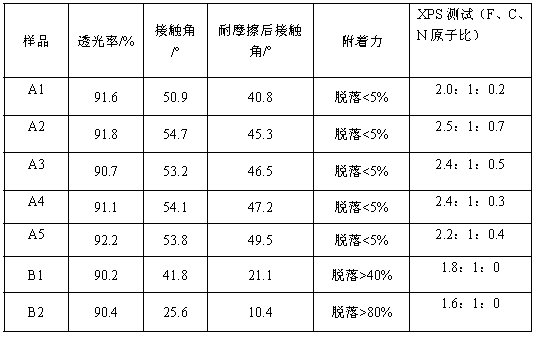

Preparation method for anti-fingerprint film and anti-fingerprint film prepared by method

ActiveCN103031528AImproves the effect of oil stainsImprove bindingVacuum evaporation coatingSputtering coatingChemistryTransmittance

The invention provides a preparation method for an anti-fingerprint film and the anti-fingerprint film prepared by the method, the method employs magnetron sputtering to form the anti-fingerprint film on the surface of a base material, the target material employed by the magnetron sputtering is a fluorine containing organic matter, a reaction gas is filled in a process of the magnetron sputtering, and the reaction gas is a mixed gas of CF4 and N2. The anti-fingerprint film prepared by the method contains three elements of F, C and N, and the ratio of fluorine to carbon is greater than or equal to 2:1. The high ratio of fluorine to carbon makes the film to have excellent antifouling effect, and the film has the characteristics of high light transmittance, strong adhesive force and good wear resistance. The anti-fingerprint film is suitable for a touch screen with a large size.

Owner:BYD CO LTD

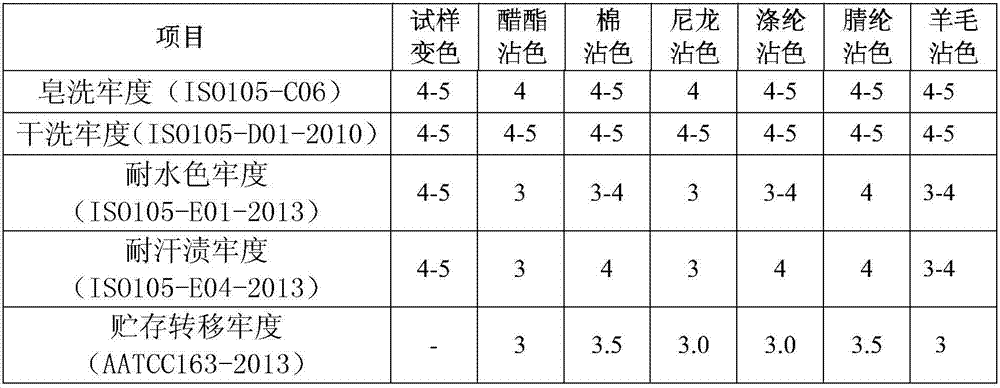

Rubbing fastness improving finishing process of deep color cotton and blended fabric thereof

ActiveCN105625060AReduce swellingReduce the chance of bondingLiquid/gas/vapor removalDyeing processRubbingSulfonic acid ester

The present invention provides a rubbing fastness improving finishing process of a deep color cotton and a blended fabric thereof. According to the present invention, a fabric is subjected to a color fixation treatment with an aromatic sulfonic acid condensate, drying is performed, and finishing is performed with a slightly-turbid-state rubbing fastness improving working liquid containing a cationic aqueous polyurethane compound, such that the dry rubbing fastness and the wet rubbing fastness of the good hydrophilicity deep color cotton and the blended fabric thereof can achieve more than or equal to grade 3, and the difficult problem that the rubbing fastness is difficult improved through the conventional processing process is effectively solved.

Owner:DYMATIC CHEM

High lead-antimony slag type for anode slime smelting process and its use method

ActiveCN101403040AReduce chemical corrosionReduce the amount of dilutionProcess efficiency improvementSmelting processPrecious metal

The invention relates to a high lead-antimony slag type which is used for smelting technique of anode mud and is used by the anode mud in the process of reduction smelting of an oxygen bottom blowing bullion lead furnace in the technique that an oxygen bottom blowing furnace smelts the anode mud and a using method, belonging to the scope of separation and extraction of precious metal and base metal; a formula thereof is the high lead-antimony slag type with low silicon, low calcium and low sodium; all the materials comprises the following ingredients according to mass ratio: 5 to 22 percent of SiO2, 1 to 8 percent of FeO, 0 to 6 percent of Na2O, 0 to 5 percent of CaO, 10 to 35 percent of PbO and 150 to 45 percent of Sb2O3, wherein, the control range of the mass ratio of the PbO and SiO2 is 1.50 to 6.0. The formula not only has good effect for prolonging the service life of a refractory material and improving the continuous operation rate and processing capacity of the bullion lead, but also leads the reduction and volatilization of arsenic and antimony and oxidation and slag formation of lead to be realized simultaneously, reduces the usage of flux and consumption of fuel and effectively separates the valuable metals.

Owner:HENAN YUGUANG GOLD & LEAD

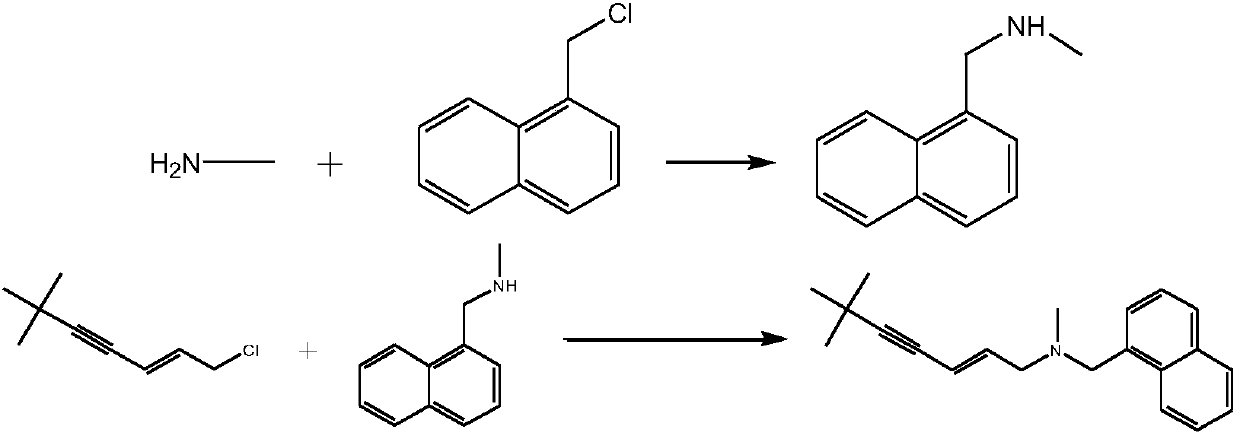

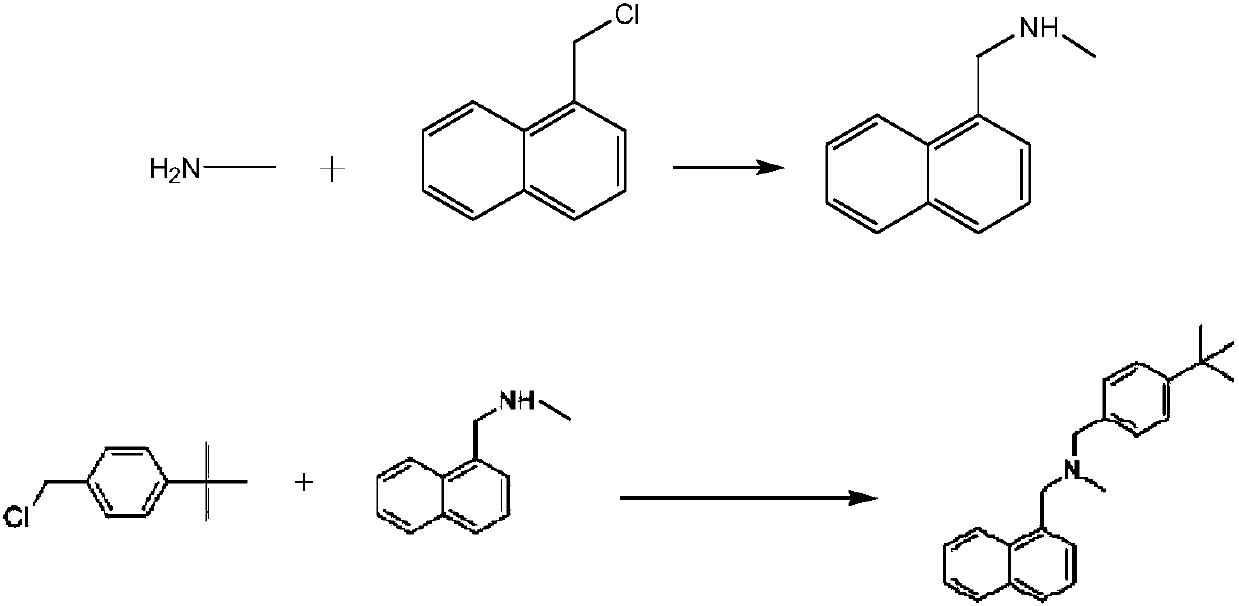

Synthetic method of terbinafine

ActiveCN108017544AHigh yieldOvercome yieldAmino preparation by functional substitutionOrganic layerAlkyne

The invention provides a synthetic method of terbinafine. Monomethylamine, 1-chloromethyl naphthalene and 1-chloro-6,6-dimethyl-2-heptene-4-alkyne are subjected to a one-step reaction to generate theterbinafine. Particularly, the monomethylamine is slowly added into a solvent, and then an acid-binding agent is added; the 1-chloromethyl naphthalene and the 1-chloro-6,6-dimethyl-2-heptene-4-alkyneare simultaneously slowly dropwise added, and a dropwise adding speed is controlled so as to enable both the 1-chloromethyl naphthalene and the 1-chloro-6,6-dimethyl-2-heptene-4-alkyne to be simultaneously dropwise added up; a temperature control reaction is performed for 2 to 3 hours at a temperature of 10 to 20 DEG C; chloroform is added to extract reaction liquid, vacuum concentration is carried out on an organic layer to a dry state, and ethyl acetate is added into residues to carry out crystallization to obtain the terbinafine. The synthetic method is high in yield, simple in step and convenient to operate, generates few byproducts, and is beneficial to industrial production.

Owner:SHANDONG BOYUAN PHARM CO LTD

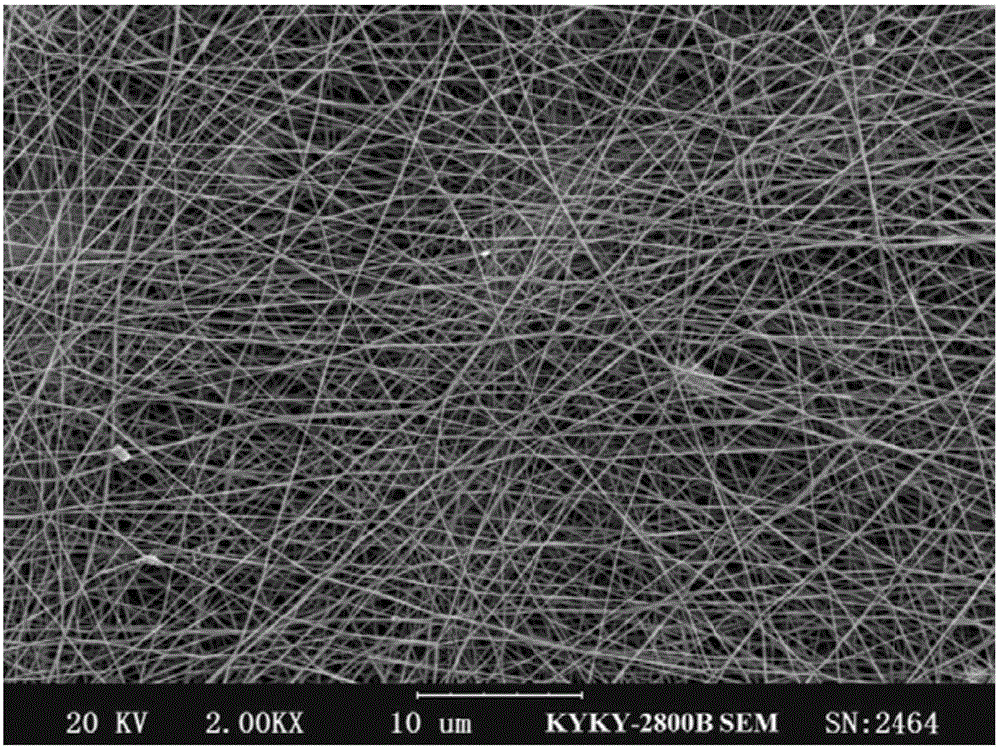

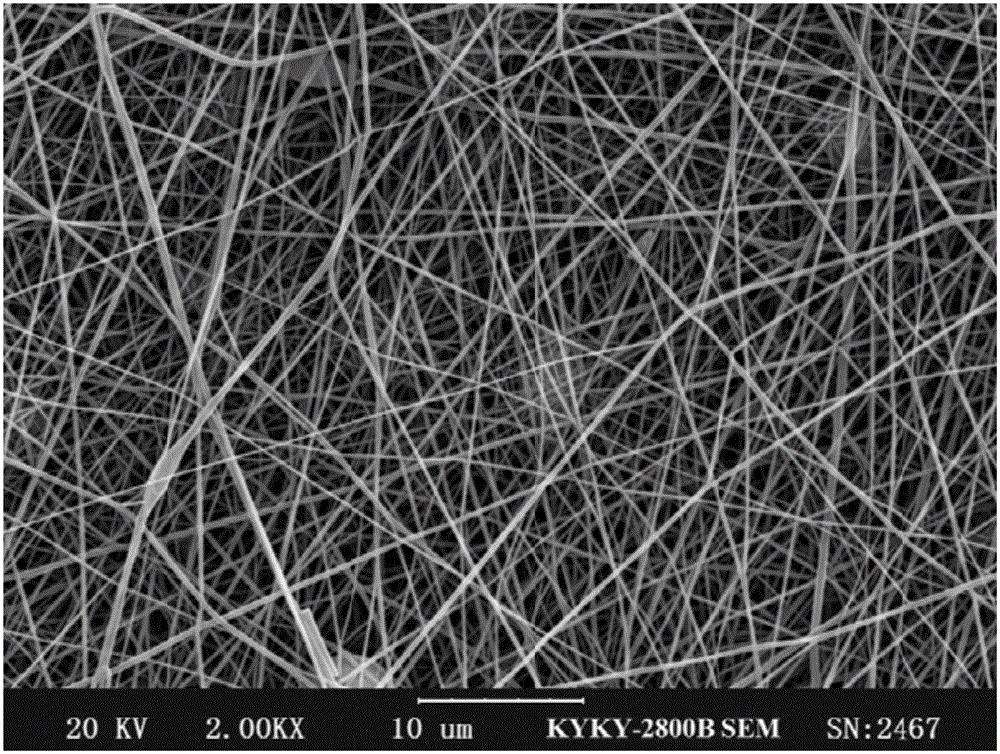

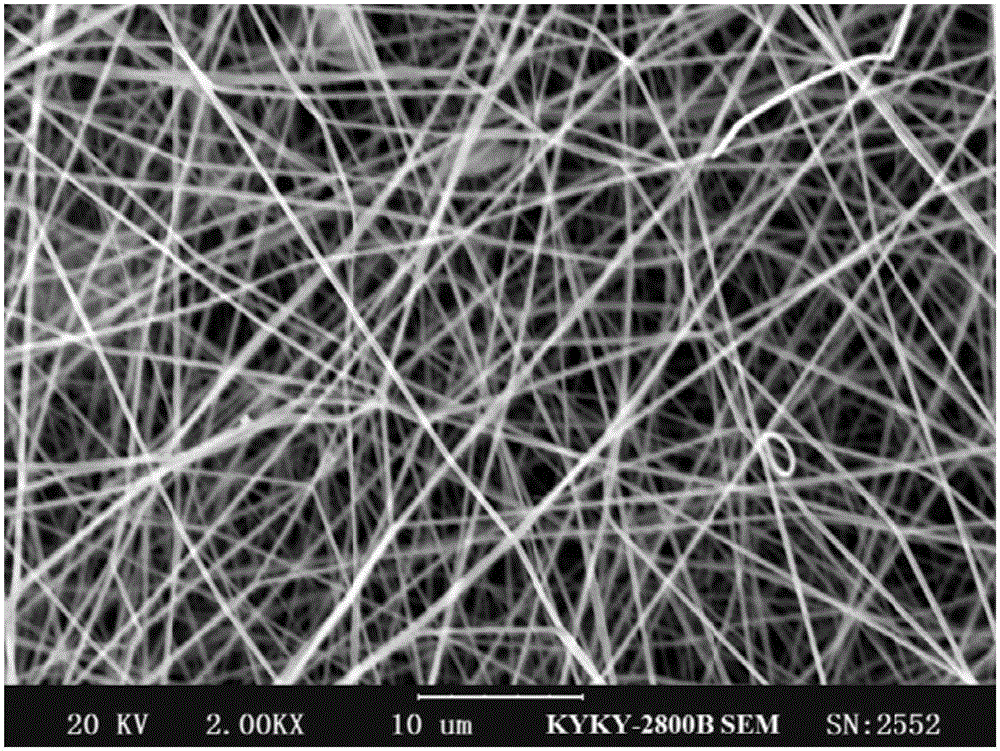

Preparation method of titanium dioxide based graphene /La3+ carbon fibers

InactiveCN105921142AExcellent spectral performanceIncreased sensitivityBiocideDisinfectantsAcetic acidCarbon fibers

The invention discloses a preparation method of titanium dioxide based graphene / La3+ carbon fibers. The preparation method includes the following steps that 1, graphene and polyacrylonitrile are dissolved in a DMF solution to prepare a graphene / polyacrylonitrile / DMF mixed solution, wherein the graphene concentration is 0.0007-0.0056 g / mL, and the polyacrylonitrile concentration is 0.08 g / mL; 2, lanthanum nitrate is added to a glacial acetic acid and tetra-n-butyl titanate mixed solution to form an La3+ doped TiO (OAc)2 solution; 3, the solution formed in the step 2 is slowly added to the graphene / polyacrylonitrile / DMF mixed solution in the step 1 under the action of mixing, and vacuum mixing is performed to obtain a spinning solution after adding is performed dropwise; 4, the spinning solution in the step 3 performs electrostatic spinning to obtain a product. The preparation method has the advantages of high strength, simple production equipment, easy and convenient operation and a good antibacterial effect.

Owner:NANTONG UNIVERSITY

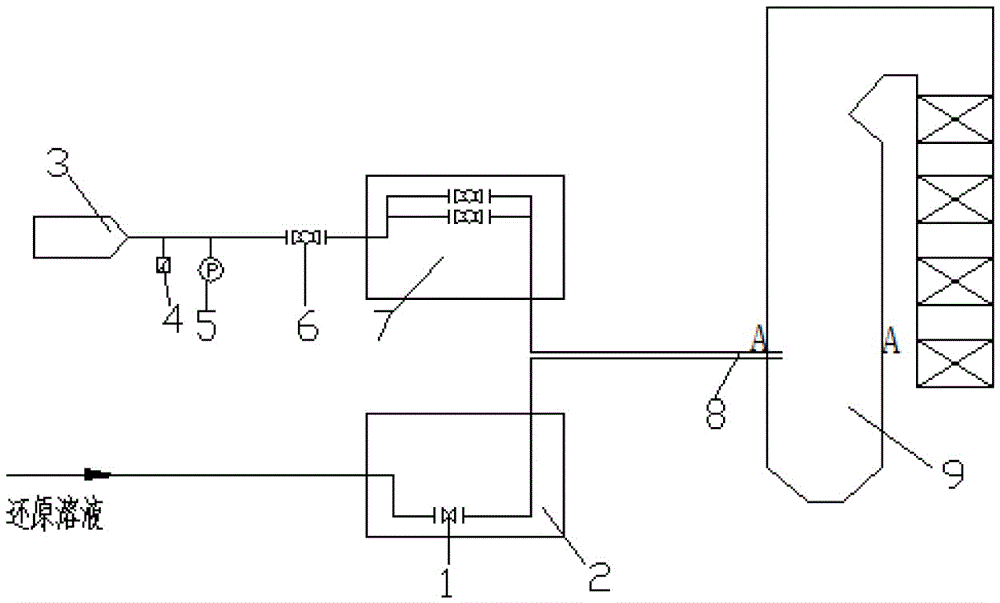

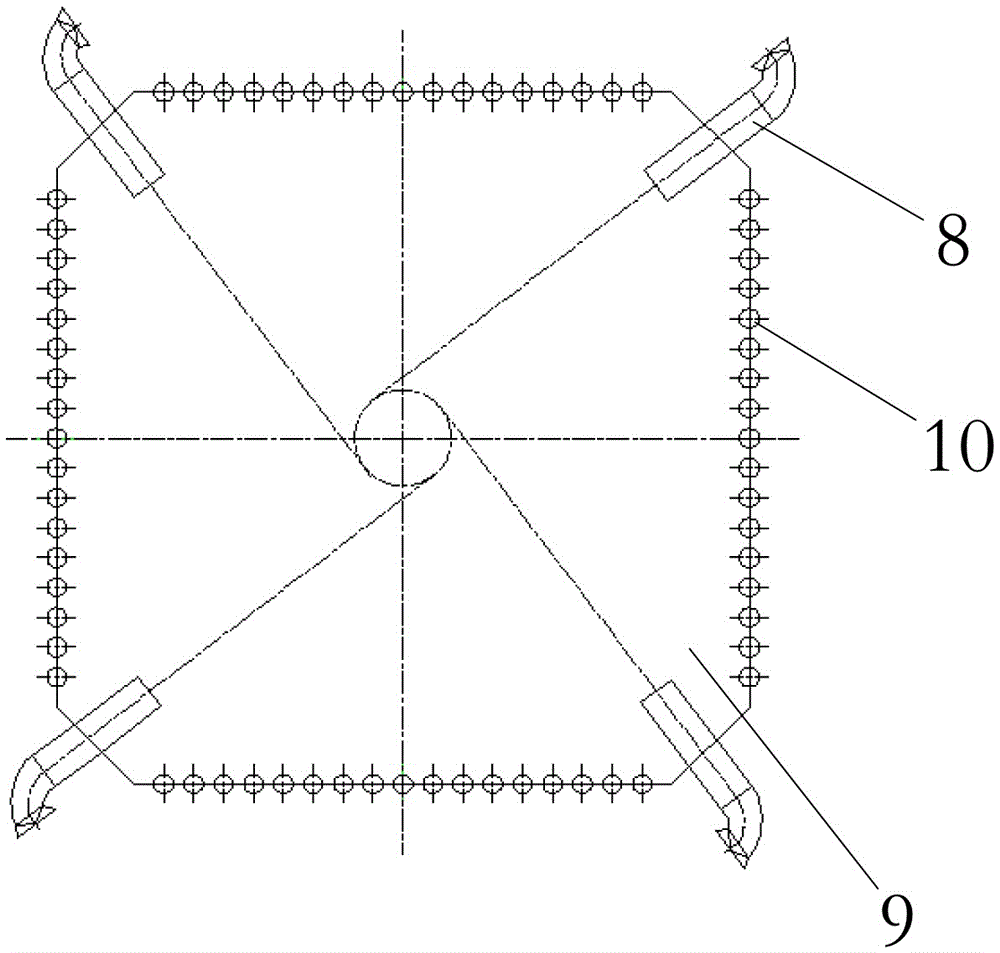

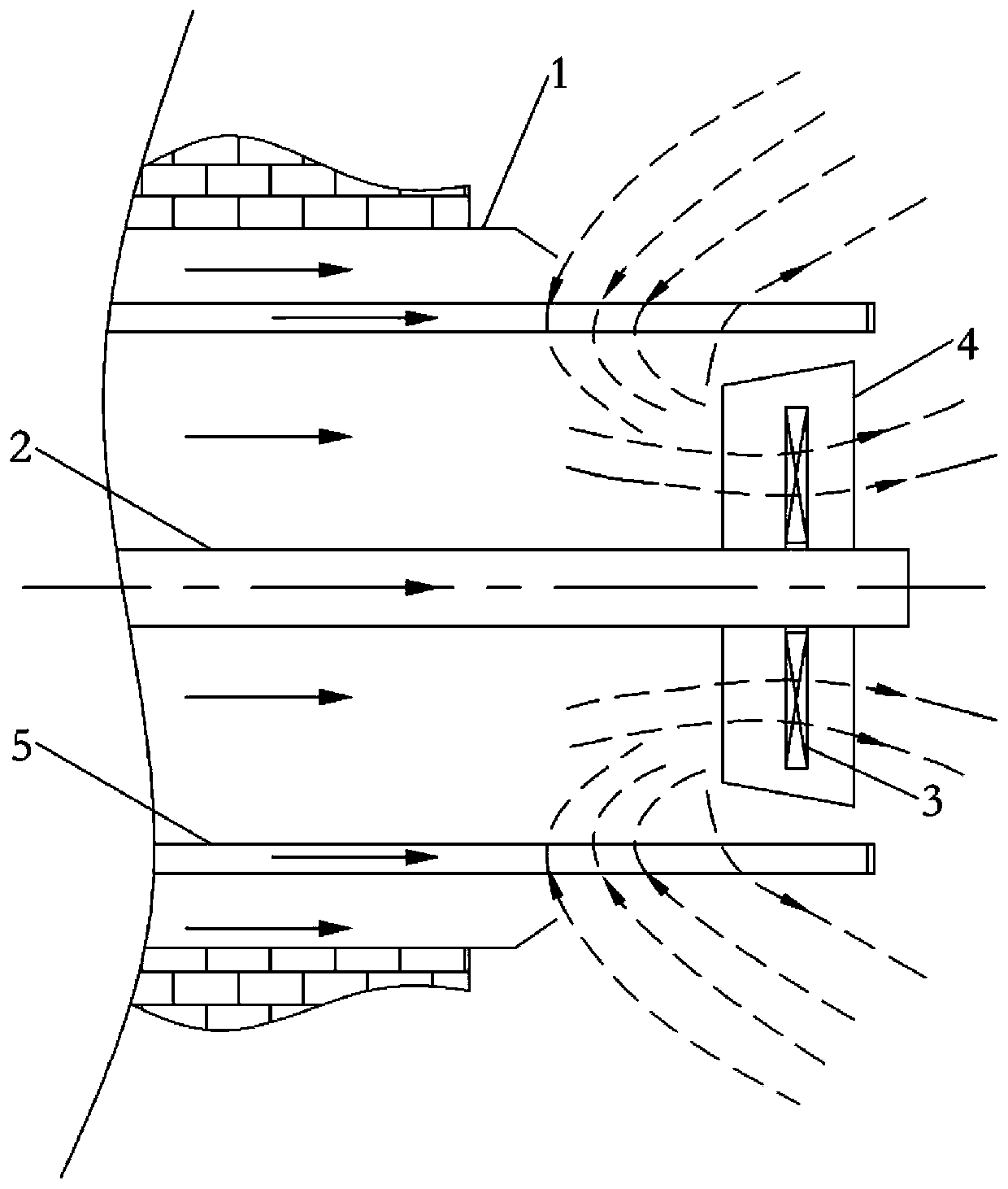

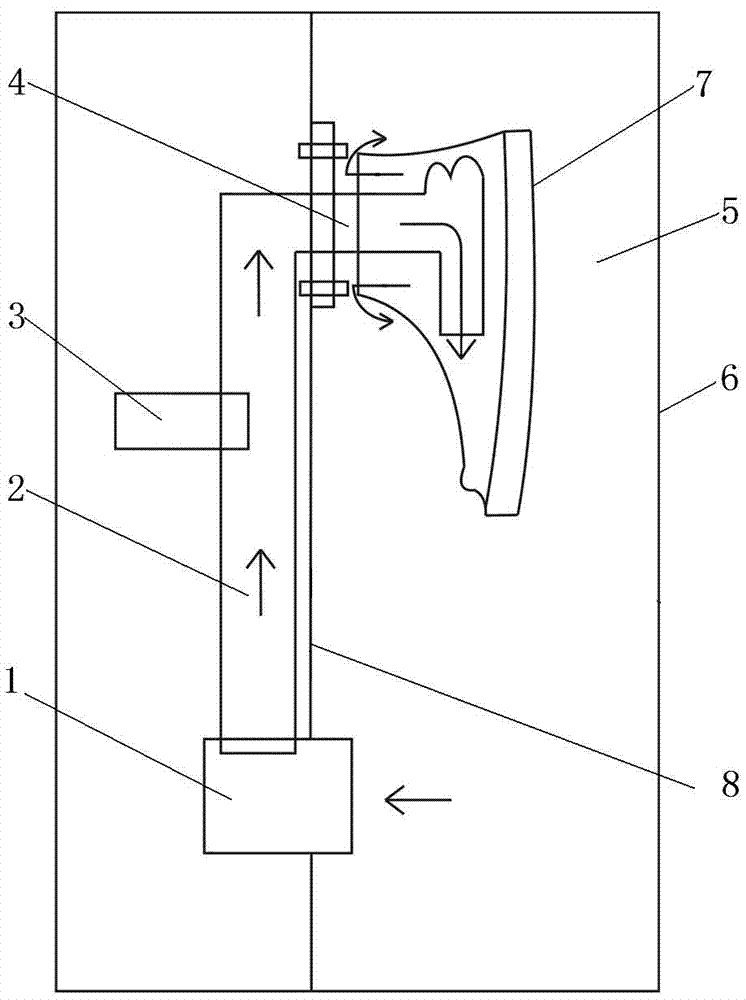

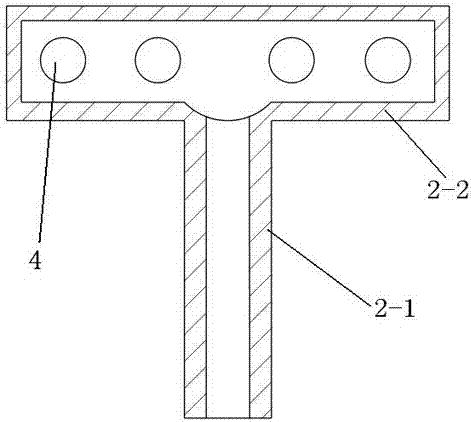

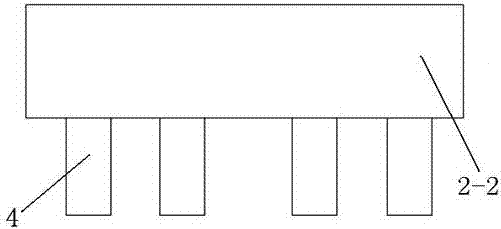

Multi-point injected ammonia water atomization reduction method for reducing NOx discharge of gas-fired boiler

InactiveCN105536487AReduce generationEmission reductionGas treatmentDispersed particle separationOxygenNitrogen gas

The invention provides a multi-point injected ammonia water atomization reduction method for reducing NOx discharge of a gas-fired boiler, aims at solving the technical problem that gas fuel is directly burned for decrease and accordingly a large amount of NOx is generated and environmental pollution is caused and belongs to the technical field of reduction of nitrogen oxide discharge of the gas-fired boiler. The multi-point injected ammonia water atomization reduction method is characterized in that after ammonia water is subjected to compressed air atomization and is jet to a main burning area (fuel-rich area) with the temperature of above 1000 degrees of a gas-fired boiler area through spray gun spray nozzles symmetrically and evenly distributed in a layered multi-point mode, so that NH3 in atomized ammonia steam and hydroxyl and NOx of the main burning area produce chemical reduction reaction, and the NOx concentration is reduced. The low-temperature atomized ammonia water is jet to the high-temperature main burning area, and local burning temperature of the area can be reduced. In addition, the atomized ammonia water can dilute oxygen concentration, reduces binding probability of nitrogen, a nitrogen compound and oxygen and accordingly reduces NOx. The NOx concentration in exhaust gas is reduced.

Owner:SHANGHAI WISEBOND TECH

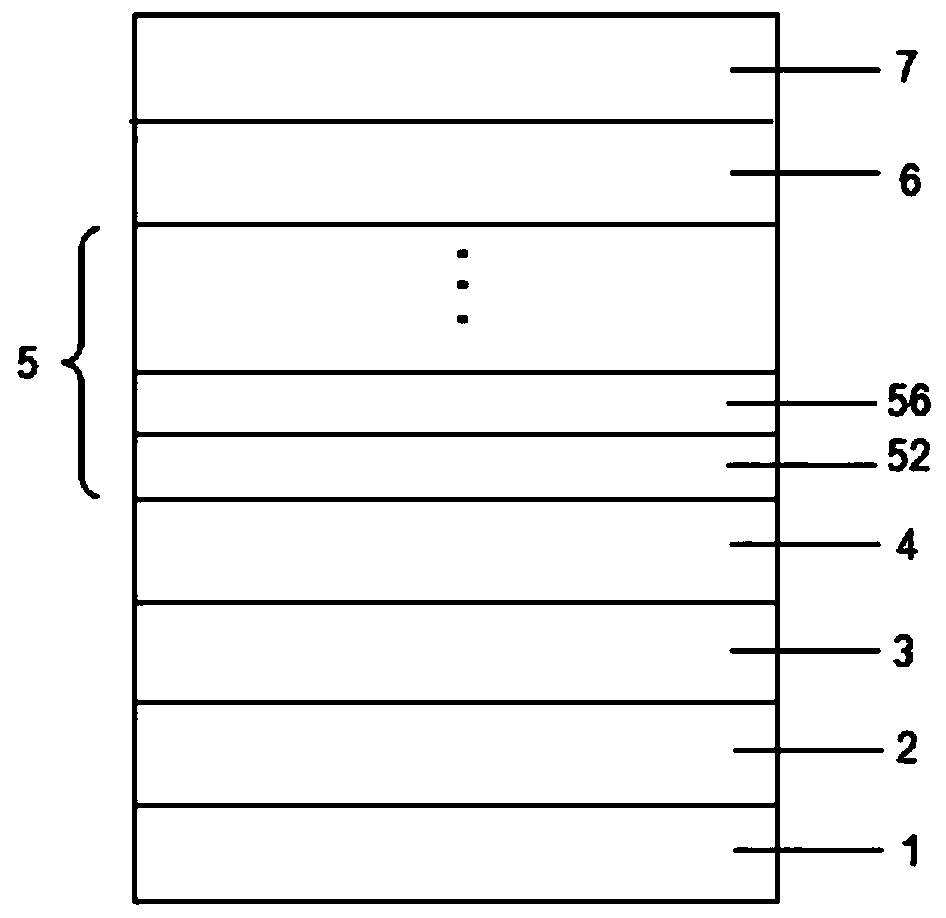

LED epitaxial growth method capable of improving luminous efficiency

ActiveCN111370540ASolve quality problemsSolve efficiency problemsFinal product manufactureChemical vapor deposition coatingPhysical chemistryElectron blocking layer

The invention discloses an LED epitaxial growth method for improving luminous efficiency. The method comprises the following steps in sequence: processing a substrate, growing a low-temperature bufferlayer GaN, growing an undoped GaN layer, growing a Si-doped N-type GaN layer, growing a multi-quantum well layer, growing an AlGaN electronic barrier layer, and growing a Mg-doped P-type GaN layer. Temperature reduction and cooling are performed. The step of growing the multi-quantum well layer sequentially comprises the substeps of growing an InGaN transition layer, growing an InGaN well layer,growing a high-temperature gradient MgN layer, growing a low-temperature gradient MgN layer, growing a linear gradient Mg-doped GaN barrier layer and carrying out Mg diffusion treatment. According tothe method, the problems of low quantum well growth quality and low quantum well radiation recombination efficiency in the existing LED epitaxial growth method are solved, so that the luminous efficiency of the LED is improved.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

Wafer cutting liquid

The invention relates to a wafer cutting liquid which is prepared from 100 of purified water, 3 of glycerin and 0.02 of silicate by weight proportion. By changing the essential component in the existing cutting liquid from soft water to the purified water, the invention reduces the component of hard ions in the cutting liquid so as to reduce the combination probability of soft ions and hard ions,and the formation probability of grains in the cutting liquid is greatly reduced.

Owner:RF360 TECH (WUXI) CO LTD

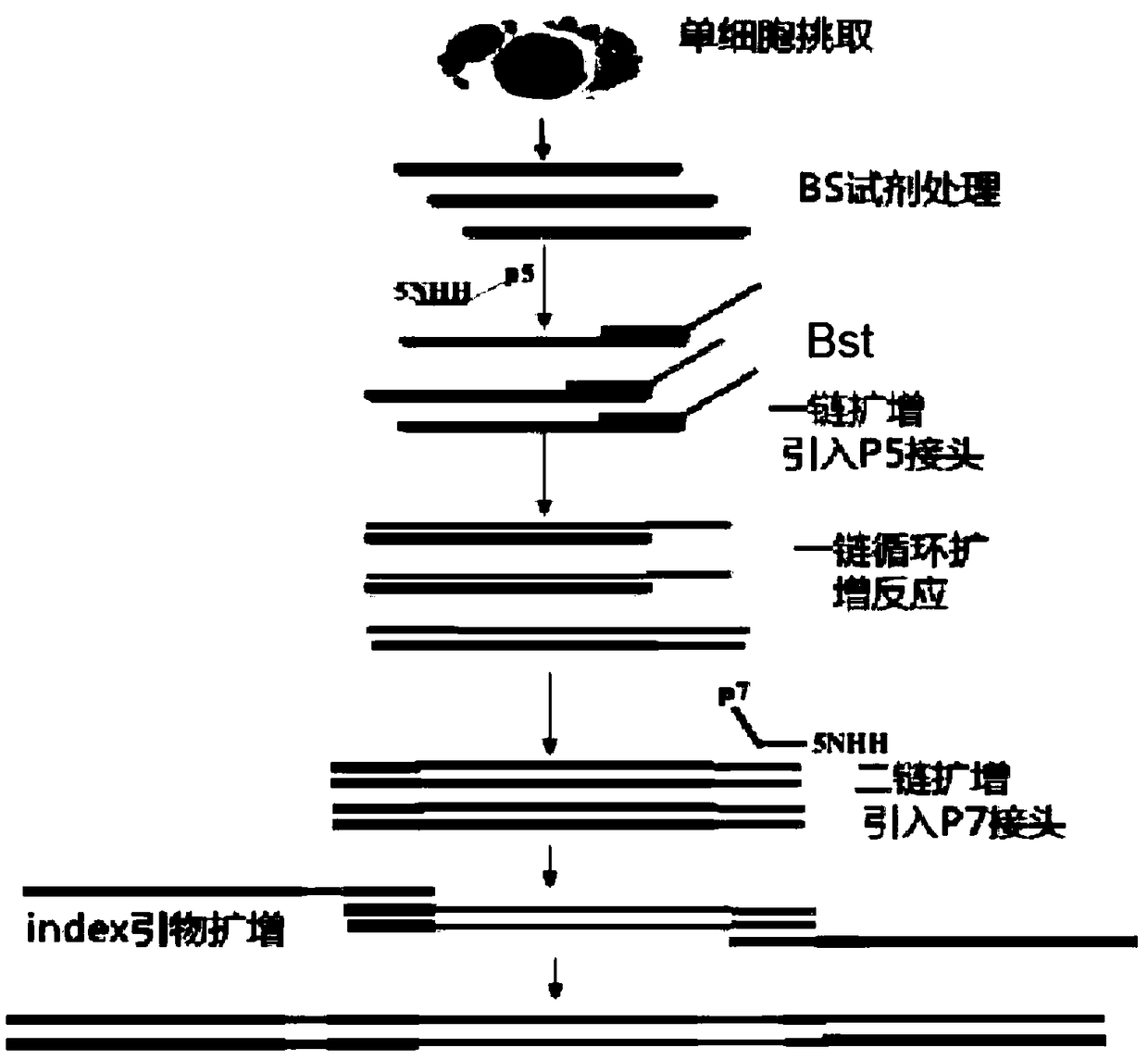

Single-cell methylation sequencing technology and application thereof

ActiveCN109295500AHas strand displacement activityGood pre-amplificationMicrobiological testing/measurementLibrary creationDNA methylationComputational biology

The invention discloses a single-cell methylation sequencing technology and an application thereof. The technology has the following advantages: (1) the technology has the characteristics of simplicity in operation, short manual operating time, and no pollution; (2) a pre-amplification primer is designed for the characteristics of a bisulfate treated genome sequence, the 3' end of the pre-amplification primer is an H base, and the H base does not complement or bind to C, so binding of the pre-amplification primer to the bisulfite converted sequence is not affected, and the probability of binding of a random primer and a linker sequence is reduced; and (3) the technology has a high Mapping rate, and effectively improves the use rate of sequencing data, and the use rate is 20-30% higher thanthe use rate (average 25%) of existing scRRBS and the use rate (average 10-30%) of scBS. The technology is of great significance for the study of single-cell DNA methylation.

Owner:CAPITALBIO CORP

Nylon taffta dispersion transfer printing color fixation and waterproof finishing method

InactiveCN106988135AEmission reductionSimple processTransfer printing processDyeing processCross-linkPulp and paper industry

The invention relates to a nylon taffta dispersion transfer printing color fixation and waterproof finishing method which comprises the following steps: (1) performing thermal transfer printing on a nylon taffta fabric; (2) performing color fixation treatment by using an acid color fixing agent, and drying; (3) rolling off water, and drying; (4) finally finishing the nylon taffta fabric by using a waterproof agent and a cross-linking agent, drying, and baking. By adopting the process route of thermal transfer printing, color fixation, rolling off water, drying and waterproof finishing, both the fastness and the excellent waterproof effect of the nylon taffta fabric can be improved, the soaping fastness transfer fastness can be up to a grade 3 or greater, meanwhile the waterproof effect can be 100% before washing, and the waterproof effect can be 80% after ten times of washing.

Owner:广东德美高新材料有限公司

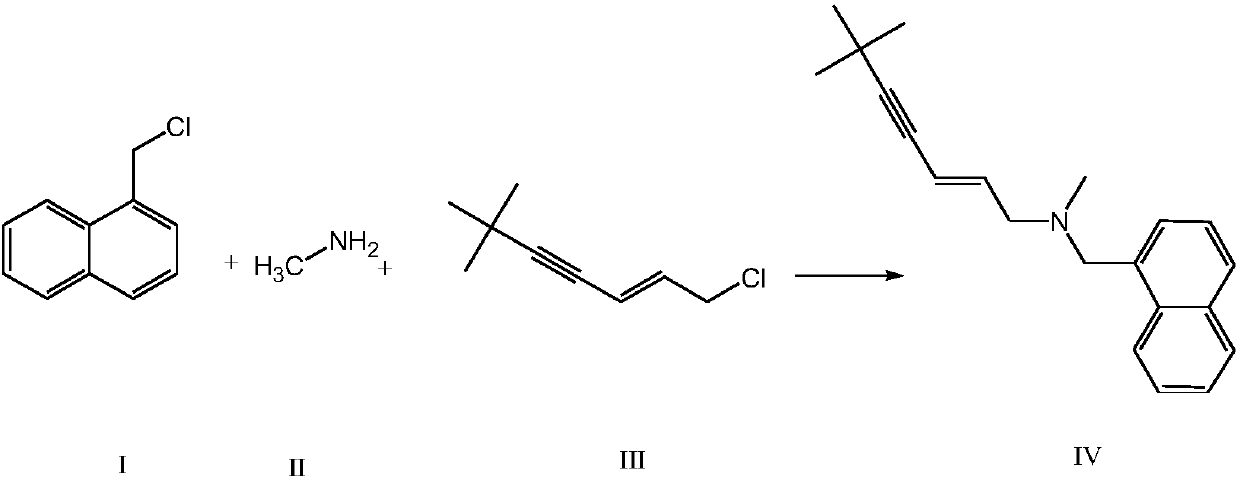

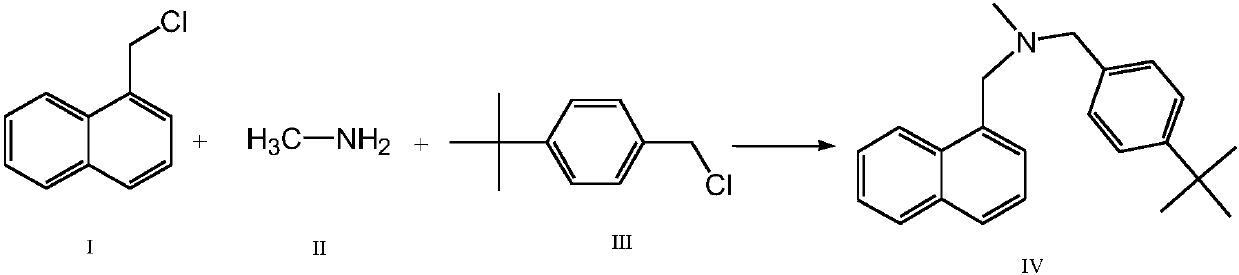

Method for synthesizing butenafine

ActiveCN108047057ASimple stepsHigh yieldAmino compound purification/separationOrganic compound preparationThermal insulationChloride

The invention provides a method for synthesizing butenafine. The method includes the steps of adding monomethylamine to a solvent and then adding an acid-binding agent; slowly dropping 1-chloromethylnaphthalene and p-tert-butylchlorobenzyl chloride at the same time, controlling the dropping rate so that dropping of 1-chloromethylnaphthalene and p-tert-butylbenzyl chloride can be completed at the same time, and then controlling the temperature to be 10-20 DEG C to perform a thermal insulation reaction for 4 hours; extracting a reaction solution with chloroform, concentrating an organic layer under reduced pressure to dryness, and adding isopropanol to residues for crystallization to obtain butenafine. The method has the advantages of having convenient operation, less by-products, high yieldand short production cycle and being conducive to industrial production.

Owner:SHANDONG BOYUAN PHARM CO LTD

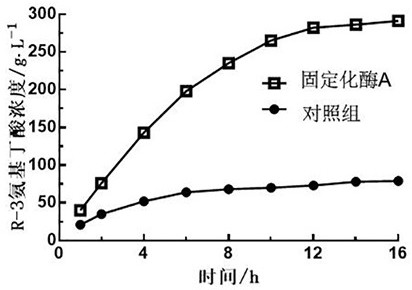

Recombinant aspartate lyase and method for preparing R-3-aminobutyric acid with high repeated utilization rate

ActiveCN112921023AIncrease the number ofAvoid damageImmobilised enzymesCarbon-nitrogen lyasesLyaseEngineered genetic

The invention discloses recombinant aspartate lyase and a method for preparing R-3-aminobutyric acid with high repeated utilization rate. Through genetic engineering, a segment of polypeptide chain with a plurality of amino groups, namely polar amino acid residues, is added at each of two ends of an original gene, an enzyme solution is obtained through biological fermentation based on the sequence, and the immobilized enzyme is obtained through immobilizing with resin. According to the immobilized enzyme, the binding probability of covalent binding of an immobilized carrier and protein to an enzyme active center is reduced, so that the damage to enzyme activity after immobilization is reduced, the enzyme activity recovery rate can be increased to 50% or above, and due to the increase of the quantity of the polar amino acids, the concentration of a substrate which can be used for conversion is increased, and the cost of the enzyme is greatly reduced and the production process is saved in the industrial enzyme fermentation engineering.

Owner:CHANGXING PHARMA

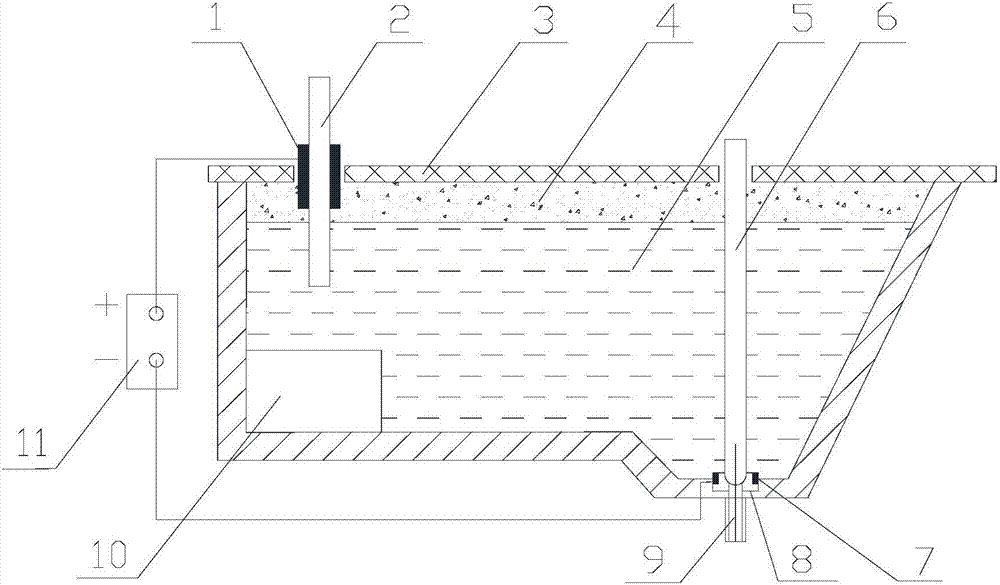

A kind of corrosion-resistant steel bar and its production method

InactiveCN105950989BReduce oxygen contentImprove corrosion resistanceChemical compositionHeating time

The invention provides an anticorrosion rebar and a production method of the anticorrosion rebar. The anticorrosion rebar comprises 0.15%-0.23% of C, 0.30%-0.65% of Si, 0.90%-1.60% of Mn, 0.030% of P or less, 0.020% of S or less, 1.40%-2.50% of Cr, 0.20%-0.40% of Cu, 0.010%-0.025% of Ti, 0.015% of N or less and 0.0020% of O or less. The electric induction furnace smelting and tapping temperature ranges from 1,650 DEG C to 1,670 DEG C, and the degree of superheat of continuous-casting molten steel is controlled to be smaller than or equal to 30 DEG C; and deoxygenation is conducted on tundish through an external electric field slag deoxygenation device, the voltage of the external electric field ranges from 5 V to 20 V, the current ranges from 600 A to 1,000 A, and the cleanliness of the molten steel is improved; the heating temperature of a rolled steel blank is controlled within the range of 1,130 DEG C to 1,170 DEG C, the heating time ranges from 1.5 h to 2.5 h, the temperature at the beginning of rolling ranges from 1,000 DEG C to 1,100 DEG C, and the finish rolling temperature ranges from 950 DEG C to 1,050 DEG C. According to the rebar, Rel is larger than or equal to 500 MPa, Rm is larger than or equal to 630 MPa, A is larger than or equal to 15%, and anticorrosion performance of the rebar is 3 to 5 times that of a HRB500 c steel rolled rebar.

Owner:海城市欣锐铸件有限公司

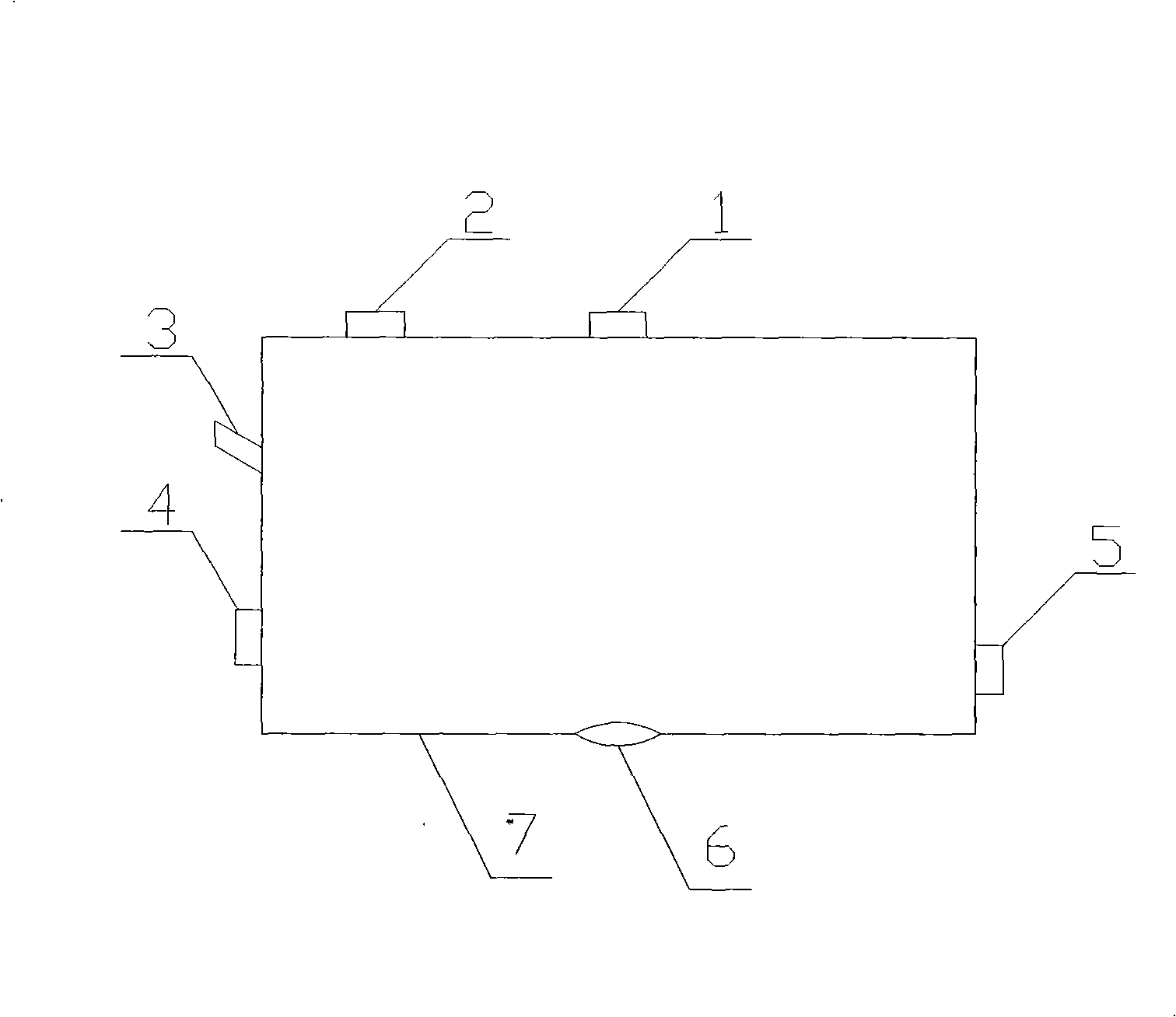

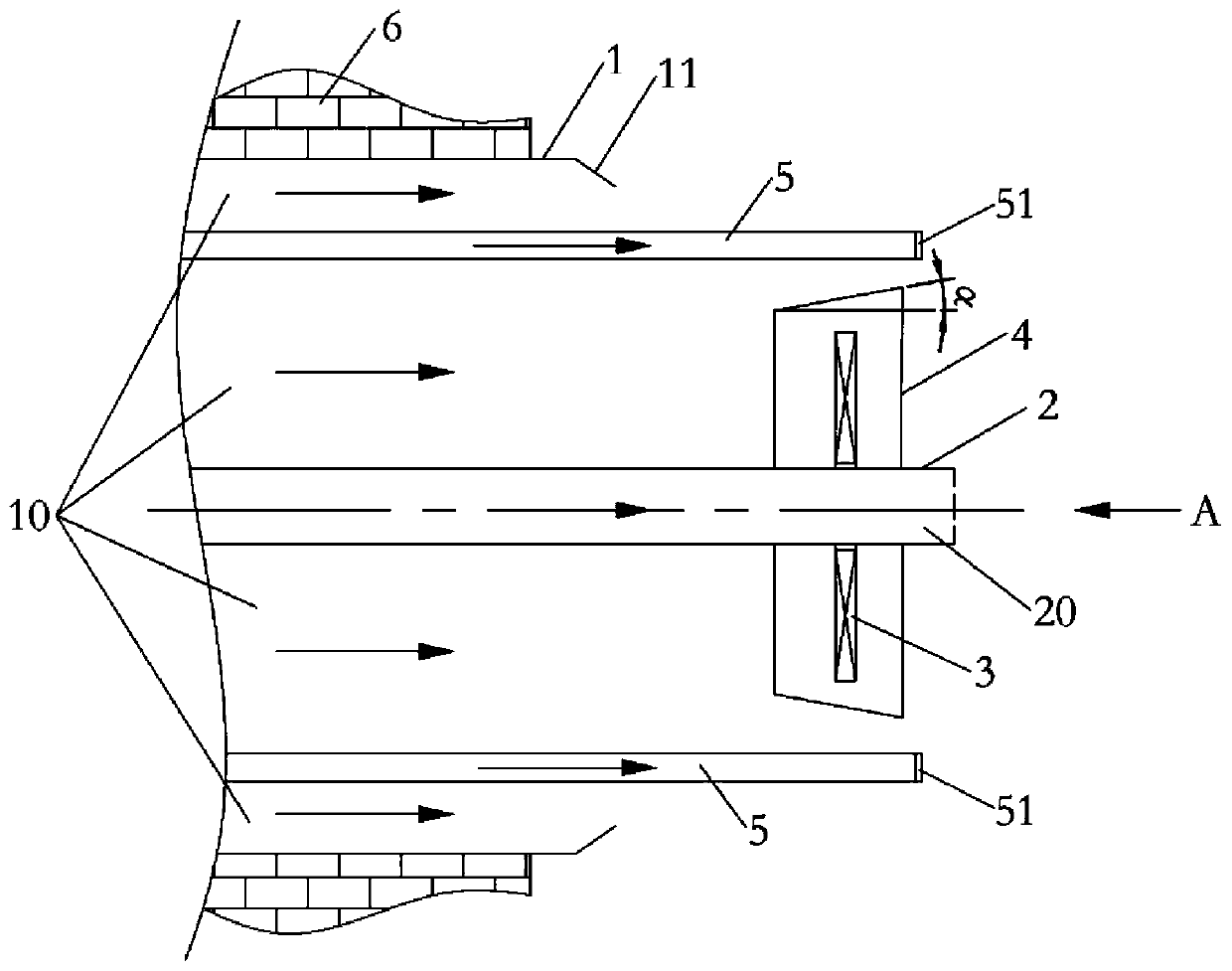

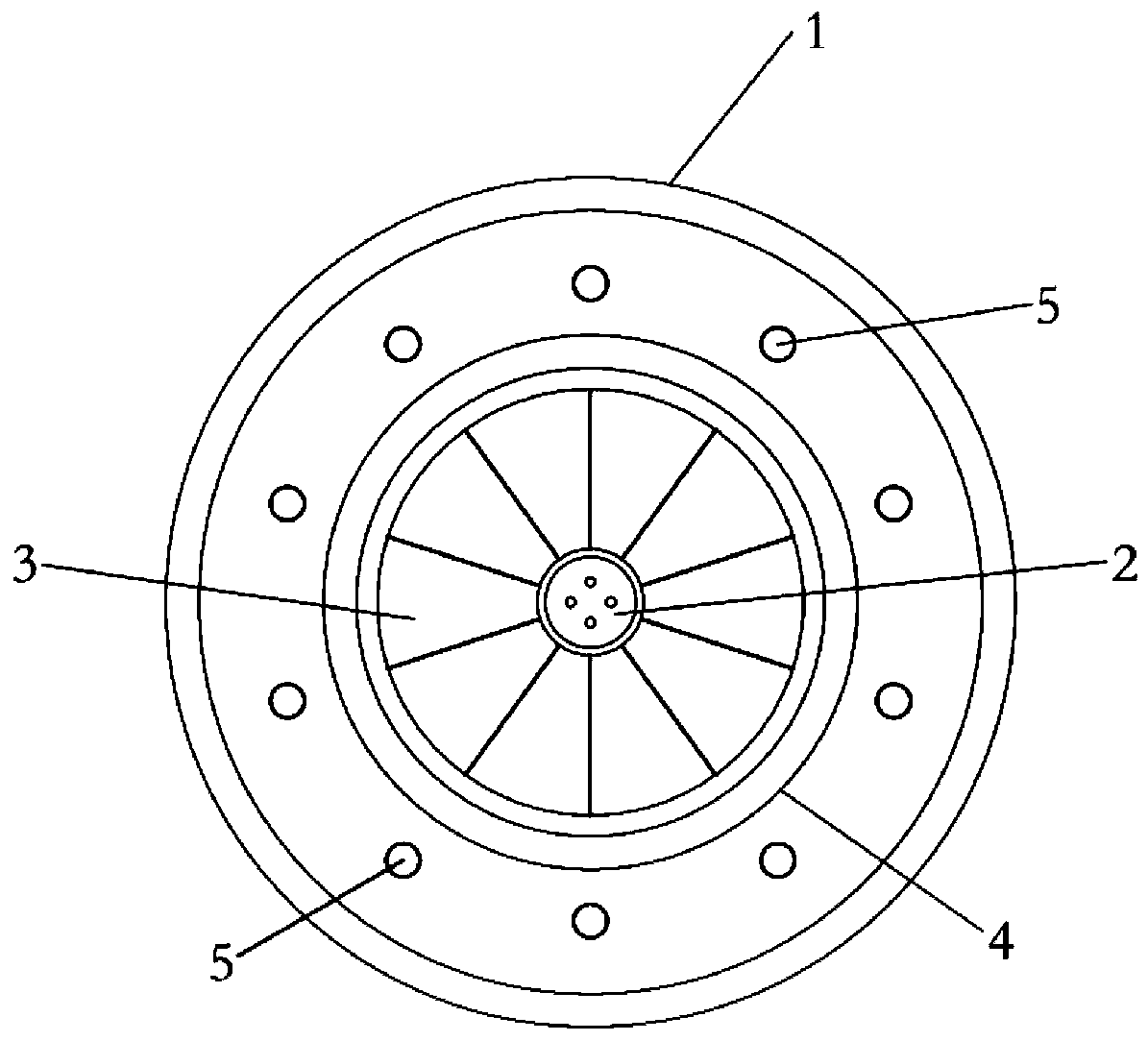

Low-nitrogen combustion device and combustion boiler

PendingCN110553262ALower peak temperatureReduce generationCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelLow nitrogenSprayer

The invention discloses a low-nitrogen combustion device and a combustion boiler and belongs to the technical field of low-nitrogen combustion components. The low-nitrogen combustion device comprisesa main air duct, a central air duct and a plurality of gas spray guns. An air outlet is formed in one end of the main air duct. A central gas pipe is arranged in the main air duct and is coaxial withthe main air duct. A flame stabilizing mechanism is arranged on the central gas pipe. The central air duct is arranged on the central gas pipe in a sleeving mode and located outside the air outlet. The flame stabilizing mechanism is located in an inner cavity of the central air duct. The end, provided with a gas outlet, of the central gas pipe stretches out of the central air duct. The multiple gas spray guns are arranged around the central air duct. In the axis direction of the main air duct, the distance between gas sprayers of the gas spray guns and the end surface of the end, provided withthe air outlet, of the main air duct is greater than that between the side, away from the gas outlet, of the flame stabilizing mechanism and the end surface. Gas combustion is started outside the airoutlet, the inner cavity of the main air duct produces no flame, gas combustion heat can be dissipated into a boiler hearth in time, the flame peak temperature is decreased, and produced thermal NOxis reduced.

Owner:SHANGHAI WISEBOND TECH +1

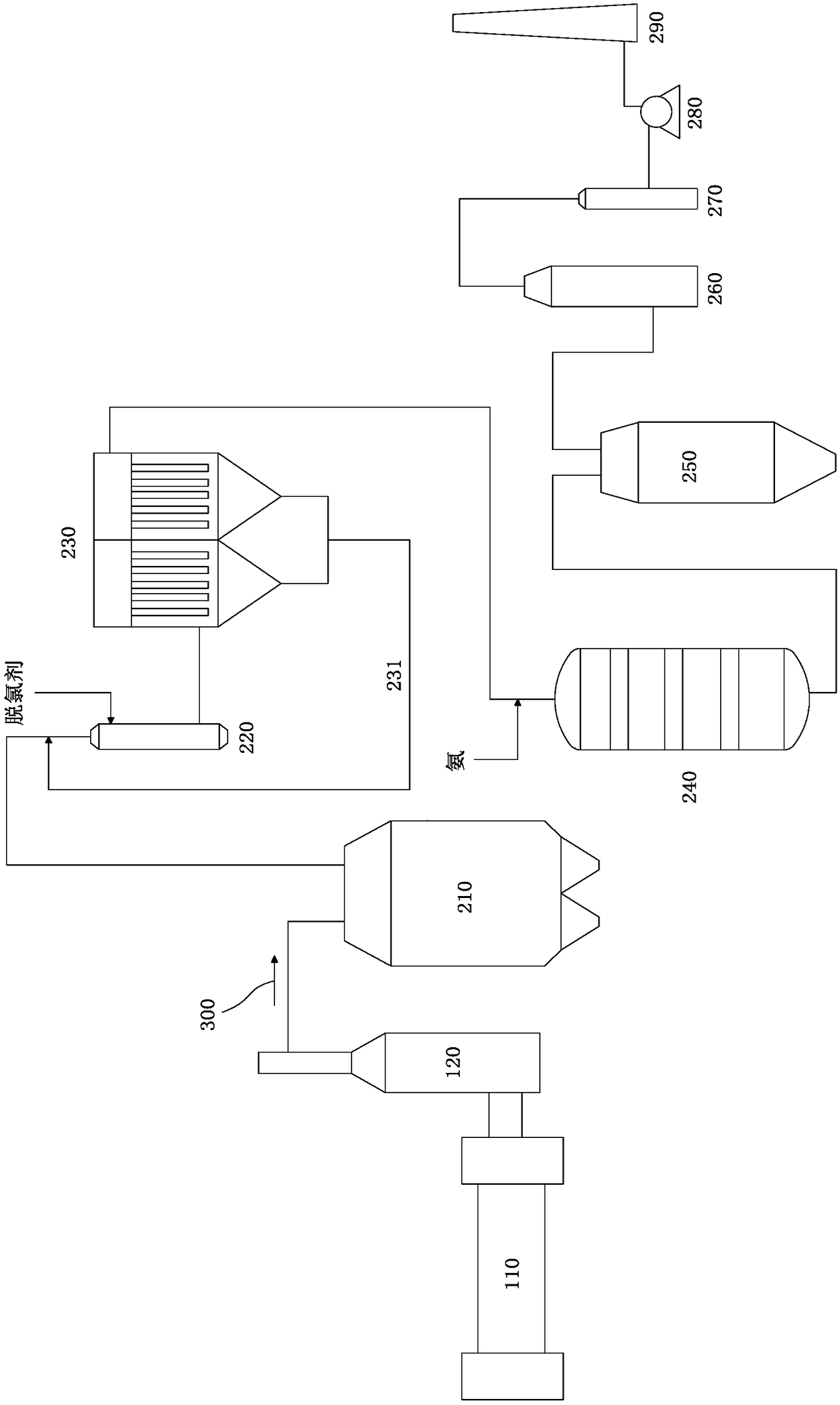

Solid waste incineration flue gas purification treatment method

ActiveCN108452663AEmission controlReduce the chance of bondingGas treatmentDispersed particle filtrationHydrogen chlorideFlue gas

The invention discloses a solid waste incineration flue gas purification treatment method so as to effectively control dioxin emission. The method comprises the following steps that dechlorination treatment is carried out on solid waste incineration flue gas, wherein the main removal target substance is hydrogen chloride; high-temperature flue gas dust removal purification treatment is conducted on the solid waste incineration flue gas after dechlorination treatment, wherein the operation is carried out in the process that the temperature of the solid waste incineration flue gas is still 400 DEG C or above. As dioxin is not likely to be formed on dust particles of the solid waste incineration flue gas through catalysis under the high-temperature state of 400 DEG C or above, at the moment,hydrogen chloride for synthesizing dioxin and the dust particles are subjected to gas-solid separation through high-temperature flue gas dust removal purification treatment, which is equivalent to that hydrogen chloride and the dust particles are separated before entering a proper temperature interval for synthesizing dioxin, and therefore the possibility of synthesizing dioxin by combining the separated hydrogen chloride with the dust particles is completely cut off.

Owner:CHENGDU INTERMENT TECH

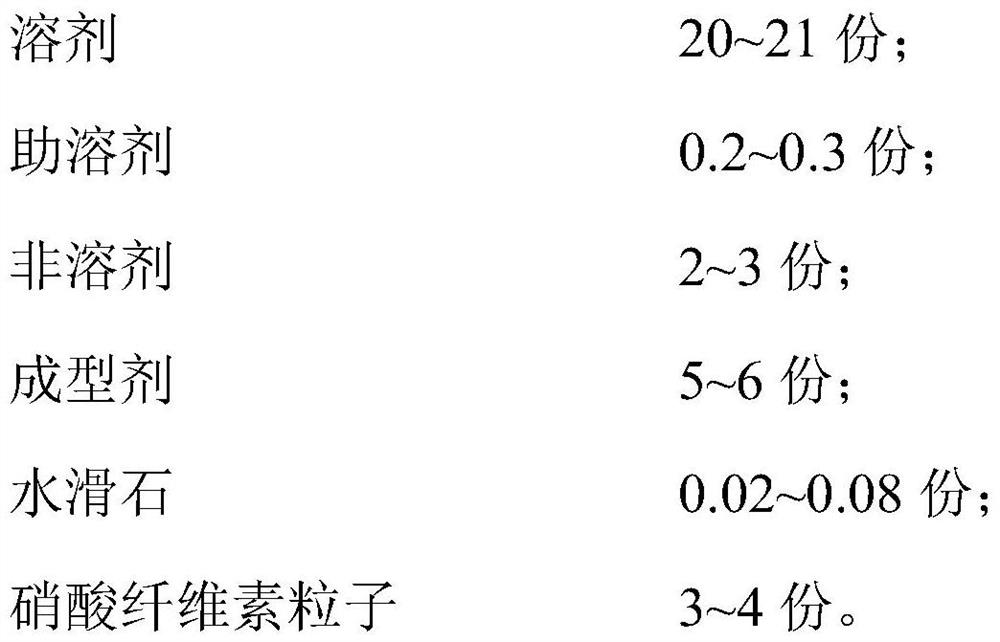

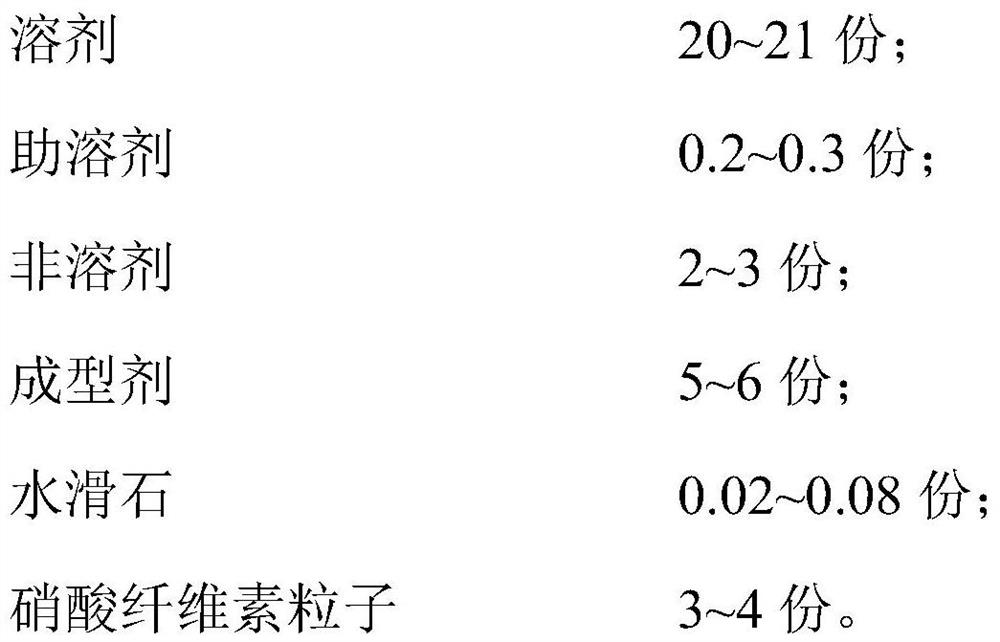

Nitrocellulose membrane and preparation method thereof

PendingCN114130373AImprove hydrophilicityPerfect effective apertureIon-exchange process apparatusOther chemical processesCelluloseNon solvent

The invention discloses a nitrocellulose membrane, which is prepared from a nitrocellulose membrane solution, and the nitrocellulose membrane solution comprises the following raw materials by weight: 20-21 parts of a solvent; 0.2 to 0.3 part of a cosolvent; 2-3 parts of a non-solvent; 5-6 parts of a forming agent; 0.02 to 0.08 part of hydrotalcite; and 3-4 parts of nitrocellulose particles. According to the nitrocellulose membrane prepared by the preparation method disclosed by the invention, the added hydrotalcite has a special layered structure, so that a functional high-molecular substance can enter interlayer gaps of the hydrotalcite, the functional high-molecular substance is expanded without changing the structure of the functional high-molecular substance, and the nitrocellulose membrane with the multi-pore-diameter supporting layer has the advantages that the effective pore diameter is perfected, and the hydrophilicity of the nitrocellulose membrane is effectively improved; meanwhile, the high binding force is achieved, and the problem that blending particles are uneven in distribution and prone to agglomeration can be solved. The aperture is effectively improved, so that the opportunity of binding with nonspecificity is reduced, and false positives generated in the using process of using the nitrocellulose membrane as a carrier are reduced.

Owner:HEFEI LUCKY SCI & TECH IND

Acrylic acid/polymethyl methacrylate/acrylonitrile copolymer water antisludging agent and preparing method thereof

InactiveCN105504176AHigh hardnessInhibit growthScale removal and water softeningPolymer scienceAcrylonitrile

The invention discloses a acrylic acid / polymethyl methacrylate / acrylonitrile copolymer water antisludging agent and a preparing method thereof. The antisludging agent is prepared from the components in percentage by weight: 50-70% of acrylic acid, 20-45% of polymethyl methacrylate and 5-25% of acrylonitrile. The preparing method comprises the following steps: (1) weighing the acrylic acid, polymethyl methacrylate and acrylonitrile proportionally, and uniformly mixing in a mixing machine; (2) performing eight-region melting and extruding on the mixed material by a double-screw extruder for pelleting. The antisludging agent has a better antisludging effect for high hardness hot water, and meanwhile, the preparing method is simple in process and low in cost.

Owner:HUBEI DIDA HEAT ENERGY TECH CO LTD

The Method of Improving the Performance of Carbonized Wood by Silica Sol Impregnation Pretreatment

ActiveCN103240780BLow viscosityLow costWood treatment detailsPressure impregnationLoss rateVolumetric Mass Density

The invention relates to a method for improving a carbonized wood property by silica sol impregnation pretreatment. The method comprises the following steps of: placing wood in a treatment tank, carrying out the silica sol infusion pretreatment on the wood, and carrying out stacking and air dry on the treated wood; carrying out common kiln drying on the treated wood so as to enable the water content ratio of the wood to be reduced to be 12-18%, and then discharging the dried wood out of a kiln, placing the wood after drying in charring equipment for carrying out hot modification carbonizing treatment; and finally taking out the wood. The method provided by the invention has the advantages that silica sol is adopted to be used as modification liquid so as to carry out the impregnation pretreatment on the wood, the front drying is not needed, the manufacturing cost is low, the mass loss rate of preparative carbonized wood is reduced, and the equilibrium water content is reduced; and the dimensional stability. the density and the mechanical strength are improved, corrosion proof and weather resisting properties are improved, flame retardant and termite proof properties can be improved to a certain degree, and the method has the characteristics of being odorless, innoxious, safe and environment-friendly.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI

Antibacterial deodorization shoe cabinet with free radicals

PendingCN106963141AReduce concentrationPlay a role in decompositionWardrobesGaseous substancesStructural engineeringNitrogen gas

The invention belongs to the field of daily necessities, and particularly relates to an antibacterial deodorization shoe cabinet with free radicals. The antibacterial deodorization shoe cabinet comprises a closed box, a small guiding draught fan installed inside the box, an air flow guiding pipe connected to an air exhausting opening of the small guiding draught fan and communicated in shoes and a free radical generator installed on the air flow guiding pipe; the air flow guiding pipe comprises a free-radical guiding main pipe arranged on one side of the small guiding draught fan and connected with an outlet of the small guiding draught fan and free-radical guiding branch pipes which are branched by the free-radical guiding main pipe to lead to all single shoes. The antibacterial deodorization shoe cabinet has the advantages that the free radicals are directly guided into in-shoe cavities through the guiding pipe, the combination probability of the free radicals and oxygen in air and nitrogen in air is reduced accordingly, and the stability before the free radicals are in contact with fetid ingredients / bacterium ingredients attached to the surfaces of substances inside shoes and the insides of fibers and the using efficiency of the free radicals are improved.

Owner:CHANGCHUN ZHONGAN HONGCHENG WEIYE ENERGY SAVING TECH CO LTD

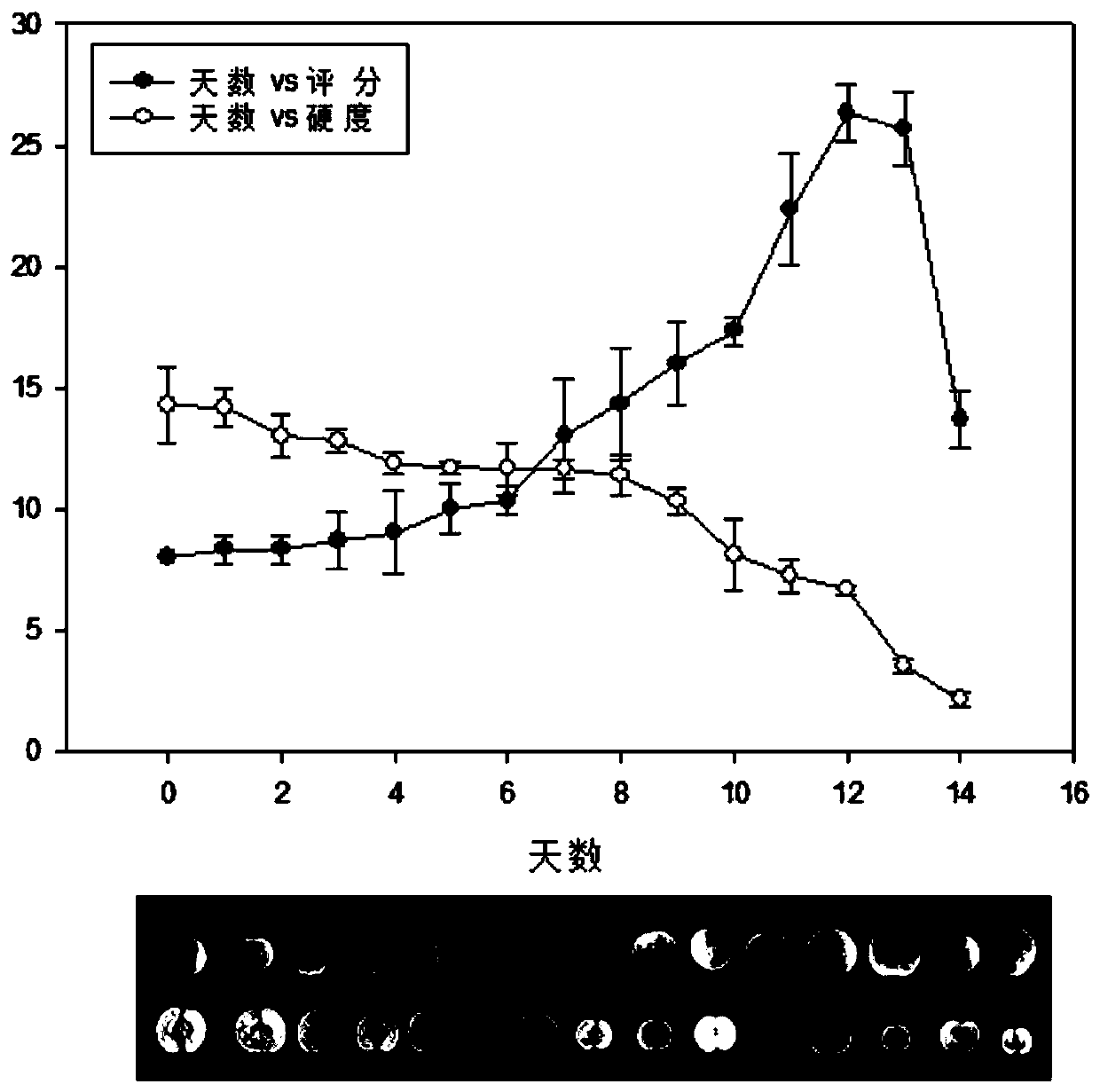

Fresh-cut Nanguo pear green preservative

ActiveCN111449130AImprove qualityGreat tasteClimate change adaptationNatural extract food ingredientsAlanineResveratrol

The invention relates to a fruit storage and fresh-keeping technology, and discloses a fresh-cut Nanguo pear green preservative. The problem that the components of a preservative and the best fresh-keeping hardness of Nanguo pears are not disclosed is solved. The fresh-cut Nanguo pear green preservative is prepared from a fresh-keeping solution and a film-forming agent. The fresh-keeping solutionis prepared from the components in parts by 100% mass: 0.4-0.6 part of watermelon peel extract, 1-1.2 parts of mangosteen peel extract, 0.8-1.2 parts of pomegranate peel extract, 3.8-4.2 parts of chrysanthemum extract, 0.5-0.8 part of resveratrol, 1.4-1.6 parts of citric acid, 1.8-2 parts of calcium chloride, and the balance of water. The film-forming agent is prepared from the components in partsby 100% mass: 30-40 parts of transformed whey protein, 10-12 parts of chitosan, 0.2-0.5 part of alanine, and the balance of water. The fresh-cut Nanguo pear green preservative can maintain the contents of titratable acid, Vc and soluble solids in Nanguo pear slices, the weight loss rate is slown down, the browning phenomenon of Nanguo pears is effectively delayed, and the storage quality of fresh-cut Nanguo pears is maintained.

Owner:BOHAI UNIV

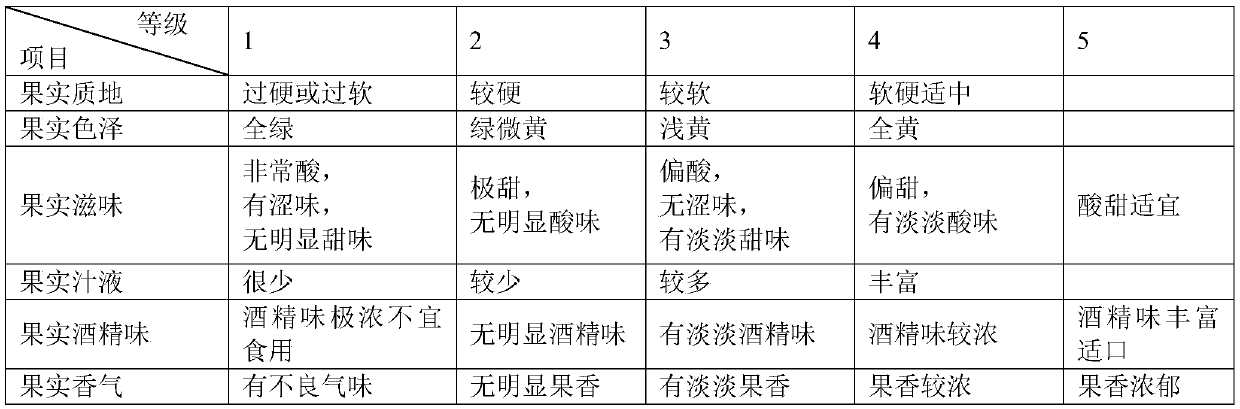

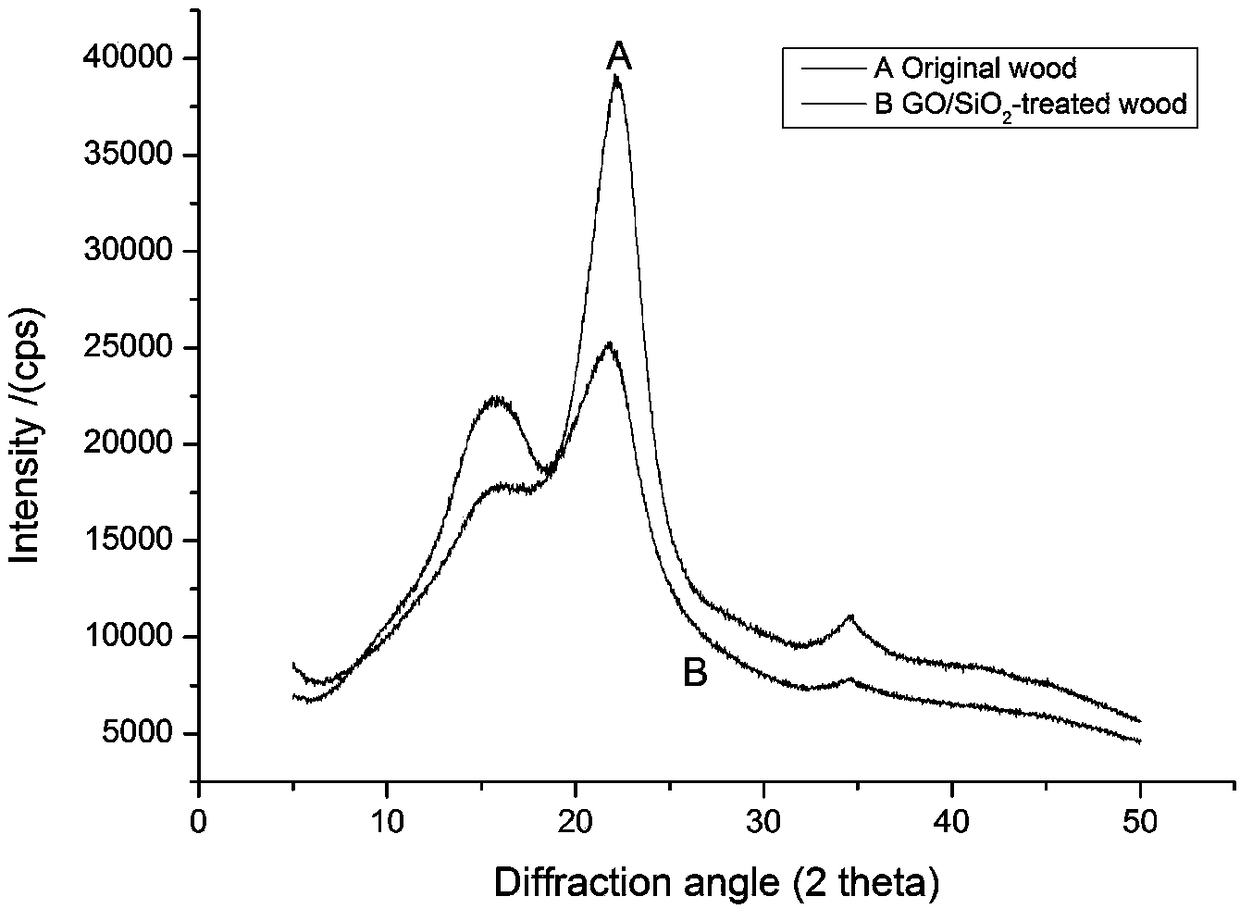

Preparation method of graphene oxide or silicon dioxide composite modifier and application thereof

InactiveCN108274569ASimple preparation processEasy to operateWood treatment detailsPressure impregnationHardnessSolvent

The invention discloses a preparation method of graphene oxide or silicon dioxide composite modifier and an application thereof, and relates to application of a modified wood. The invention aims to solve the problems that an existing wood modification is complex in preparation process, a modified solvent causes a pollution, the modified solvent is high in cost, and is single in function are solved. The composite modifier comprises the following components of, by volume, (0.25wt%) 10% of graphene oxide dispersion liquid, (30wt%) 5%-20% of nano-scale neutral silica sol solution, and 70%-85% of deionized water, wherein the sum of the volume percentages of the components is 100%. The composite modifier is used for carrying out impregnation treatment on the wood, so that the water absorption rate of the wood can be reduced, and the dimensional stability and the surface hardness of the wood can be improved; and the preparation process of the preparation method of the graphene oxide or the silicon dioxide composite modifier and the application thereof has the characteristics of no toxicity, no harm, safety, environmental protection, low cost, and simplicity in operation.

Owner:BEIJING FORESTRY UNIVERSITY +1

Method for improving quality of animal products

InactiveCN113785795AAchieve passivationImprove adsorption capacityFood processingAnimal feeding stuffAnimal productFeed additive

The invention relates to the technical field of animal feeding, and particularly discloses a method for improving quality of animal products. The method at least comprises the following steps: adding a heavy metal pretreatment agent into animal drinking water for feeding animals for 3-7 days; stopping adding the heavy metal pretreatment agent, then adding a feed additive to animal feed for feeding the animals, and at the same time, adding a drinking water additive to animal drinking water for feeding the animals; wherein the feed additive comprises the following components: a plant residue powdery activated material, polyacrylamide, fulvic acid, a non-metal nano mineral material, ferrous sulfate, walnut powder, jujube powder, ganoderma lucidum powder, ginseng powder and pseudo-ginseng powder. According to the method for improving the quality of the animal products, heavy metal can be effectively adsorbed, adsorption is stable, desorption is not prone to occurring, safety is high, metabolism of the animal bodies is improved, and damage to the animal bodies is avoided.

Owner:郭云征

Wafer cutting liquid

Owner:RF360 TECH (WUXI) CO LTD

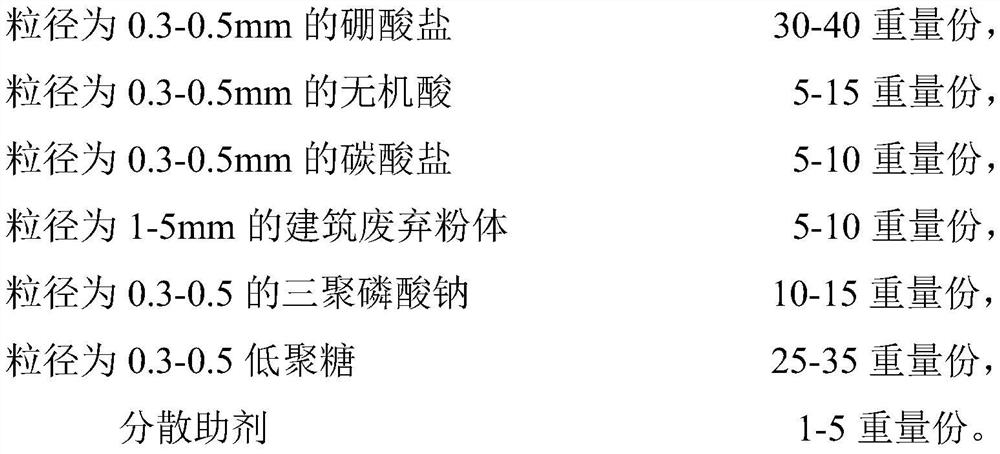

Retarder for novel water-resistant quick-hardening inorganic cementing material and preparation method thereof

The invention discloses a retarder for a novel water-resistant quick-hardening inorganic cementing material and a preparation method thereof. The retarder is characterized by being prepared from the following raw materials: borate, an inorganic acid, carbonate, construction waste powder, sodium tripolyphosphate, oligosaccharide and a dispersing aid according to a weight ratio of (30-40): (5-15): (5-10): (5-10): (10-15): (25-35): (1-5). Firstly, borate, inorganic acid, carbonate and sodium tripolyphosphate are mixed to prepare an inorganic retarder, and then the inorganic retarder, organic retarder oligosaccharide and construction waste powder are mixed. The inorganic retarder and the organic retarder cooperate with each other to achieve a retarding effect on the novel water-resistant quick-hardening inorganic cementing material. The method is simple and easy to implement and low in production cost, the prepared retarder has a good retarding effect on a novel water-resistant quick-hardening inorganic cementing material, and a foundation is laid for industrial application of the novel water-resistant quick-hardening inorganic cementing material.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

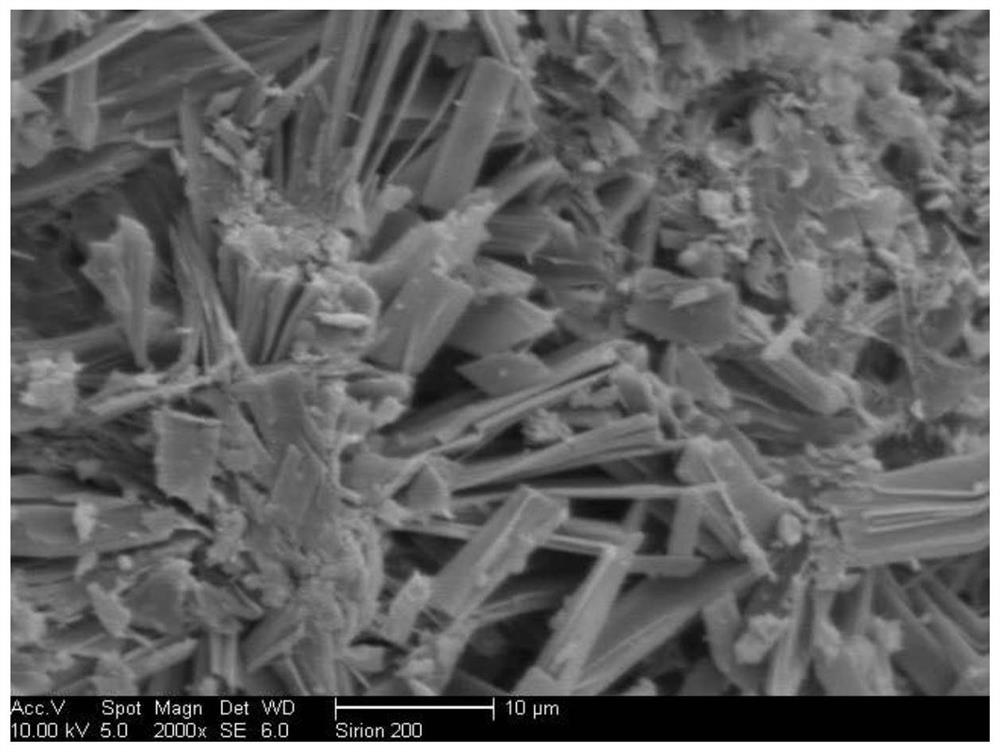

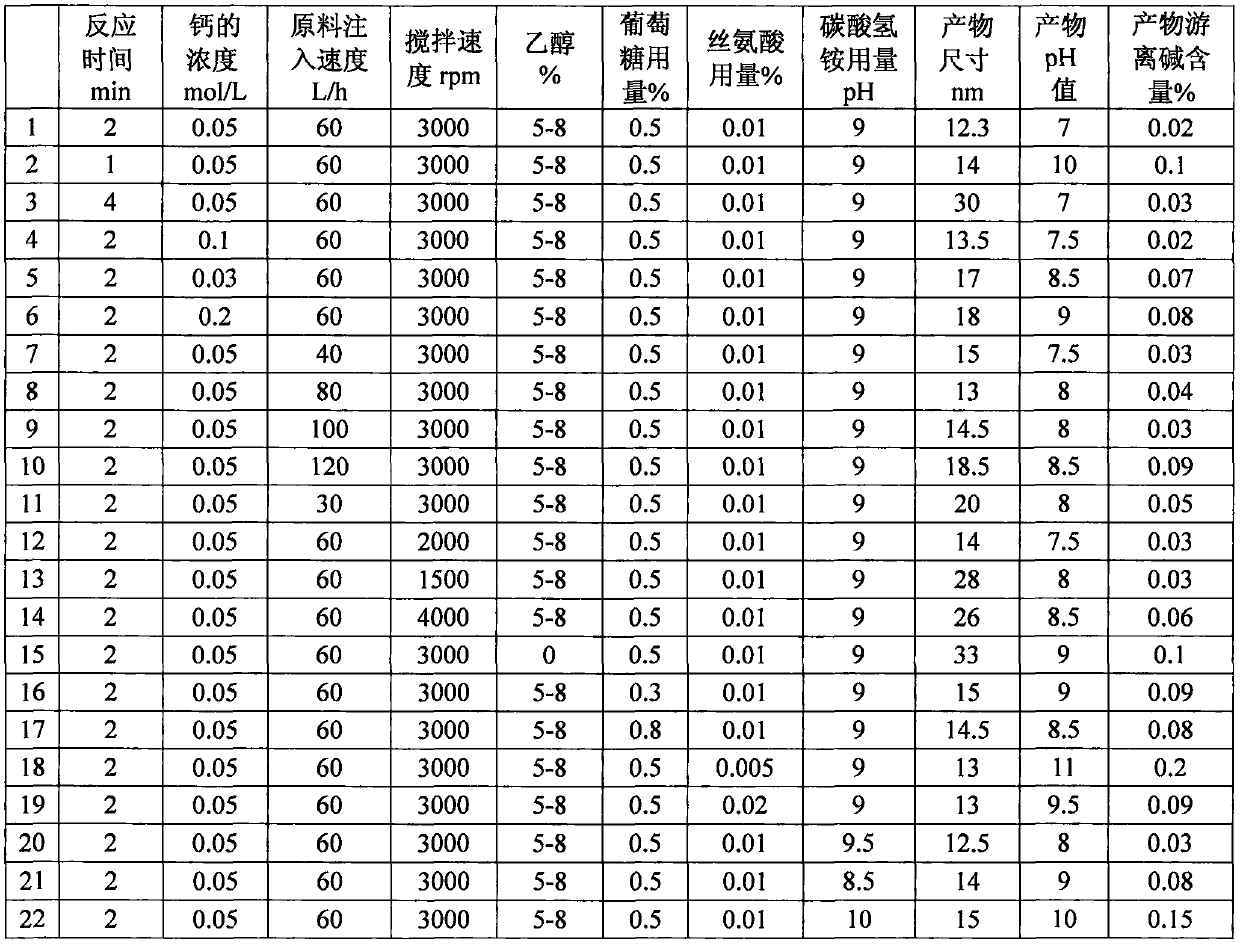

A method for preparing hollow calcium oxide powder

ActiveCN107986310BGood monodispersityRapid responseCalcium/strontium/barium oxides/hydroxidesSolventCalcium carbonate

The invention relates to a method for preparing hollow calcium oxide powder. According to the method, super-fine calcium carbonate is prepared by virtue of a rapid settling method, and the particle sizes of particles are controlled by controlling the concentration of a reactant, a solvent, the reaction time, a jetting speed and a stirring speed. By taking surface activated pollen as a core, the surfaces of pollen particles are uniformly coated with super-fine calcium carbonate particles in a high-density manner; by controlling the thermal treatment temperature and time, the pollen particles are removed, and the super-fine calcium carbonate particles are thermally decomposed and converted into calcium oxide; and meanwhile, by controlling the fusion among the particles, the surfaces of hollow calcium oxide particles are dense and smooth.

Owner:重庆一帆钙业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com