Patents

Literature

82results about How to "Extended feeding time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

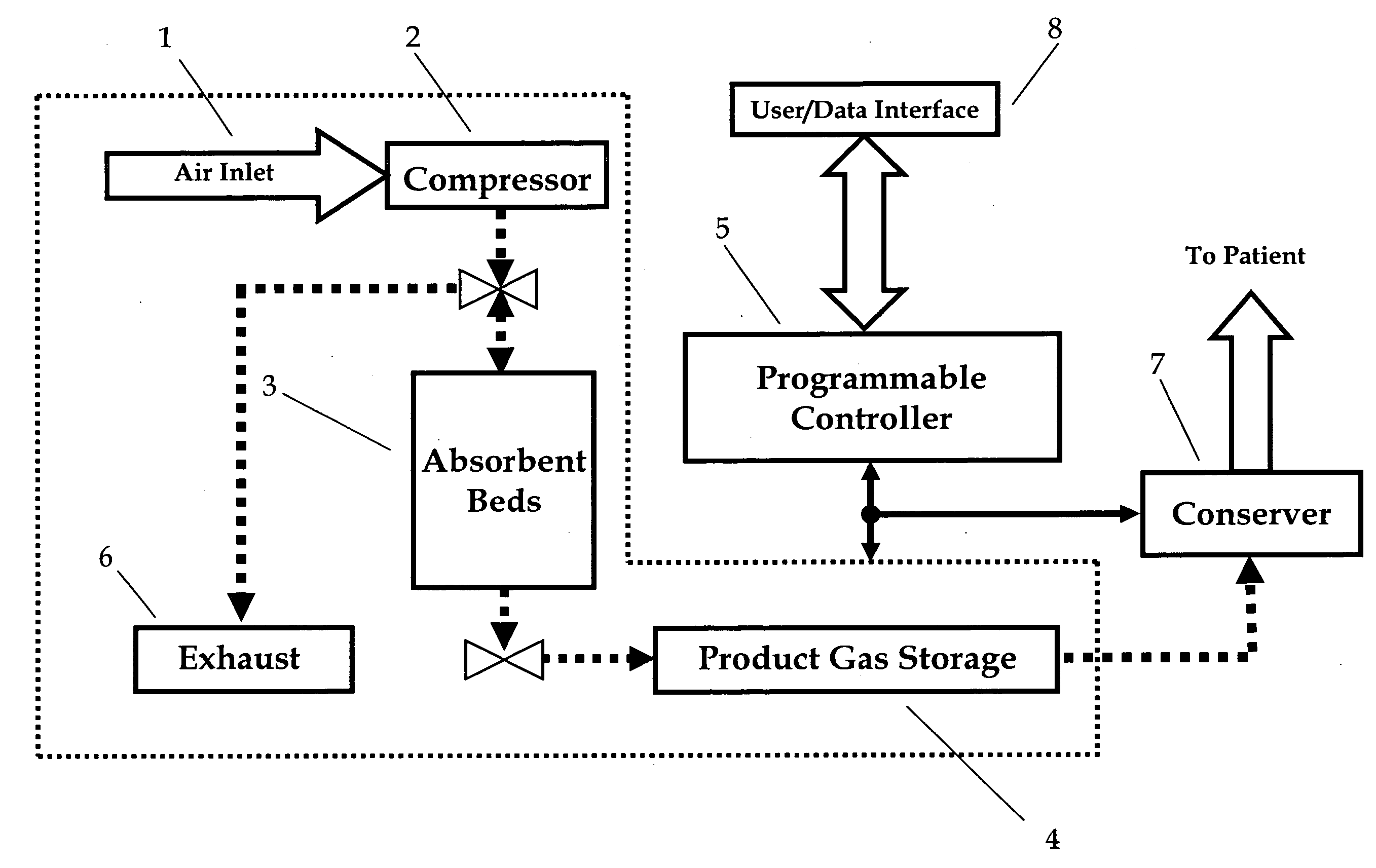

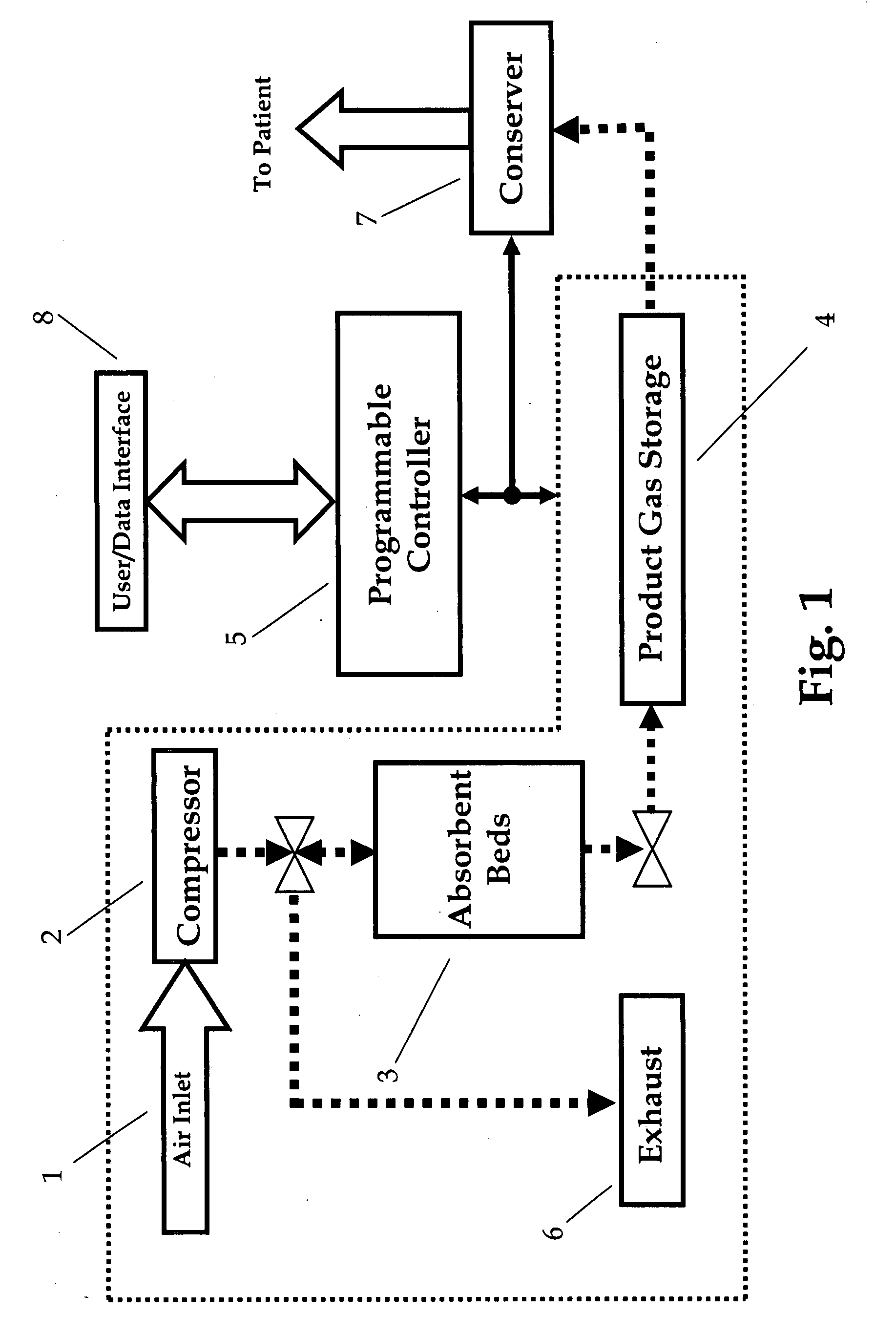

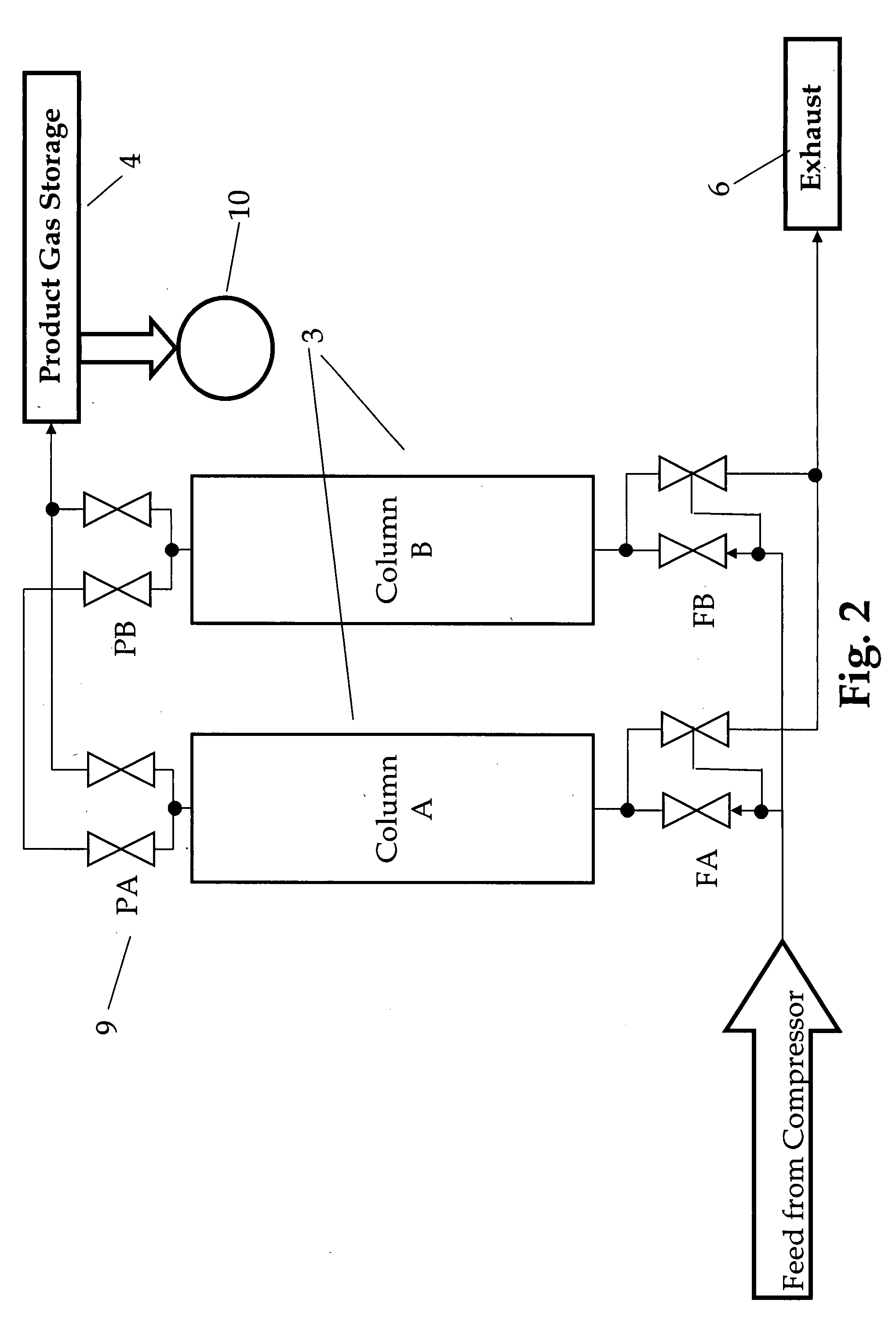

Adsorbent bed pressure balancing for a gas concentrator

ActiveUS20080110338A1Lengthens purge timePreserving intended cycle timeRespiratorsGas treatmentEngineeringPressure balance

A system and a method are described for monitoring pressure imbalances in the adsorbent beds of a portable gas concentrator. Using the programmability features found in modern portable concentrators, various mitigative procedures to adjust for pressure imbalances and to predict the need for service are disclosed.

Owner:INOGEN SA

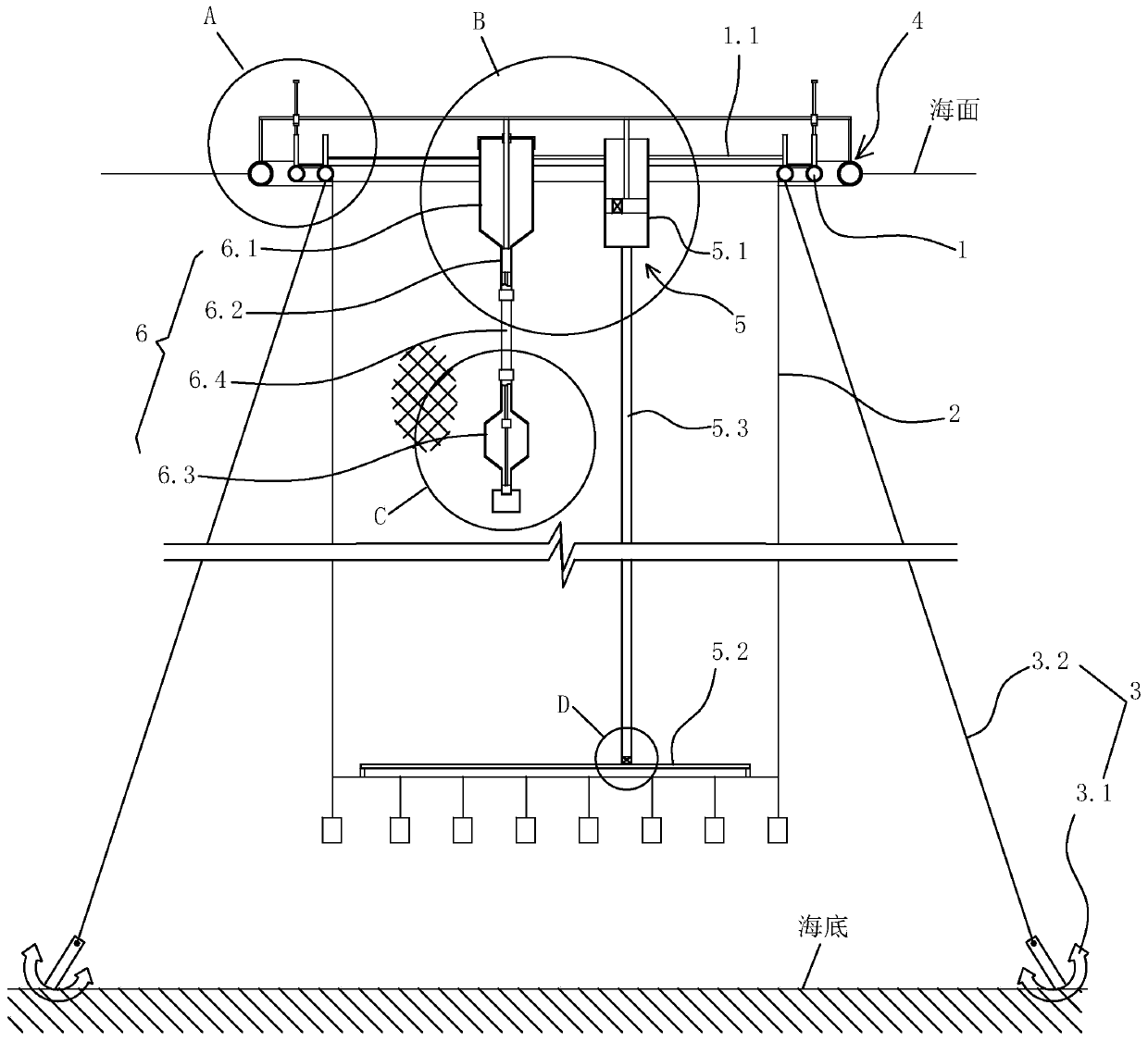

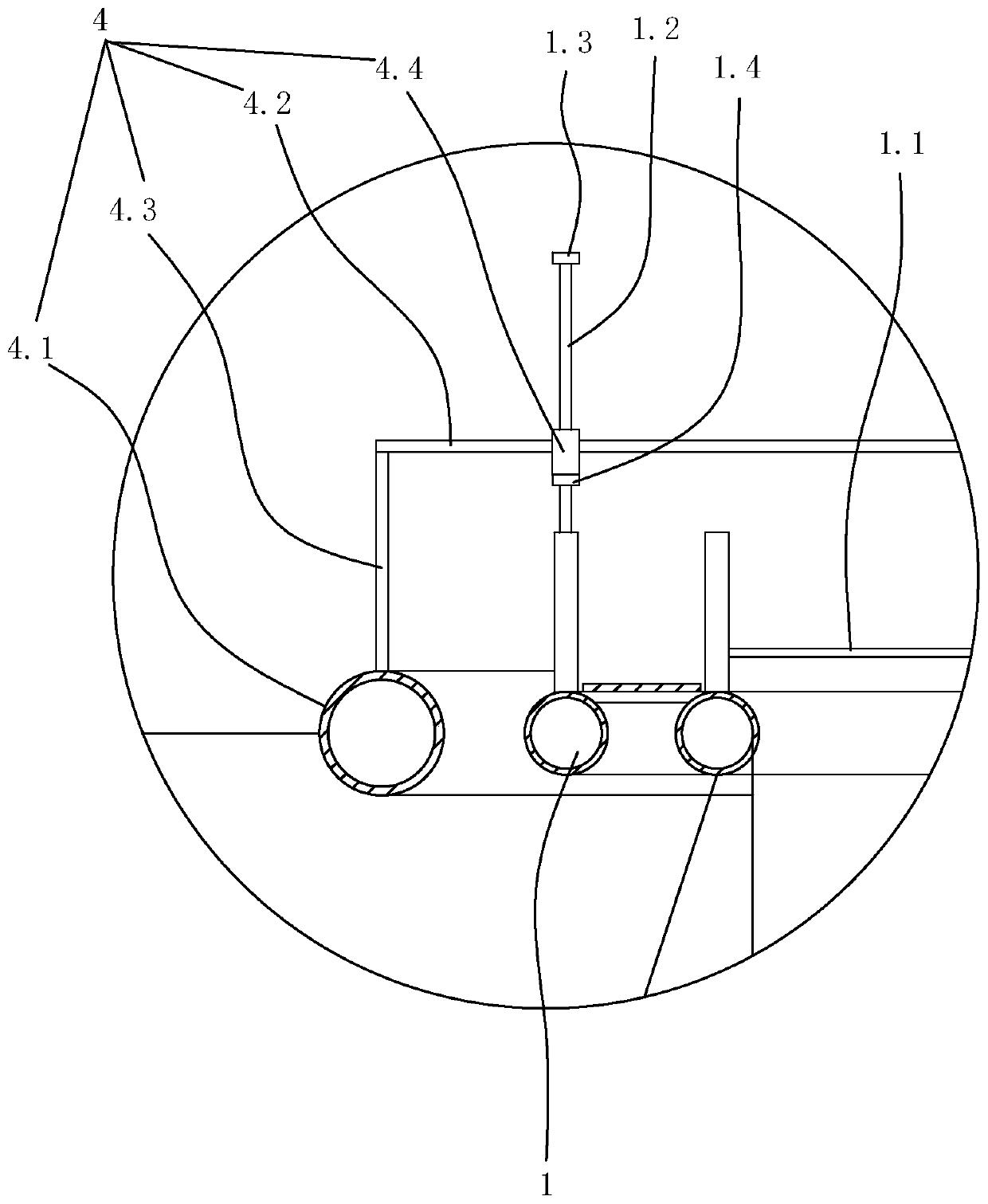

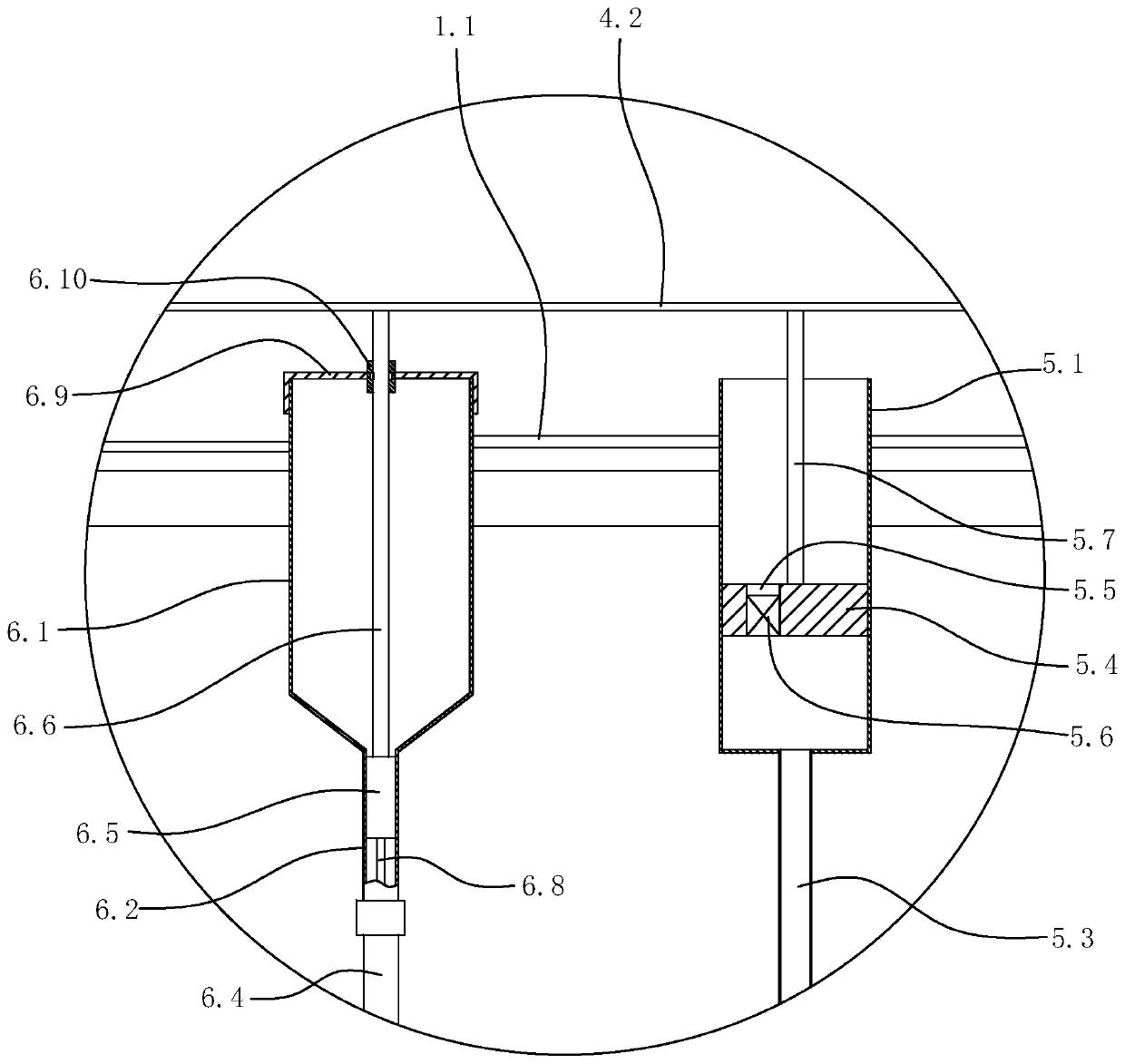

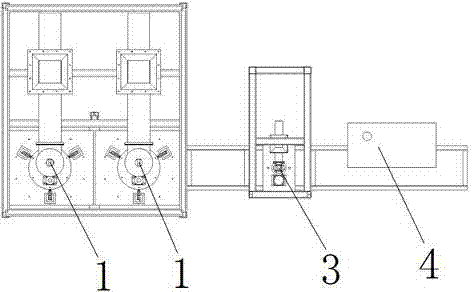

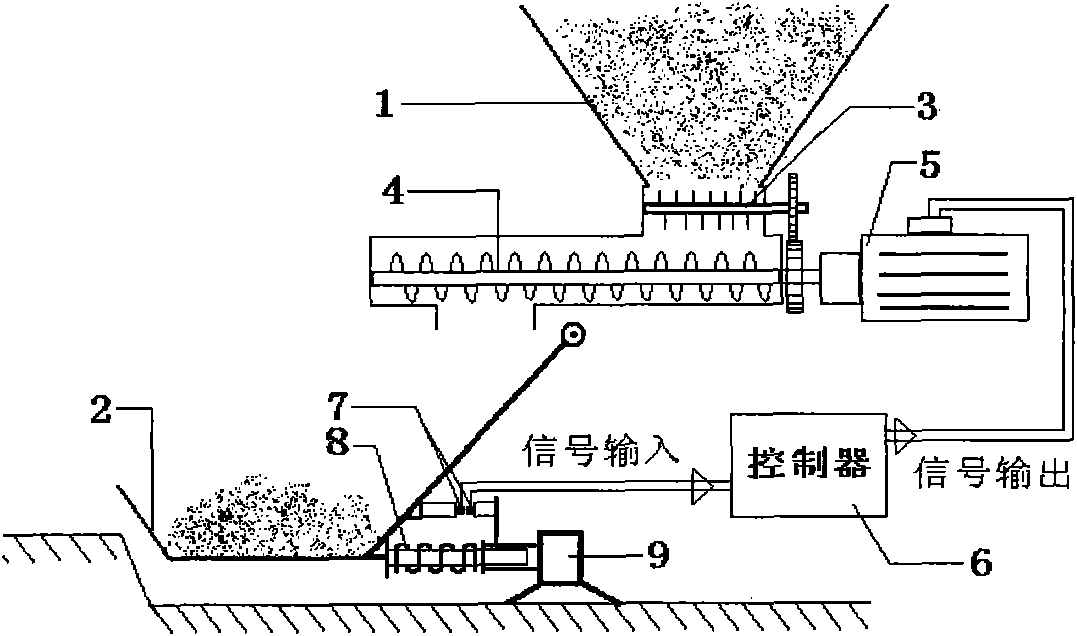

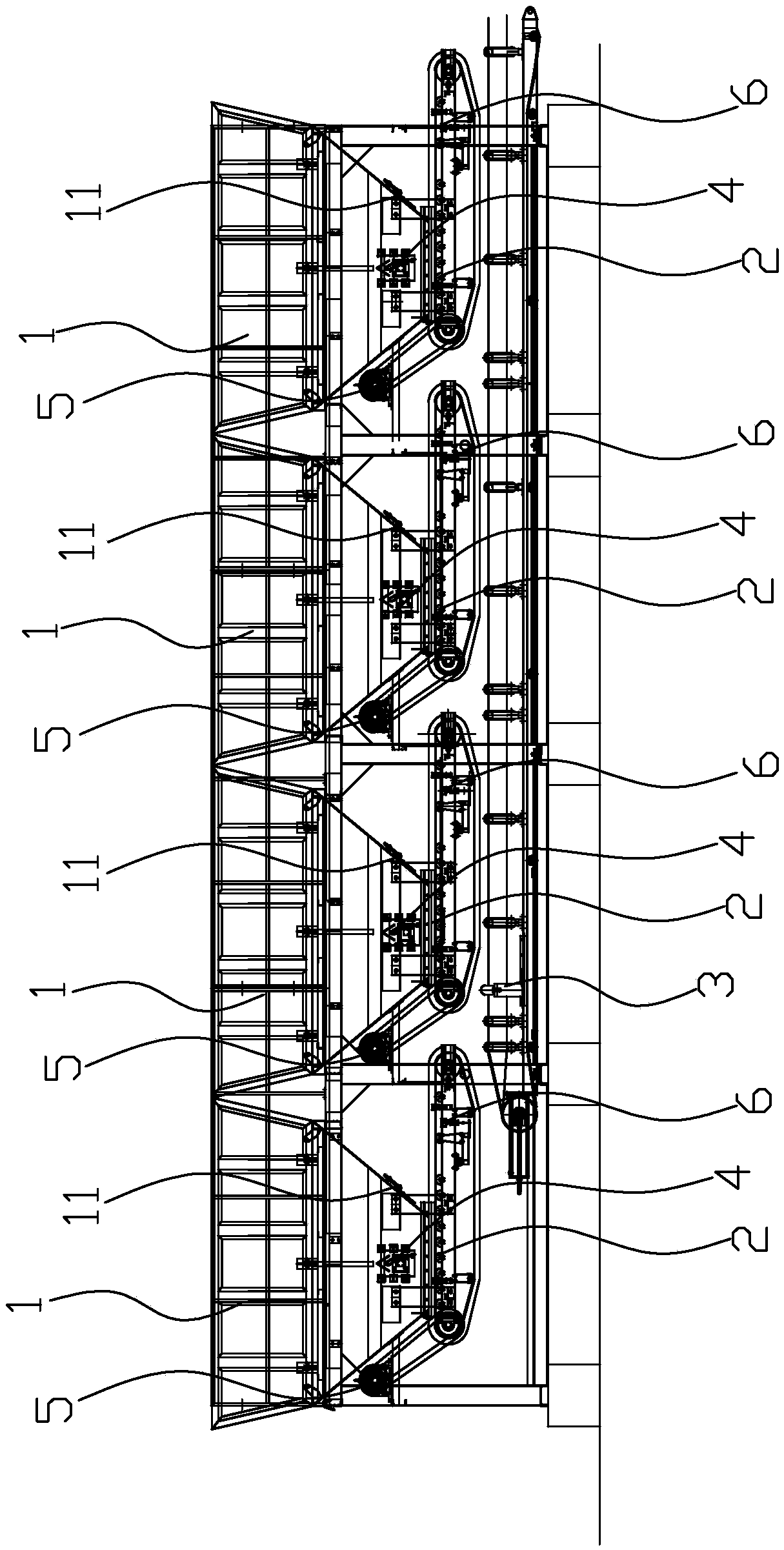

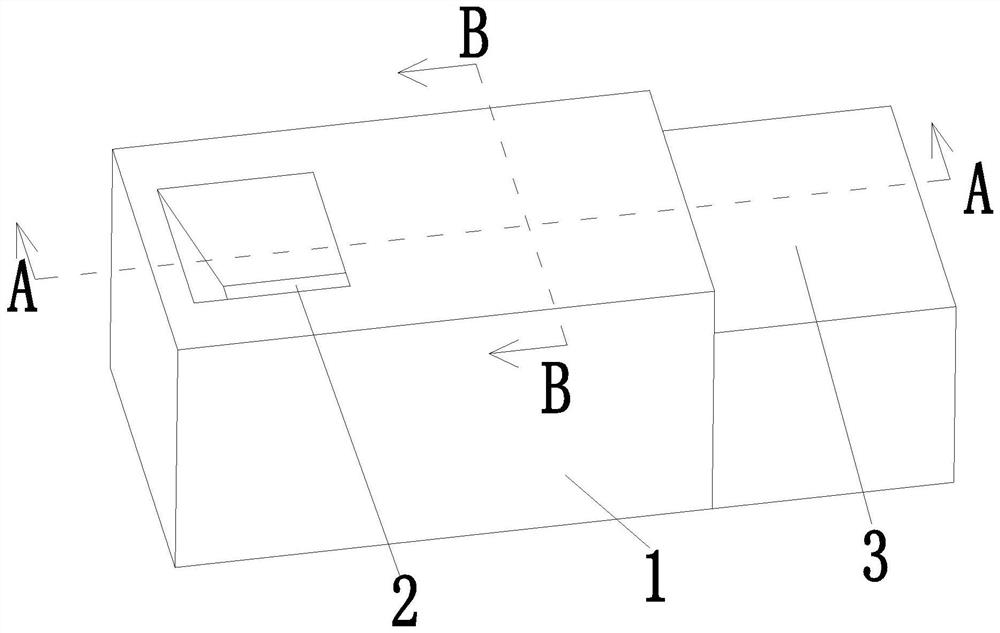

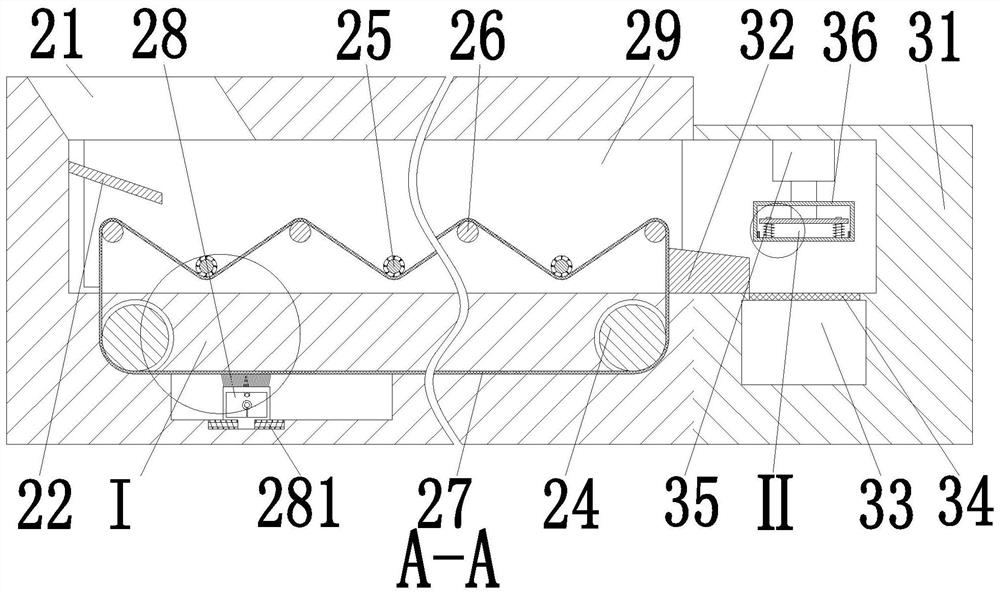

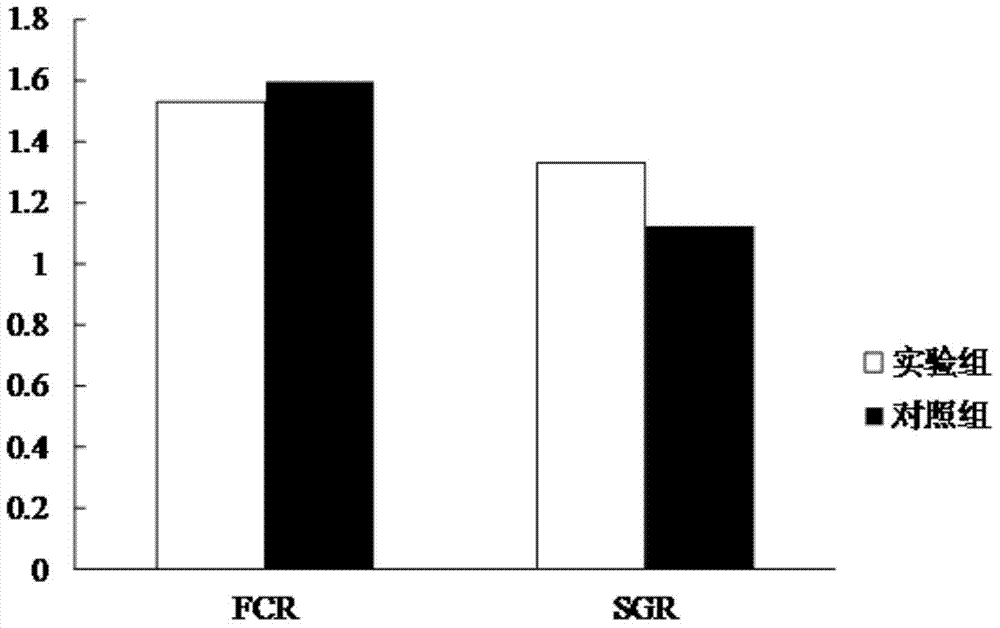

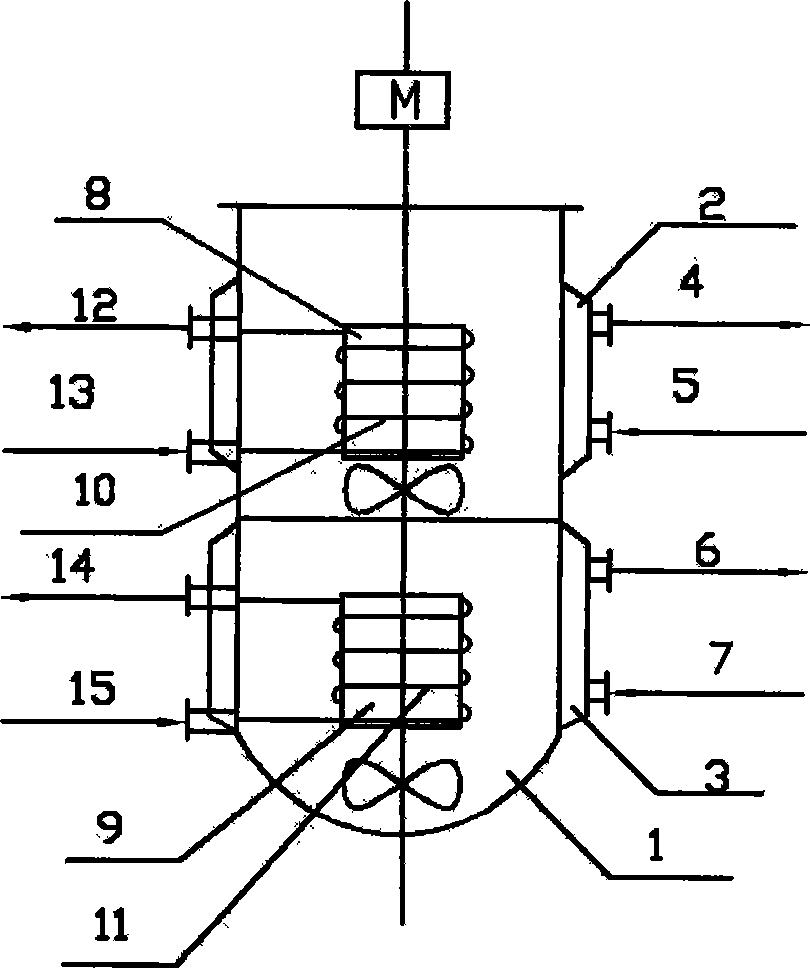

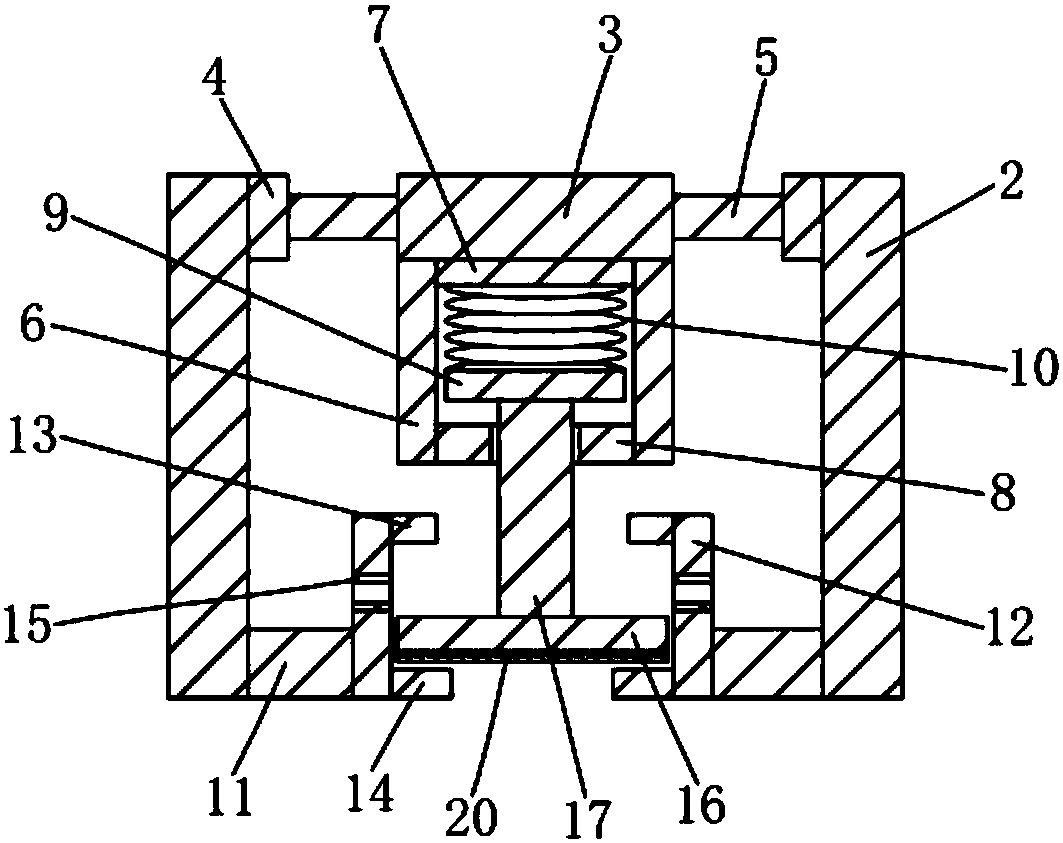

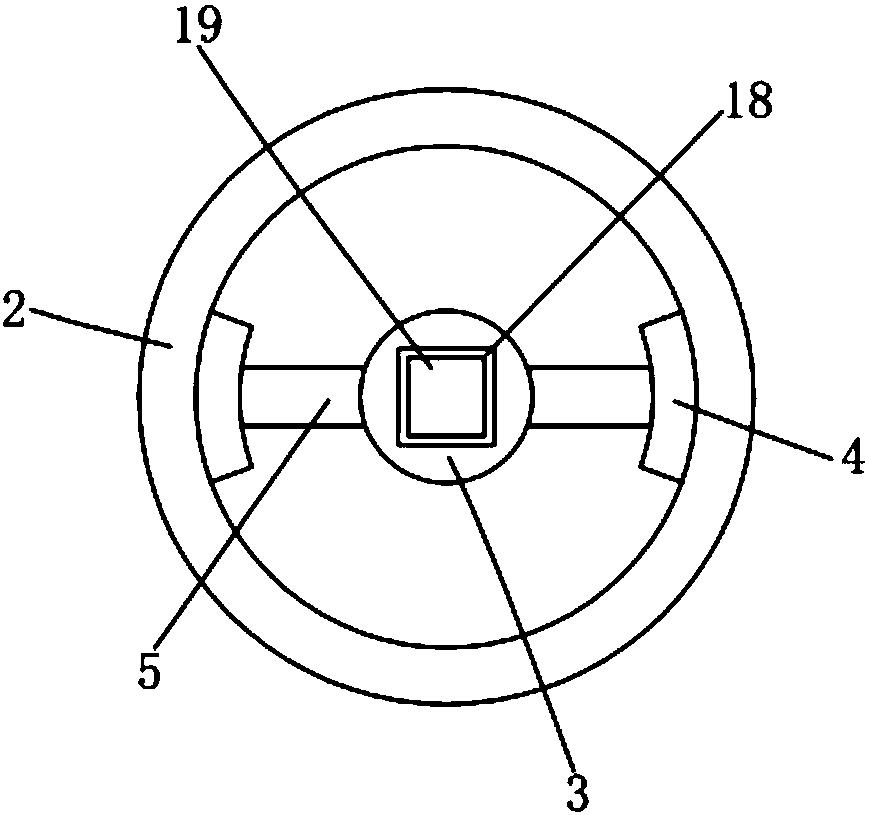

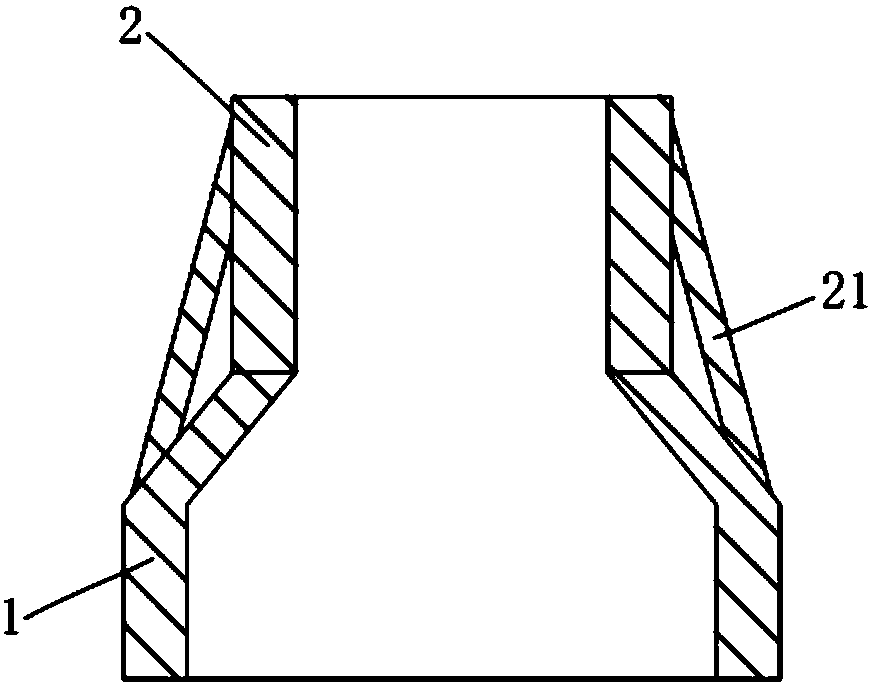

Deep sea cultivation net cage utilizing wave energy

ActiveCN110036960AExtended feeding timeReduce the amount of baitClimate change adaptationPisciculture and aquariaEngineeringOxygen supply

The invention discloses a deep seat cultivation net cage utilizing wave energy. The deep seat cultivation net cage comprises an annular support floating rack, a cultivation net cage body, an annular floating rack, an intermittent feeding mechanism and an oxygen supply device and is characterized in that the annular support floating rack floats on the sea surface and is provided with vertical guiderods; the edge of the upper-end opening of the cultivation net cage body is fixed to the annular floating rack; the intermittent feeding mechanism feeds bait into the cultivation net cage body in anintermittent manner; the oxygen supply device supplies oxygen for the bottom of the cultivation net cage body. The deep seat cultivation net cage utilizing the wave energy has the advantages that theintermittent feeding manner is used to prolong feeding time and reduce the bait feeding quantity of each time, and the problems that a large amount of bait sinks to penetrate the cultivation net cagebefore being eaten by fish in the cultivation net cage, severe bait waste is caused, and the large amount of residual bait deposited to the sea bed affects sea bottom soil environments are solved.

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

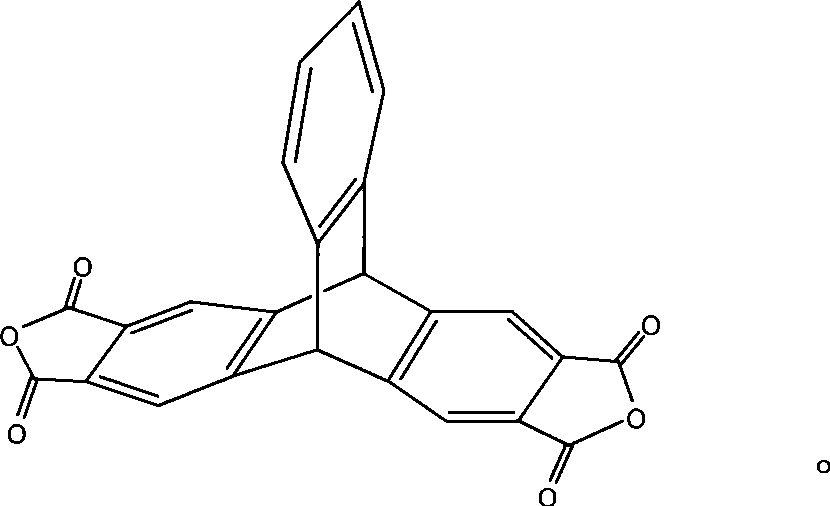

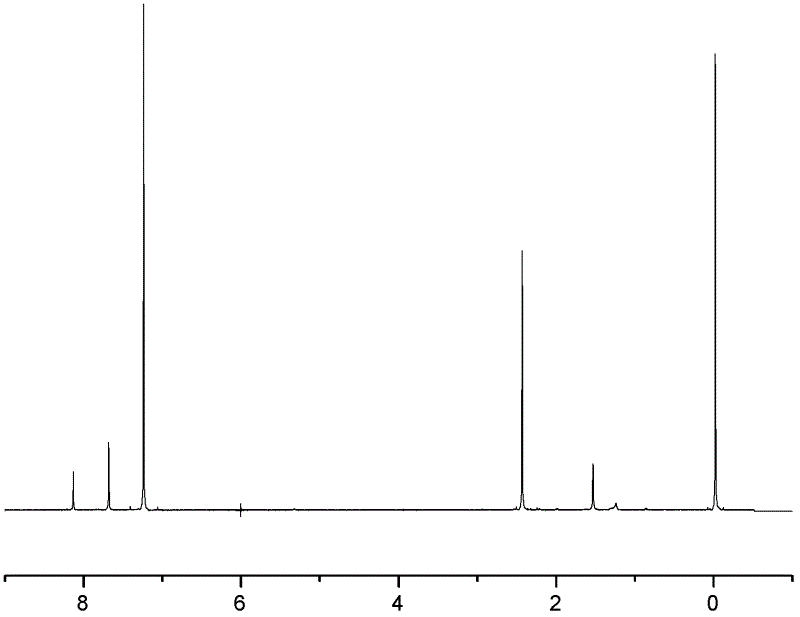

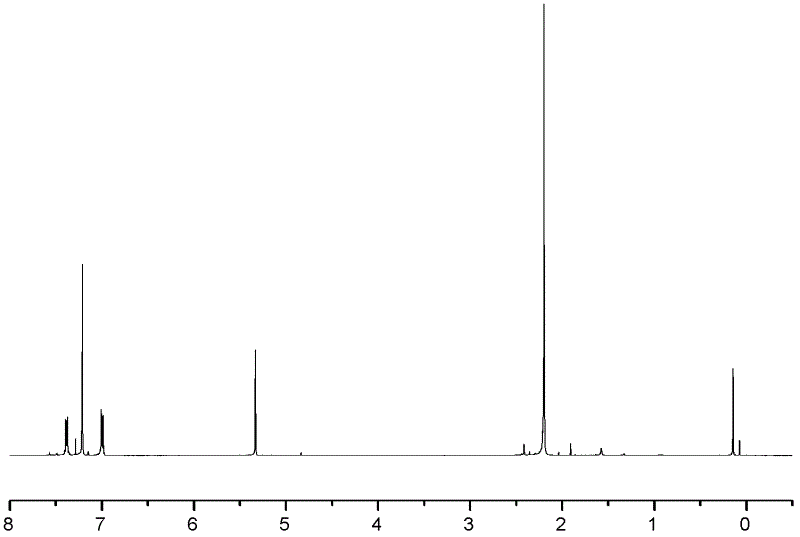

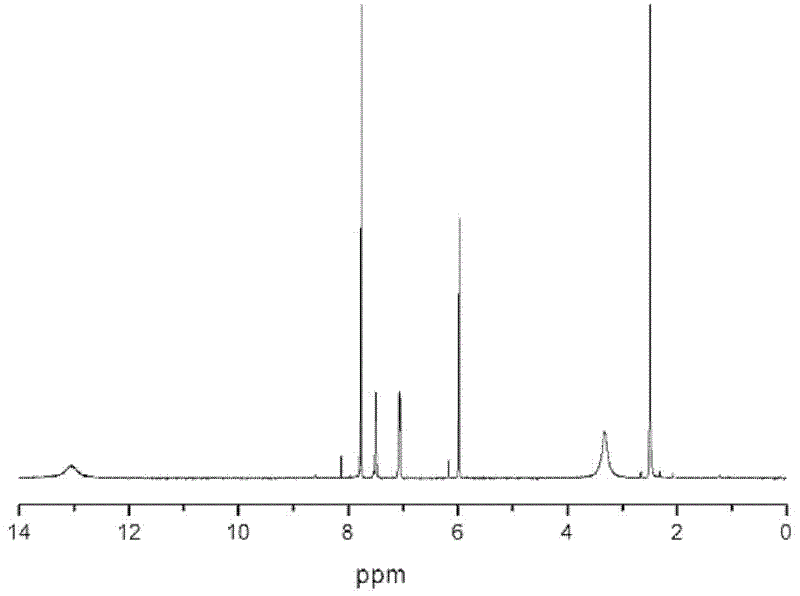

2,3,6,7-tetracarboxylic dianhydride triptycene and method for synthesizing the same

The invention discloses 2,3,6,7-tetracarboxylic dianhydride triptycene and a synthetic method thereof. The synthetic method comprises the following steps: preparing 2,3-dimethyl anthracene by a series of reaction of oxylene and phthalic anhydride which are cheap and easily obtained, and further reacting with 2-amino-4,5-hemellitic acid to obtain 2,3,6,7-tetramethyl triptycene; obtaining high-purity 2,3,6,7-tetramethyl triptycene by simple and rapid separation on columns, further oxidizing by potassium permanganate to obtain 2,3,6,7-tetracarboxylic acid triptycene, then obtaining the 2,3,6,7-tetracarboxylic dianhydride triptycene by dehydration. The method has the advantages of cheap and easily-obtained raw material, simple preparation method, high product purity which is up to 98% and the like, and the obtained product dianhydride monomer is fit for preparation of polyimide materials with good heat resistance and dissolubility.

Owner:HUAQIAO UNIVERSITY

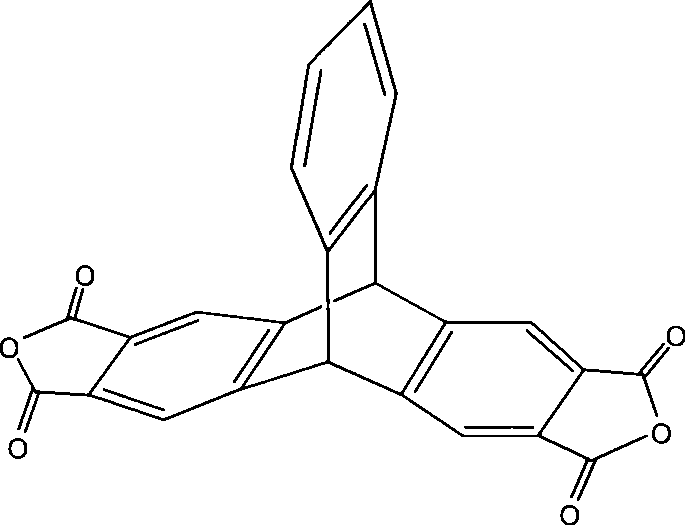

Synthesis method for 2,3,6,7-triptycene tetracarboxylic dianhydride

InactiveCN102617587AHigh yieldHigh product purityOrganic chemistryChromatographic separationAcetic anhydride

The invention discloses a synthesis method for 2,3,6,7-triptycene tetracarboxylic dianhydride. The method comprises the following steps of: 1) preparing 2,3,6,7-tetramethylanthracene from o-xylene and benzyl alcohol or methylene chloride under the catalysis of anhydrous aluminum trichloride; 2) diazotizing the 2,3,6,7-tetramethylanthracene, anthranilic acid and amyl nitrite to generate a crude product 2,3,6,7-tetramethyl triptycene; 3) performing chromatographic separation on the crude product 2,3,6,7-tetramethyl triptycene, and flushing the separated 2,3,6,7-tetramethyl triptycene by using a mixed eluting agent to obtain 2,3,6,7-tetramethyl triptycene; 4) oxidizing the 2,3,6,7-tetramethyl triptycene in a mixed solvent consisting of potassium permanganate, pyridine and water under a reflux condition to generate 2,3,6,7-triptycene tetracarboxylic acid; and 5) refluxing and dehydrating the 2,3,6,7-triptycene tetracarboxylic acid in acetic anhydride to generate the 2,3,6,7-triptycene tetracarboxylic dianhydride. The method has the characteristics of readily available and low-cost raw materials, high yield and high product purity.

Owner:HUAQIAO UNIVERSITY

Bait feeding method for baby grey sea horses

ActiveCN103444612AImprove feeding efficiencyExtended feeding timePisciculture and aquariaFisheryZoology

The invention provides a bait feeding method for baby grey sea horses. The method is conducted under the condition of a cultivation system and a cultivation environment and is characterized in that bait of different specifications is fed according to baby grey sea horse growing requirements in a cultivation period; newly hatched artemia strengthened through highly unsaturated fat acid is fed before the baby grey sea horses are 4 centimeters in height, and feeding density is 10-12 pieces per milliliter; when the baby grey sea horses are 4-4.5 centimeters in height, 4-5-day old artemia is fed, the artemia is strengthened by highly unsaturated fat acid before feeding, the feeding density is 5-6 pieces per milliliter; when the baby grey sea horses are 5.5-6 centimeters in height, 5-7-day old artemia is fed, the artemia is strengthened by highly unsaturated fat acid before feeding, and the feeding density is 5-6 pieces per milliliter; when the baby grey sea horses are more than 6.5 centimeters in height, adult artemia is fed, the artemia is strengthened by highly unsaturated fat acid before feeding, and the feeding density is 3-4 pieces per milliliter; feeding is conducted twice a day according to the bait feeding method, and excrement and dead bait are siphoned four times a day.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

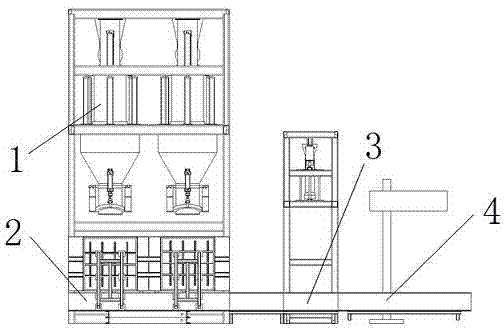

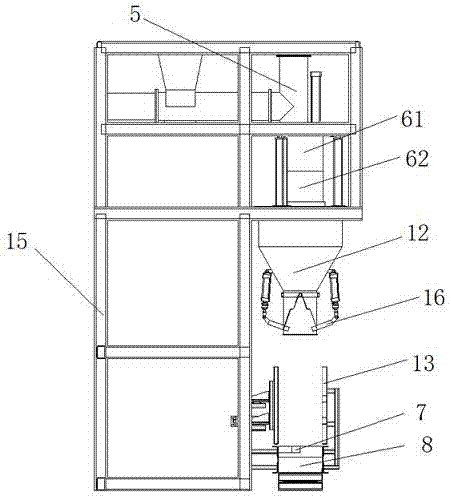

Automatic weighing and packing device for fine powdery material and method thereof

InactiveCN104494852AReduce volumeSolve the problem of not being able to load the materials that need to be weighedSolid materialControl systemEngineering

The invention relates to the field of automation, particularly relates to an automatic weighing and packing device for a fine powdery material and a method thereof, and solves the technical problems of providing the automatic weighing and packing device for the fine powdery material and the method thereof which are precise to pack and convenient to stack. The device comprises a coarse feeding device, a shaping and vibration transportation device, a measuring and weighing device and an edge-fold sewing device, wherein the coarse feeding device is arranged above the shaping and vibration transportation device; the coarse feeding device comprises a feeding control system, a support, a spiral feeder, a quantitative hopper and a bag holder, wherein the spiral feeder, wherein the quantitative hopper and the bag holder are sequentially arranged on the support, and the spiral feeder is connected with the upper end of the quantitative hopper; the shaping and vibration transportation device comprises a belt conveyor and a vibrator; the measuring and weighing device comprises a belt weigher, a feeder, a spiral feeder and a lifting sleeve, wherein the spiral feeder and the lifting sleeve are installed on the feeder. The automatic weighing and packing device provided by the invention has the effects of being quick and accurate in material packing efficiency and convenient to stack.

Owner:欧国艳

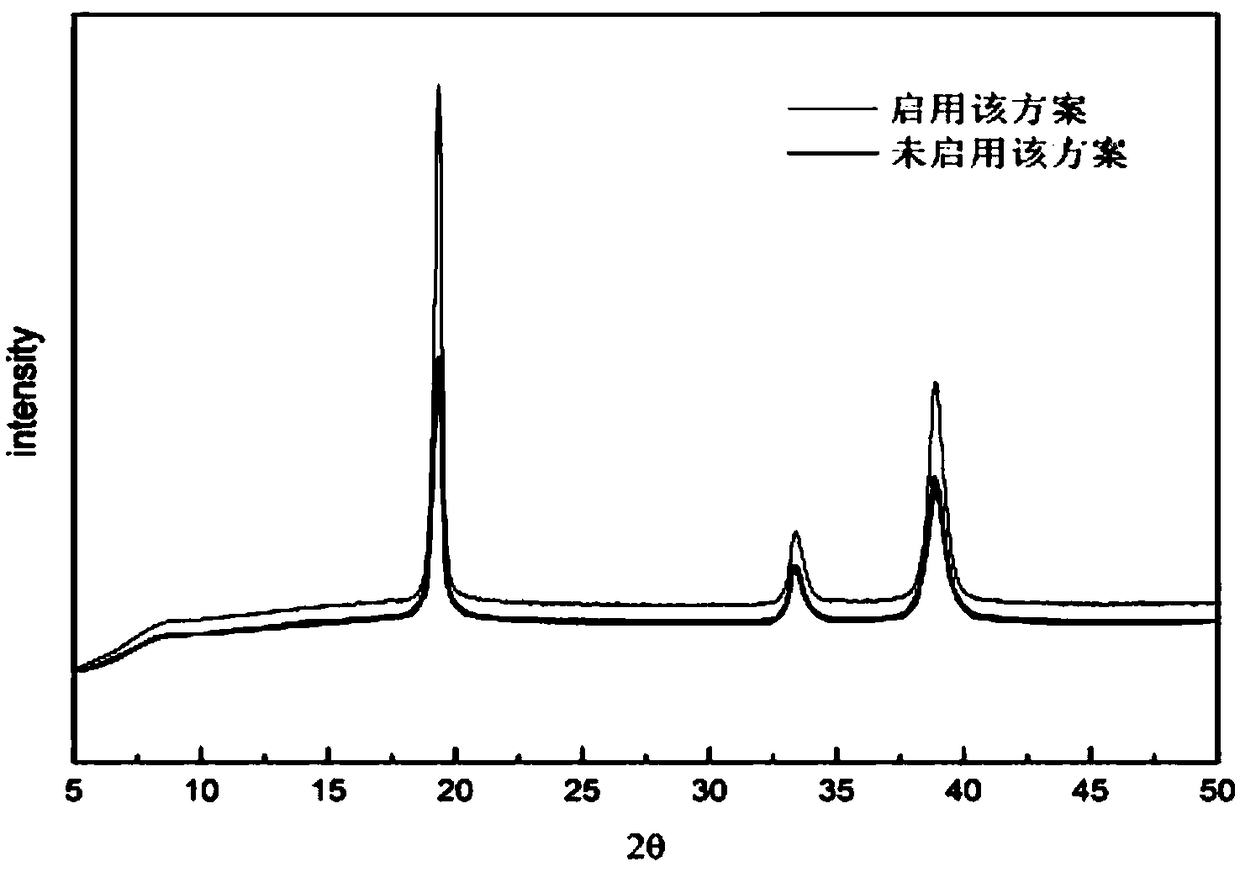

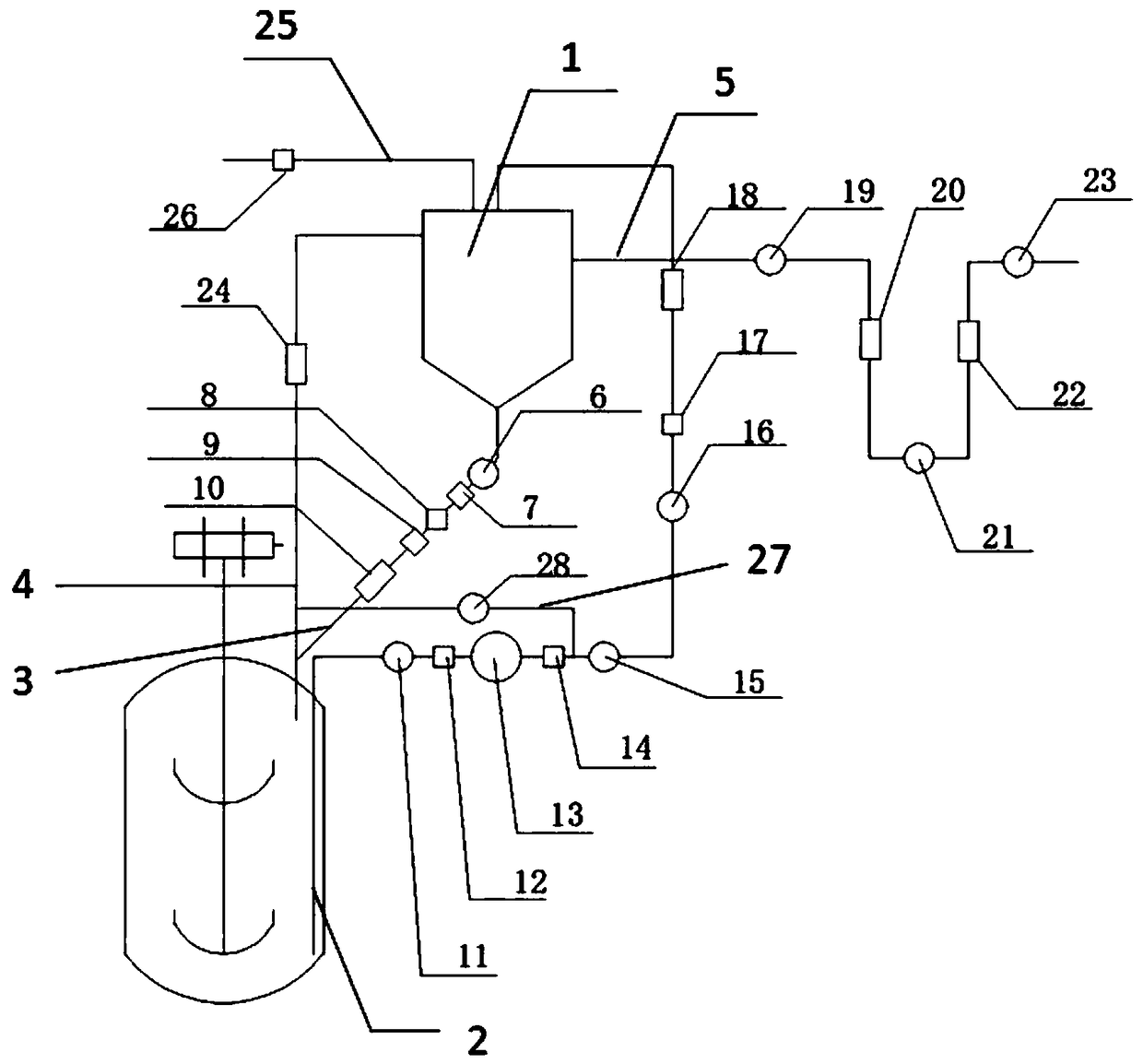

Thick hopper control system and method for synthesizing ternary precursor by utilizing same

PendingCN108786708AExtended stayExtended feeding timeProcess control/regulationChemical/physical/physico-chemical stationary reactorsManganeseEngineering

The invention relates to the technical field of preparation of a ternary positive electrode material for lithium ion batteries, in particular to a method for synthesizing a nickel-cobalt-manganese ternary precursor by utilizing a thick hopper control system. According to the invention, slurry at the bottom of a reaction kettle is pumped into a thick hopper through a pump on a material feeding pipeline, and no stirring is carried out in the thick hopper; gravity is utilized to carry out sedimentation and realize solid-liquid separation; then thick slurry is refluxed into the reaction kettle toincrease the solid content; at the same time, clear liquid is discharged to the outside through a clear liquid discharge pipeline; the system can be applied to continuous production and upgrading, canalso be used for intermittent production and upgrading, and can be opened in any process of production. When the system is in operation, the proportion of the clear liquid discharge can be increasedby increasing the material feeding flow rate, and the flow rate of the thick slurry can be changed by the opening degree of a thick slurry reflux pipeline valve. By adopting the method provided by theinvention, the production cost is effectively reduced, the operation difficulty is reduced, and the safety is improved; the precursor produced by the invention has more excellent physical and chemical indexes, and a sintered positive electrode material has more excellent performance.

Owner:HUAYOU NEW ENERGY TECH (QUZHOU) CO LTD +1

Piglet forage ingredient and its preparation method and use

ActiveCN103271241AShorten fasting timeImprove solubilityAnimal feeding stuffEnzymatic hydrolysisAdditive ingredient

The invention relates to a piglet forage ingredient and its preparation method and use. The preparation method comprises the following steps of carrying out controlled-enzymatic hydrolysis of lactalbumin to a hydrolysis degree of 15 to 20%, carrying out sterilization at a temperature of 80 to 95 DEG C for 10 to 30min, concentrating the sterilized enzymatic hydrolysis product into an enzymatic hydrolysis product concentrated solution having solid content of 30-40%, adding 0.1 to 0.3% of ethyl maltol into the enzymatic hydrolysis product concentrated solution, and carrying out heat preservation at a temperature of 100 to 120 DEG C for 1 to 3h to obtain the piglet forage ingredient. Through being used in weaned piglet forage, the piglet forage ingredient can obviously improve piglet forage attraction to a weaned piglet.

Owner:深圳安佑康牧科技有限公司

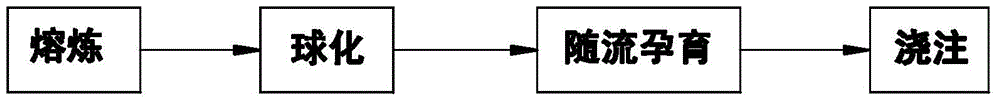

Production technology for as-cast spheroidal graphite iron casting QT600-7

The invention discloses a production technology for an as-cast spheroidal graphite iron casting QT600-7 and belongs to the technical field of casting. The production technology comprises the steps of feeding Q10 raw iron, Q235 waste steel and a foundry returns into a furnace for smelting to obtain liquid iron; putting Cu, Ni and an RE-Mg balling agent as well as a SiBaCa nucleating agent at the bottom of a foundry ladle, and pouring the smelted liquid iron into the foundry ladle for balling; adding the powdered SiBaCa nucleating agent along with the flow during ladle transferring of the balled liquid iron; pouring the nucleated liquid iron into a casting mold to obtain the as-cast spheroidal graphite iron casting QT600-7. The material intensity of the spheroidal graphite iron casting produced by the production technology is higher than or equal to 600Mpa, and the elongation rate is greater than or equal to 7 percent. The as-cast spheroidal graphite iron casting QT600-7 has comprehensive performance of high elongation rate of ferrite spheroidal graphite iron and high intensity of pearlyte spheroidal graphite iron; the pearlyte content is 35-60 percent, the balling rate is about 85 percent, and stable production that the as-cast spheroidal graphite iron casting 600-7 has standard performance is realized.

Owner:SHANDONG QIU CHEN MACHINERY MFG

Intestine protecting milk powder and its compounding process

InactiveCN1370412AImprove gastrointestinal functionExtended feeding timeMilk preparationFood preparationSide effectMedicine

The intestine protecting milk powder is produced by mixing Geweibao granule in 20-30 wt% and milk powder in 70-80 wt% and through further spray drying and disinfection. The Geweibao granule is prepared with Radix Puerariae, fern root and Chinese yam. The intestine protecting milk powder as one kind of dietotherapeutic green food has the same appearance and taste as common milk powder, the effect of improving gastrointestinal function and no toxic side effect.

Owner:王文伟

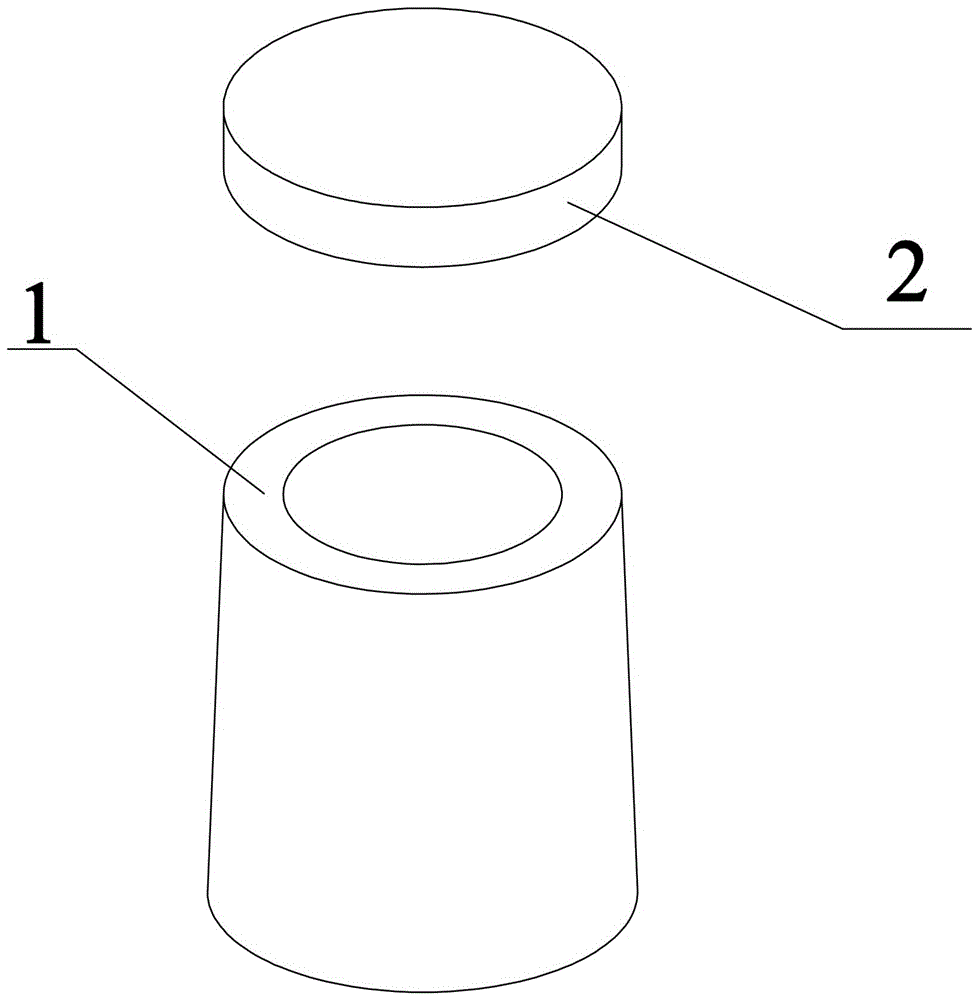

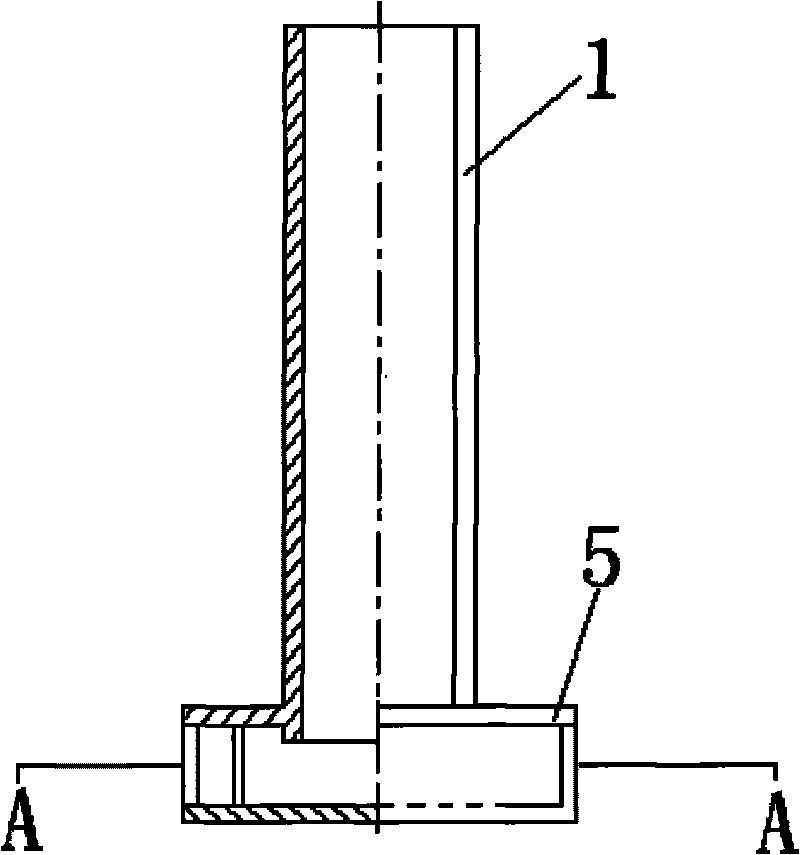

Cast steel exothermic riser sleeve

The invention relates to a casting riser sleeve, in particular to a cast steel exothermic riser sleeve. The two ends of the exothermic riser sleeve are opened. A top cover is arranged at the top end of the exothermic riser sleeve. The top cover is made of precoated sand. The exothermic riser sleeve is adopted for replacing a sand mold overflow riser in the prior art, the setting time is prolonged, heat supply is uniform, and the interior of an exothermic riser is free of defects, deformation and expansion; and the surface of a casting is bright and clean, the appearance is tidy, the technology yield is increased by 4.6%, and the production cost is reduced.

Owner:西峡飞龙特种铸造有限公司

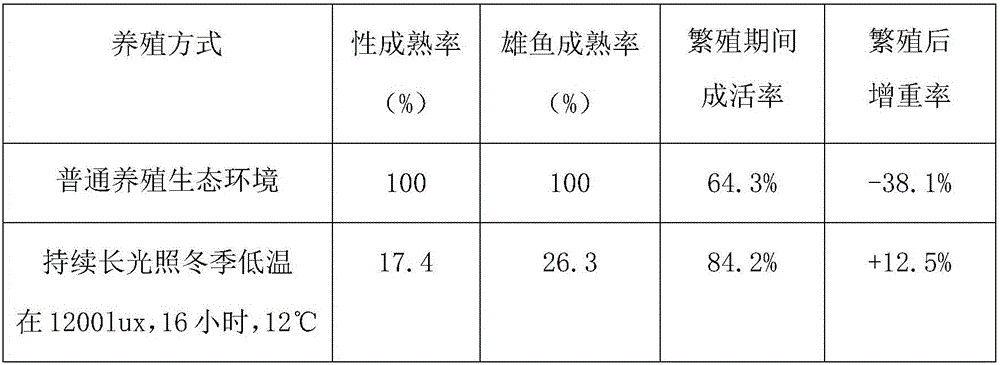

Method for increasing survival rate and growth rate of alosa sapidissima in breeding season

ActiveCN105850802AImprove survival rateIncrease motivationClimate change adaptationPisciculture and aquariaInjury causeSalinity

The invention discloses a method for increasing the survival rate and the growth rate of alosa sapidissima in a breeding season. The rhythmic seasonal change of daily light period, temperature and salinity of a breeding environment is controlled according to an anti-ecological rhythm principle, the gonad development process is delayed or inhibited, bioenergy consumption of gonad development is reduced, sexual behavior of male alosa sapidissima is inhibited, injuries caused during sexual pursuit are reduced, and the survival rate of alosa sapidissima in the breeding period is increased. The method has the most remarkable effects that the survival rate of alosa sapidissima in the breeding period is remarkably increased, more importantly, the weight of alosa sapidissima is remarkably increased instead of being reduced as before in the breeding period lasting for three months and no drugs are required for treatment of injuries; the method is simple, reliable and low in cost and has a remarkable effect and wide application prospect.

Owner:SUZHOU FISHSEEDS BIOLOGICAL TECH CO LTD

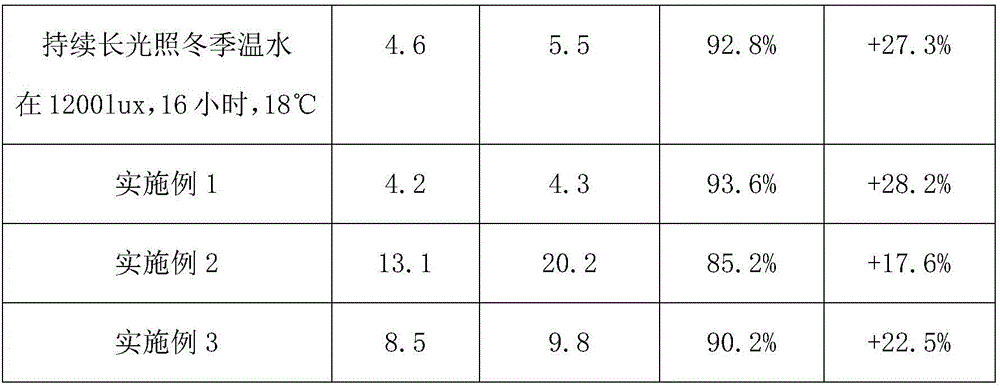

High-efficient feeding trough for cattle

InactiveCN102100183AAvoid picky eatersBalanced intakeAnimal feeding devicesLivestock breedingDigestion

The invention relates to the production field in the livestock industry and discloses an invention scheme of a high-efficient feeding trough for cattle, which can be used for solving the problems of low feed reward and waste of feed resources caused by picky eating behavior of the cattle. The high-efficient feeding trough for the cattle is characterized by comprising an upper storage trough 1, a lower intake trough 2 and a middle condition control feed conveying device, wherein the condition control feed conveying device comprises rake teeth 3, an orthogonal wheel 4, an electric motor 5, a controller 6, movable and fixed contacts 7 and a spring 8. The condition control feed conveying device can convey feed in the storage trough into the intake trough in batches, the feed amount conveyed each time is very low (2-3kg), and a prerequisite for conveying the feed each time is that the feed in the intake trough is completely taken by the cattle; therefore, the picky eating behavior of the cattle can be limited, and synchronicity and balance of feed intake can be further improved. The use of the trough has to be based on total mixed ration (TMR) feeding. By adopting the method, the occurrence of the picky eating behavior of the cattle can be thoroughly avoided, the situation of enabling the cattle to intake balanced nutrients can be ensured, the feed reward can be improved, and the feed resources can be saved. The uniform feed intake can be ensured, and the synchronicity of feed digestion can be improved, thus the high-efficient feeding trough is conductive to maintaining an environment in a normal rumen; the feed is more sanitary; the frequency of artificial feeding is reduced, and the labor intensity is reduced; and the intake time of the cattle is increased, and the intake amount is improved.

Owner:杨光

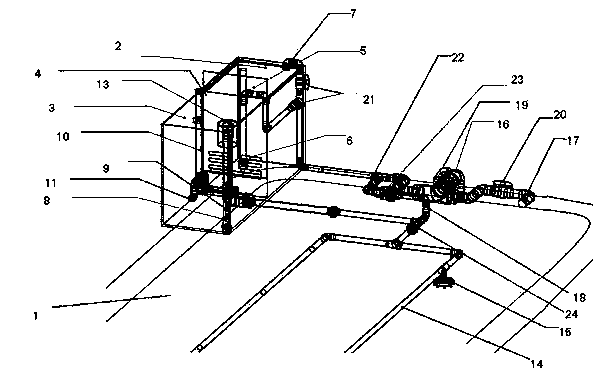

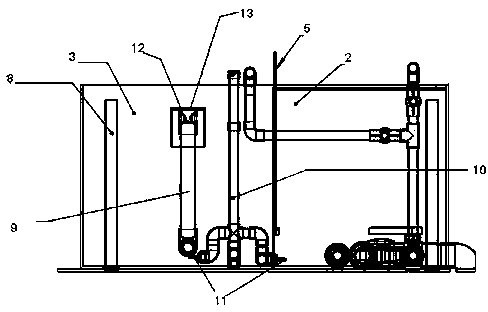

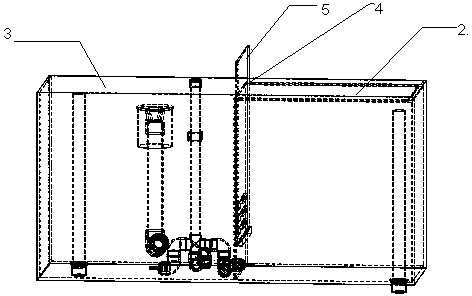

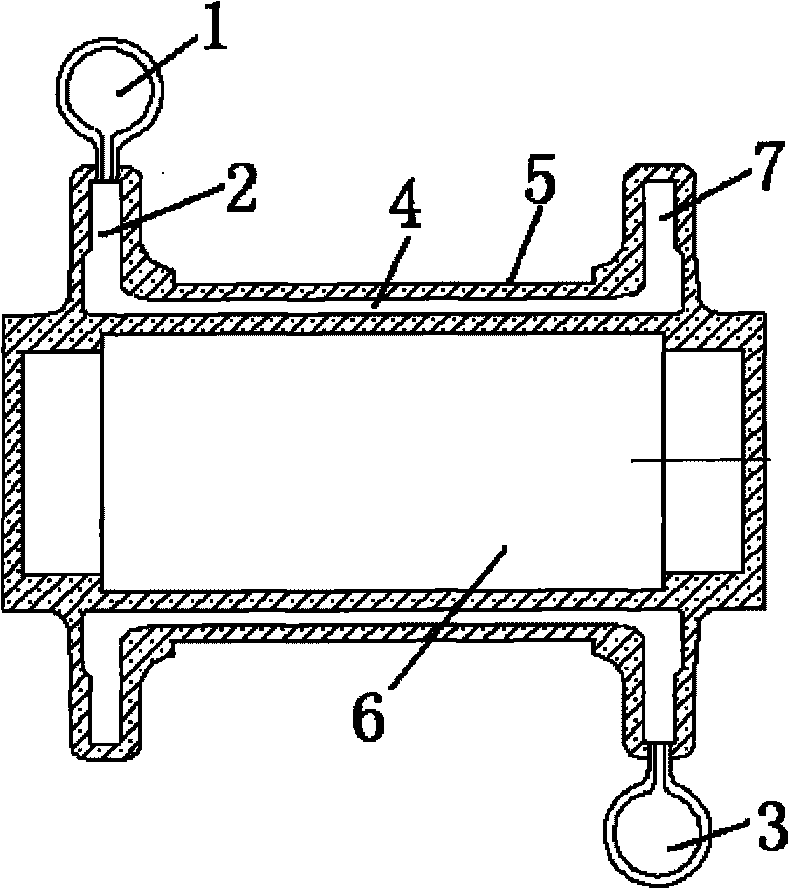

Siphoning type zooplankton feed incubation and feeding system and using method thereof

ActiveCN103988803AReduce stocking densityImprove survival rateClimate change adaptationPisciculture and aquariaZooplanktonGas supply

The invention discloses a siphoning type zooplankton feed incubation and feeding system and a using method thereof. The siphoning type zooplankton feed incubation and feeding system comprises a bait tank, a culture pond and a connection pipeline, wherein the bait tank comprises an incubation tank and a siphoning feeding tank which are partitioned by a partition tank, a shading incubation baffle can be inserted into the partition tank, and a live insect separation tank opening is formed in the in the bottom of the separation tank. Bait tank water inlet pipes are respectively arranged at the tops of the incubation tank and the siphoning feeding tank, and a water discharging port is formed in the bottom. A bait discharging pipe and an air supply pipeline are perpendicularly arranged in the siphoning feeding tank, air supply nozzles are arranged at the bottom of the air supply pipeline and respectively supply air to the incubation tank and the siphoning feeding tank, a siphon sleeve is sleeved with the top of the bait discharging pipe connected with the feeding end of a feeding pipeline of the culture pond, and the output end of the feeding pipeline is connected with a diffuser. The using method of the siphoning type zooplankton feed incubation and feeding system comprises the steps of incubation, feeding and cleaning. Incubation, impurity separation and feeding are integrated into one system, so that labor in zooplankton culture is saved, and feeding efficiency is increased.

Owner:宁德市富发水产有限公司

Compound premix for livestock

InactiveCN107259176AIncrease production capacityEfficient SupplementAnimal feeding stuffAccessory food factorsSodium bicarbonateBrick

The invention relates to a formula of feed for livestock, and particularly discloses a compound premix for livestock. The pecking feed part of the compound premix is prepared from the following components: barley, water, L-lysine hydrochloride, DL-methionine, ferrous sulfate, zinc sulfate, copper chloride hydroxide, manganese sulfate, sodium selenite, calcium iodate, vitamin complex for chicken, mildew preventive, magnesium sulfate, sodium bicarbonate, potassium chloride, calcium formate, calcium hydrophosphate, ethoxyquinoline, dextrin and starch. The raw materials are uniformly mixed and pressed into cake to obtain the compound premix. The compound premix has the advantages that (1) natural habits of livestock for pecking and ingesting can be met, and pickingill of chicken can be prevented; (2) the components are reasonably proportioned, the production performance of feeding chicken can be remarkably improved; (3) the ingesting time of feeding chicken can be effectively prolonged, and nutritional substances can be effectively absorbed; (4) the components in the feed cannot be layered due to proportion difference in the feeding chicken pecking process.

Owner:GUANGHAN LONGDA FEED

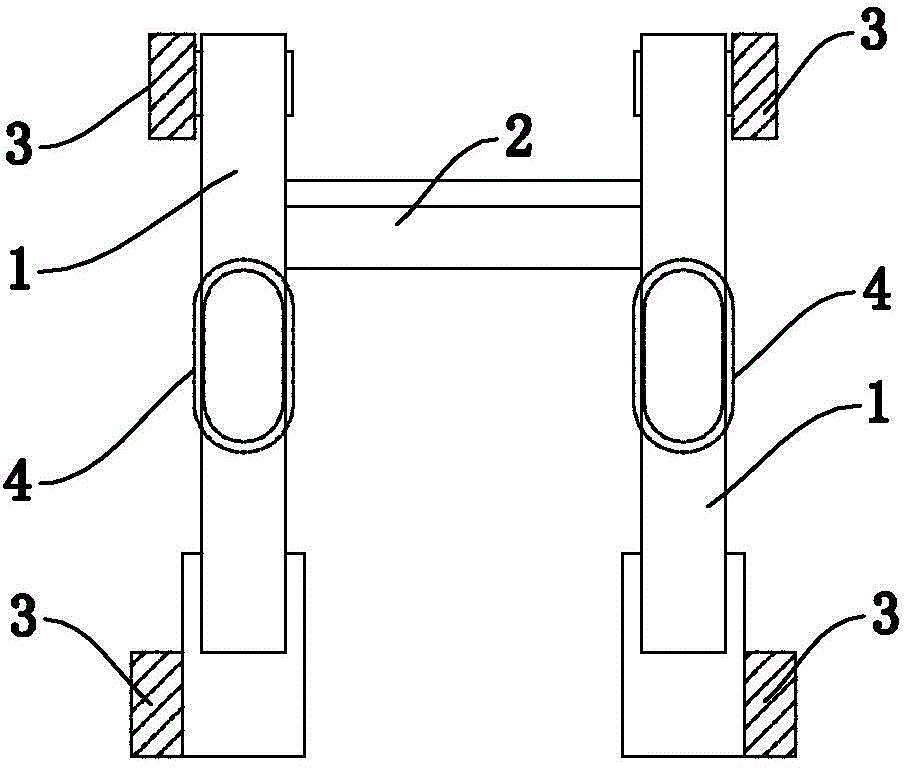

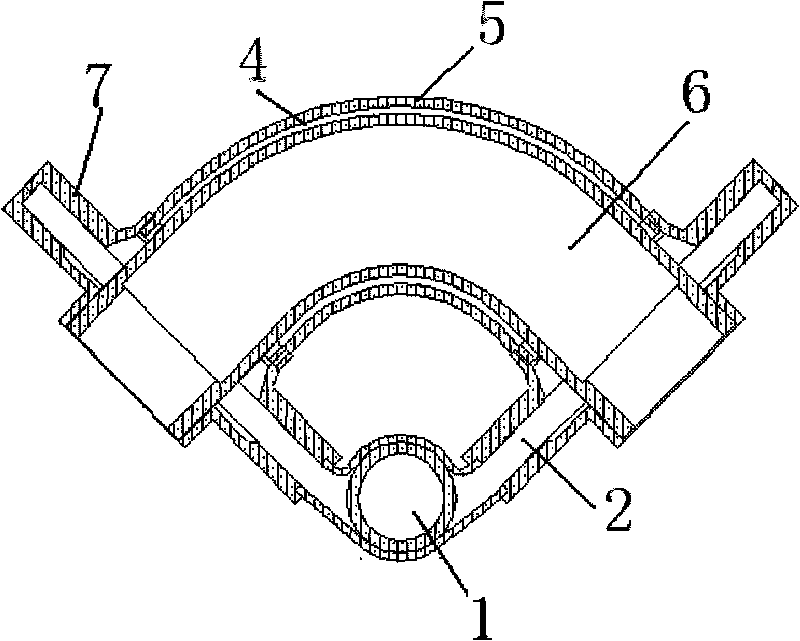

Novel device and method for moulding pipe

InactiveCN101693286AFlat surfaceReduces porosity defect formationFoundry mouldsFoundry coresMaterials scienceDual layer

The invention provides a novel device for moulding pipes, which is applied to the field of pipe processing. The novel device for moulding pipes comprises a straight sprue (1), an inner sprue (2) and a riser (3). The device is characterized in that the novel device for moulding pipe also comprises a pipe sand mold (4); one or more straight sprues (1) are communicated with one or more inner sprues (2); the inner sprue (2) is communicated with the pipe sand mold (4) which has a clearance structure formed by dual-layer materials; and the pipe sand mold (4) is communicated with one or more risers (3). The invention also relates to a method for moulding the pipe simultaneously. By adopting the technical proposal, the formation of pore defect of the casting can be reduced, the process stability is improved, the process yield of the casting is improved, the cost is reduced, and the labor productivity and efficiency can be greatly improved, thus reducing the cost of the product.

Owner:WUHU JINMAO FLUID TECH CO LTD

Intelligent delivery device and method for various concrete materials

PendingCN108818952AQuality improvementControl delivery ratioMixing operation control apparatusIngredients proportioning apparatusLevel sensorEngineering

The invention relates to the technical field of concrete, and provides an intelligent delivery device and method for various concrete materials, wherein the intelligent delivery device includes a plurality of feeding bins, a plurality of branch conveying mechanisms, a general conveying mechanism, a plurality of decelerating motors, a plurality of material level sensors, a plurality of weighing sensors and a PLC controller. The branch conveying mechanisms are arranged under discharge ports of all the feeding bins side by side and are used for receiving and conveying materials delivered out fromthe feeding bins. The general conveying mechanism is arranged under the branch conveying mechanisms and is used for conveying the entirety of the materials of all the feeding bins conveyed by all thebranch conveying mechanisms to the next process of concrete preparation, and regulating gates of all the feeding bins and driving motors of all the decelerating motors and the general conveying mechanism driving roll cylinder are each connected with and controlled by the PLC controller. The problem that inaccurate material delivery of conventional conveying device for various concrete materials affects the quality of concrete is solved.

Owner:FUJIAN XINDA MACHINERY

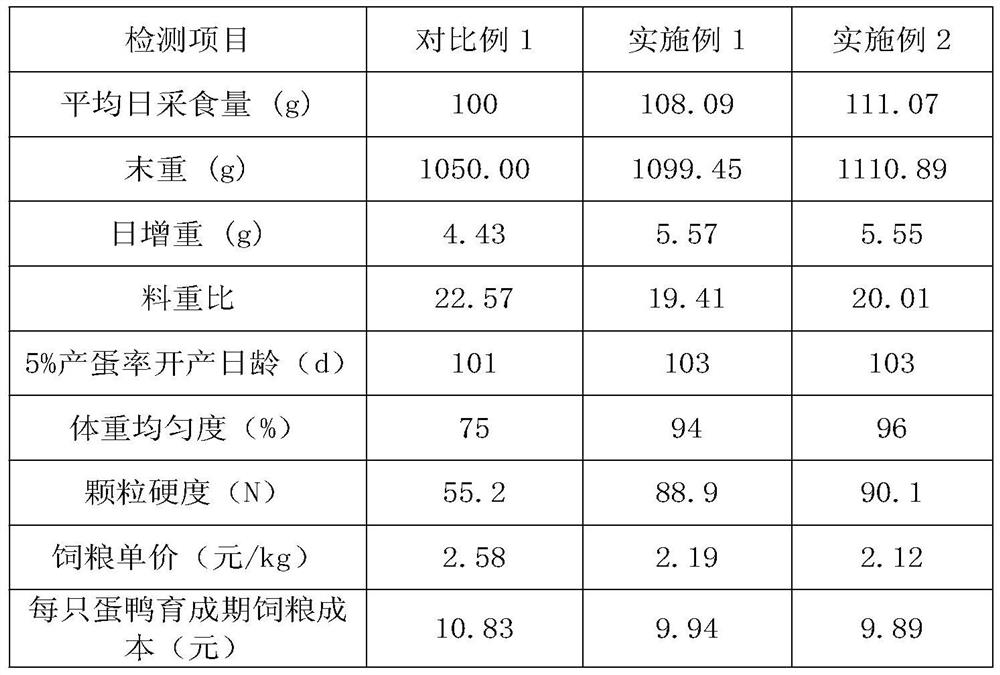

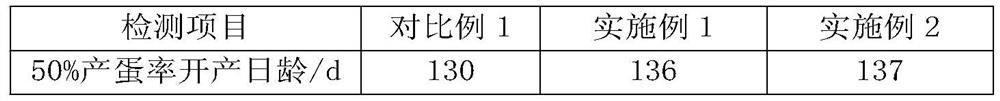

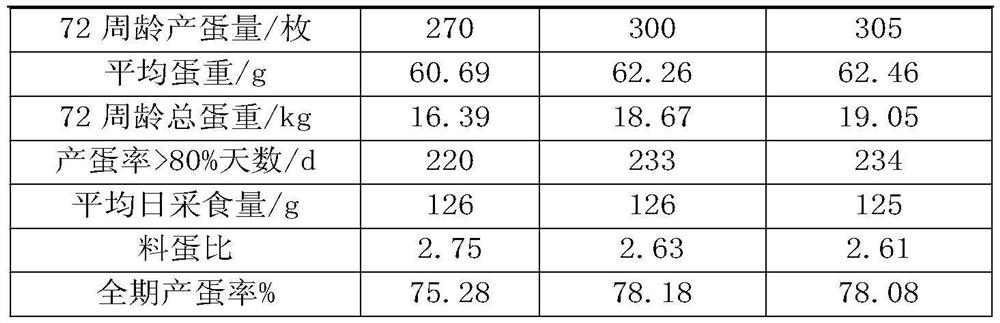

Limited feeding grain for laying ducks in breeding period and preparation method of limited feeding grain

PendingCN111700185AUnlimited feed intakeHigh hardnessFood processingAnimal feeding stuffBiotechnologyAnimal science

The invention provides limited feeding grain for laying ducks in a breeding period and a preparation method of the limited feeding grain. The limited feeding grain comprises the following raw materials in percentage by weight: 35%-50% of corn, 3%-6% of soybean meal, 4%-5% of rapeseed meal, 10%-20% of wheat middling, 8%-10% of wheat bran, 3%-5% of fermented alfalfa meal, 4%-6% of edible fungus bran, 4%-10% of bentonite, 2%-4% of stone powder and 2%-4% of a premix. The preparation method comprises the following steps: step 1, obtaining a raw material mixture with a grain size of 1.5-2.0 mm; step2, heating the raw material mixture to 80-85 DEG C and keeping the raw material mixture at the constant temperature for 25-50 s to prepare a cooked raw material mixture; and step 3, preparing granular limited feeding grain from the cooked raw material mixture by a granulator. The limited feeding grain is low in cost, the egg laying peak rises fast and high and lasts for a long time, and the preparation method is easy in parameter control and high in practicability.

Owner:湖南省畜牧兽医研究所

Floatable fish fodder

The invention discloses a floatable fish fodder, which is formed by raw materials of Chinese wildrye, rumex, soybean cake and corn. The floatable fish fodder disclosed by the invention contain relatively high nutrition, can float in water for a long time, and prolongs the ingestion time of fish in the water; and the fodder prepared at a high temperature is subjected to a sterilization process.

Owner:胡淏斐

Plant feed and production method thereof

ActiveCN102132761AGood quality meatReduce cholesterolFood processingAnimal feeding stuffAgricultural engineeringAgricultural science

The invention discloses plant feed for reducing using amount of concentrated feed such as grain and the like and a production method thereof, which aim to solve the problems of large grain consumption and high production cost in the conventional feed. The plant feed comprises auxiliary ingredients serving as grain and major ingredients serving as greenfeed dry powder, wherein the weight percentage of the greenfeed dry powder is between 30 and 60 percent, the balance is the grain, and the total sum is 100 percent. The plant feed reduces the consumption of the grain and production cost, has high palatability and long refreshing time and is convenient to popularize industrially.

Owner:浙江叁叁环保技术控股集团有限公司

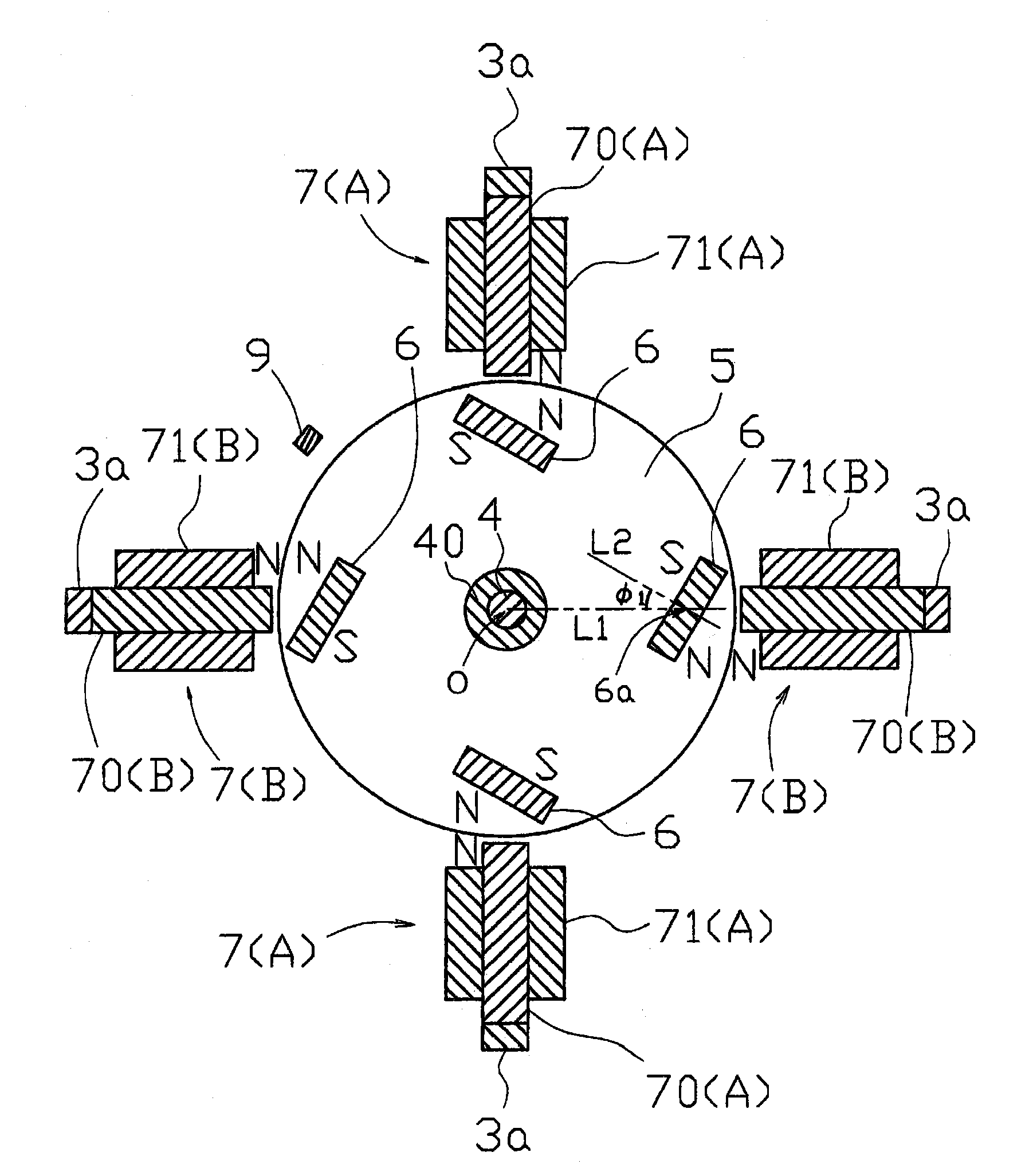

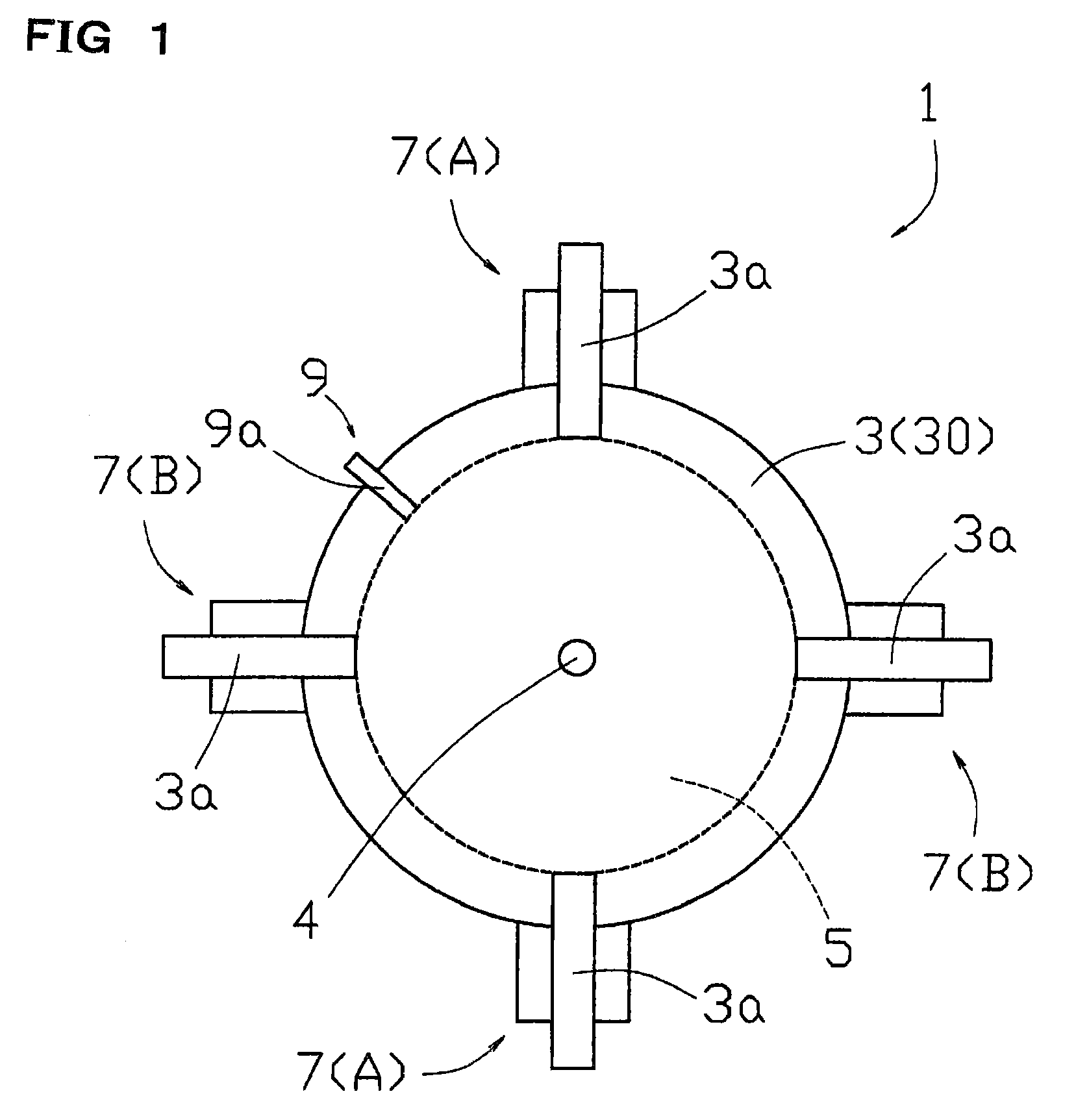

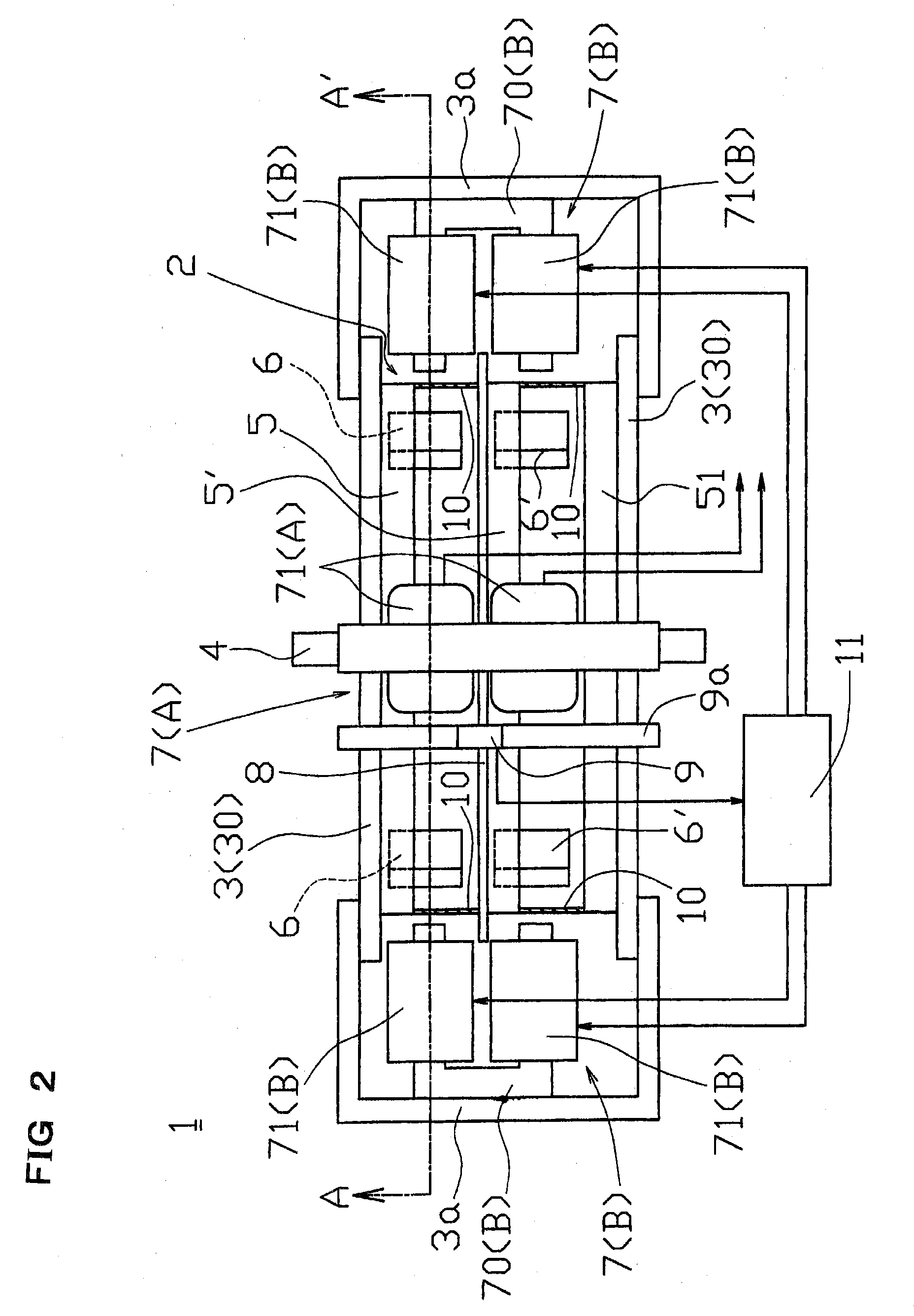

Unidirectionally-energized brushless DC motor including AC voltage output winding and motor system

InactiveUS8294317B2Large widthHigh torqueUltrasonic/sonic/infrasonic diagnosticsDynamo-electric brakes/clutchesCircular discElectric machine

A unidirectionally-energized brushless DC motor includes a disk attached to a frame, a plurality of plate-like permanent magnets disposed on the disk at equal intervals around the disk, magnetic cores fixed to the frame according to the plurality of permanent magnets, windings each of which is wound around the magnetic core and to which DC power is supplied, a predetermined number of magnetic cores fixed to the frame, and windings each of which is wound around the magnetic core and connected to a power consumption device. The permanent magnets are located such that an angle formed by a straight line passing through the center of the disk and the center of the permanent magnet and a normal line in the center of a magnetic pole plane of the permanent magnet ranges from 0° to 60°.

Owner:KOMATSU YASUHIRO +3

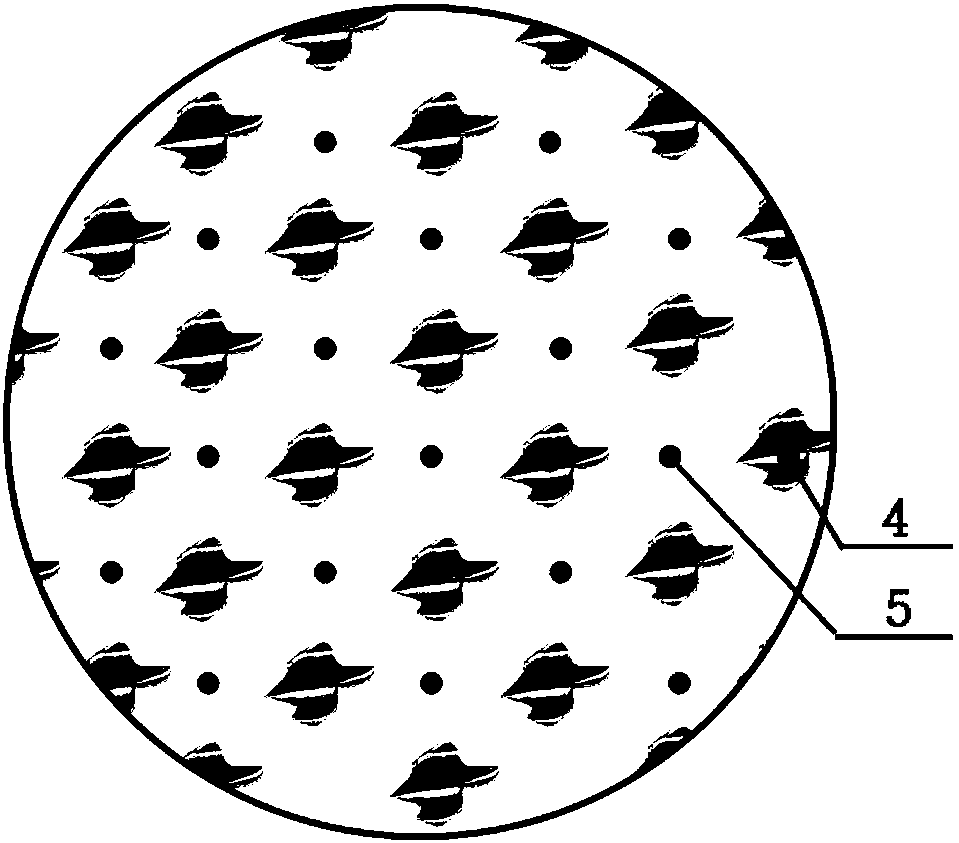

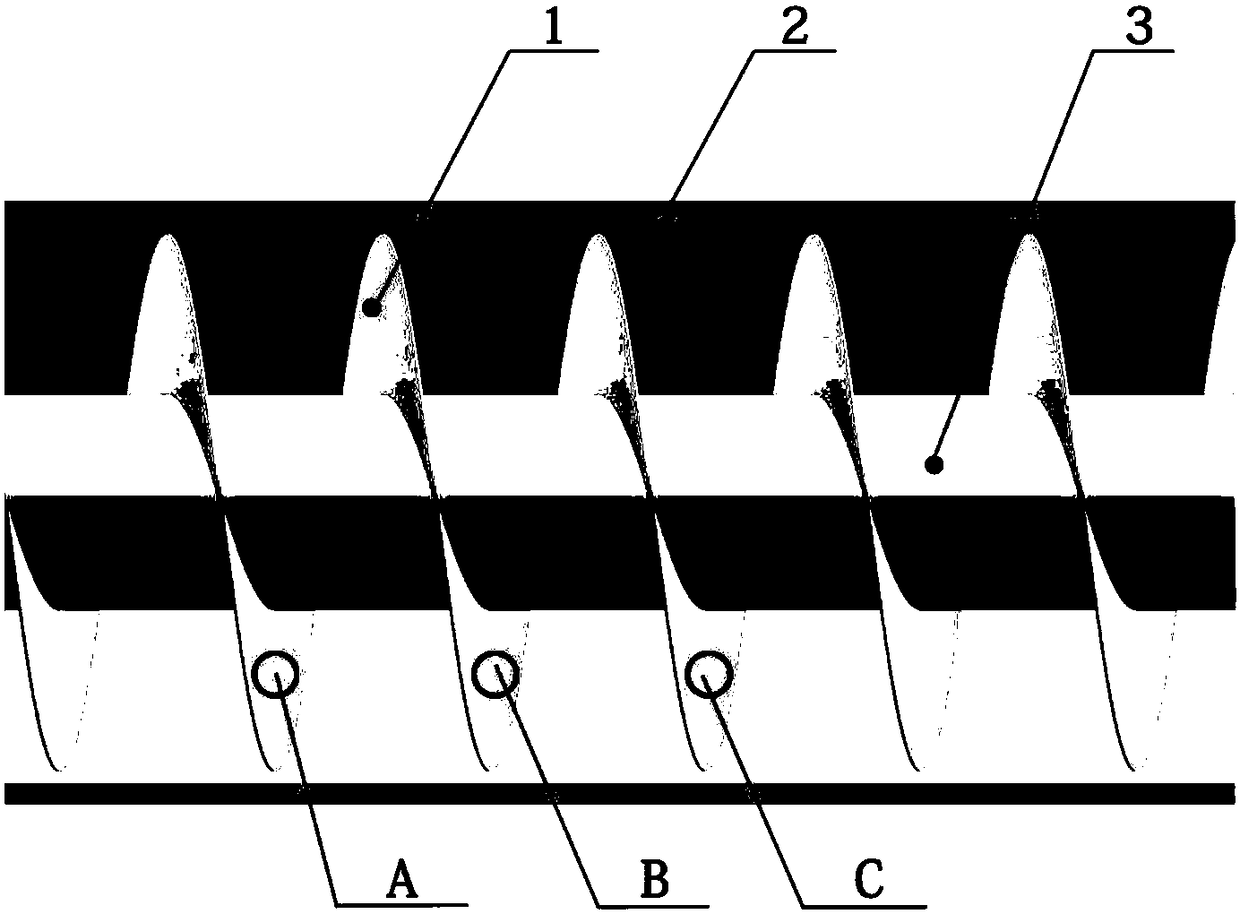

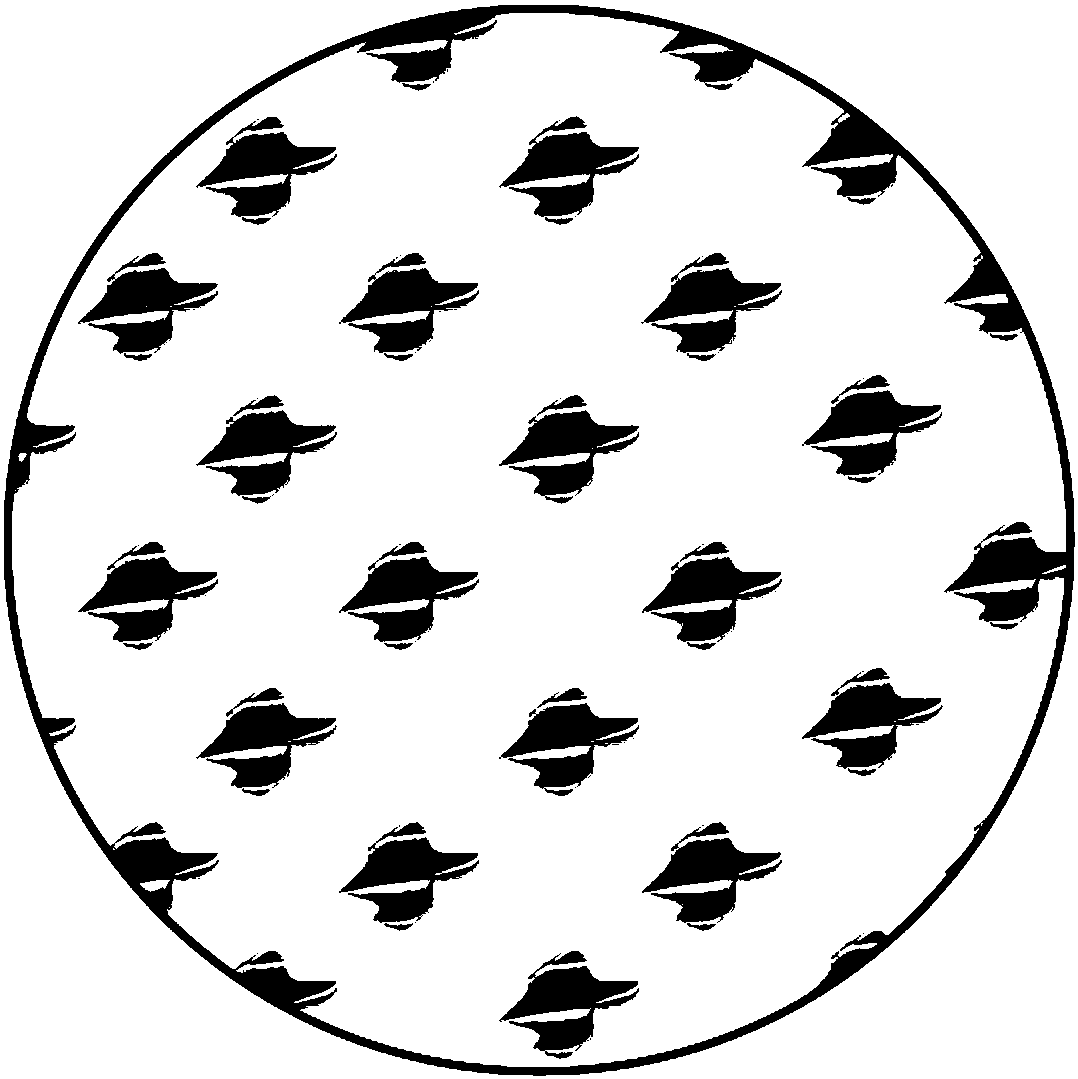

Feeder provided with bionic sharkskin placoid scale structure and resistance reducing particles and manufacturing method

ActiveCN108177938AEquipment power loss reductionSmooth feed time extensionPackagingEngineeringSharkskin

The invention belongs to the field of application of engineering bionics techniques, and particularly relates to a feeder provided with a bionic sharkskin placoid scale structure and resistance reducing particles and a manufacturing method. The feeder comprises a feeding machine, the bionic sharkskin placoid scale structure and the resistance reducing particles, wherein the bionic sharkskin placoid scale structure and the resistance reducing particles are distributed on the surface of blades of the feeding machine. The manufacturing method is characterized in that the surface of the sharkskinis scanned to obtain the placoid scale structure which is copied to the surfaces of the blades. With the adoption of the feeder, the frictional force between the blades of the feeding machine and materials in the conveying process can be effectively reduced.

Owner:SHANDONG UNIV OF TECH

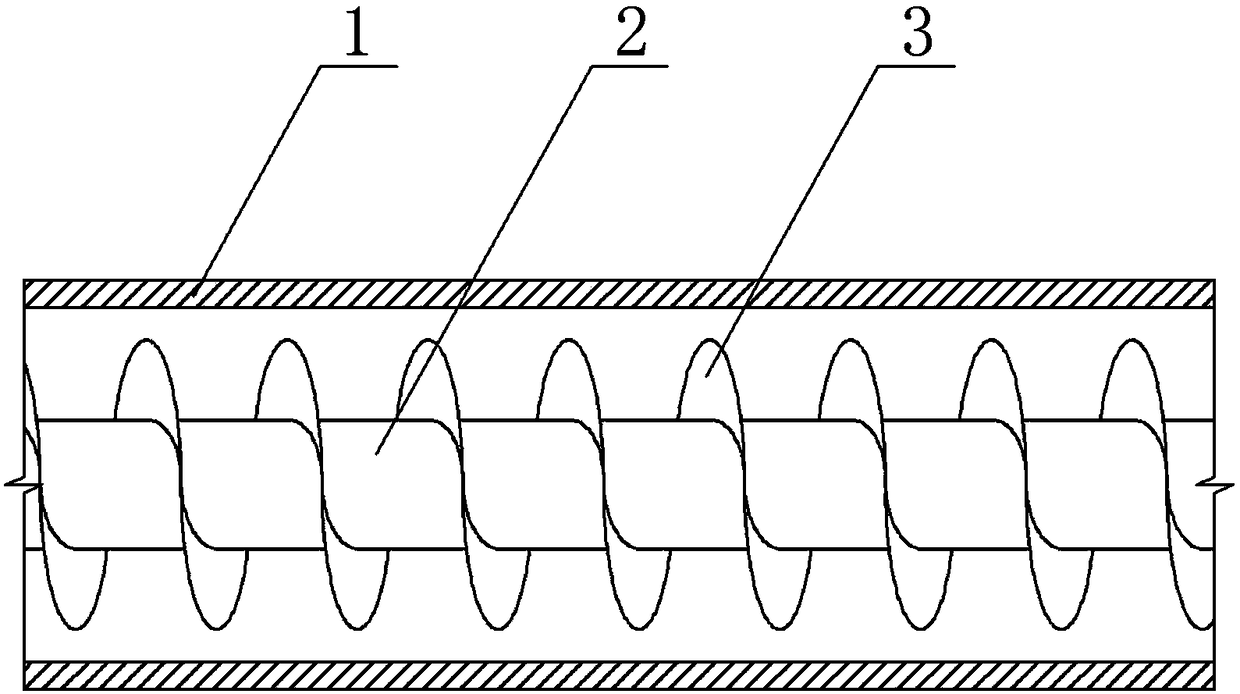

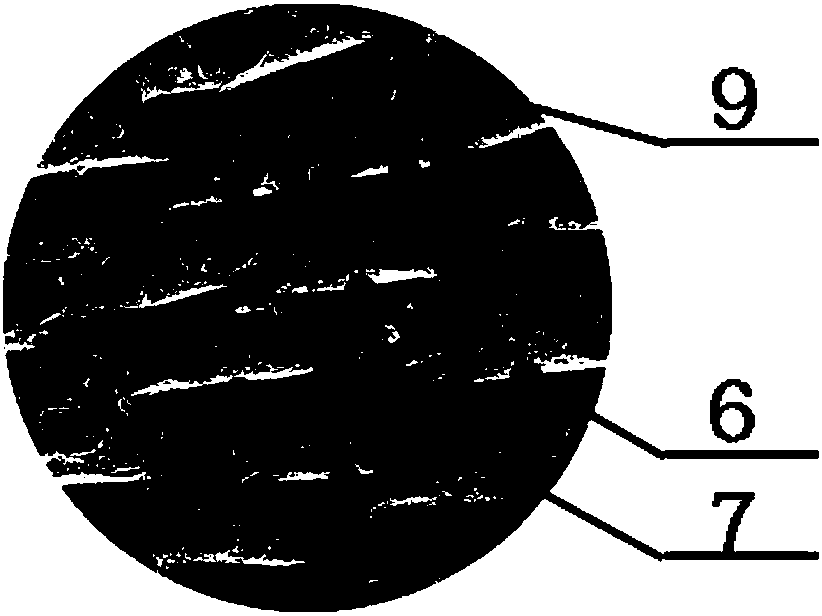

Feeder with bionic sharkskin placoid scale structure and manufacturing method of feeder

ActiveCN108147023AAlleviate or solve the problem of sticking screw bladesIncrease stickinessPackagingSpiral bladeScale structure

The invention discloses a feeder with a bionic sharkskin placoid scale structure and a manufacturing method of the feeder. The manufacturing method specifically comprises the steps that a shark placoid scale structure biological template is manufactured after pretreatment is conducted on a shark body skin, the relative positions and overall surface appearance data of a single shark placoid scale structure and a plurality of shark placoid scales in a large area are obtained through scanning, direct or indirect processing duplication is conducted on a spiral blade according to a certain scalingand ruler, the spiral blade with the bionic sharkskin placoid scale structure is mounted in a spiral feeder and used for conveying materials being high in viscidity, prone to caking, and poor in mobility, and thus the effects of reducing resistance and noise, prolonging the life of a feeding mechanism and guaranteeing smooth feeding are achieved.

Owner:SHANDONG UNIV OF TECH

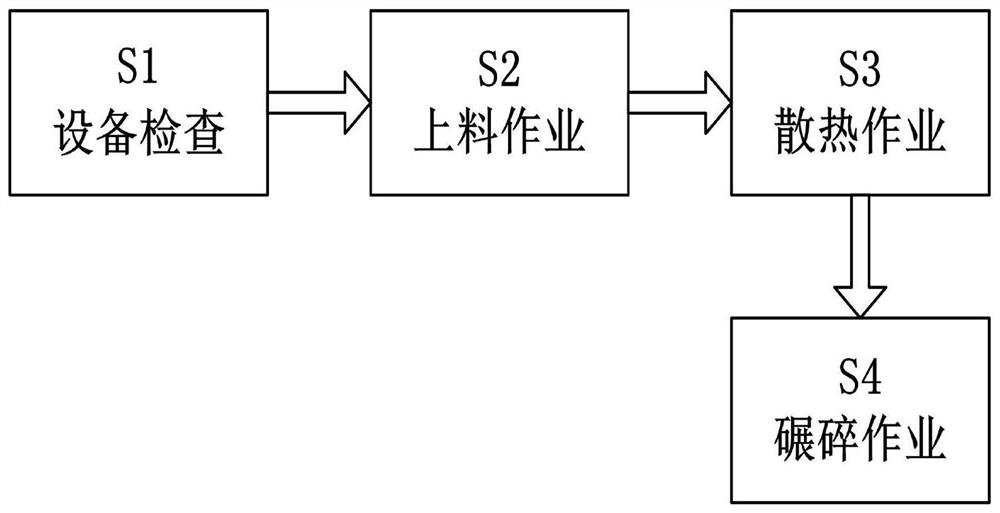

Power station solid waste disposal method

InactiveCN111822078AExtended feeding timeGuaranteed cleaning effectCleaningGrain treatmentsPower stationEnvironmental engineering

The invention relates to a power station solid waste disposal method. The power station solid waste disposal method uses a solid waste disposal device. The solid waste disposal device comprises a base, a cooling unit and a smashing unit. The cooling unit is disposed on the inner wall of the rear end of the base. The smashing unit is disposed at the right end of the base. By guiding a conveying belt in a wave form, feeding time of power station solid waste is prolonged, power station solid waste is rolled to be cooled, heat in the power station solid waste is released by smashing, and thereforethe power station solid waste can be slowly and naturally cooled; and by means of a mechanical mechanism, cleaning brushes vibrate so as to shake off dust attached thereon, and the cleaning effect ofthe cleaning brushes is ensured.

Owner:丁健

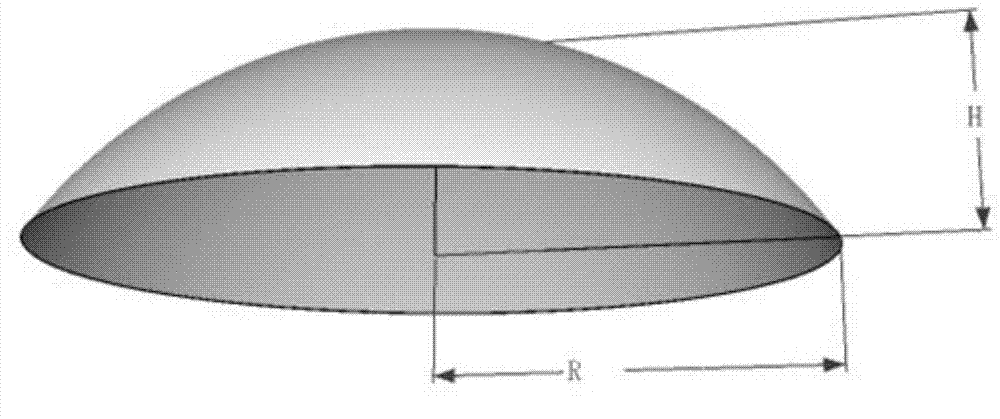

Stichopus japonicus dish-shaped granulated feed

ActiveCN103689278ADoes not cause turbidityWill not cause churnAnimal feeding stuffFood shapingStichopusFeed conversion ratio

The invention discloses a stichopus japonicus dish-shaped granulated feed, which belongs to the technical field of aquatic feeds. The bottom side of the feed is planar circle-shaped, and the upper surface is arc-shaped. Due to the unique shape of the stichopus japonicus granule, the resistance of the granule in water and feed conveying pipelines is reduced, and the feed is applicable to a mechanical feeding mode; in addition, due to the advantages that the side part of the dish-shaped granulated feed is thin and easy to be floppy and the middle part is thick and long in shape-preserving time, the ingestion time of stichopus japonicus is prolonged; the feed is rich in nutrition, natural phycocolloid sodium alginate is high in adhesion capability, the components of the feed are not easy to be lost, small cultivation water pollution is caused, and the problem that a great deal of feed is wasted in stichopus japonicus cultivation modes such as net cage, caisson box, hung cage, factory and pond is solved; the food coefficient is about 1.5, the feed conversion rate is high, the cultivation cost is saved, and the cultivation benefits are increased.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI +2

Bait for juvenile sea cucumber in growing periodand preparation method of bait

The invention relates to a bait for a juvenile sea cucumber in the growing period and a preparation method of the bait. The bait is prepared from the following components in weight percentage: 60% of sargassumthunbergii powder, 10% of common mussel meat powder, 4% of soybean meal, 6% of defatted fish meal, 2% of spirulina powder, 1.5% of baker's yeast powder, 0.5% of compounded mineral substance, 0.5% of multivitamin powder, 1.5% of immune polysaccharides and 14% of dry sea mud powder. In the bait for the juvenile sea cucumber in the growing period, the components are in mutualcompatibility, the contained nutritional ingredients can meet the rapid growing need of the juvenile sea cucumber, the juvenile sea cucumber then grows fast in the opening stage and grows to 2 mm from 0.5 mm averagely after being fed with the bait for 20 days, and the rate of survival is up to more than 80%.

Owner:WENDENG AQUATIC PROD TECH PROMOTION STATION

Novel crystallizer for preparing alkali

InactiveCN101053703AImprove heat transfer effectReduce the temperatureSolution crystallizationEngineeringHeat transfer

The invention discloses a novel crystallizer for producing alkali, comprising a tank, upper and lower jackets enwrapping the outer wall of said tank, and upper and lower draft tubes mounted in said tank. The productive capacity is enhanced because in the invention the scroll and crystal heat transfer capability are increased and the temperature of inner crystallizer reduces to delay the feeding time of hydrate crystallizer for 11 min per time than the crystallizer used at present.

Owner:TIANJIN BOHUA YONGLI CHEM IND

Method for preparing phagostimulant by using krill for aquiculture animals

InactiveCN1502230AExtended feeding timeShorten feeding timeClimate change adaptationPisciculture and aquariaProtein solutionPrawn

The present invention relates to a method for preparing phagostimulant for aquaculture animals by utilizing euphausiid, and said method includes the following steps: pulverizing euphausiid, heating, self-dissolving, adding alkali, continuously ehating to make hydrolysis, solid-liquid separation, the obtained liquid is euphausiid protein solution, adding alkali intothe obtained solid euphausiid shell to make deacetylation, separating out solid chitosan, acid-dissolving chitosan to obtain chitosan colloid solution, mixing the chitosan colloid solution and the above-mentioned euphausiid protein solution, after flocculation separating precipitate and vacuum drying so as to obtain the invented product which can raise food intake of animal, raise utilization rate of bait and raise the nutrient level of bait.

Owner:OCEAN UNIV OF CHINA

High-energy riser bush structure

ActiveCN108057846AImprove insulation effectAvoid distributingFoundry mouldsFoundry coresHigh energyArchitectural engineering

The invention discloses a high-energy riser bush structure which comprises a riser bush shell. The top end of the riser bush shell is provided with a barrel, the top end of an inner cavity of the barrel is provided with a supporting base, fixed bases are installed on the left side and the right side of the top end of the inner wall of the barrel, the fixed base is connected with the supporting base through a supporting rod, the bottom end of the supporting base is provided with a cylinder body, the upper end and the lower end of the inner wall of the cylinder body are provided with an upper plug plate and a lower plug plate correspondingly, a piston plate is installed in an inner cavity of the cylinder body, the piston plate is connected with the upper plug plate through a reset spring, the bottom end of the inner wall of the barrel is provided with a baffle, the inner wall of the baffle is provided with a hollow barrel, and the upper end and the lower end of the inner wall of the hollow barrel are provided with an upper clamping base and a lower clamping base correspondingly. According to the high-energy riser bush structure, by means of the cooperation of the cylinder body, the piston plate and a sealing plate, the heat insulation effect on the riser bush shell is improved, feeding time is prolonged, and the casting appearance quality is improved.

Owner:重庆乐迪机车车辆配件有限公司

Fluorescent powder special for energy-saving lamp in broiler farm

The invention discloses a fluorescent powder special for an energy-saving lamp in a broiler farm. The fluorescent powder comprises a red rare earth powder component, a green rare earth powder component and a blue rare earth powder component, wherein the red rare earth powder component, the green rare earth powder component and the blue rare earth powder component are mixed in a weight proportion of 53.6: 36.49: 9.46; and the general formula of the red rare earth powder component is Y203: Eu, the genera formula of the green rare earth powder component is CeMgAl11019: Tb, and the general formula of the blue rare earth powder component is BaMgAl10017: (Eu.Mn). The special fluorescent powder has a color temperature of 4100K and a color rendering index of more than 80Ra. The fluorescent powder has the characteristics of high lighting effect, good color rendering property, long service life, wide applicability and low production cost, and is effective in energy conservation; and the preparation method is convenient for operation and easy to achieve, and equipment is simple.

Owner:YIXING SONOS LIGHTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com