Limited feeding grain for laying ducks in breeding period and preparation method of limited feeding grain

A technology for laying ducks in the breeding period, which is applied in the field of laying ducks, can solve the problems of increased feed consumption, increased feed cost, and inability to ensure energy, so as to improve digestion and utilization, reduce feed intake, and improve palatability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

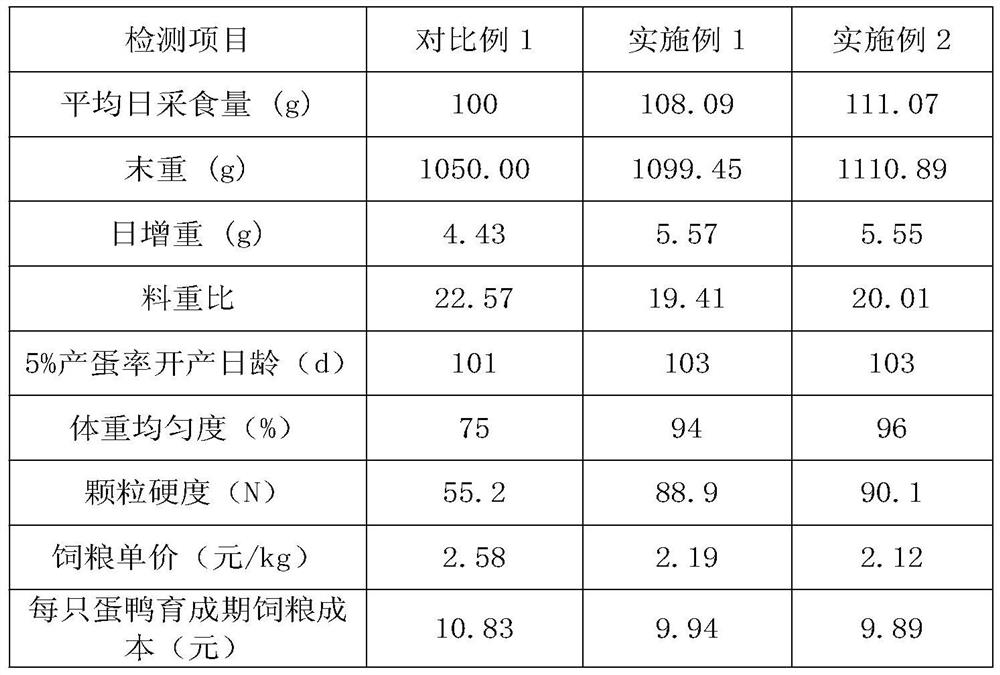

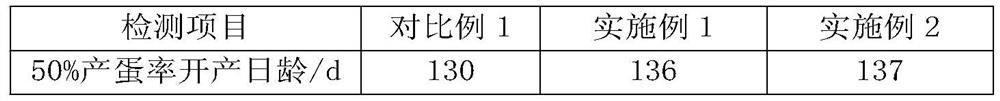

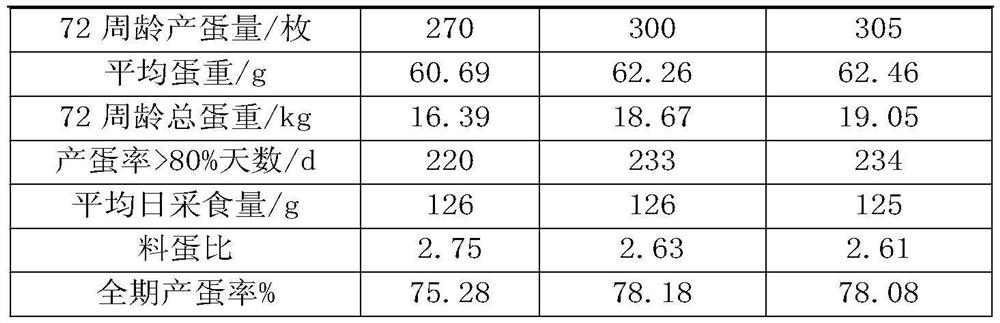

Examples

Embodiment 1

[0029] A limited feed ration for laying ducks in the breeding period, comprising the following raw materials in weight percentage: 47% of corn, 6% of soybean meal, 5% of rapeseed meal, 17.3% of secondary meal, 8% of wheat bran, fermented alfalfa powder 3%, edible mushroom chaff 5%, bentonite 4%, stone powder 2% and premix 2.7%.

[0030] Based on 1 ton of the restricted ration, the premix includes the following components: 2-5kg lysine, 1-2.5kg methionine, 8-11kg calcium hydrogen phosphate, 2-3kg salt, VA 12 -15g, VB 1 1-2 g, VB 2 5-15 g, VB 6 2-4 g, VD 3 2-4g, VE8-12g, VK 3 0.5-0.8g, biotin 0.1-0.2g, folic acid 0.1-0.2g, D-pantothenic acid 40-60g, niacin 40-60g, choline 500-800g, ethoxyquinoline 100-120g, copper sulfate pentahydrate 24-32g, ferrous sulfate heptahydrate 200-300g, manganese sulfate monohydrate 150-250g, zinc sulfate heptahydrate 180-300g, potassium iodide 0.3-0.6g, sodium selenite 0.22-0.44g, sepiolite 7-10kg .

[0031] A preparation method for a restricted...

Embodiment 2

[0041] A limited feed ration for laying ducks in the breeding period, comprising the following raw materials in percentage by weight: 42% of corn, 4% of soybean meal, 5% of rapeseed meal, 17% of secondary meal, 10% of wheat bran, fermented alfalfa powder 5%, edible mushroom chaff 5%, bentonite 7.1%, stone powder 2% and premix 2.9%. Others are all the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com