Automatic weighing and packing device for fine powdery material and method thereof

A powder material, automatic weighing technology, applied in the field of automation, can solve the problems of affecting the packaging accuracy, the packaging efficiency cannot be improved, and the specific gravity of the material cannot be adapted, so as to improve the packaging efficiency, reduce the amount of weighing refills, and reduce the weight of the weighing machine. The effect of heavy error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

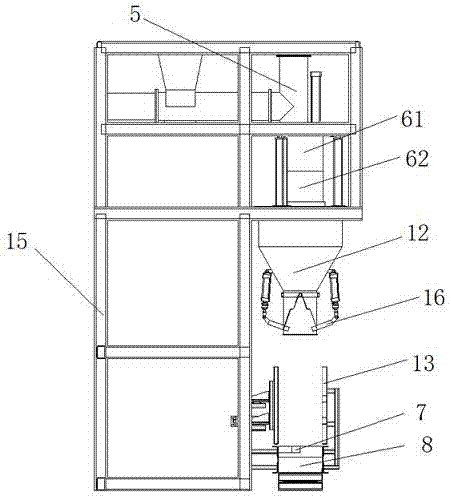

[0044] In a preferred embodiment, a material level sensor 17 is provided at the lower end of the lifting sleeve 11 . In this way, the material level sensor 17 detects that the outlet of the lifting sleeve 11 is as close as possible to the surface of the material, which reduces the impact of flying materials on the weighing accuracy and is also convenient for dust removal.

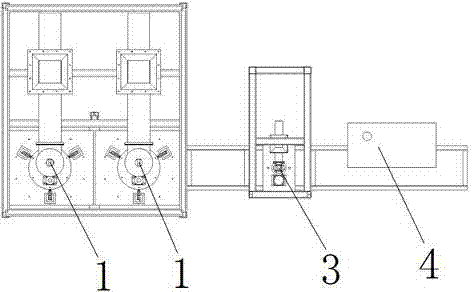

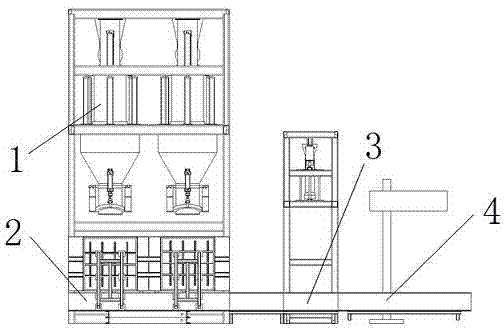

[0045] In order to further improve packaging efficiency, as a preferred embodiment, the number of the rough feeding device 1 and the shaping vibration conveying device 2 are two to four. The rough feeding device 1 and the shaping and vibrating conveying device 2 are installed up and down like this, and can be a whole body. Since there are two to four whole bodies, they can be connected in series or in parallel. In this way, the number of material bags for the first feeding increases, and the two feedings are reasonably distributed, which improves the packaging efficiency.

[0046] A packaging method based ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com