Power station solid waste disposal method

A processing method and technology for power plants, applied in grain processing, cleaning methods and appliances, chemical instruments and methods, etc., can solve problems such as difficult heat dissipation of solid waste in power plants, difficulty in heat dissipation, high heat of solid waste in power plants, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

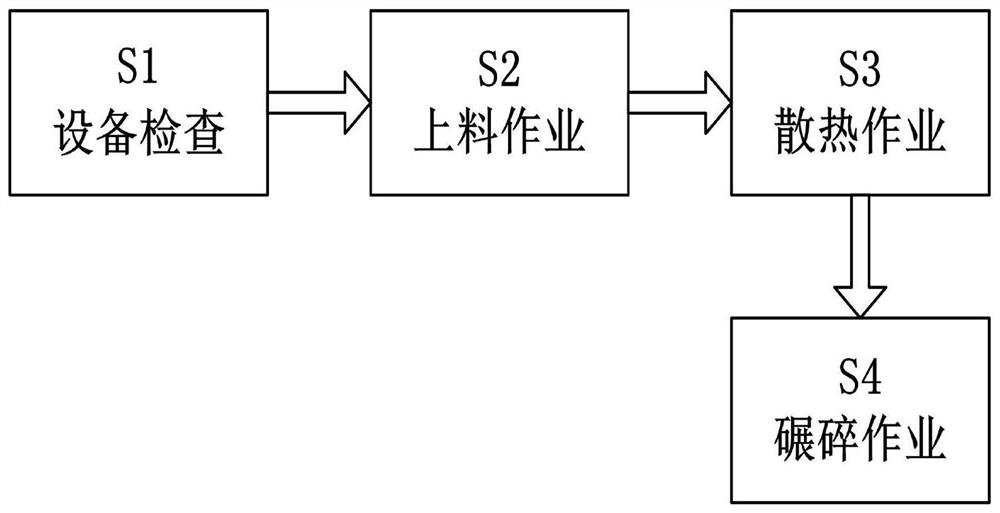

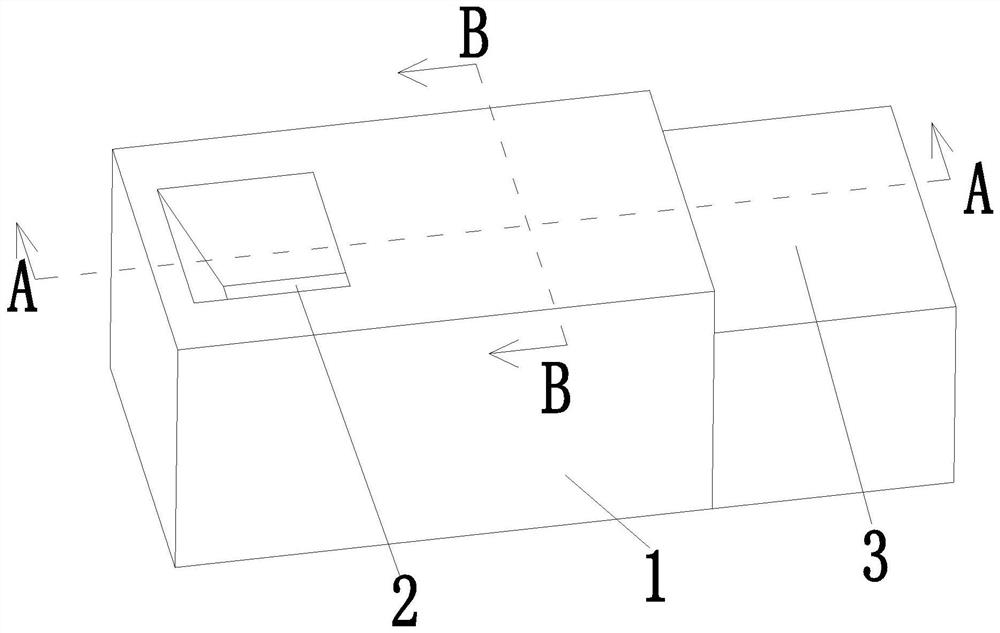

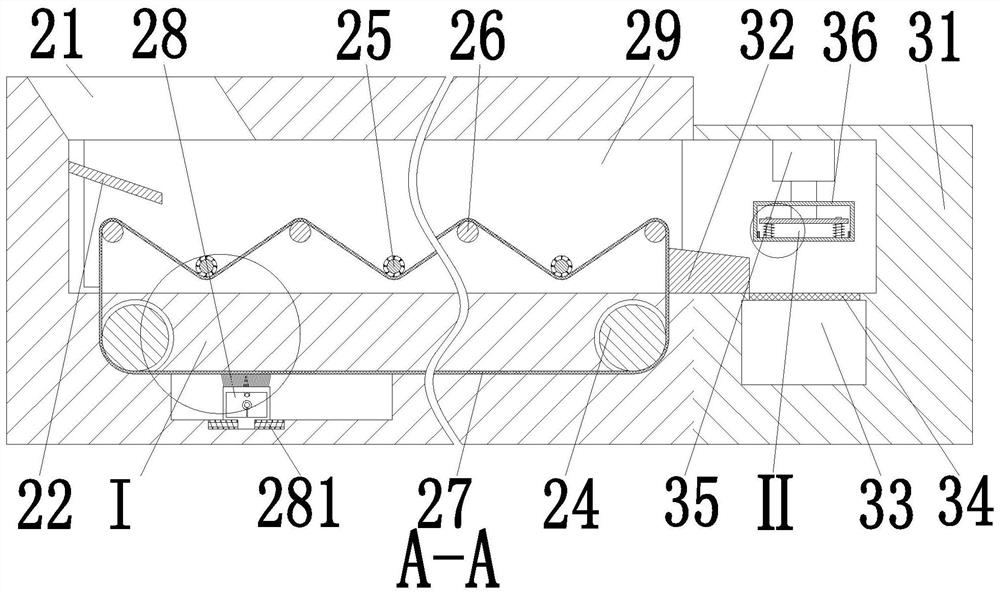

[0031] Such as Figure 1 to Figure 6 As shown, a solid waste treatment method of a power plant uses a solid waste treatment device, the solid waste treatment device includes a base 1, a heat dissipation unit 2 and a crushing unit 3, and the solid waste treatment device of the power plant is used to treat the solid waste of the power plant The processing method also includes the following steps:

[0032] S1. Equipment inspection: Before starting the device, conduct a routine inspection on the device manually;

[0033] S2. Feeding operation: guide the solid waste of the power plant to the upper end of the guide belt 27 through the discharge port 21;

[0034] S3. Heat dissipation operation: through the heat dissipation unit 2, the solid waste of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com