High lead-antimony slag type for anode slime smelting process and its use method

A technology of anode slime and high lead, which is applied in the field of separation and extraction of noble and base metals, high lead and antimony slag, can solve the problems of short furnace life, achieve the effects of prolonging the feeding time, reducing chemical corrosion, and improving processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

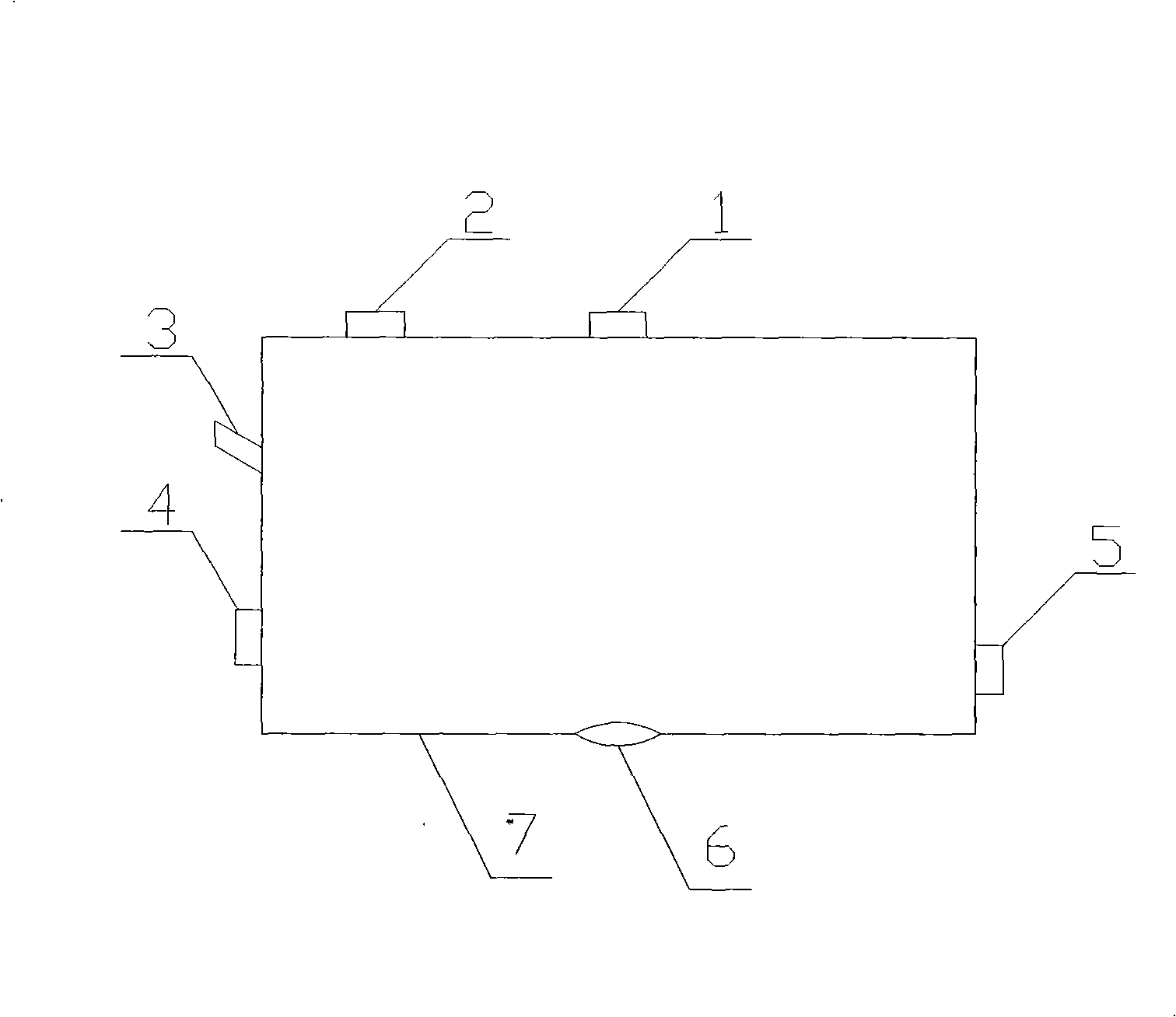

Image

Examples

Embodiment 1

[0026] Example 1: A high-lead antimony slag type used in the anode slime smelting process, the specific formula is a high-lead antimony slag type with low silicon, low calcium and low sodium, and the raw materials are composed according to the mass ratio: SiO 2 5 tons for FeO, 1 ton for FeO, Na 2 O is 0 tons, CaO is 0 tons, PbO is 10 tons, Sb 2 o 3 15 tons, PbO and SiO 2 The proportion control is 1.50~6.0. Slag melting point 900~1250℃, slag density: 3.9~4.6g / cm 3 .

Embodiment 2

[0027] Example 2: A high-lead antimony slag type used in the anode slime smelting process, the specific formula is a high-lead antimony slag type with low silicon, low calcium and low sodium, and the raw materials are composed according to the mass ratio: SiO 2 22 tons, FeO 8 tons, Na 2 O is 6 tons, CaO is 5 tons, PbO is 35 tons, Sb 2 o 3 45 tons, PbO and SiO 2 The proportion control is 1.50~6.0.

Embodiment 3

[0028] Example 3: A high-lead antimony slag type used in the anode slime smelting process, the specific formula is a high-lead antimony slag type with low silicon, low calcium and low sodium, and the raw materials are composed according to the mass ratio: SiO 2 17 tons, FeO 7 tons, Na 2 O is 0-6%, CaO is 1 ton, PbO is 33 tons, Sb 2 o 3 is 42 tons, that is, SiO 2 , FeO, CaO, PbO and Sb 2 o 3 The mass ratio of the five oxides is 100 tons, and the ratio of the five oxides is 17:7:1:33:42; PbO:SiO 2 =1.94; that is, PbO and SiO 2The ratio is controlled between 1.50 and 6.0. Slag melting point 900~1250℃, slag density: 3.9~4.6g / cm 3 . Slag melting point 900~1250℃, slag density: 3.9~4.6g / cm 3 .

[0029] A method for using the above-mentioned high-lead-antimony slag type used in the anode slime smelting process is characterized in that: there are the following three steps:

[0030] 1. Preparation for smelting: A molten pool with a certain depth must be formed before the smel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com