Patents

Literature

69results about How to "Squeeze hard" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

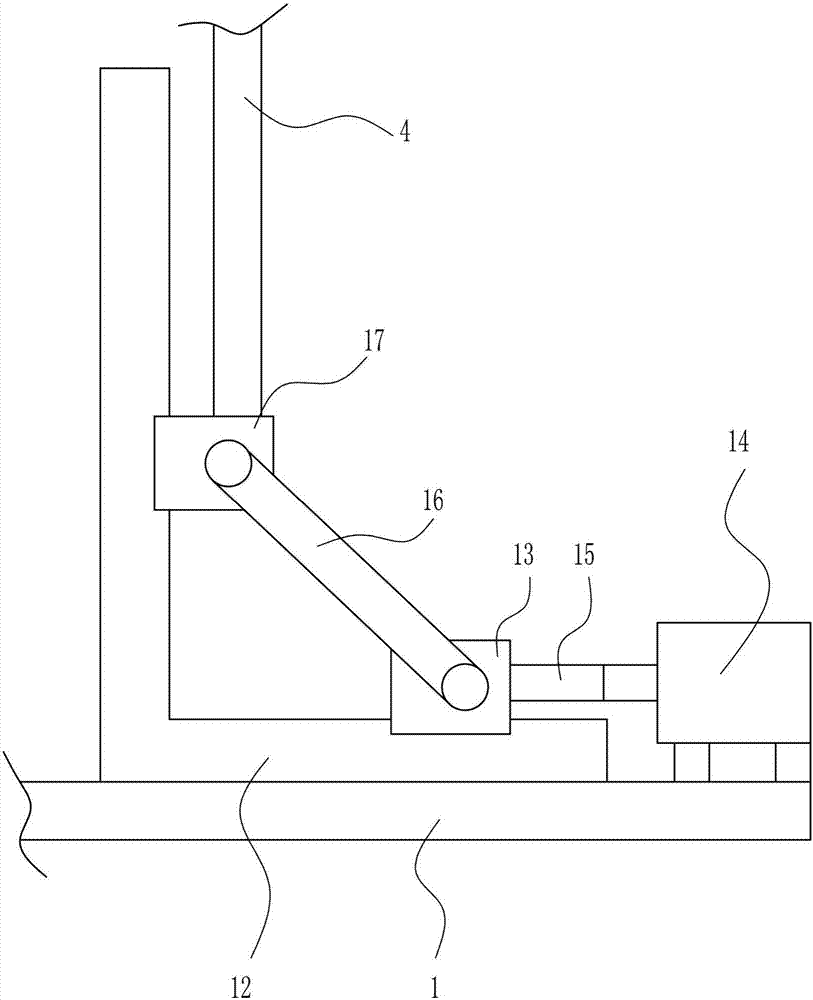

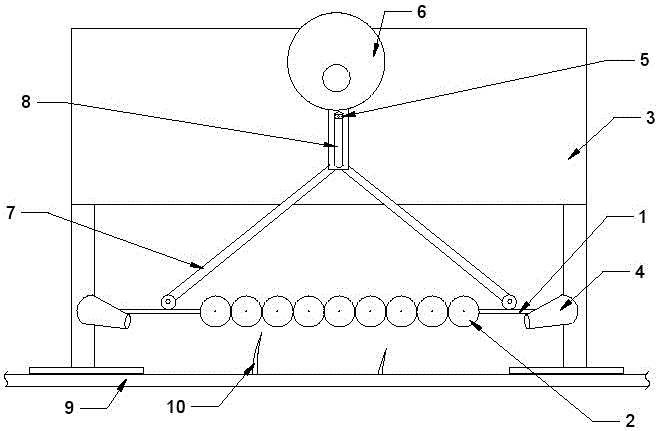

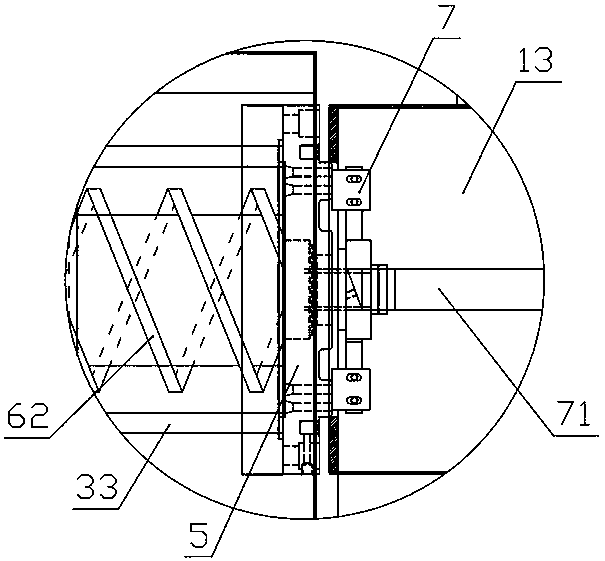

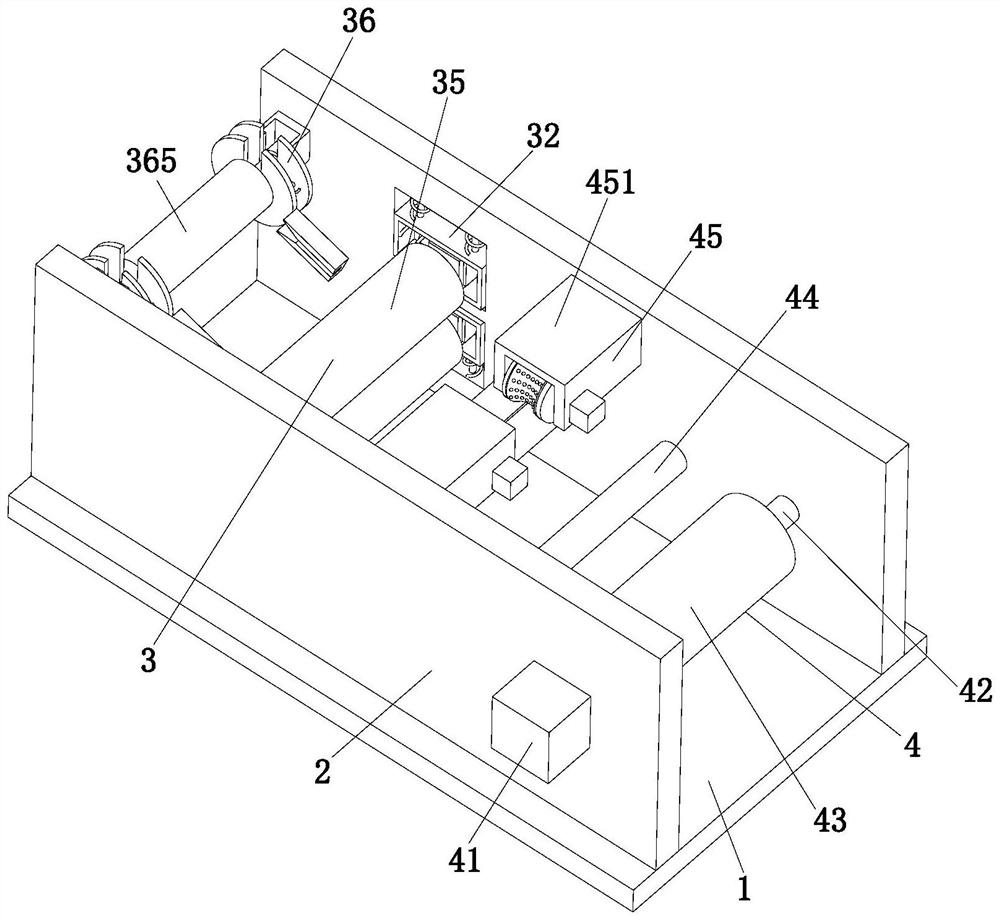

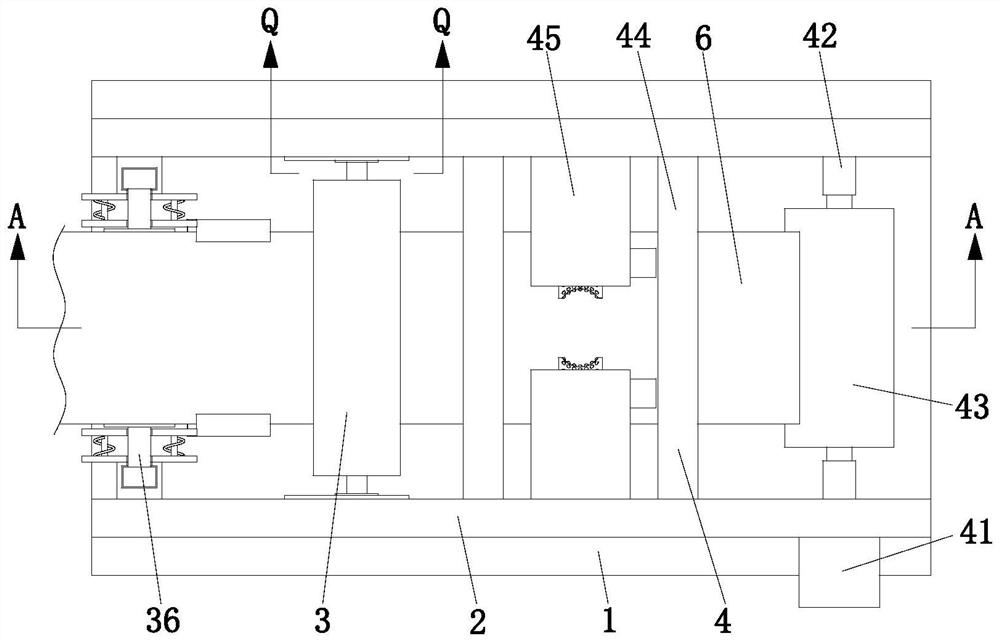

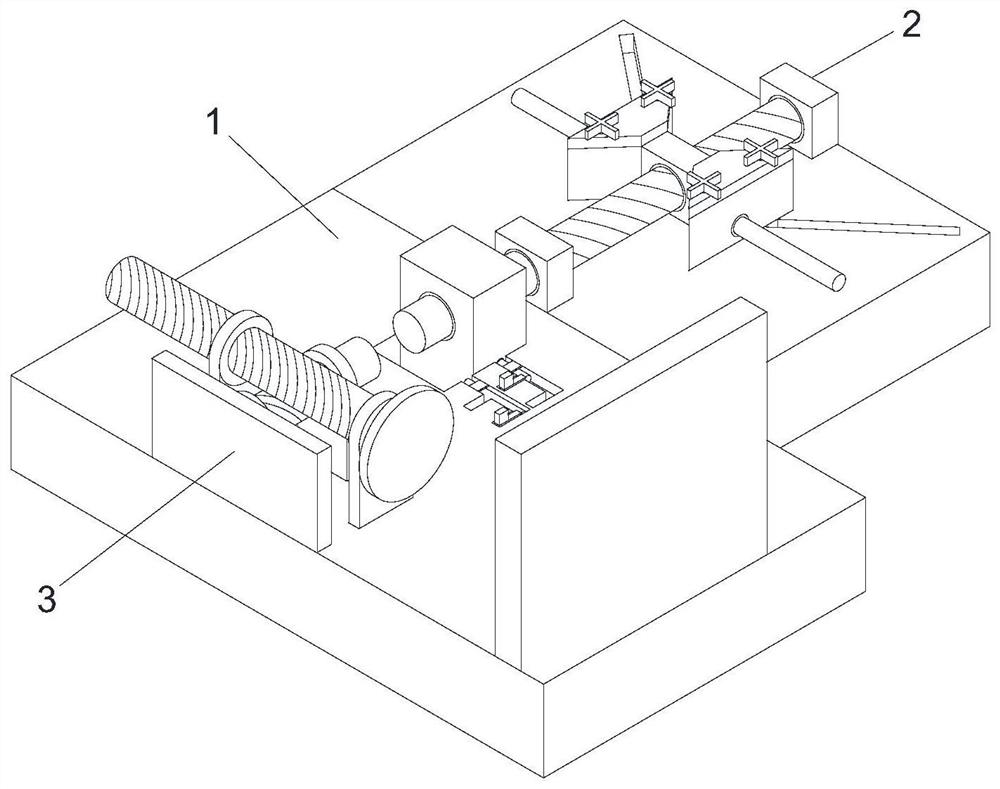

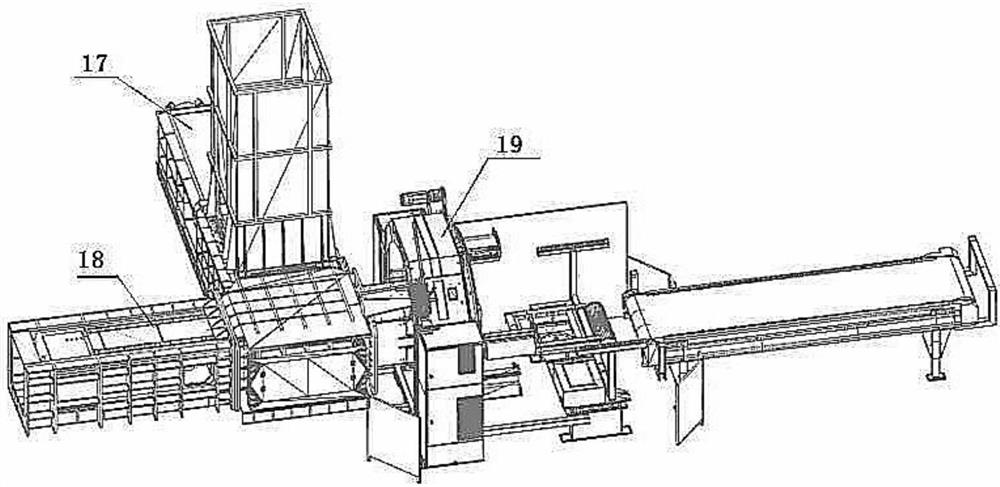

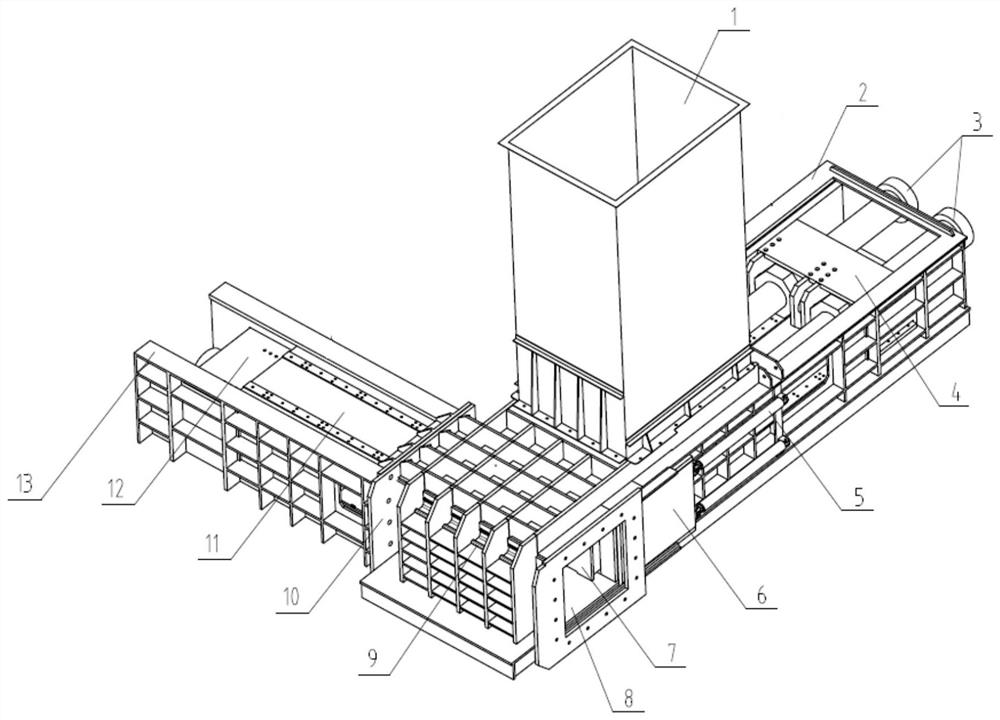

Environment-friendly recycling treatment system for waste plastic bottles

ActiveCN106608004AAvoid pollutionProtect the ecologyPlastic recyclingMechanical material recoveryPollutionMechanization

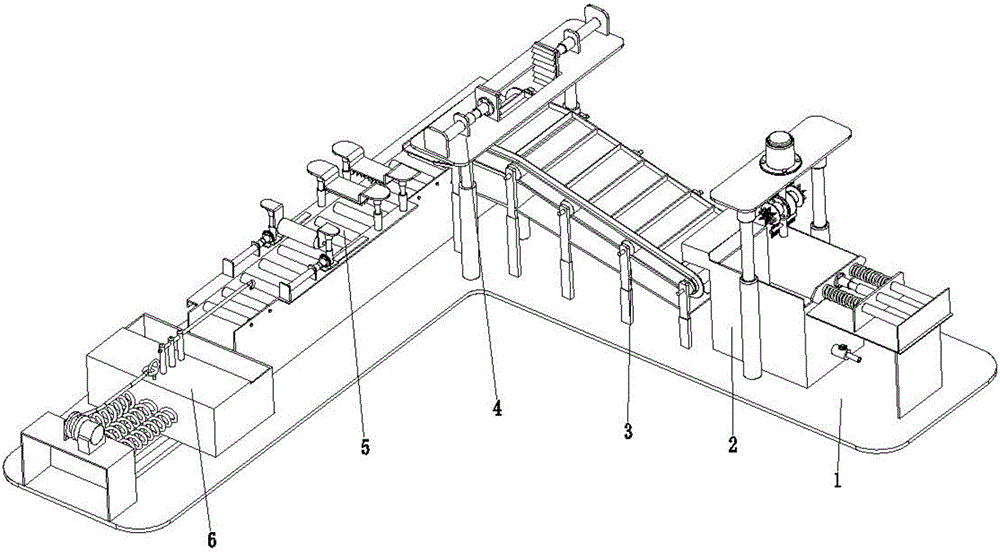

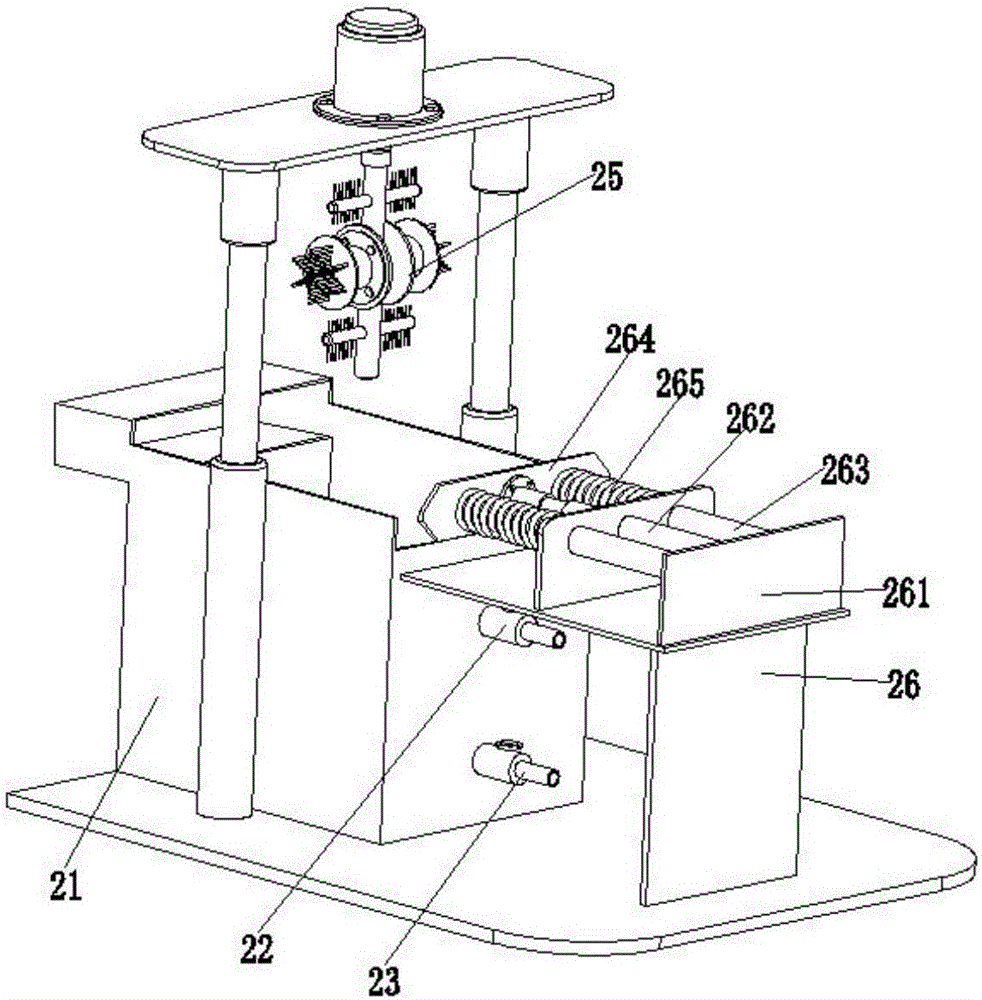

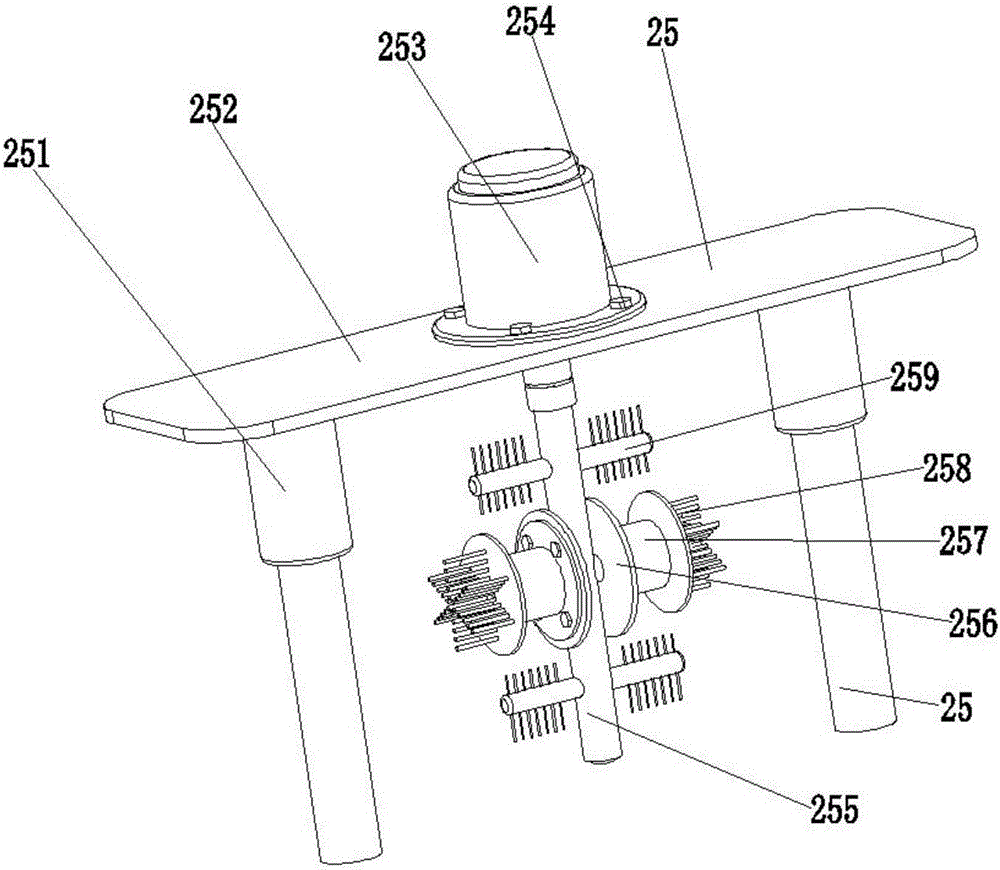

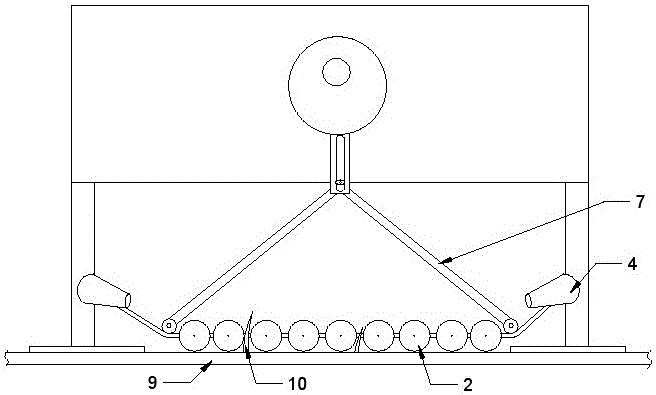

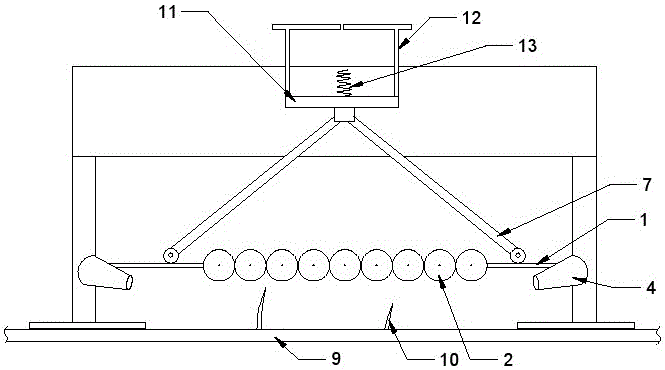

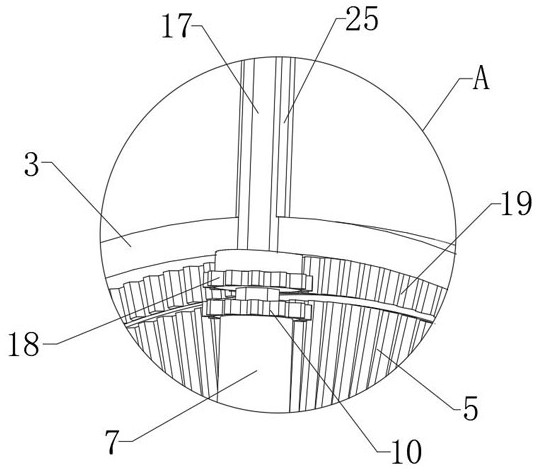

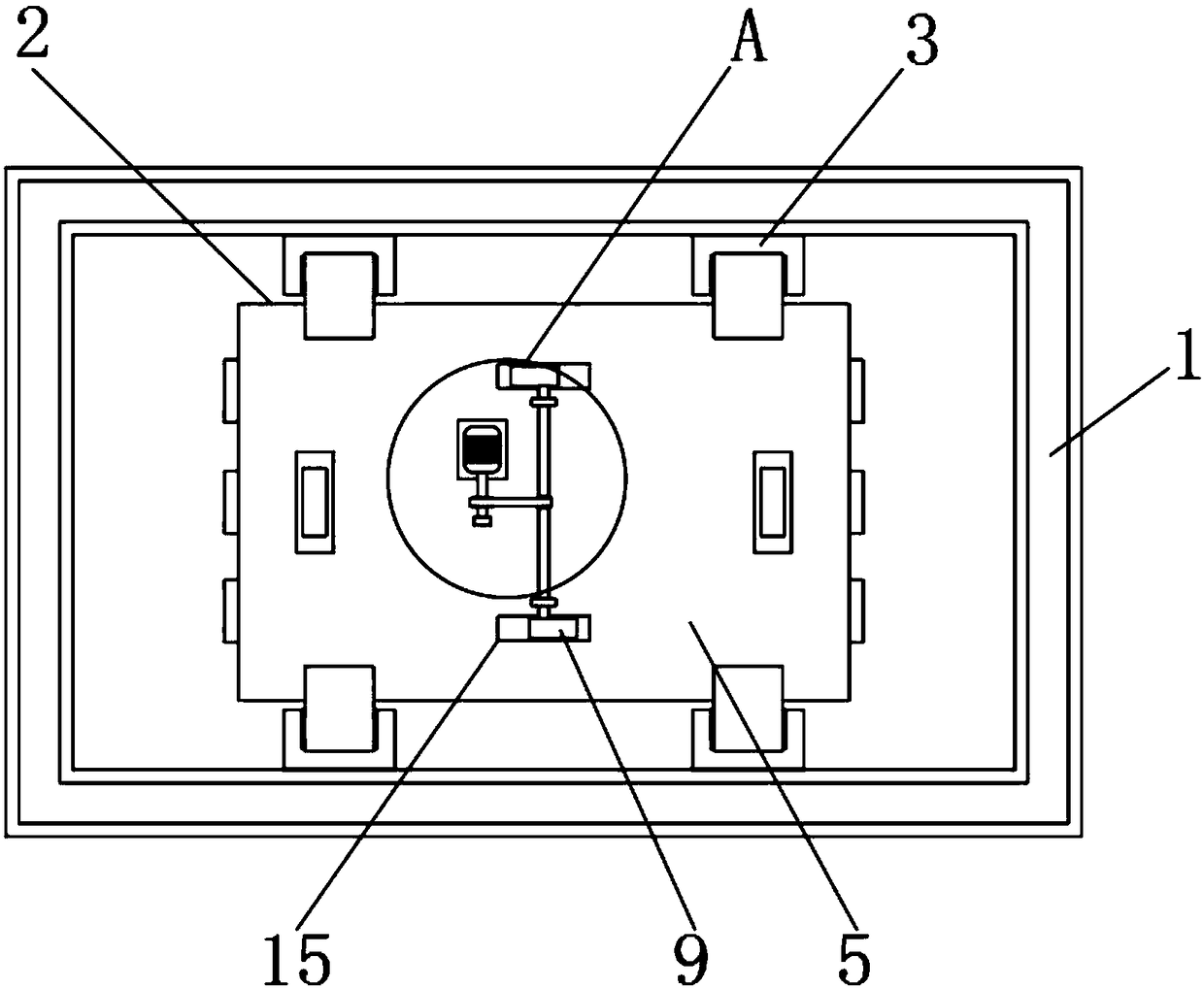

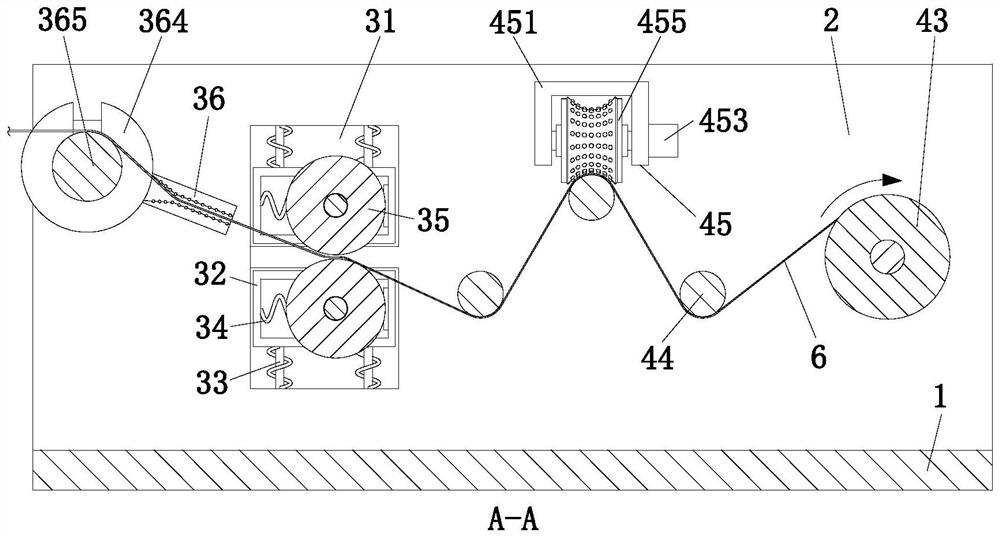

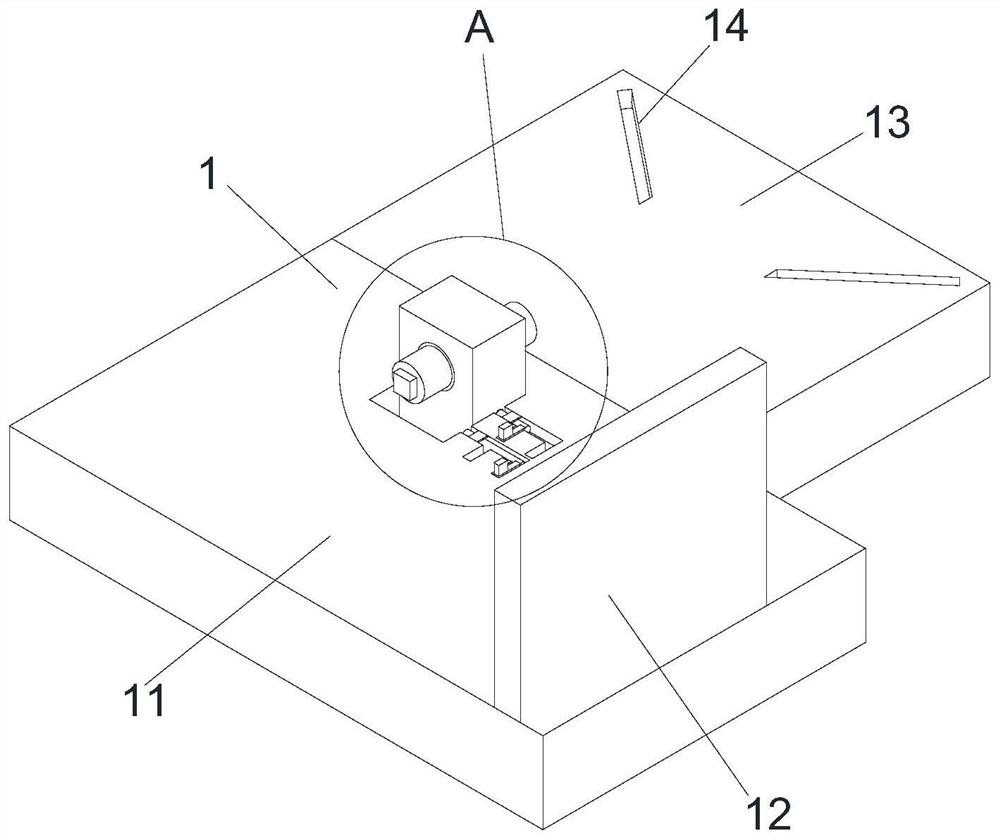

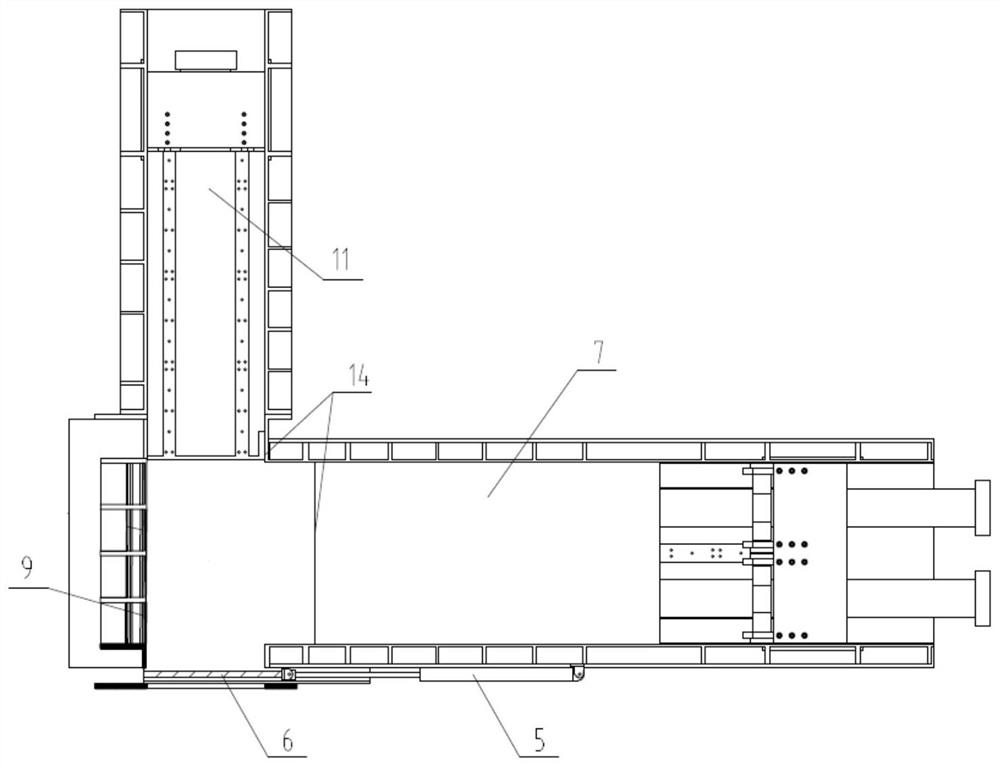

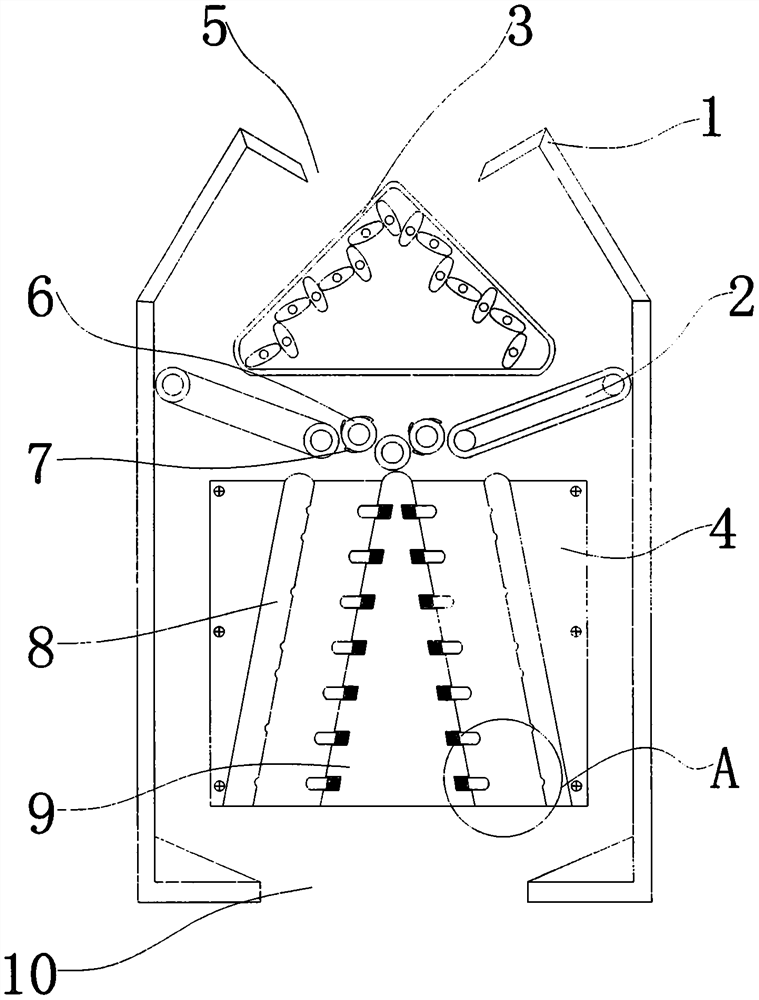

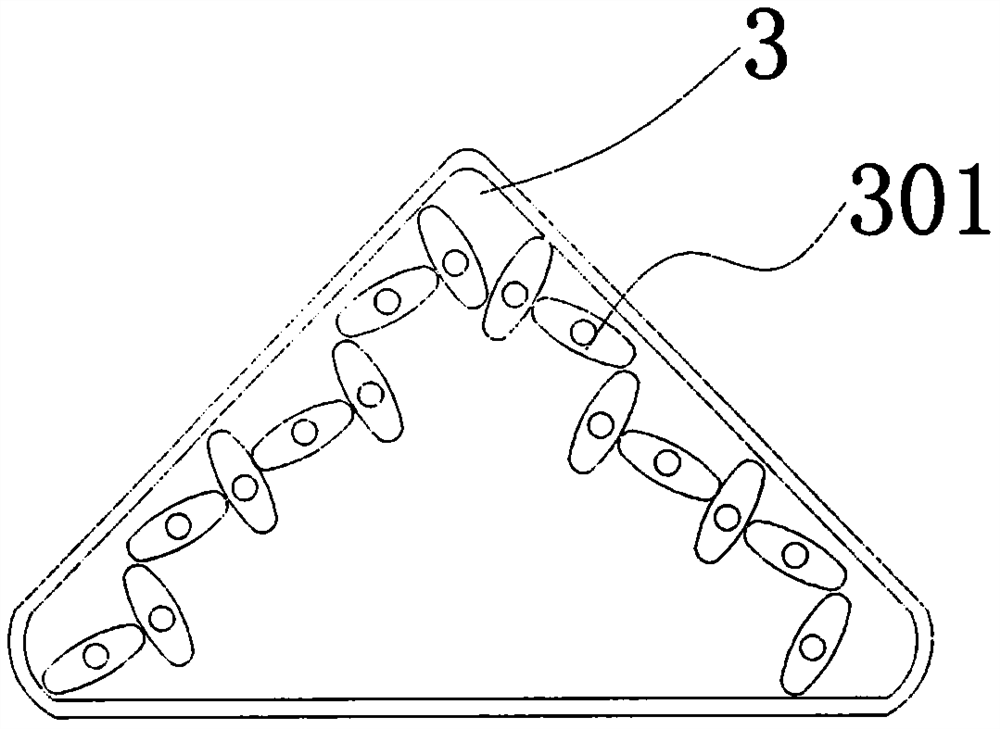

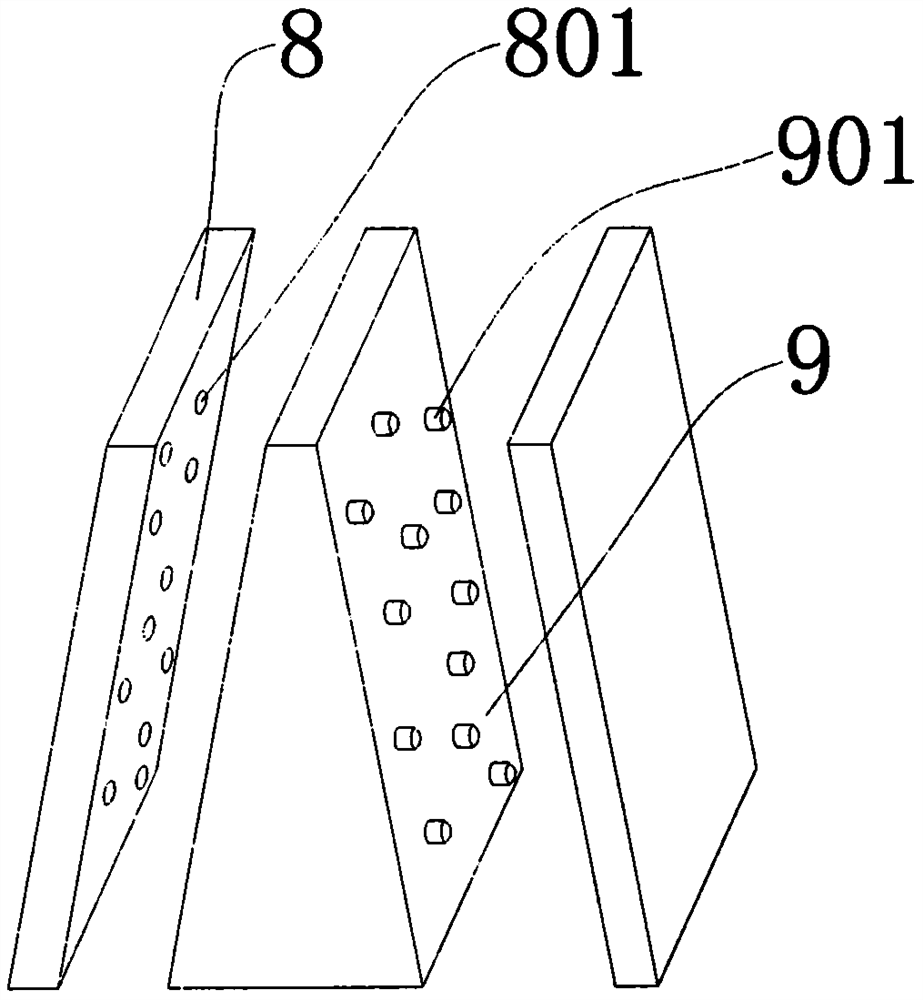

The invention relates to an environment-friendly recycling treatment system for waste plastic bottles. The environment-friendly recycling treatment system comprises a base plate, a cleaning and feeding device, a conveying device, a squeezing device, a crushing device and a storage device. The base plate is of an L-shaped structure. The cleaning and feeding device is located at the front side end of the base plate. The conveying device is located right on the rear portion of the cleaning and feeding device, and the conveying device and the cleaning and feeding device are located on the same straight line. The squeezing device is located at an outlet in the rear side of the conveying device. The crushing device and the conveying device are vertically arranged, and the crushing device is fixedly connected with the base plate. The storage device is installed at the left side of the crushing device. By means of the environment-friendly recycling treatment system, the waste plastic bottles can be cleaned, pushed, fed, conveyed, squeezed, crushed and stored, and the whole recycling treatment of the waste plastic bottles is realized; moreover, the treatment process is high in degree of mechanization, a large number of labor force is saved, and treatment efficiency is improved; and meanwhile, pollution to the environment by the waste plastic bottles is avoided, and the environment and ecology are protected.

Owner:同信生态环境科技有限公司

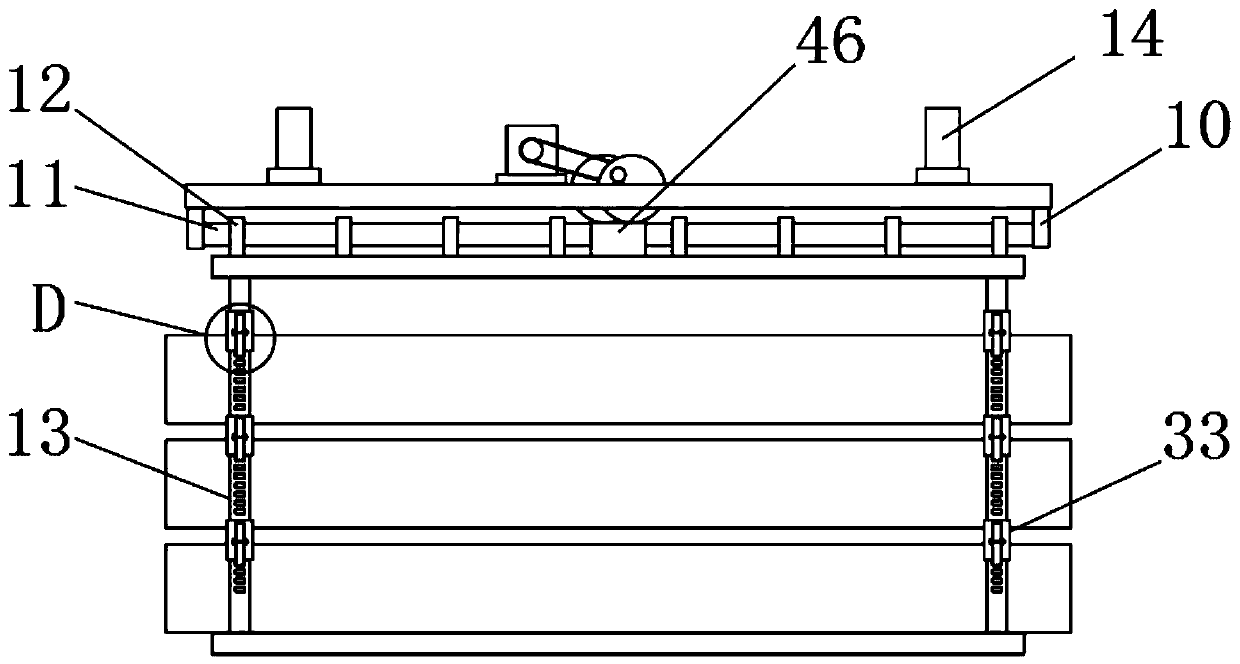

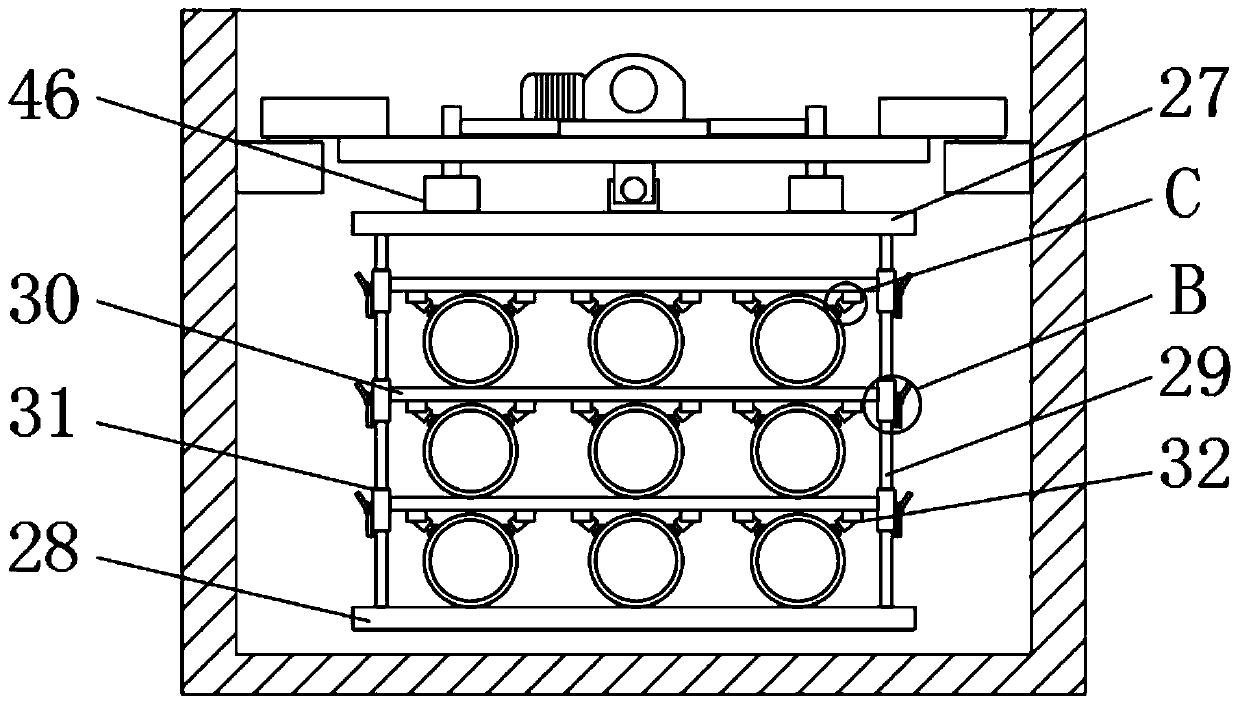

Sludge dewatering equipment

InactiveCN106892548AThoroughly dehydratedFully dehydratedSludge treatment by de-watering/drying/thickeningMoving filtering element filtersSludge dewatering

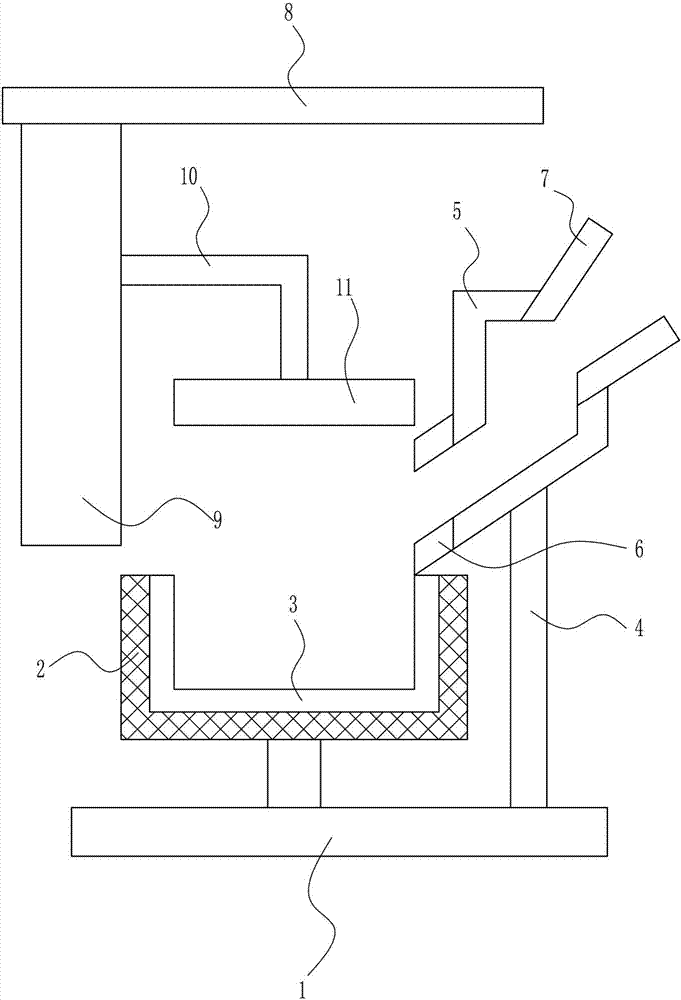

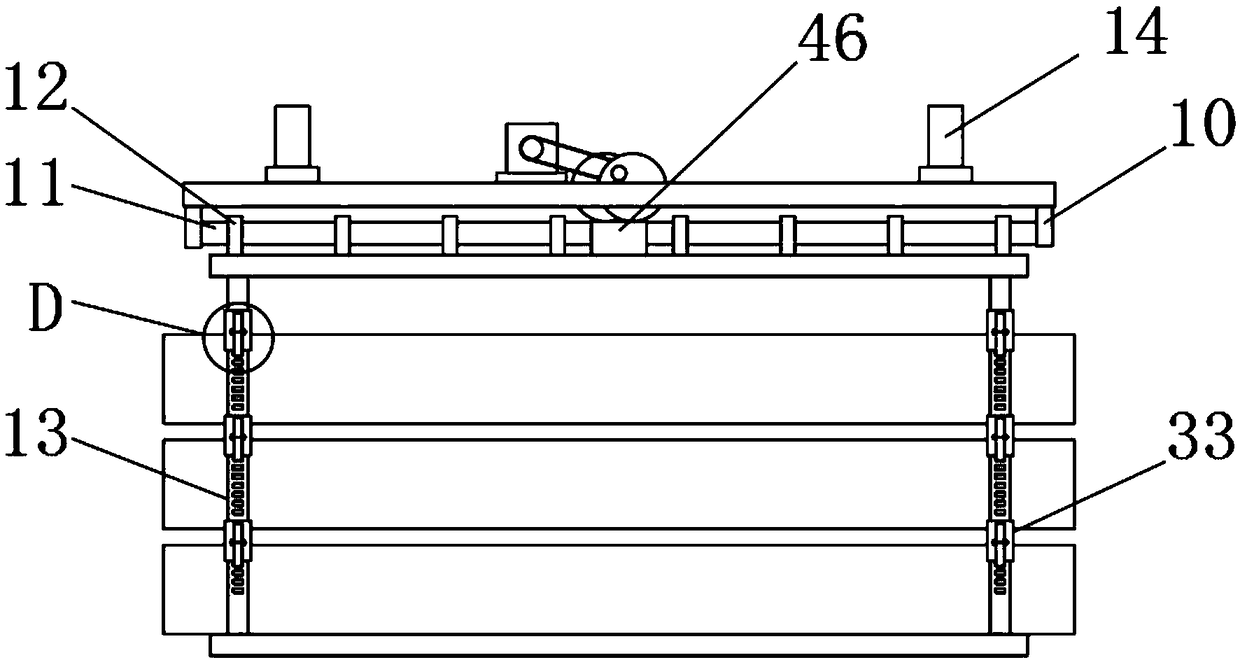

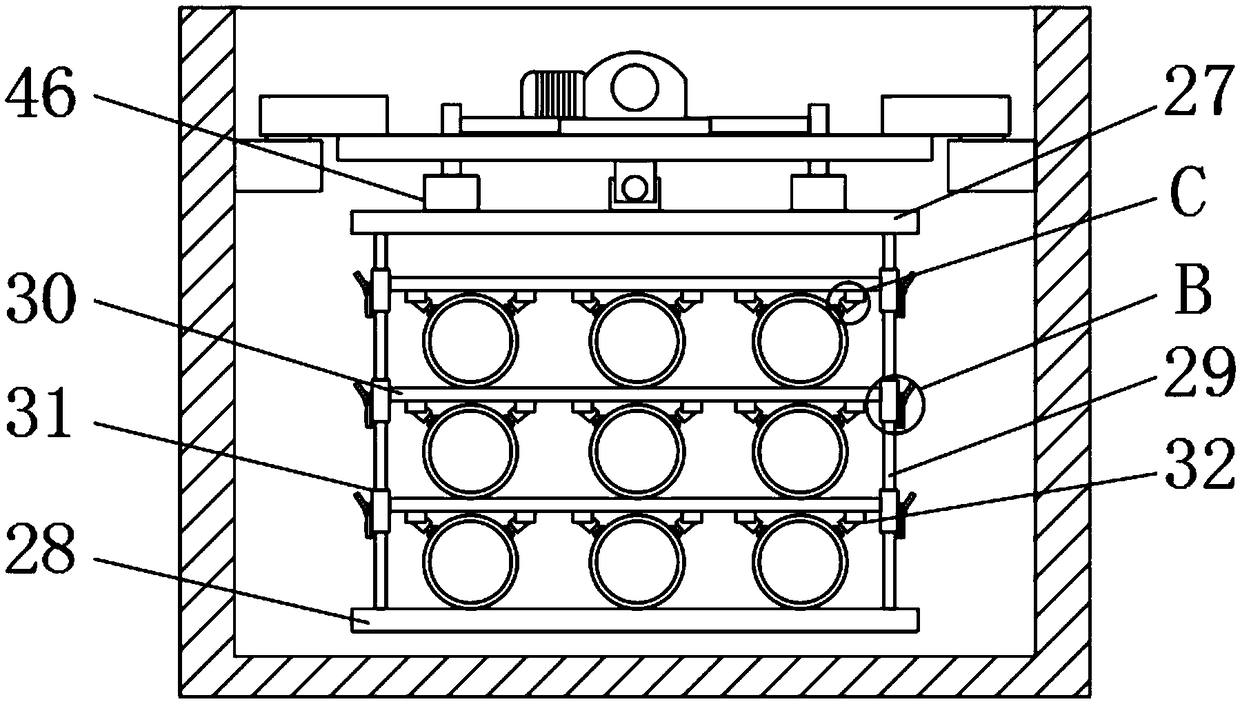

The invention relates to a dewatering device, in particular to a sludge dewatering device. The technical problem to be solved by the present invention is to provide a sludge dehydration equipment which can thoroughly dewater sludge, crush the sludge before compression, replace the pressing plate and beat the feed box. In order to solve the above technical problems, the present invention provides such a sludge dewatering equipment, which includes a bottom plate, a filter frame, a filter membrane, a bracket, a feed box, a first feed hopper, a second feed hopper, etc.; The side is connected with a filter frame, the filter frame is provided with a filter membrane, the top right side of the bottom plate is connected with a support, the top of the support is connected with a feed box, and the left side of the bottom of the feed box is connected with a first feed hopper, the first feed hopper is located at Above the right side of the filter frame, a second feed hopper is connected to the top right side of the feed box. The present invention designs a sludge dewatering device, which moves the pressure plate up and down by starting the first motor to rotate clockwise and counterclockwise, so that the sludge in the filter frame can be squeezed powerfully.

Owner:林安益

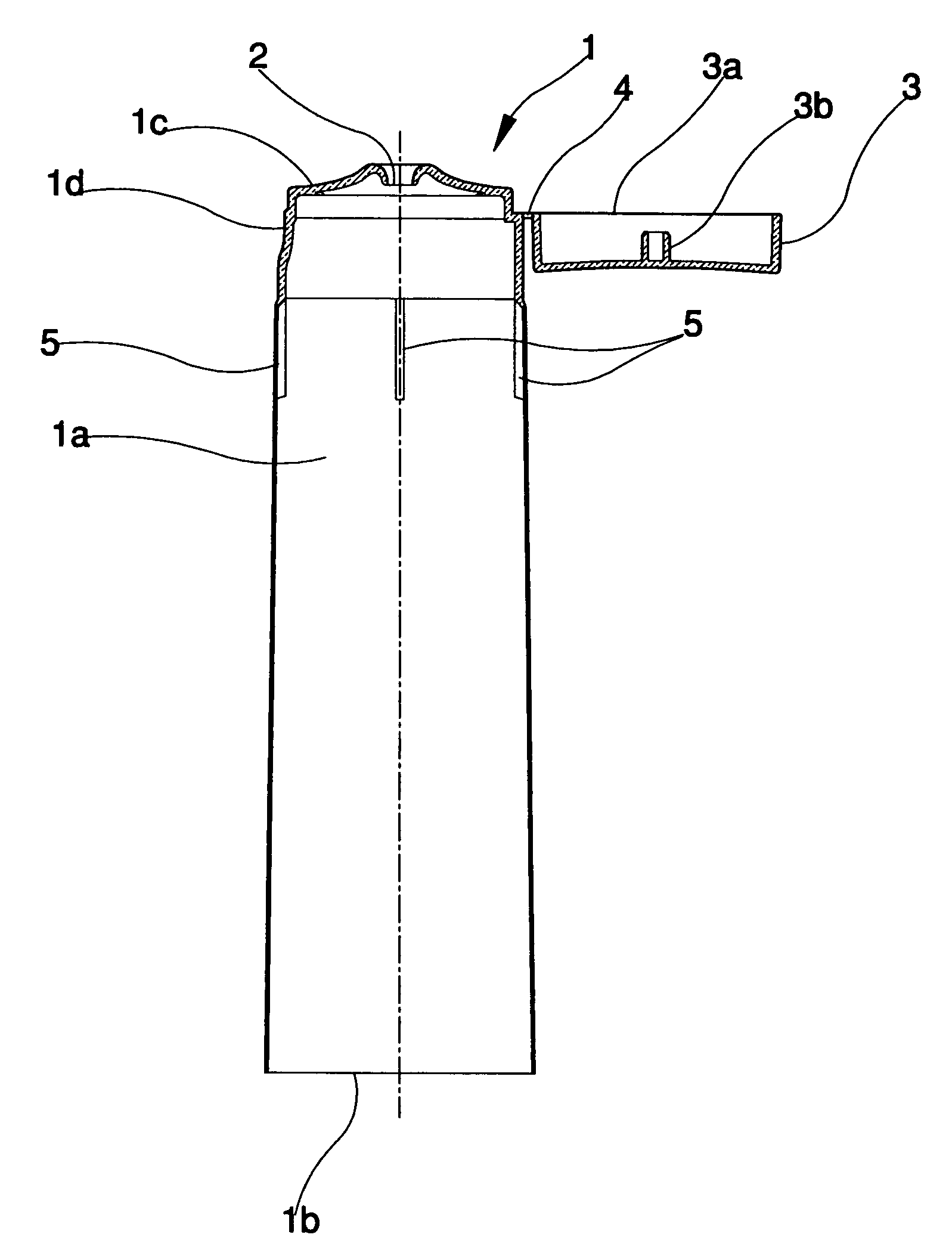

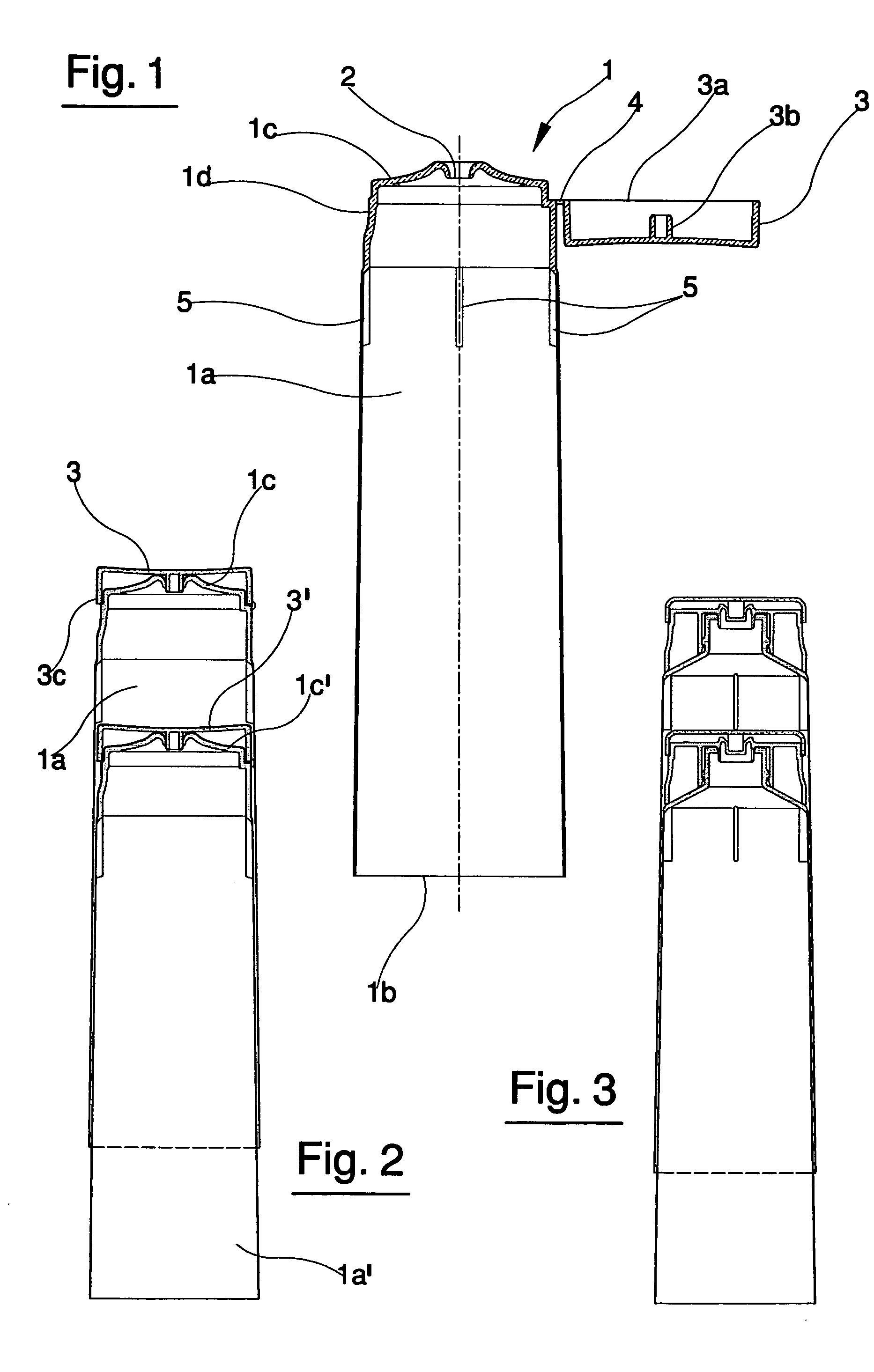

Plastic single-piece tube

InactiveUS20050242132A1Great consistencyHigh productivityClosuresLiquid flow controllersHinge angleEngineering

Owner:BORMIOLI ROCCO & FIGLIO

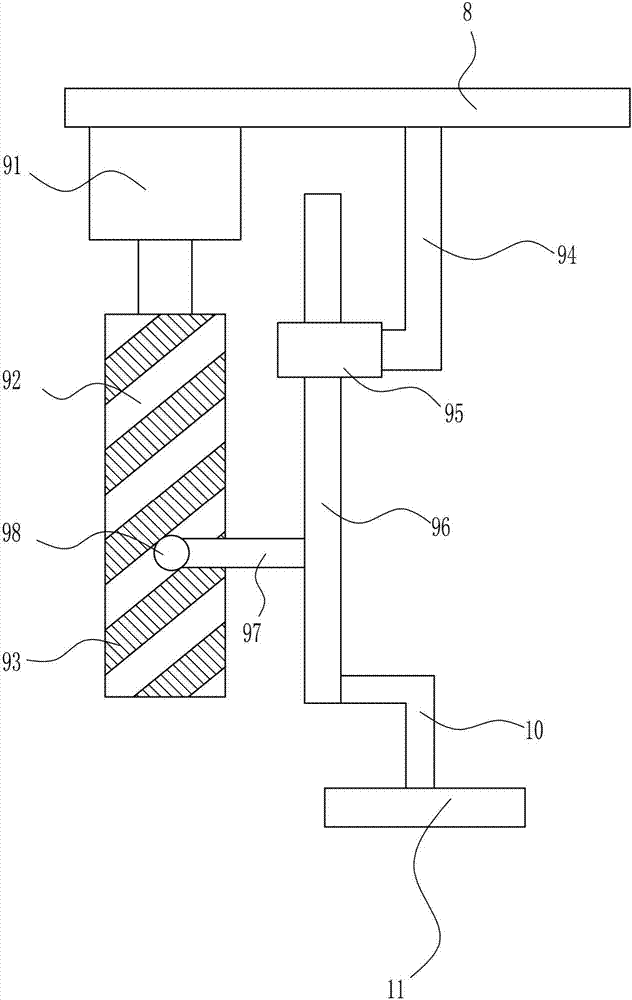

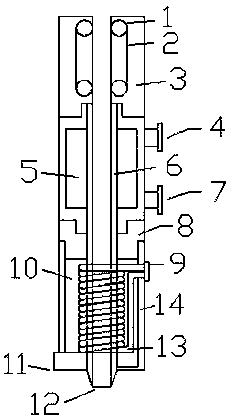

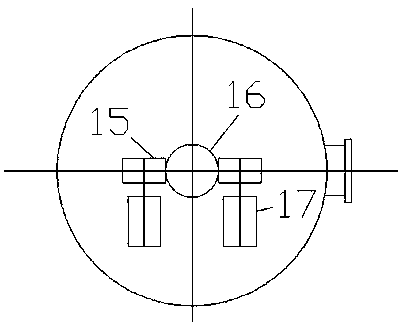

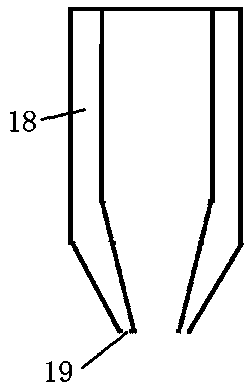

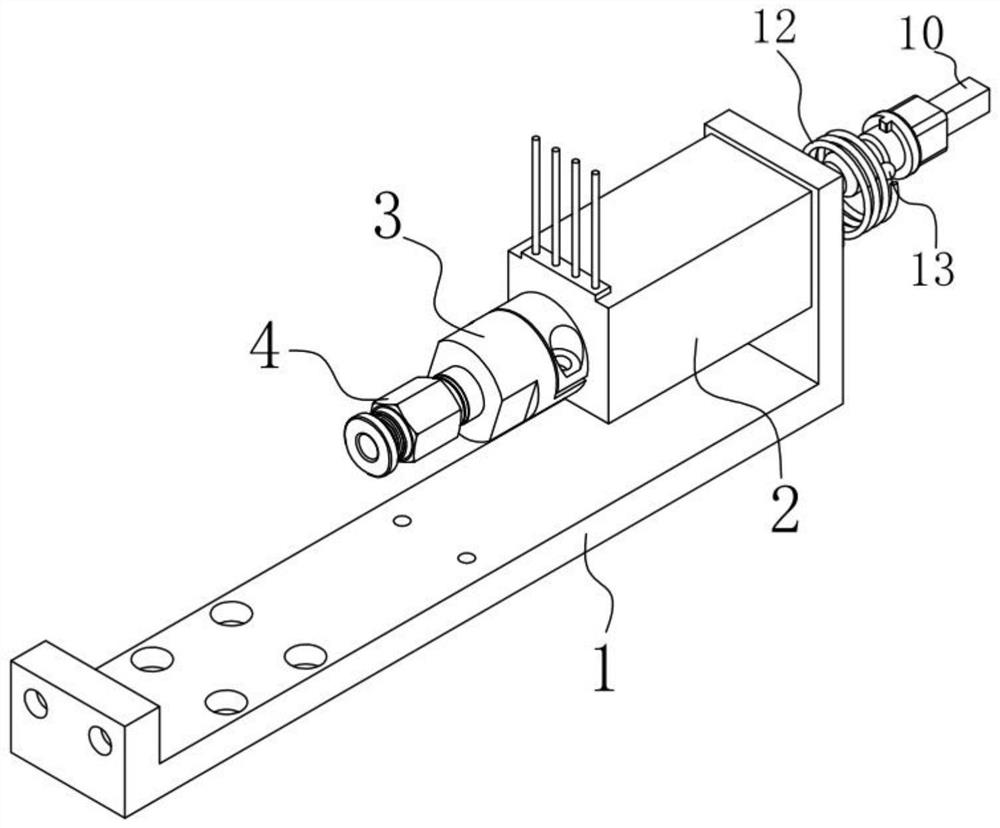

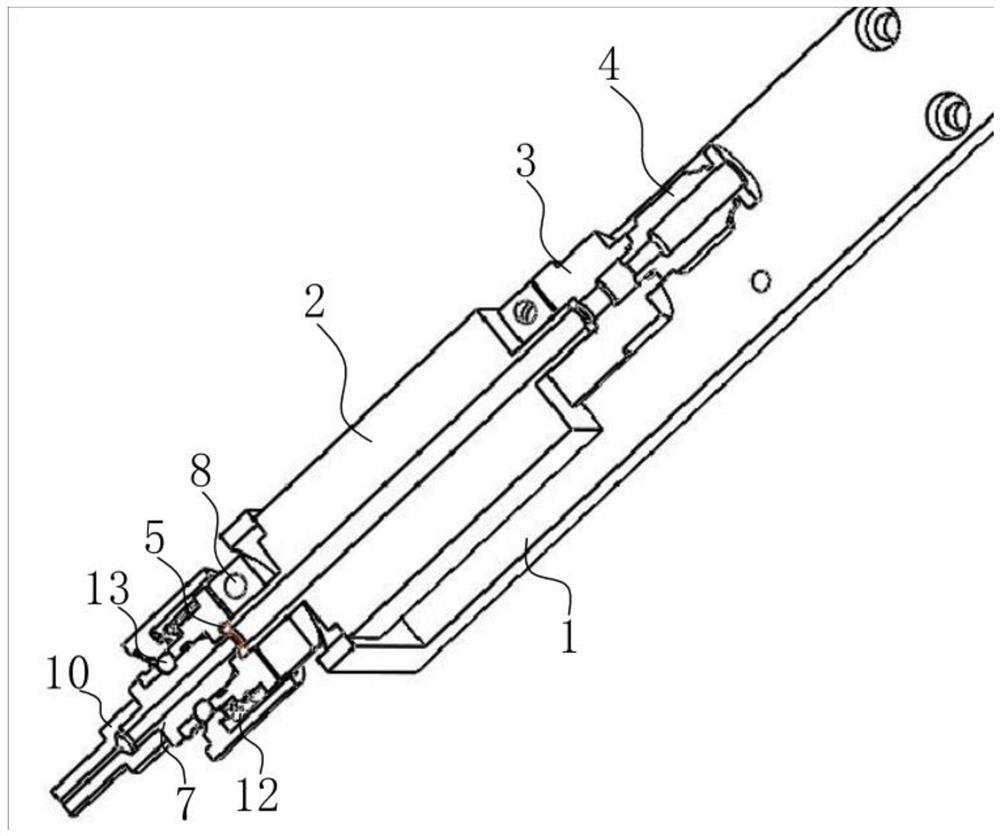

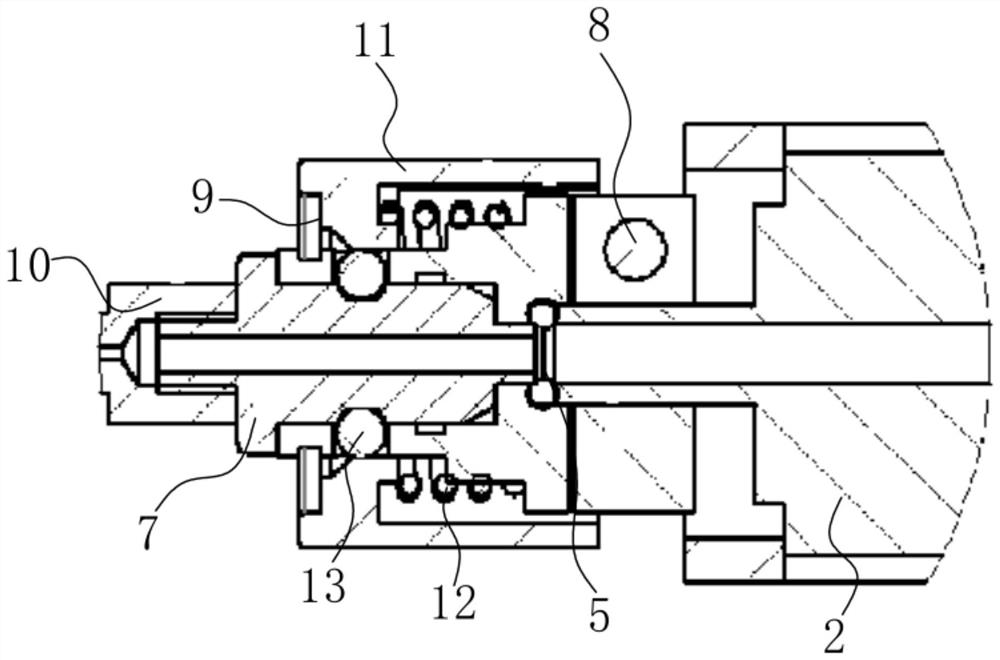

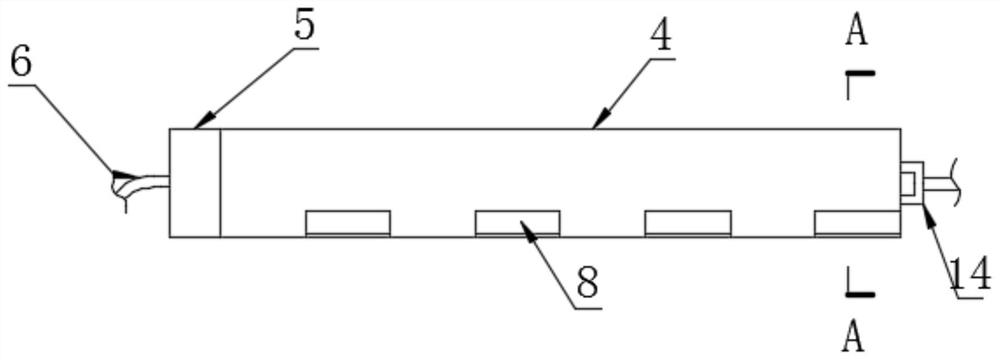

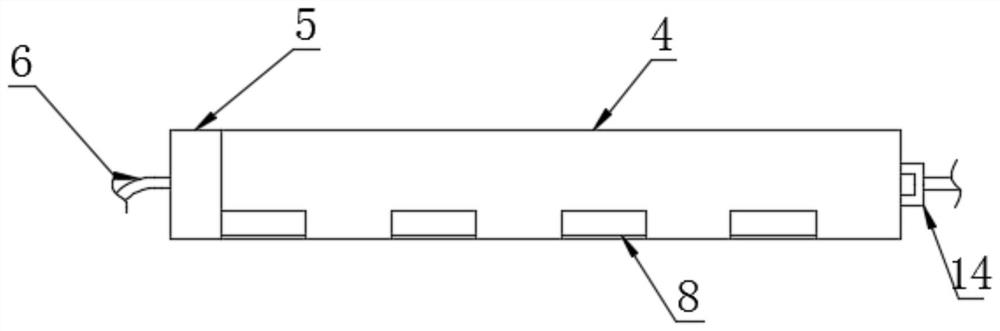

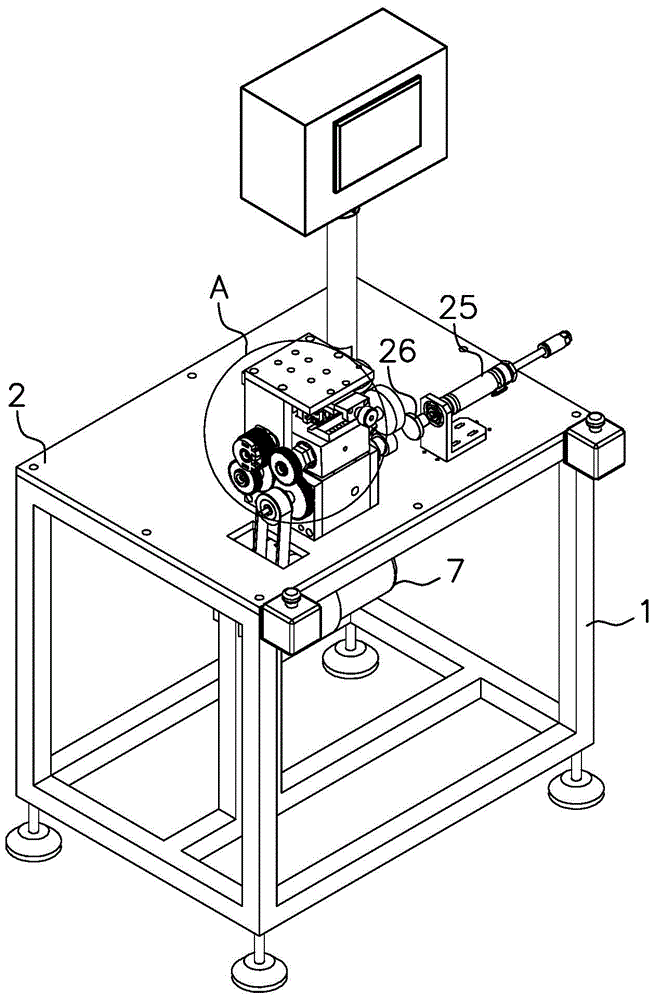

Metal amorphous 3D printing conveying device

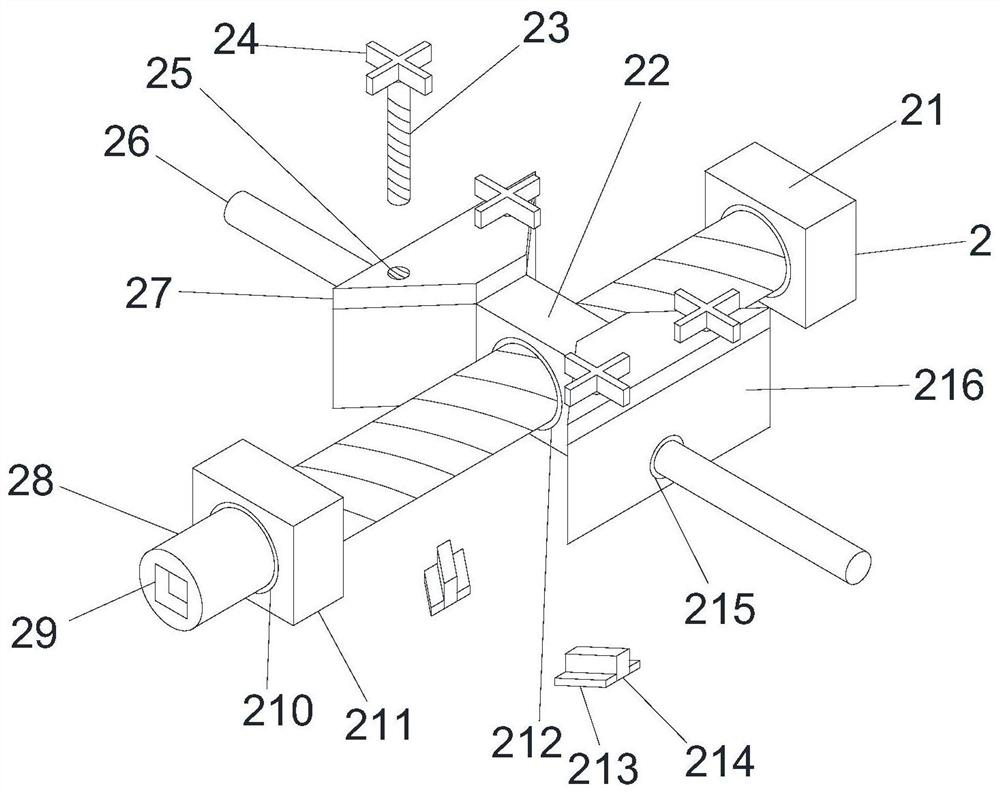

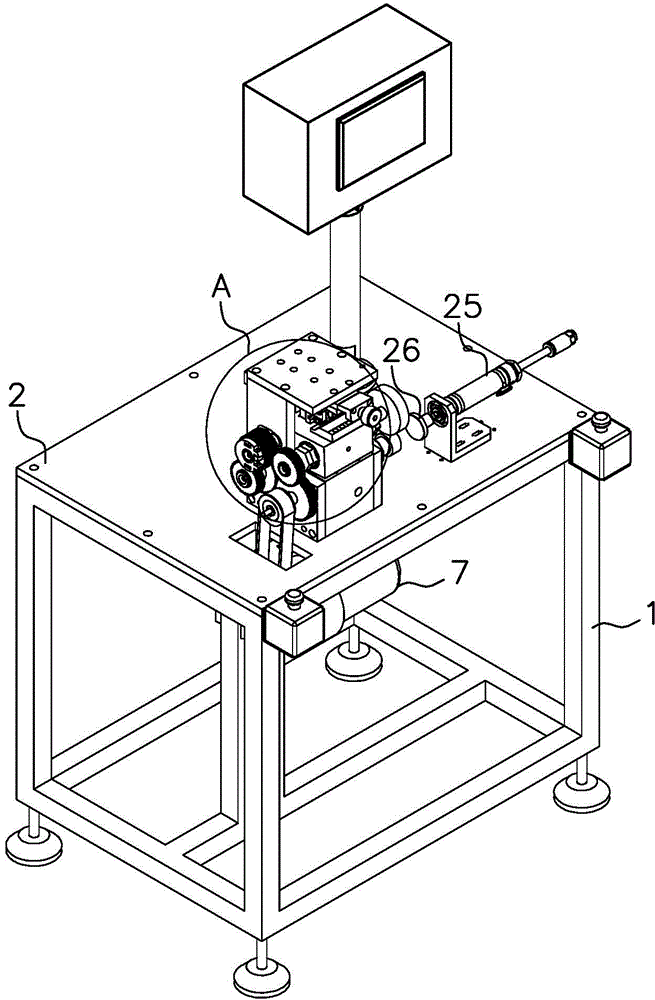

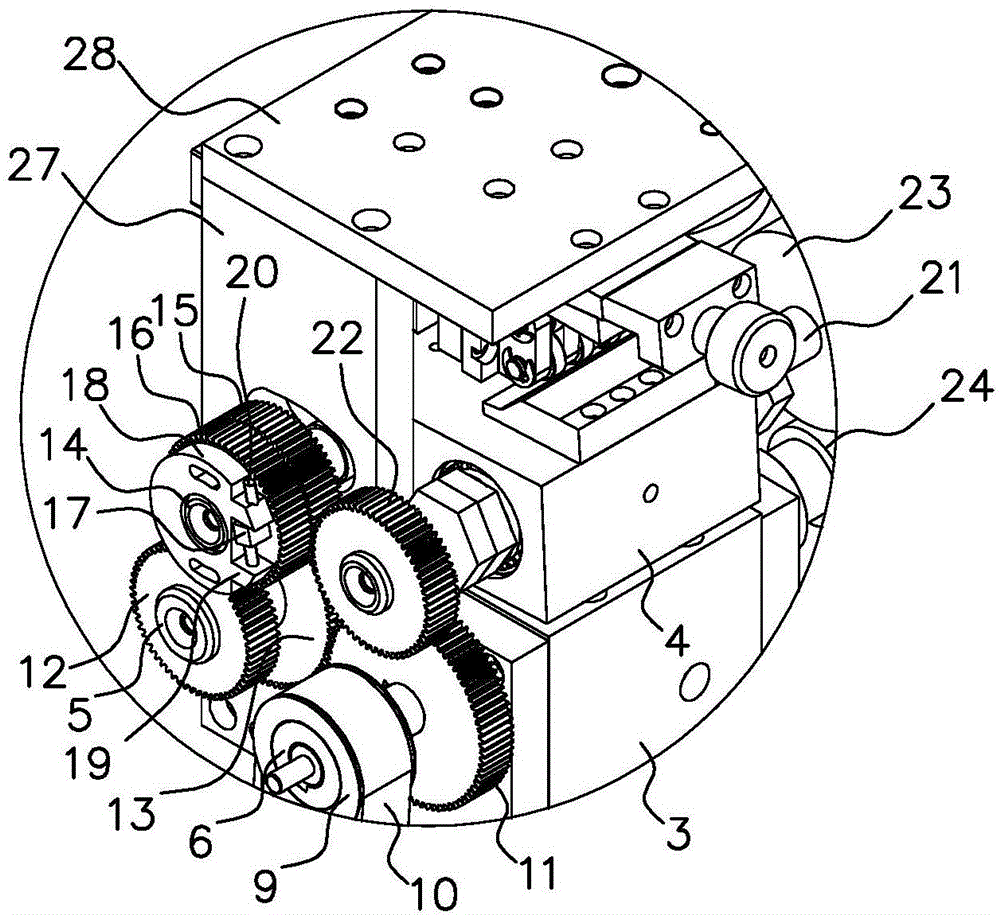

ActiveCN108465816ASqueeze hardInhibit swellingAdditive manufacturing apparatusCeramic compositeLiquid metal

The invention discloses a metal amorphous 3D printing conveying device, and belongs to the technical field of 3D printing technologies. The metal amorphous 3D printing conveying device comprises a first metal sleeve, a second metal / ceramic composite sleeve and a ceramic wire feeding throat pipe; the extrusion force to a metal wire material is increased by arranging protrusions on the surface of anextrusion chain; a spiral solenoid heat exchanger is arranged, a water cooling method is adopted, the cooling speed is increased, and accordingly, the situation that equipment is damaged by the hightemperature is avoided; in addition, wire material expansion caused by the high temperature can be prevented by increasing the cooling speed, and the situation that a sleeve pipe is blocked due to thefact that the wire material is melt too early is effectively avoided; and by arranging an ultrasonic vibrator in the position of a rotary nitrogen spray nozzle, ultrasonic vibration is transmitted into molten liquid metal, structure crystal grains are refined, after metal melt is thrown out by rotating the nitrogen spray nozzle, then, liquid nitrogen is sprayed out, metal liquid drops are quicklycooled, accordingly, the amorphous structure is formed, and the structure property of a printed product is more excellent.

Owner:ZHONGBEI UNIV

Device for clearing pig hair with cereals

ActiveCN106305947AAvoid slipperyPrevents the problem of not being able to pull it out easilySlaughtering accessoriesHair rootsArray data structure

The invention discloses a device for clearing pig hair with cereals. The device comprises a rack and is characterized by further comprising steamers and multiple hair pulling mechanisms arranged on the rack horizontally, wherein each hair pulling mechanism comprises elastic ropes and multiple rice grains, the multiple rice grains are transversely arranged on the elastic ropes in a penetrating manner, when the elastic ropes reach 20%-50% of the maximum stretching length, the two adjacent rice grains are butted against each other, two ends of each elastic rope are detachably connected onto the rack, outlets of the steamers face the space below the hair pulling mechanisms, and a reciprocating drive mechanism for pushing the hair pulling mechanisms to move up and down is arranged on the rack. With the implementation of the technical scheme, the problem that hair roots are prone to be left in pig skin with an existing hair pulling technology is solved.

Owner:CHONGQING GUANGHENG FOOD DEV

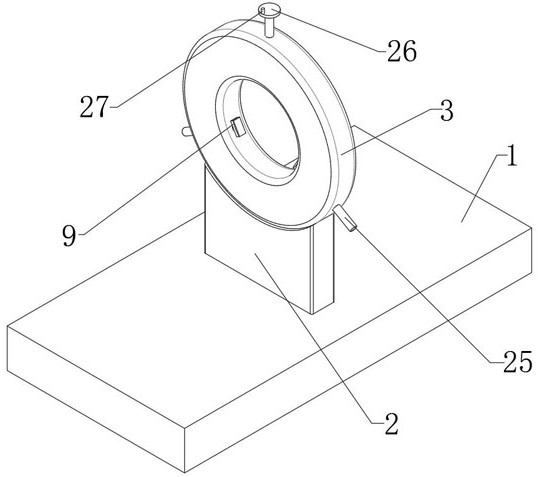

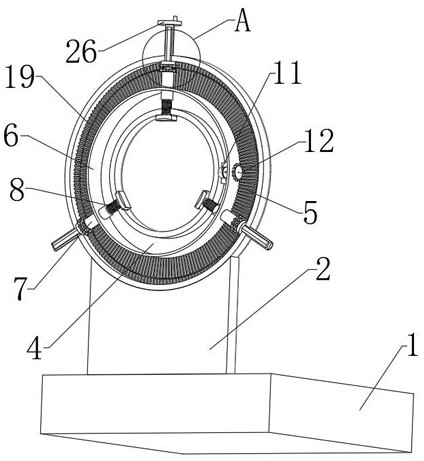

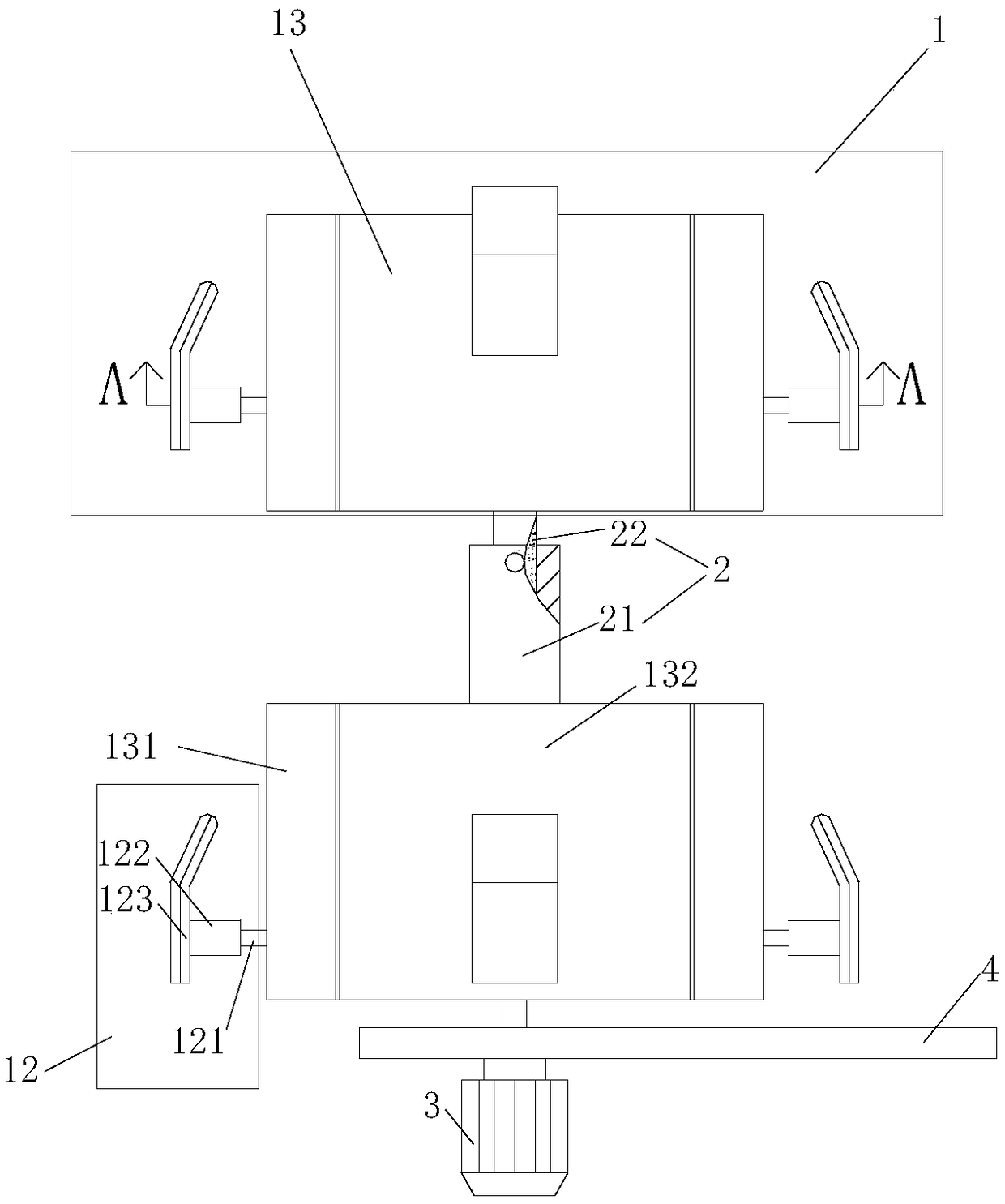

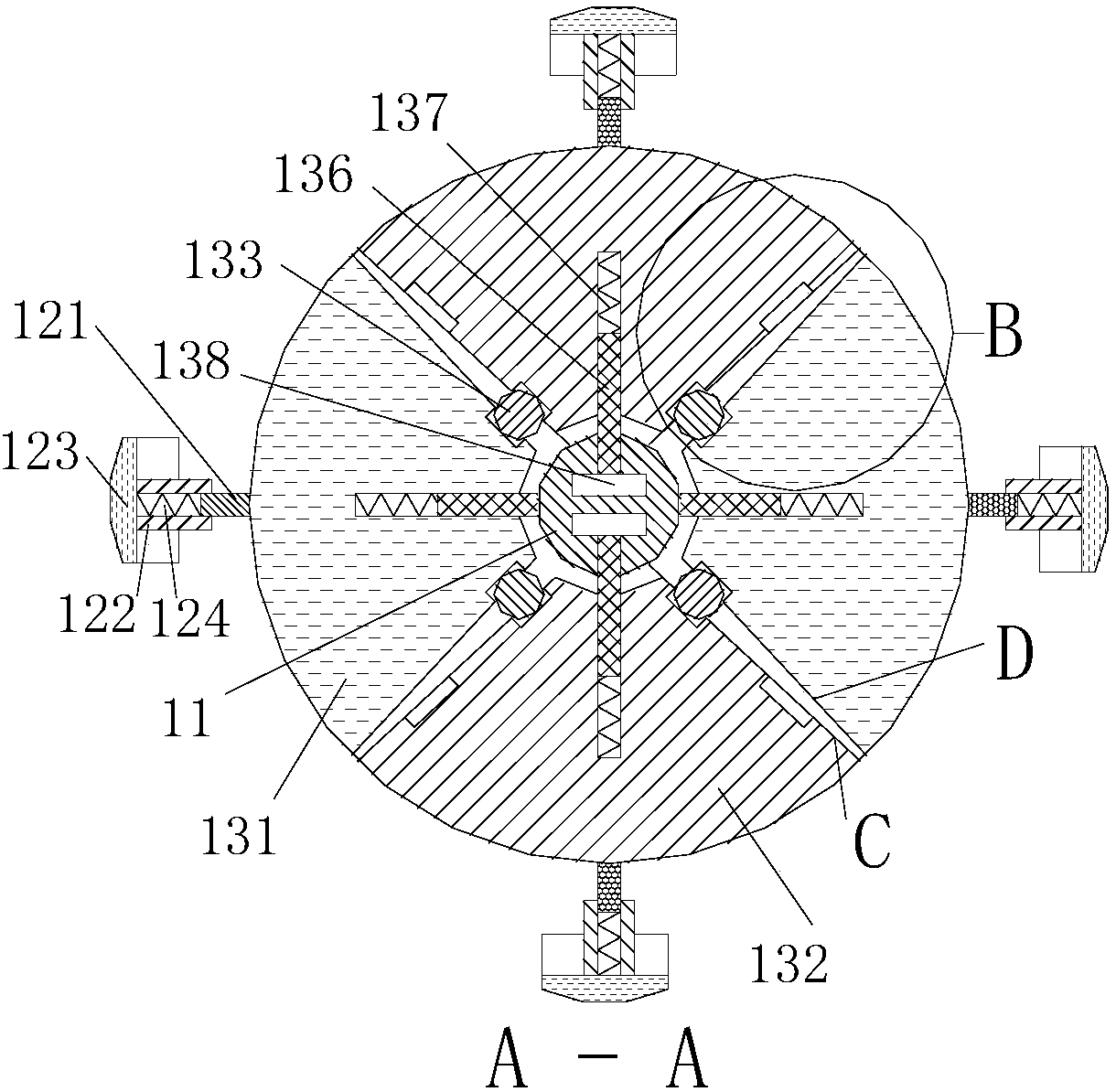

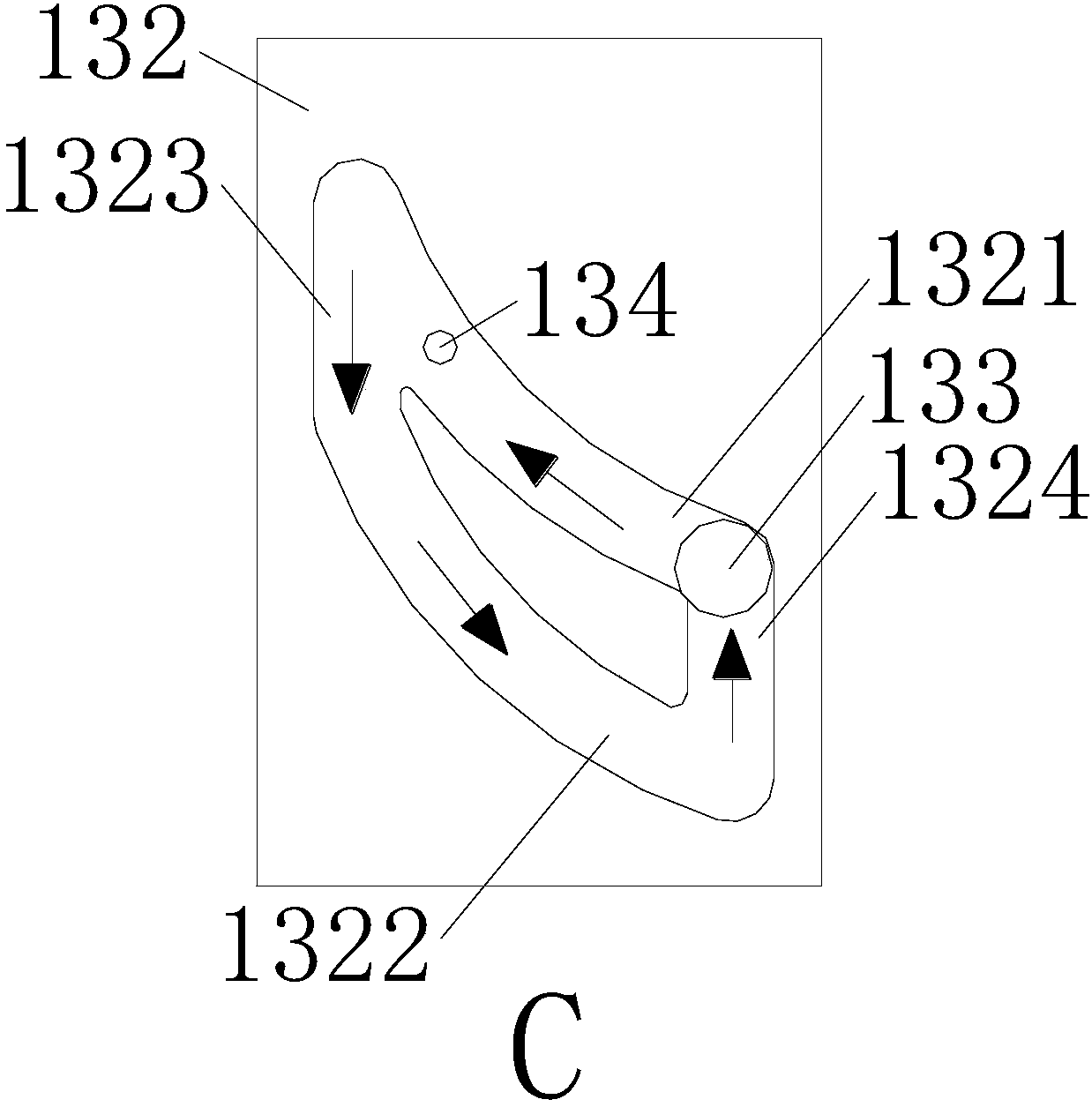

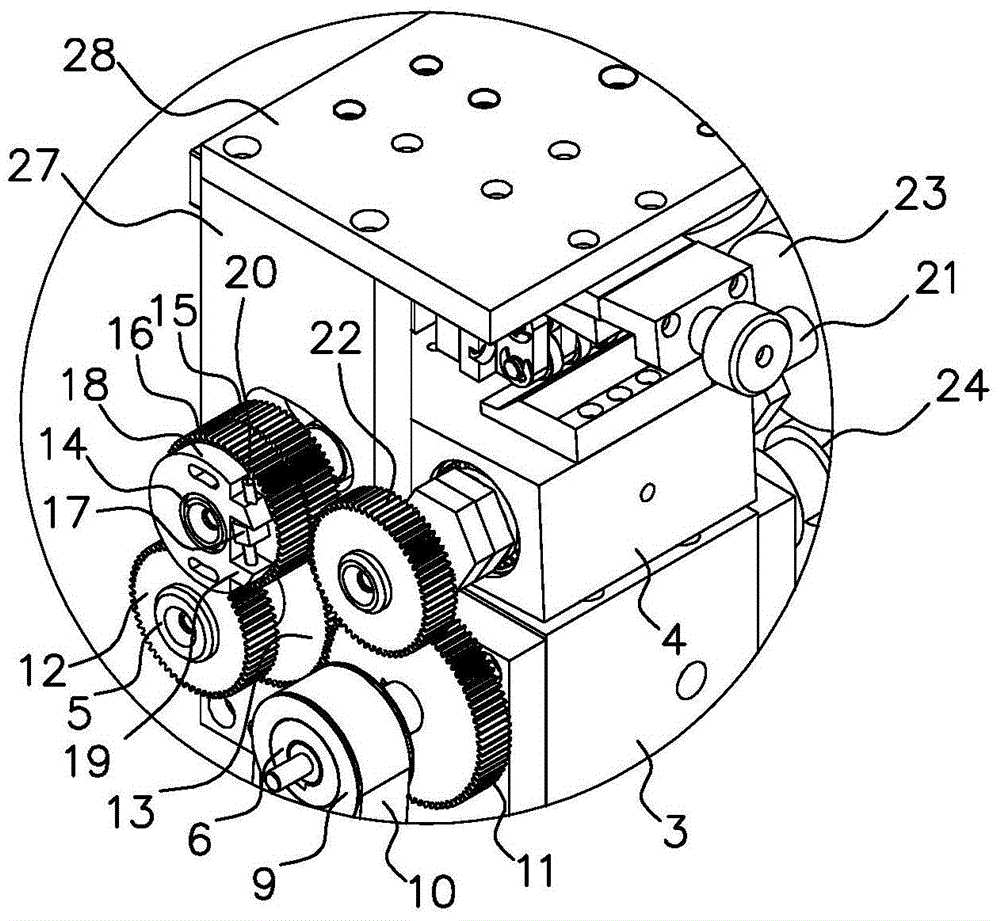

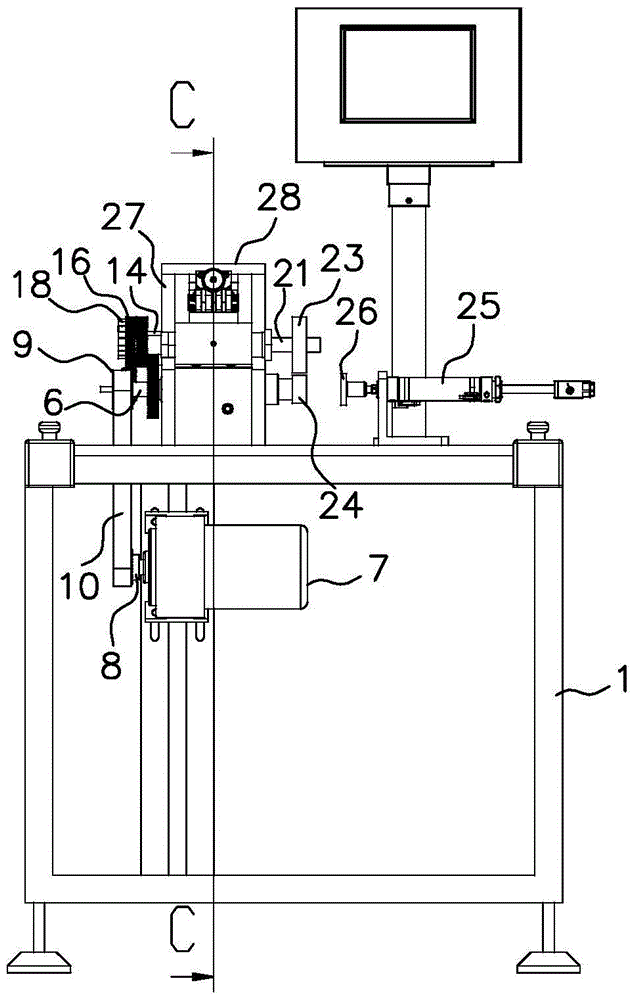

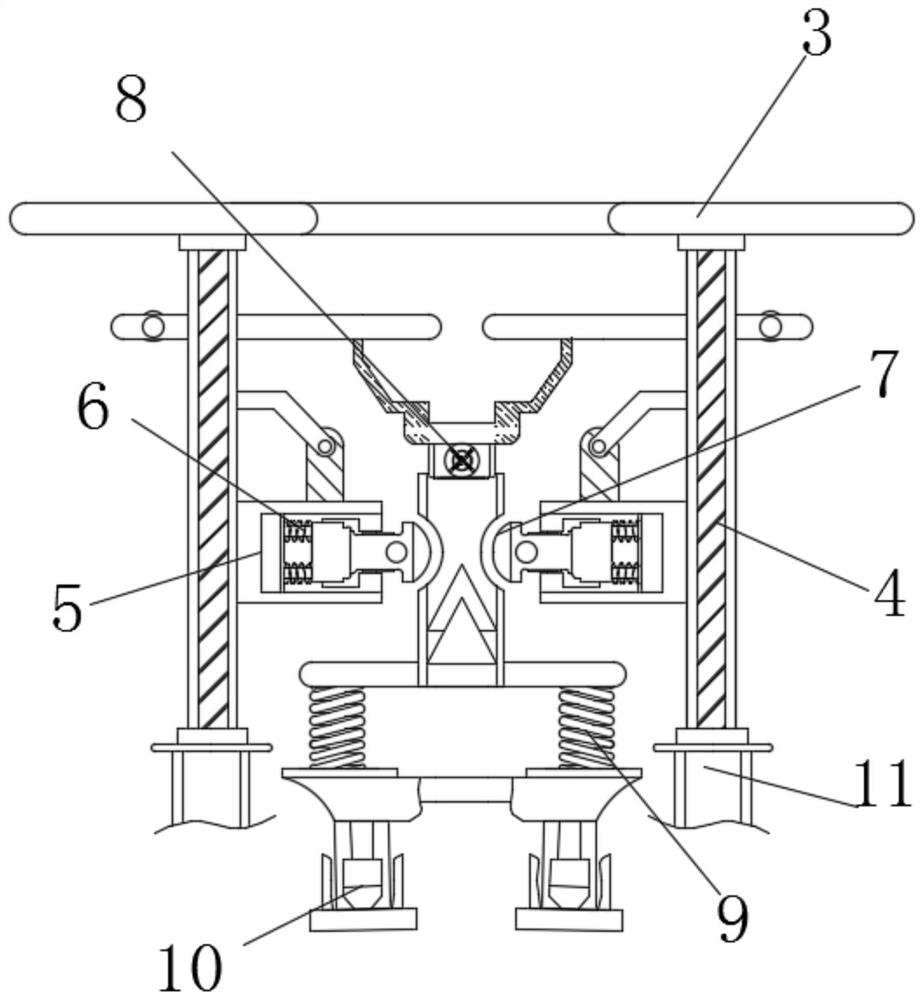

Steel pipe body clamping and positioning mechanism for steel pipe production

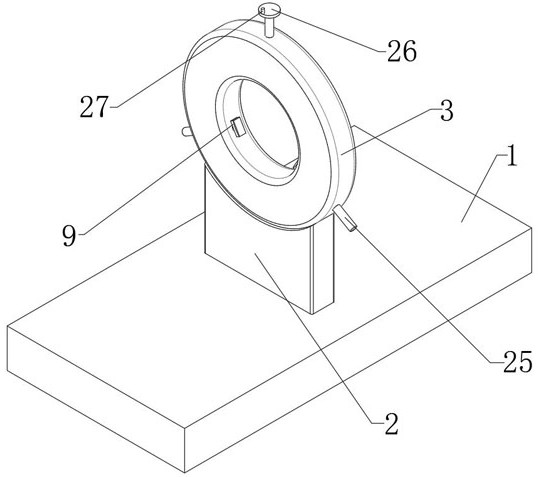

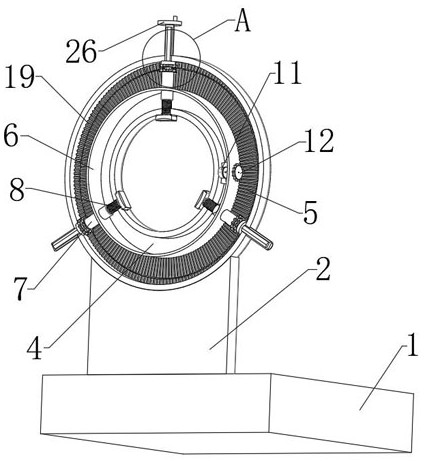

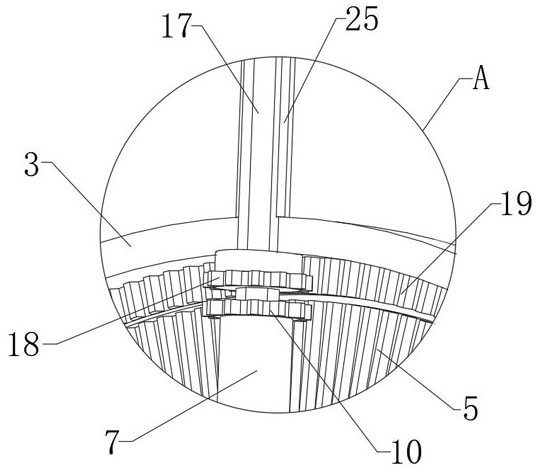

ActiveCN113579805ASame clamping forceAvoid damageWelding/cutting auxillary devicesAuxillary welding devicesGear wheelClassical mechanics

The invention discloses a steel pipe body clamping and positioning mechanism for steel pipe production. The steel pipe body clamping and positioning mechanism comprises a fixing plate arranged on a machining platform and a clamping device fixedly connected with the fixing plate, the clamping device is annular, an annular groove is formed in the clamping device, and an annular wall is fixedly connected in the annular groove; and a plurality of threaded cylinders are rotationally connected to the annular wall, the multiple threaded cylinders are arranged in the circumferential direction, and a threaded rod is rotationally connected into each threaded cylinder through threads. The steel pipe body clamping and positioning mechanism has the beneficial effects that a motor can drive the multiple threaded cylinders to rotate simultaneously through a first gear ring, a first gear and other structures, so that the multiple threaded rods stretch out to clamp a pipe simultaneously in multiple directions, the pipe is prevented from being damaged in the clamping process, it can be guaranteed that the clamping force of the multiple threaded rods is the same, and the whole device is better in clamping effect, suitable for pipes with different thicknesses and convenient and fast to use.

Owner:南通圣峰防腐钢塑有限公司

Fully-automatic sealed acid-circulation pickling tank

The invention discloses a fully-automatic sealed acid-circulation pickling tank, comprising a pickling tank body and a steel pipe pickling rack. The inner walls of both sides of the pickling tank aresymmetrically fixed with two fixture blocks; and buckles are arranged at the corresponding positions of the two sides of the steel pipe pickling rack. According to the invention, through clamp connection of the buckles and the fixture blocks, an eccentric wheel rotates under the driving of a driving device, so a fixed mount is allowed to shake so as to realize stirring of a pickling solution in the pickling tank, and thus, the layering of the pickling solution is prevented, and the phenomena of excessive pickling and insufficient pickling are avoided; an elastic limit device is fixed on the fixed mount and can limit steel pipes to prevent the disengagement of the steel pipes during shaking; the position of a limit rod can be adjusted through clamp connection between a limit member and a limit hole, so steel pipes of different internal diameters can be mounted and fixed; and steel pipes do not contact with each other, so the surfaces of the steel pipes are totally immersed in the pickling solution, which enables pickling efficiency to be improved.

Owner:上上德盛集团股份有限公司

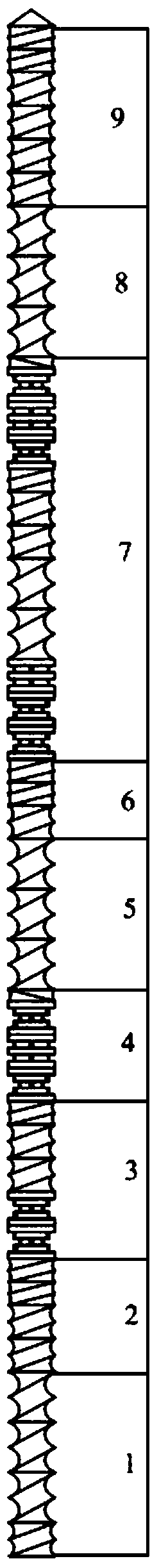

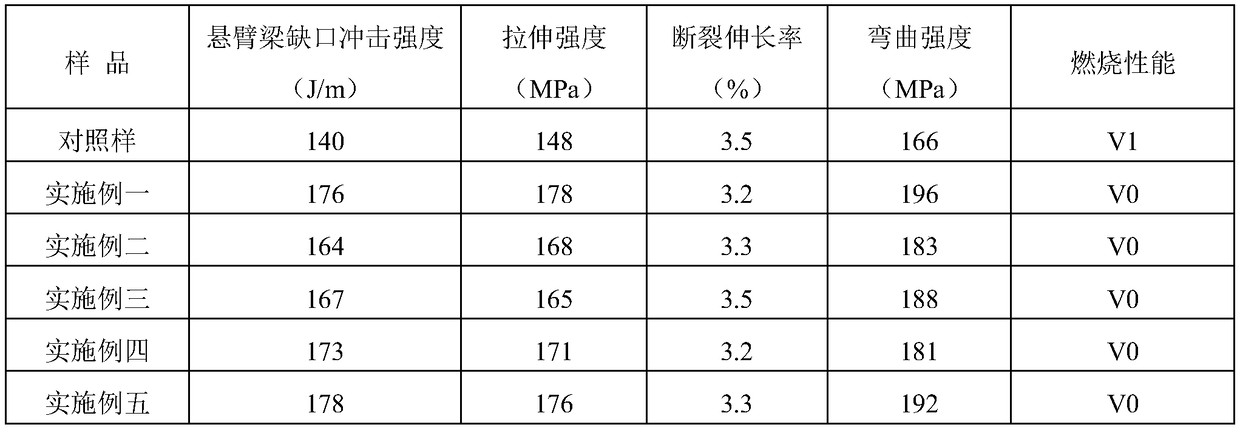

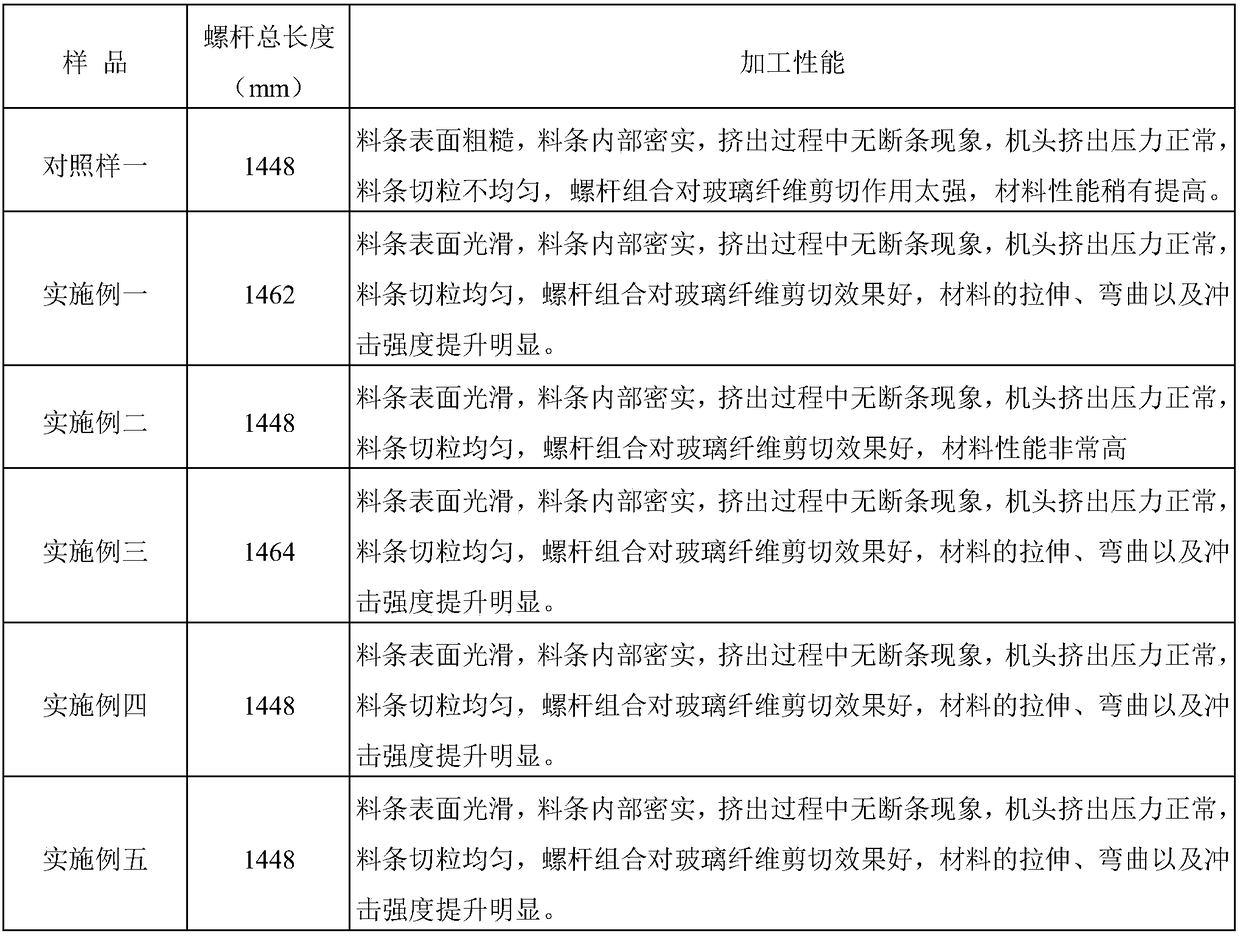

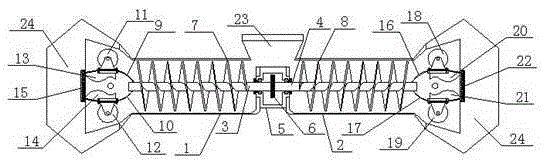

Double-screw assembly for extrusion molding processing of nylon and glass fiber, and processing method thereof

Owner:QINGDAO GON TECHNOLOGY CO LTD

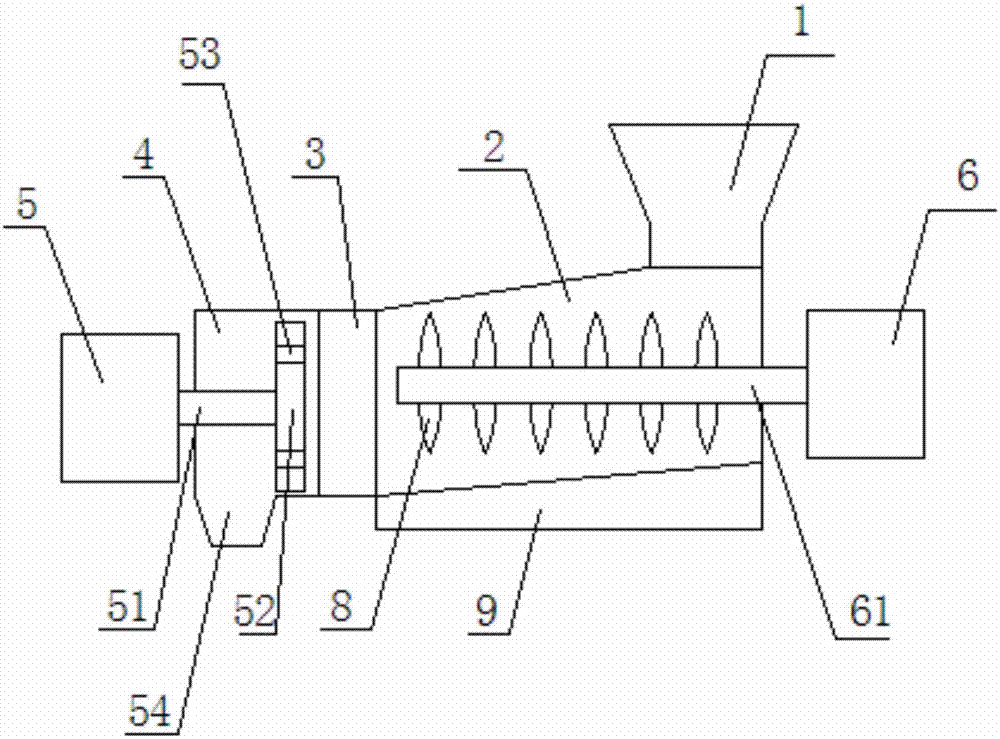

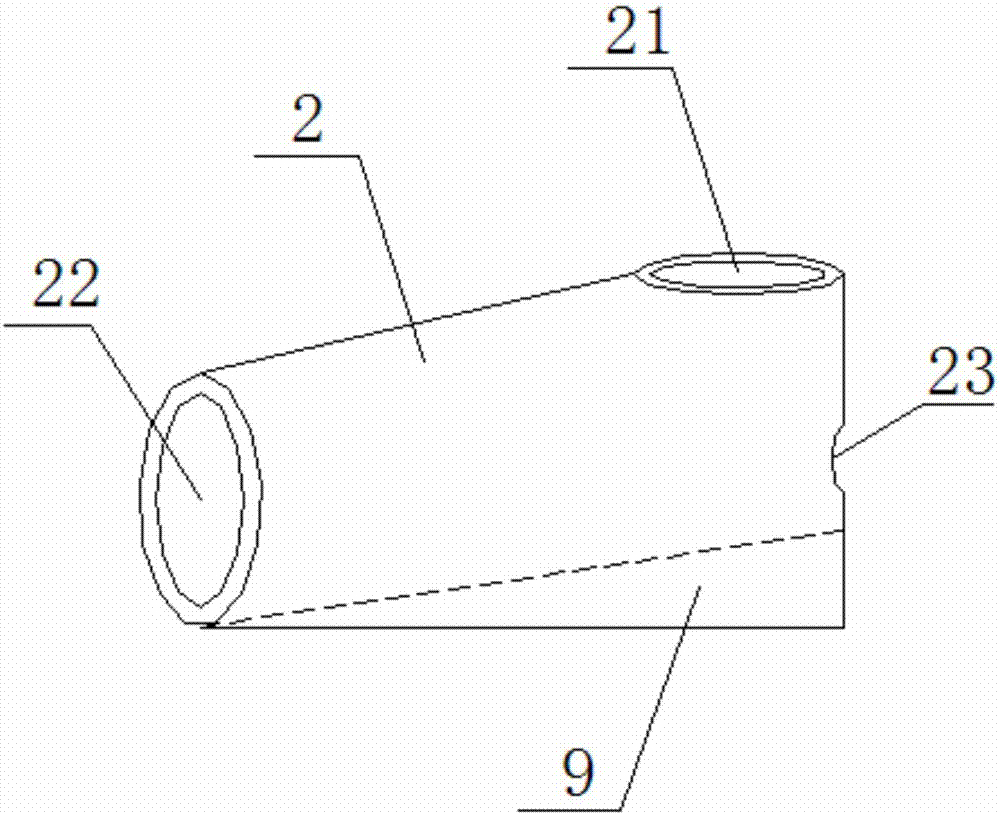

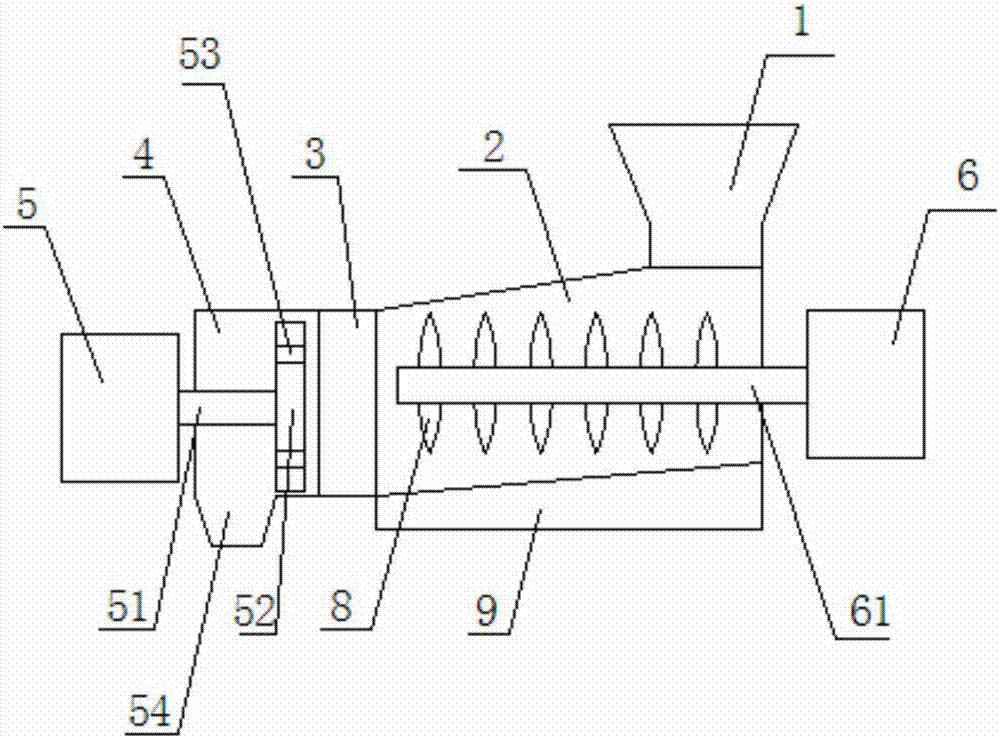

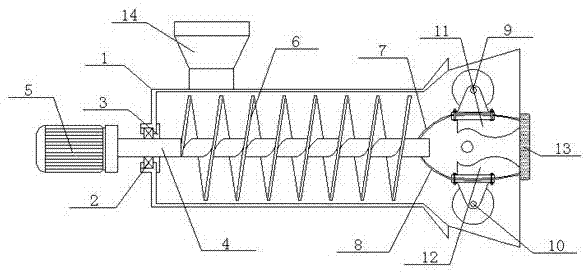

Film squeeze dehydrator

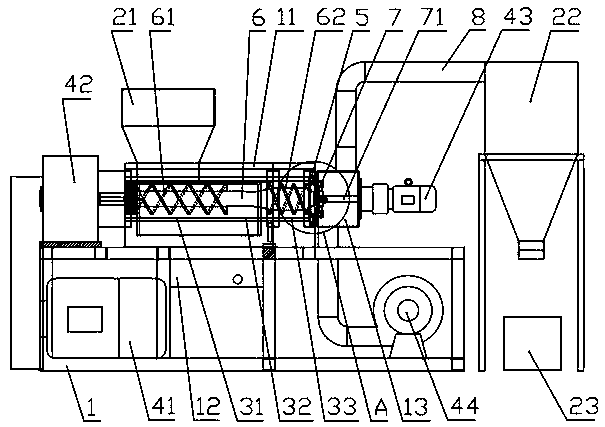

The invention discloses a film squeeze dehydrator. A machine barrel and a housing are arranged on a stand; the machine barrel consists of a feed section machine barrel, a compression section machine barrel and a plastifying section machine barrel; a feed hopper is arranged on the feed section machine barrel; a screw rod is inserted in the machine barrel; a first thread section is arranged on the screw rod extending in the feed section machine barrel; the screw rod in the compression section machine barrel is a polish rod; a second thread section is arranged on the screw rod extending in the plastifying section machine barrel; a first driving device is arranged at the outer side of the feed section machine barrel; a discharge template covers in an opening of the plastifying section machine barrel; a cutting device driven by a second driving device is arranged at the outer side of the discharge template; conical drain holes are formed in the walls of the feed section machine barrel and the compression section machine barrel; the first and second thread sections are both double threads; the thread pitch of the first thread section is greater than the thread pitch of the second thread section; and a material stop box with a conveying device is arranged at the outer side of the plastifying section machine barrel. The film squeeze dehydrator has the advantages of good squeeze dehydration and granulation effects, high working efficiency and low energy consumption.

Owner:ZHANGJIAGANG BEISIJIA MACHINERY

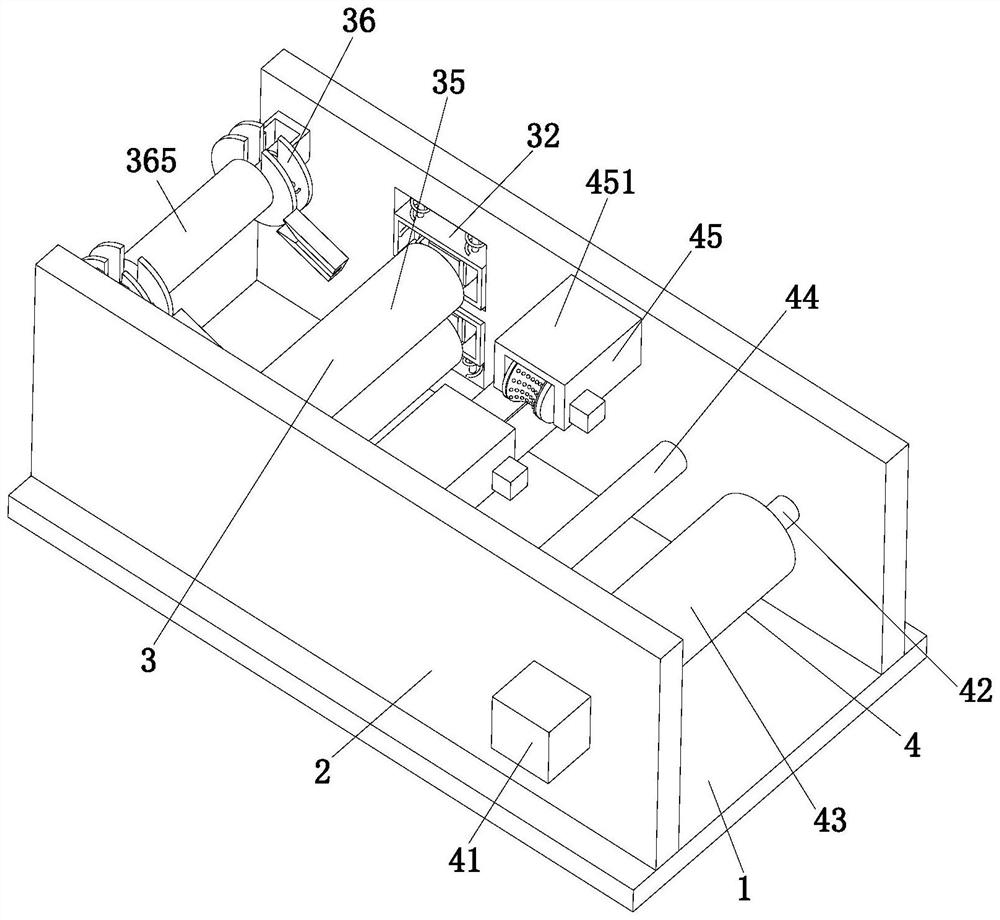

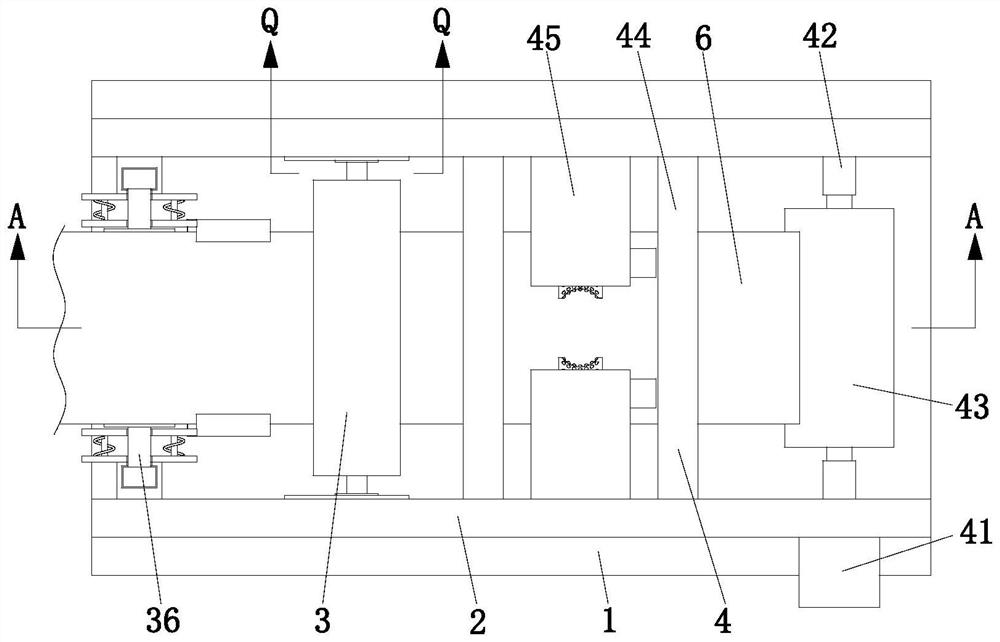

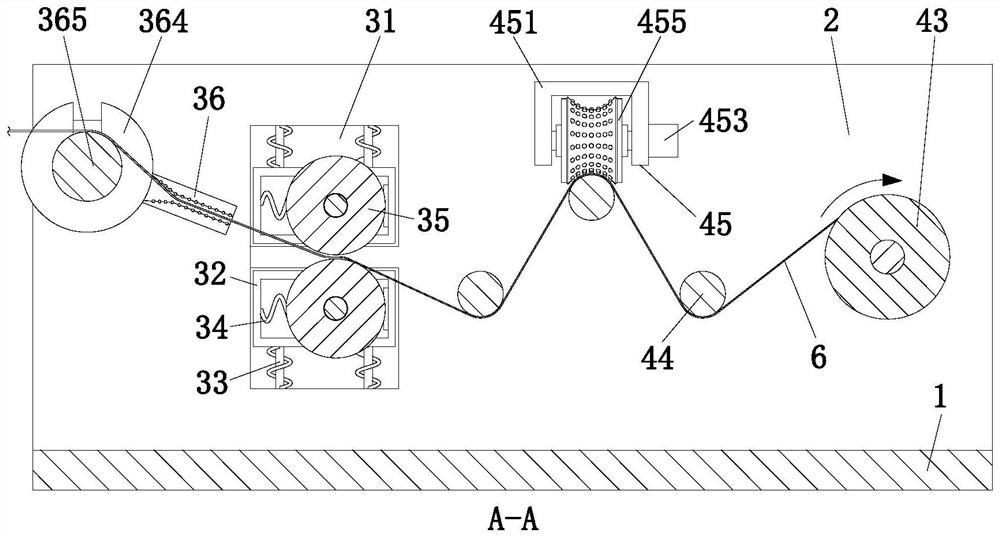

Flattening treatment device for copper foil production

ActiveCN114054544AImprove flattening effectIncrease contact areaMetal-working feeding devicesPositioning devicesMetallurgyEngineering

The invention relates to the technical field of copper foil production, in particular to a flattening treatment device for copper foil production. The device comprises a worktable, bearing plates, a rolling unit and a winding unit, wherein the two bearing plates are symmetrically arranged at the front and back of the upper end of the worktable, and the rolling unit and the winding unit are sequentially arranged on the opposite sides of the bearing plates from left to right. An existing flattening device has the following problems that: when the existing device is used for flattening copper foil with different thicknesses, the device needs to be correspondingly adjusted, and the operation is tedious; and the device cannot perform all-directional flattening treatment on the copper foil, and flattening dead angles exist, so that the flattening effect on the copper foil cannot be ensured. The flattening treatment device can be used for flattening the copper foil with different thicknesses, and does not need to be frequently adjusted, so that the workload can be reduced; and the copper foil can be subjected to all-directional flattening treatment through flattening elastic pieces, so that the flatness of the copper foil can be ensured, and the flattening effect on the copper foil is ensured.

Owner:GUANGDONG FINE YUAN SCI TECH CO LTD

Printing press paper coiling assembly, and usage method thereof

InactiveCN108529273AImprove clamping stabilityWon't slipWebs handlingRolling paperPulp and paper industry

The invention provides a printing press paper coiling assembly. The printing press paper coiling assembly comprises at least two paper coiling portions which are arranged linearly. A telescopic portion is arranged between every two adjacent paper coiling portions, is connected with both the two corresponding paper coiling portions, and can adjust the distance between the two corresponding paper coiling portions. Each paper coiling portion comprises a rotary shaft and a pretensioning portion arranged in the circumferential direction of the rotary shaft. When one pretensioning portion is sleevedwith a paper element in a connected manner, the pretensioning portion can move relative to the paper element in the direction perpendicular to the inner surface of the paper element when making elastic contact with the paper element. An abutting portion connected with one rotary shaft and the corresponding pretensioning portion is further arranged between the rotary shaft and the pretensioning portion, and can drive the pretensioning portion to move in the direction perpendicular to the inner surface of the paper element. The printing press paper coiling assembly is good in clamping stabilityand can be suitable for paper elements of various length specifications and various diameter specifications.

Owner:胡程珏

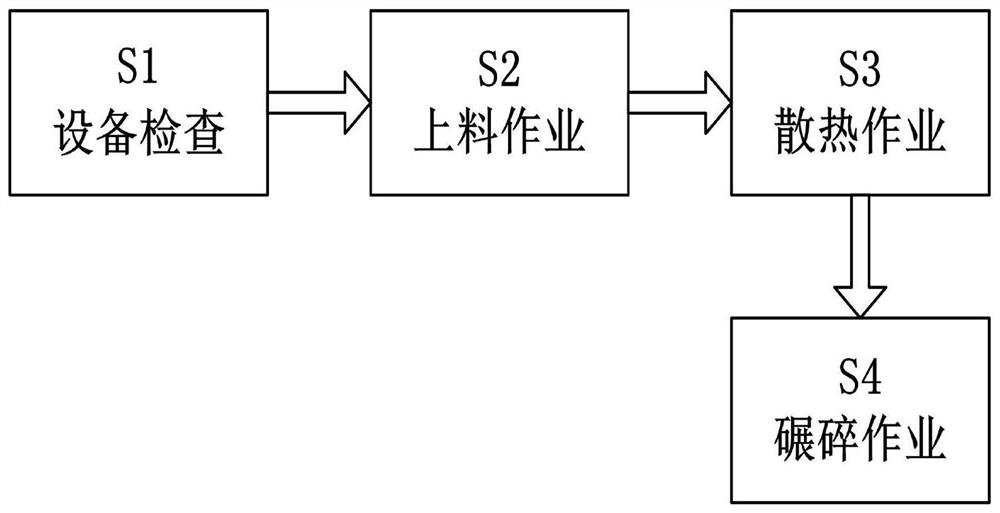

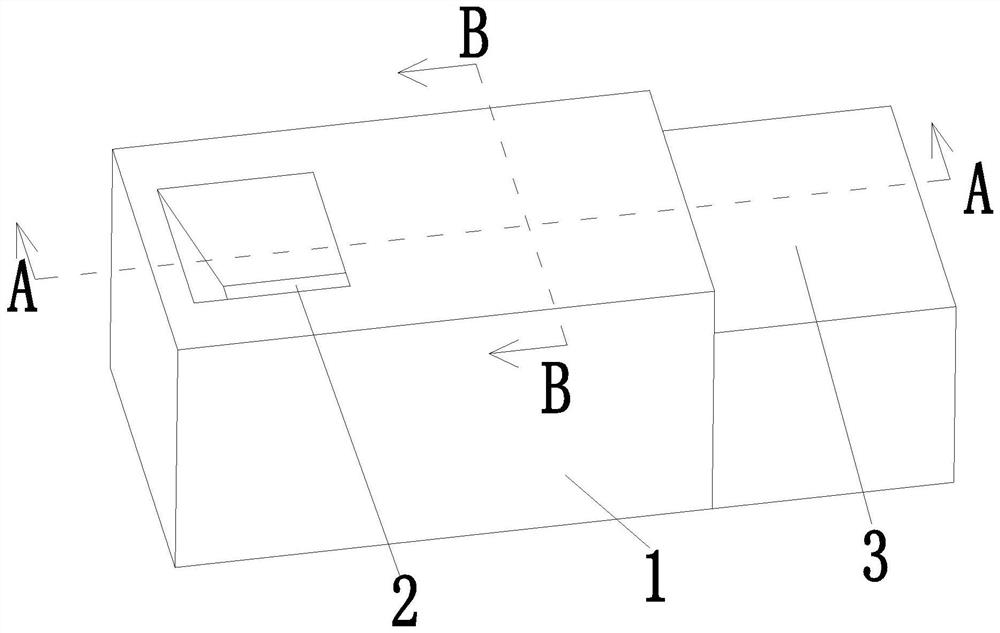

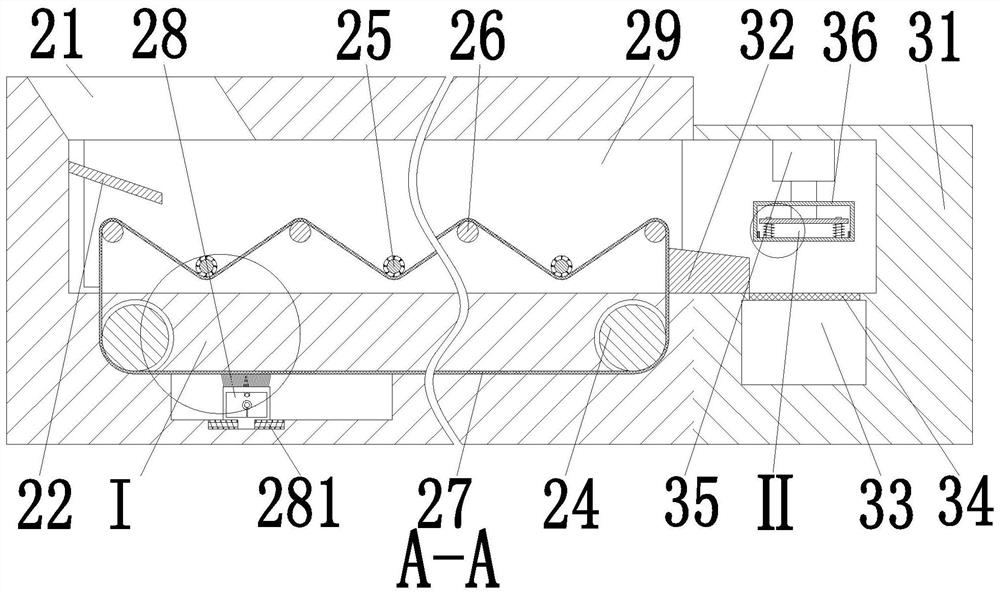

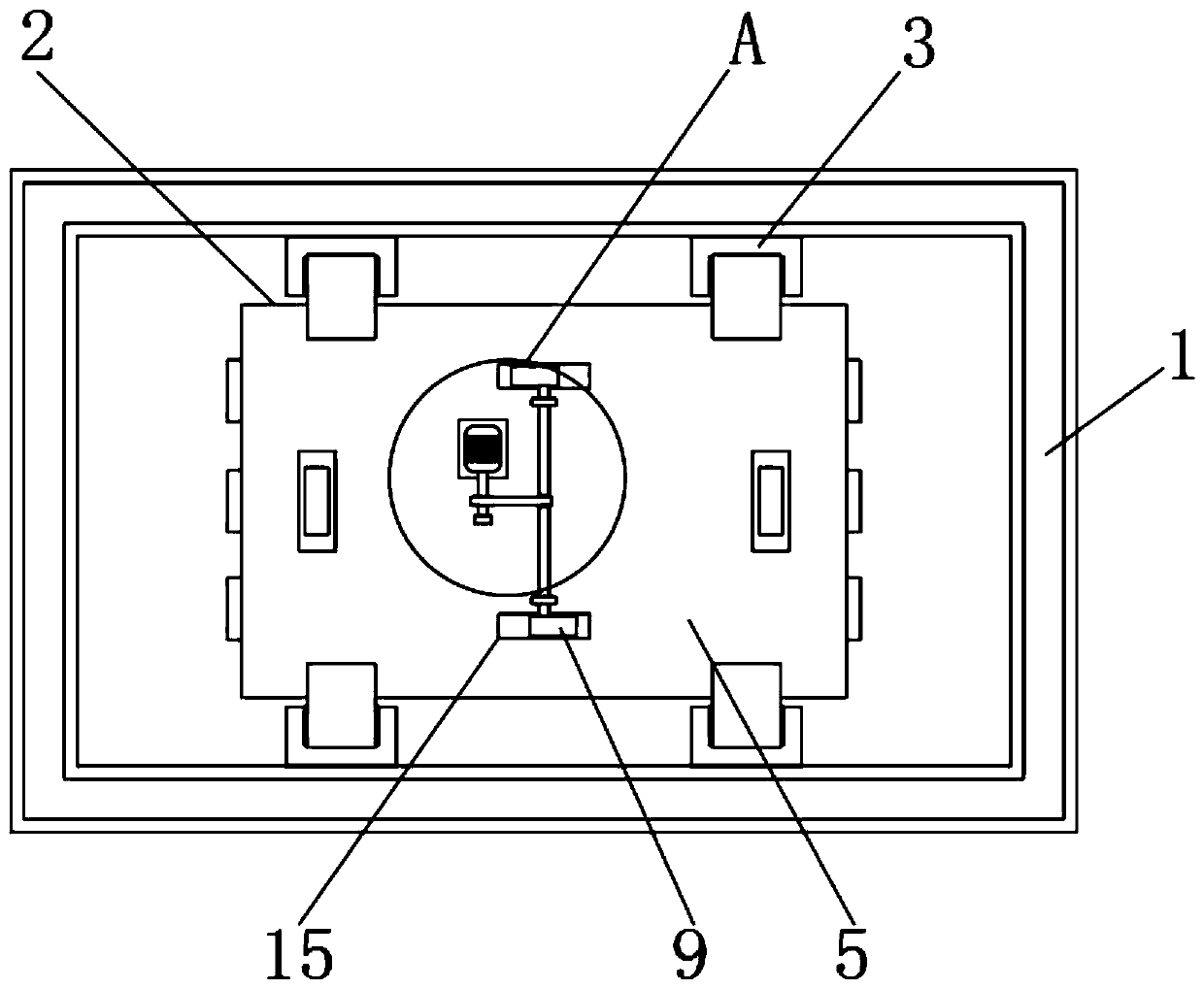

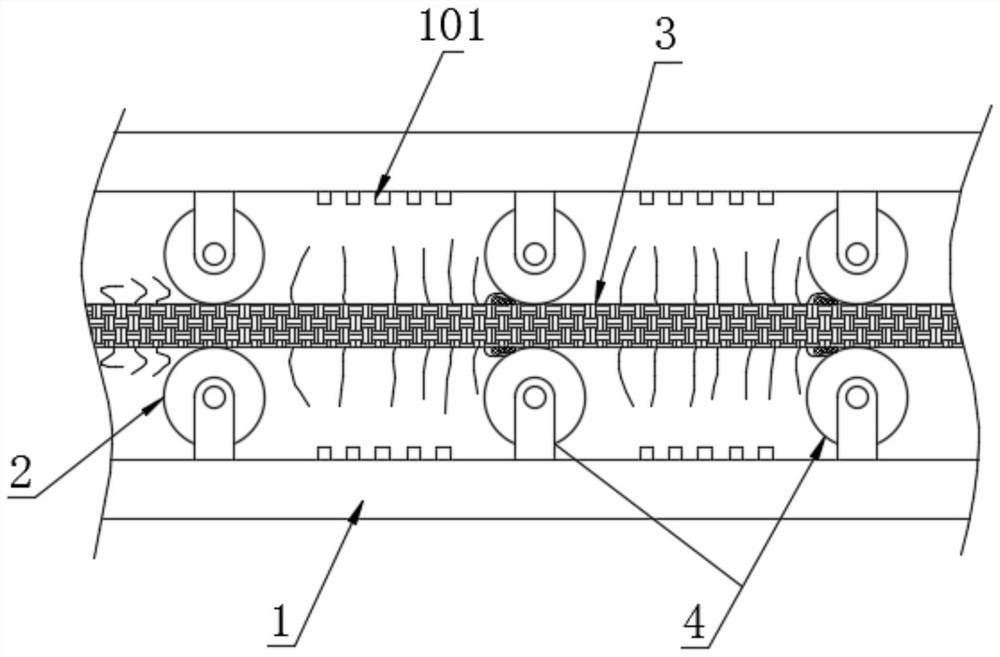

Power station solid waste disposal method

InactiveCN111822078AExtended feeding timeGuaranteed cleaning effectCleaningGrain treatmentsPower stationEnvironmental engineering

The invention relates to a power station solid waste disposal method. The power station solid waste disposal method uses a solid waste disposal device. The solid waste disposal device comprises a base, a cooling unit and a smashing unit. The cooling unit is disposed on the inner wall of the rear end of the base. The smashing unit is disposed at the right end of the base. By guiding a conveying belt in a wave form, feeding time of power station solid waste is prolonged, power station solid waste is rolled to be cooled, heat in the power station solid waste is released by smashing, and thereforethe power station solid waste can be slowly and naturally cooled; and by means of a mechanical mechanism, cleaning brushes vibrate so as to shake off dust attached thereon, and the cleaning effect ofthe cleaning brushes is ensured.

Owner:丁健

A fully automatic sealed acid circulation pickling pool

The invention discloses a fully-automatic sealed acid-circulation pickling tank, comprising a pickling tank body and a steel pipe pickling rack. The inner walls of both sides of the pickling tank aresymmetrically fixed with two fixture blocks; and buckles are arranged at the corresponding positions of the two sides of the steel pipe pickling rack. According to the invention, through clamp connection of the buckles and the fixture blocks, an eccentric wheel rotates under the driving of a driving device, so a fixed mount is allowed to shake so as to realize stirring of a pickling solution in the pickling tank, and thus, the layering of the pickling solution is prevented, and the phenomena of excessive pickling and insufficient pickling are avoided; an elastic limit device is fixed on the fixed mount and can limit steel pipes to prevent the disengagement of the steel pipes during shaking; the position of a limit rod can be adjusted through clamp connection between a limit member and a limit hole, so steel pipes of different internal diameters can be mounted and fixed; and steel pipes do not contact with each other, so the surfaces of the steel pipes are totally immersed in the pickling solution, which enables pickling efficiency to be improved.

Owner:上上德盛集团股份有限公司

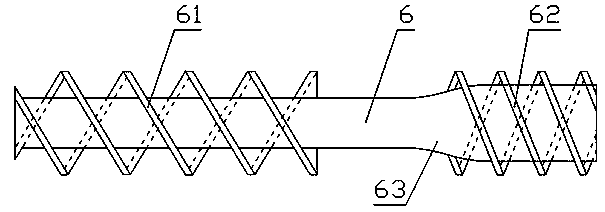

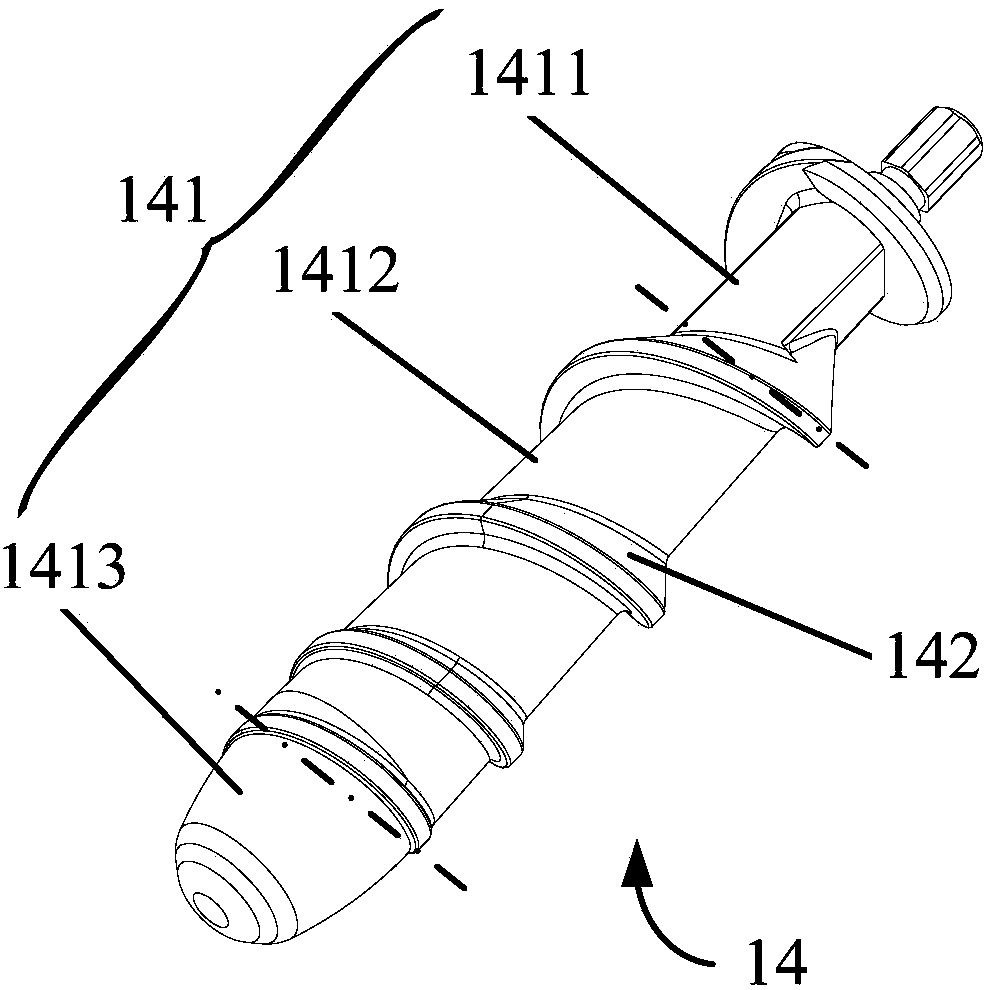

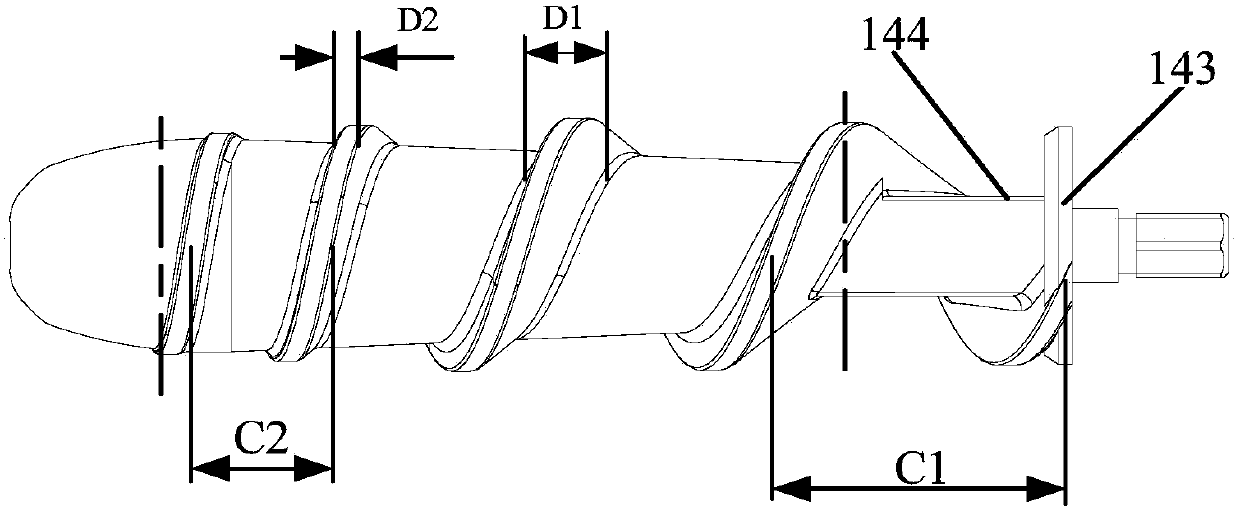

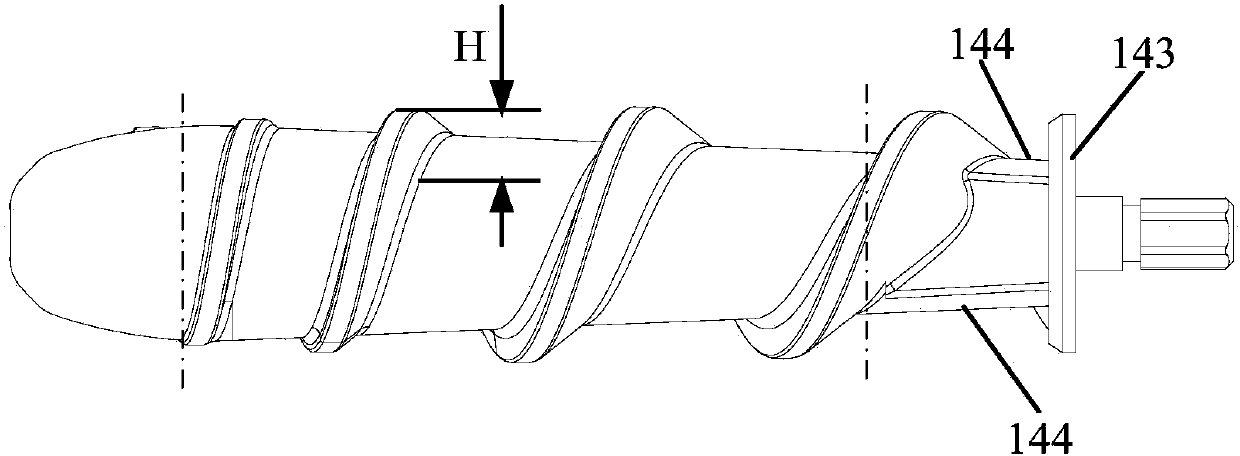

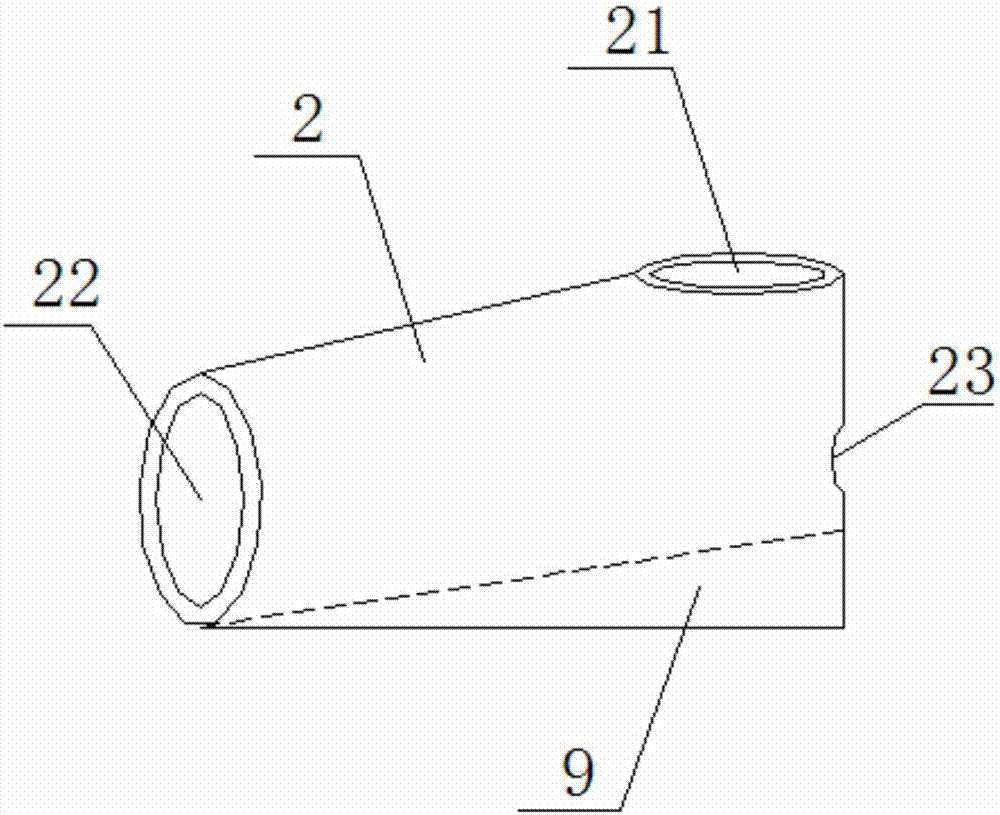

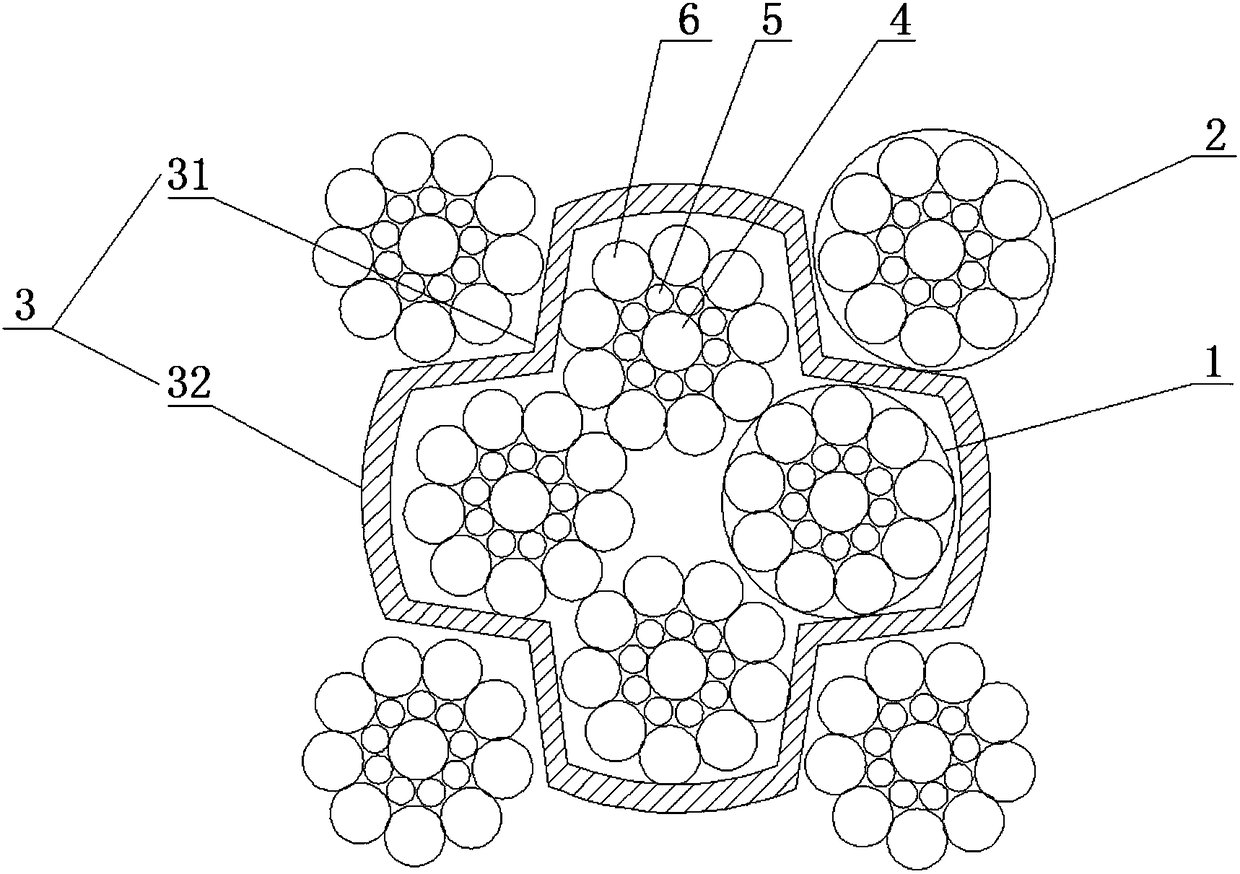

Squeezing screw, squeezing assembly and food processor

The invention provides a squeezing screw, a squeezing assembly and a food processor. The squeezing screw comprises a screw body, and the screw body comprises a feeding section, a squeezing section connected with the feeding section and a residue discharging section connected with the squeezing section; the area of the cross section of the screw body is gradually increased from the feeding sectionto the squeezing section. According to the technical scheme, the juice squeezing and residue discharging stress direction of the squeezing screw is consistent with the thrust direction of the screw body, thus, the juice squeezing force and the residue discharging force can be increased to make food residues at a residue discharging port discharged more easily, accordingly, the phenomenon that foodresidues block the residue discharging port can be reduced, and meanwhile the phenomenon that food residues can not be discharged thoroughly can be avoided; besides, the area of the cross section ofthe screw body is gradually increased from the feeding section to the squeezing section, that is to say, the thickness of the screw body is gradually increased from the feeding section to the squeezing section, thus, a squeezing channel formed by the squeezing screw and the inner wall of a first barrel can be narrowed gradually, and accordingly the squeezing strength, acting on food, of the squeezing screw and the inner side wall of the first barrel can be increased so as to increase the juice yield.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD +1

Granulator

InactiveCN107186915ANovel structural designExtended service lifeEpoxy resin coatingsPelletizingEngineering

The invention provides a granulator and relates to the technical field of granulation. The granulator comprises a feeding hopper, a material cylinder, a buffer chamber and a granulation chamber. A first motor is arranged on one side of the material cylinder. A first rotary shaft is connected to the first motor. The first rotary shaft extends into the material cylinder. Spiral blades are arranged on the first rotary shaft. A second motor is arranged on one side of the granulation chamber and connected with a second rotary shaft. The second rotary shaft extends into the granulation chamber. A granulation cutter is arranged at the end of the second rotary shaft. Granulation holes are formed in the granulation cutter. The height of the inner wall, close to one side of the buffer chamber, in the material cylinder is lower than that of the inner wall, close to one side of the first motor, in the material cylinder. A heater is arranged at the bottom of the material cylinder. Through the design of a material cylinder special structure, all the raw materials in the material cylinder enter the buffer chamber under the effect of the dead weight, and it can be avoided that the raw materials are deposited at the bottom of the material cylinder and consequentially the materials are wasted; and the extrusion strength of the raw materials in the buffer chamber can be increased, and the generation speed of plastic particles is increased.

Owner:合肥英源新材料科技有限公司

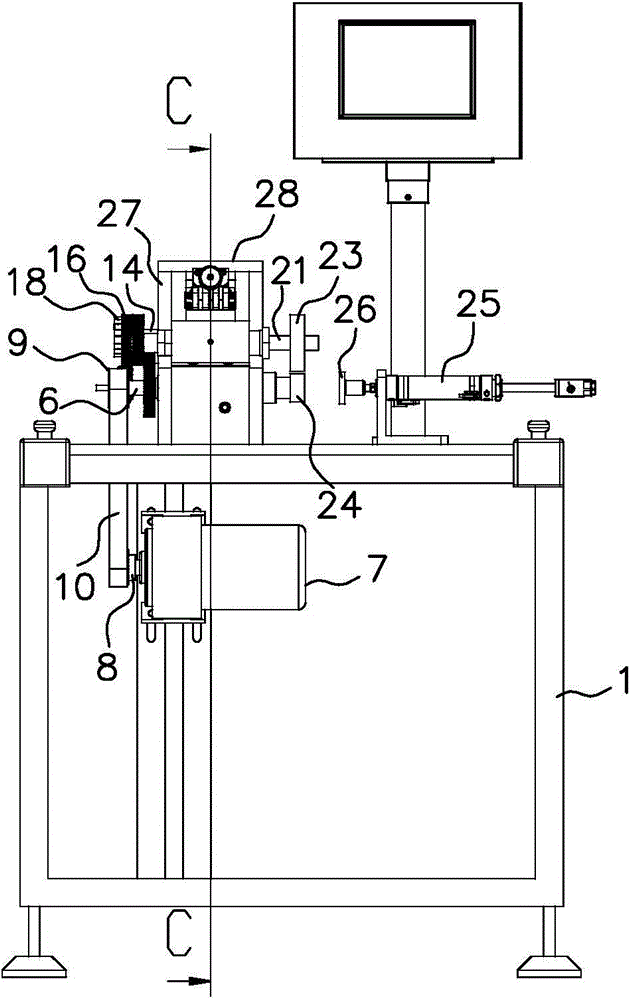

Multifunctional detection device for automobile parts

PendingCN111982659AStrong stretchWide detection rangeMaterial strength using tensile/compressive forcesStructural engineeringMechanical engineering

The invention discloses a multifunctional detection device for automobile parts, and relates to the technical field of automobile part detection. The multifunctional detection device for the automobile parts comprises a device body, the device body comprises a front plate, a rear plate and a first vertical plate. The first vertical plate is arranged on the upper surface of the front plate; the lower surface of the first vertical plate is fixedly connected with the right end of the upper surface of the front plate; an extrusion device is arranged in the middle of the upper surface of the frontplate; a rectangular groove is formed in the middle of the rear end of the upper surface of the front plate; an electric device is arranged in the rectangular groove; a first screw rod rotates to enable the movable block to move backwards; the movable block moves to drive the two movable blocks to continuously get away from each other; the tensile strength detection effect is achieved by continuously stretching the detection piece, compared with a manual tensile detection mode, the tensile force is larger, the detectable range is wider, the stretching device and the extrusion device are arranged in the same equipment, and compared with the situation that an extrusion and tensile detection devices are independently arranged, the space is saved.

Owner:王春宇

Character rolling machine

The invention discloses a character rolling machine comprising a rack. A fixed table and a turnover table hinged to the fixed table are mounted on the top face of the rack, a first rotating shaft and a second rotating shaft are mounted on the fixed table and the turnover table respectively in a running fit manner, a supporting wheel used for sleeving a workpiece is mounted on the first rotating shaft, and a rolling wheel used for squeezing the workpiece is mounted on the second rotating shaft; the first rotating shaft and the second rotating shaft are linked through a drive part, the drive part comprises at least one joint shaft, a first gear synchronously linked with the first rotating shaft and a second gear synchronously linked with the second rotating shaft are mounted on the joint shafts, and at least one of the first and second gears is in rotary location fit with the joint shafts. Being in rotary location fit with the joint shafts, the first gear and / or the second gear can rotate relative to the joint shafts, and the first rotating shaft and / or the second rotating shaft is driven to rotate, so that the support wheel and / or the rolling wheel can rotate synchronously with the first rotating shaft and / or the second rotating shaft so as to eliminate dislocation between the support wheel and the rolling wheel.

Owner:ZHEJIANG AXILONE SHUNHUA ALUMINUM IND

Efficient concrete mixing device

InactiveCN105397911ASimple structureSqueeze hardDischarging apparatusCement mixing apparatusPower equipmentEngineering

The invention discloses an efficient concrete mixing device. The efficient concrete mixing device comprises a shell body a, a shell body b, a mixing shaft a and a mixing shaft b. One end of the shell body a and one end of the shell body b are connected with a power shaft a and a power shaft b respectively. One end of the power shaft a and one end of the power shaft b are both connected to power equipment inside a machine body. The mixing shaft a is connected with a set of bracket a and bracket b which are arranged symmetrically. The bracket a is provided with a driving extrusion wheel a. The bracket b is provided with a driven extrusion wheel a. The driving extrusion wheel a and the driven extrusion wheel a are connected with an extrusion block a and an extrusion block b respectively. The extrusion block a and the extrusion block b are both connected to a discharging plate a at the other end of the shell body a. According to the efficient concrete mixing device, the structure is simple, mixing is conducted simultaneously through the shell body a and the shell body b which are arranged symmetrically, so that the working efficiency is greatly improved, and the device is suitable for mass mixing operation; in addition, the extrusion wheels are adopted for extruding and discharging, the extrusion force is large, the discharging speed is high, and the performance is stable.

Owner:TAICANG LUNWEN MACHINERY CO LTD

Manufacturing process for granulator material barrel

The invention discloses a manufacturing process for a granulator material barrel, and relates to the technical field of granulation. The manufacturing process comprises the following steps: (1) rolling forming for the material barrel: taking nodular cast iron as a raw material, and preparing the material barrel through a rolling forming technology, wherein an opening in the vertical direction is formed in one end of the material barrel, and an opening in the horizontal direction is formed in the other end of the material barrel; (2) spraying treatment for the inner wall of the material barrel: carrying out spraying treatment on the inner wall of the material barrel through an electrostatic spraying technology, and naturally placing the material barrel for 10 days after spraying is concluded, wherein a preparation method for a spraying liquid comprises the following steps: placing 25 parts of epoxy resin, 5 parts of titanium dioxide, and the like in a stirring container, and uniformly stirring and mixing; and (3) heat treatment: placing the material barrel in a heat treatment furnace and carrying out heat treatment for 0.5h at 200 DEG C, and naturally cooling to obtain the product. The material barrel is novel in structural design and long in service life. The manufacturing process is reasonable in procedure arrangement, and the spraying liquid with a special design is sprayed on the inner wall of the material barrel, so that the wear resistance of the inner wall of the material barrel is remarkably enhanced.

Owner:合肥英源新材料科技有限公司

Quick-change sealed vacuum suction head structure design

PendingCN113335687AExtended replacement timeSqueeze hardLabelling machinesElectric machineEngineering

Owner:常州鼎毅电子科技有限公司

Environment-friendly textile fabric surface fluff scraping device

InactiveCN112501856ASolve the problem of low cleaning efficiencyGuaranteed scrapeTextile shapingYarnEngineering

The invention provides an environment-friendly textile fabric surface fluff scraping device which comprises a supporting frame, wherein a first magnetism isolating plate is arranged in a fixing shaft,a magnetic column is connected into the first magnetism isolating plate, a scraper slides in a sliding groove, a swing rod is rotationally connected into a fluff scraping device, an arc-shaped magnetic block corresponding to a small magnetic block is arranged at one end of the swing rod, a blocking disc corresponding to an air groove is arranged at the other end of the swing rod, and a second magnetism isolating plate corresponding to the arc-shaped magnetic block is arranged in the fluff scraping device. The small magnetic block extrudes the arc-shaped magnetic block to rotate anticlockwise,so that the arc-shaped magnetic block drives the blocking disc to be separated from the air groove; the air groove adsorbs fluff on textile fabric to be close to the scraper due to the fact that an air suction head, an air suction pipe and the air groove are in communication with one another, and therefore an extrusion force of the scraper and the fluff is increased; due to the fact that the scraper is arc-shaped, the intensity of pressure on the curved surface of the scraper is increased, the fluff on the textile fabric is further attached to the scraper, and the structure solves the problems that the fluff on the surface of yarn is low in removal efficiency and cannot be suitable for yarn fabric made of different materials.

Owner:王礼山

Comprehensive film bundling machine

PendingCN112093103AEasy to collectIncrease productivityConveyor wrappingEngineeringMechanical engineering

The invention discloses a comprehensive film bundling machine, and belongs to the technical field of environmental protection. The comprehensive film bundling machine comprises an extrusion mechanism,a pushing mechanism, a packaging mechanism and a flange, wherein the extrusion mechanism is arranged on a horizontal plane; the pushing mechanism is vertically connected and communicated with the front end of the side surface of the extrusion mechanism through the flange; the packaging mechanism is perpendicularly connected and communicated with the front end of the other side face of the extruding mechanism through the flange; the output end of the pushing mechanism penetrates through the extruding mechanism to reach an inlet of the packaging mechanism; and a cavity structure with the four sides sealed is achieved through an extruding push disc, a bag pushing push disc, a side plate and a side door, and materials are compressed and pushed out through regular telescoping of an oil cylinder. According to the comprehensive film bundling machine, the materials can be compressed, bundled and conveyed at a time, so that the manual participation mode is reduced; and formed bags are tight and not prone to loosening, and meanwhile, if the materials contain water, the materials can be collected in order, so that the comprehensive film bundling machine is quite environmentally friendly, practical and capable of saving cost.

Owner:东莞市嘉铭环保设备有限公司

A steel pipe body clamping and positioning mechanism for steel pipe production

ActiveCN113579805BSame clamping forceAvoid damageWelding/cutting auxillary devicesAuxillary welding devicesGear wheelElectric machinery

The invention discloses a steel pipe body clamping and positioning mechanism for steel pipe production, which comprises a fixing plate placed on a processing platform and a clamping device fixedly connected with the fixing plate, the clamping device is ring-shaped, and the clamping An annular groove is opened in the device, and an annular wall is fixedly connected to the annular groove, and a plurality of threaded barrels are rotatably connected to the annular wall, and the plurality of threaded barrels are arranged circumferentially, and each threaded barrel is threaded The swivel connection has a threaded rod. The advantage of the present invention is that the motor can simultaneously drive a plurality of threaded barrels to rotate through the gear ring 1 and the gear 1, so that a plurality of threaded rods can stretch out from multiple directions to clamp the pipe at the same time, preventing the pipe from being While being damaged during clamping, it can ensure the same clamping force of multiple threaded rods, the clamping effect of the whole device is better, and it is suitable for pipes of different thicknesses, and it is convenient and quick to use.

Owner:南通圣峰防腐钢塑有限公司

type rolling machine

The invention discloses a character rolling machine comprising a rack. A fixed table and a turnover table hinged to the fixed table are mounted on the top face of the rack, a first rotating shaft and a second rotating shaft are mounted on the fixed table and the turnover table respectively in a running fit manner, a supporting wheel used for sleeving a workpiece is mounted on the first rotating shaft, and a rolling wheel used for squeezing the workpiece is mounted on the second rotating shaft; the first rotating shaft and the second rotating shaft are linked through a drive part, the drive part comprises at least one joint shaft, a first gear synchronously linked with the first rotating shaft and a second gear synchronously linked with the second rotating shaft are mounted on the joint shafts, and at least one of the first and second gears is in rotary location fit with the joint shafts. Being in rotary location fit with the joint shafts, the first gear and / or the second gear can rotate relative to the joint shafts, and the first rotating shaft and / or the second rotating shaft is driven to rotate, so that the support wheel and / or the rolling wheel can rotate synchronously with the first rotating shaft and / or the second rotating shaft so as to eliminate dislocation between the support wheel and the rolling wheel.

Owner:ZHEJIANG AXILONE SHUNHUA ALUMINUM IND

Concrete stirring device

InactiveCN105437369AEasy to moveReduce stuck phenomenonDischarging apparatusCement mixing apparatusDischarge efficiencyMechanical engineering

The invention discloses a concrete stirring device which comprises a shell, a power shaft, a stirring shaft, a driving extrusion wheel and a driven extrusion wheel. The power shaft is connected to one end of the shell through a bearing and a sealing ring. A motor is connected to one end of the power shaft, and the stirring shaft is connected with the other end of the power shaft. A set of support a and support b are connected to the stirring shaft symmetrically. The driving extrusion wheel is arranged on the support a, and the driven extrusion wheel is arranged on the support b. The driving extrusion wheel and the driven extrusion wheel are connected with an extrusion block a and an extrusion block b respectively. The extrusion block a and the extrusion block b are connected with a discharging plate arranged at the other end of the shell. The shell is further provided with a feed inlet. The concrete stirring device is simple in structure; the extrusion wheels are adopted for extrusion discharging, the extrusion intensity is high, and the middle of the extrusion block a and the middle of the extrusion block b are convex, so that material flowing is facilitated, the discharging speed is high, the discharging efficiency is effectively improved, the phenomenon that a device body gets stuck is reduced, and performance is stable.

Owner:TAICANG LUNWEN MACHINERY CO LTD

Square eight-strand torsion-resistant steel wire rope

The invention discloses a square eight-strand torsion-resistant steel wire rope which comprises six inner-layer rope strands and six outer-layer rope strands. The six inner-layer rope strands are arranged annularly, and the twisting direction is leftward. A central rope strand is also arranged at a central gap of the six inner-layer rope strands, and the periphery of the central rope strand is also provided with six cotton-linen woven strips subjected to grease soaking treatment. In the square eight-strand torsion-resistant steel wire rope, a sponge core layer is also arranged between the sixinner-layer rope strands and the six outer-layer rope strands, when the grease amount in the cotton-linen woven strips is excessively saturated, a large amount of grease is extruded out of the steel wire rope through slight extrusion, and grease waste is caused. After the sponge core layer wrapping the inner-layer rope strands is arranged, excessive grease can be absorbed by the sponge core layerand can be secondarily utilized, excessive grease from the sponge core layer can be stored in a circular-arc portion, the outer-layer rope strands extrude the sponge core layer, the grease from a bentportion is extruded out, excessive grease from the circular-arc portion gradually flows to the bent portion, and the sustained use time of grease is prolonged.

Owner:顾青

A flattening treatment device for copper foil production

ActiveCN114054544BImprove flattening effectIncrease contact areaMetal-working feeding devicesPositioning devicesCopper foilMechanical engineering

The invention relates to the technical field of copper foil production, in particular to a flattening treatment device for copper foil production, comprising a worktable, a support plate, a rolling unit and a winding unit. The upper end of the worktable is symmetrically arranged with two supporting The support plate, the opposite side of the support plate is provided with a rolling unit and a winding unit in sequence from left to right; the existing flattening device has the following problems: when the existing device is flattening copper foils of different thicknesses, The device needs to be adjusted accordingly, and the operation is complicated; the device cannot perform all-round flattening treatment on the copper foil, and there is a flattening dead angle, so that the flattening effect of the copper foil cannot be guaranteed; The flattening treatment does not require frequent adjustment of the device, thereby saving the workload; the present invention can flatten the copper foil in all directions by flattening the elastic sheet, so the flatness of the copper foil can be ensured, thereby ensuring that the copper foil is flattened. Flattening effect of foil.

Owner:GUANGDONG FINE YUAN SCI TECH CO LTD

A sauerkraut squeezing device

ActiveCN110250550BSqueeze water with high efficiencyIncrease contact areaFood shapingEngineeringMechanical engineering

The invention provides a sauerkraut squeezing device, which comprises an outer casing, a shaking mechanism and a conveying mechanism. At the opening, an extruding mechanism is arranged below the conveying mechanism. The extruding mechanism includes an extruding inclined plate, an extruding middle plate and a limiting plate. Both the extruding inclined plate and the limiting plate are arranged on one side of the extruding middle plate. The extruding inclined plate and the limiting plate are not located on the same side. The extrusion mechanism and the transmission mechanism provided can squeeze the sauerkraut with high efficiency, and in the process of squeezing the water, the inwardly inclined extrusion slant plate cooperates with the extrusion middle plate to increase the distance between the sauerkraut and the extrusion mechanism. At the same time, by cooperating with the setting of the water squeezing hole and the water squeezing convex plate, the squeezing force in the process of squeezing sauerkraut can be increased, and the water squeezing effect can be further increased.

Owner:甘肃圆根香生物科技股份有限公司

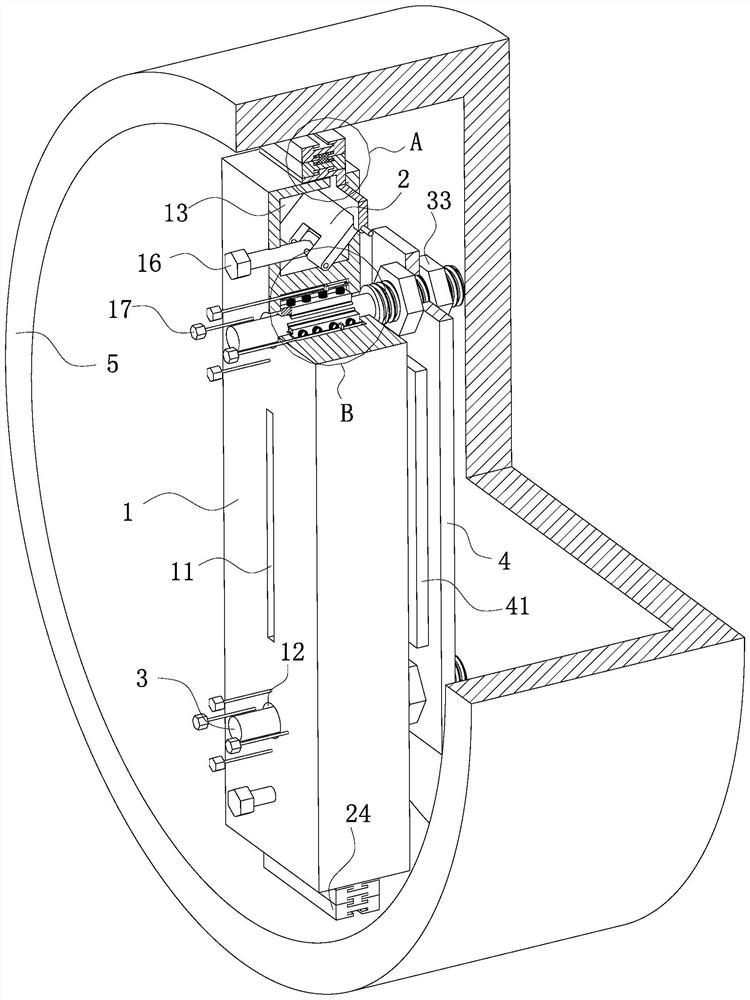

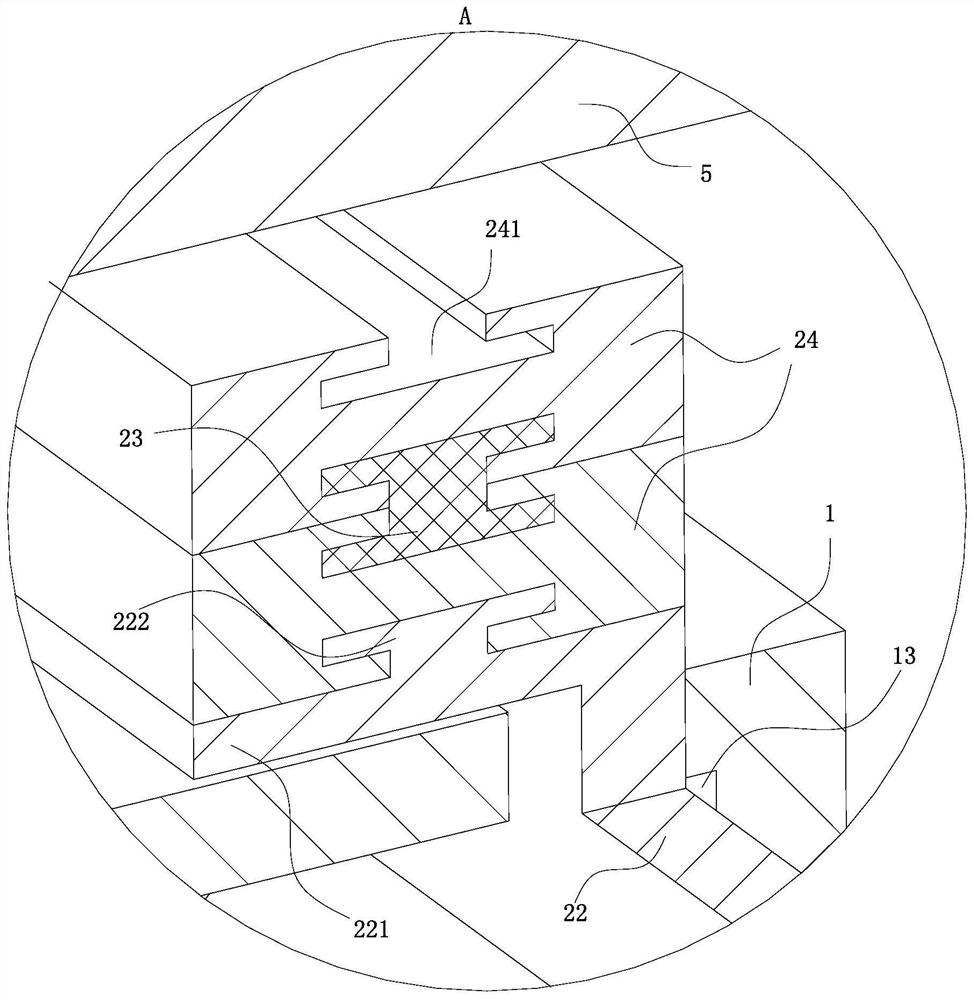

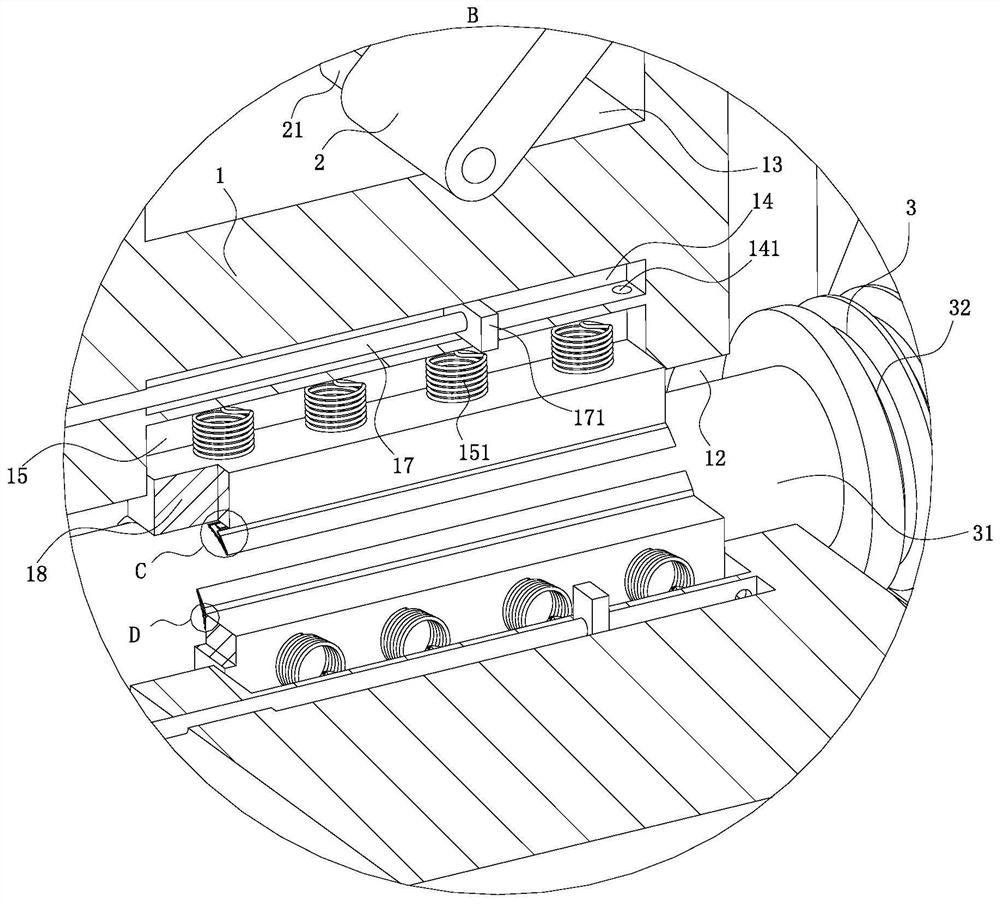

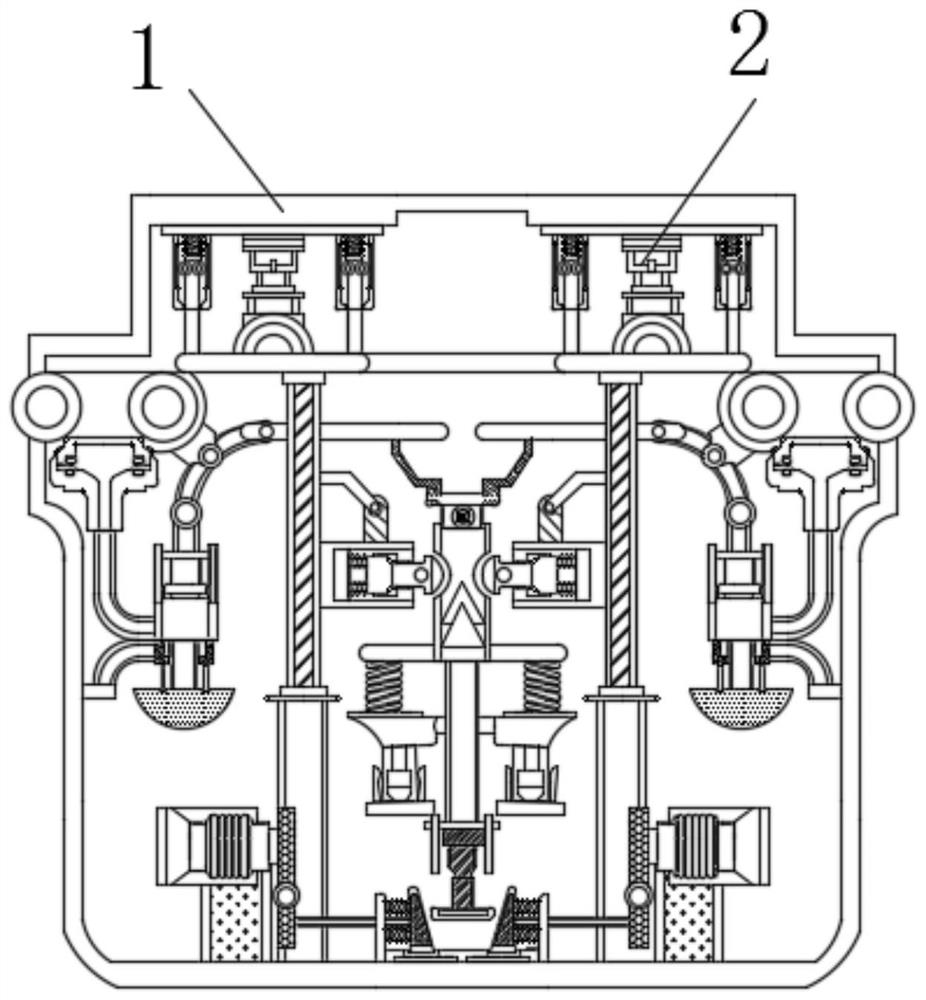

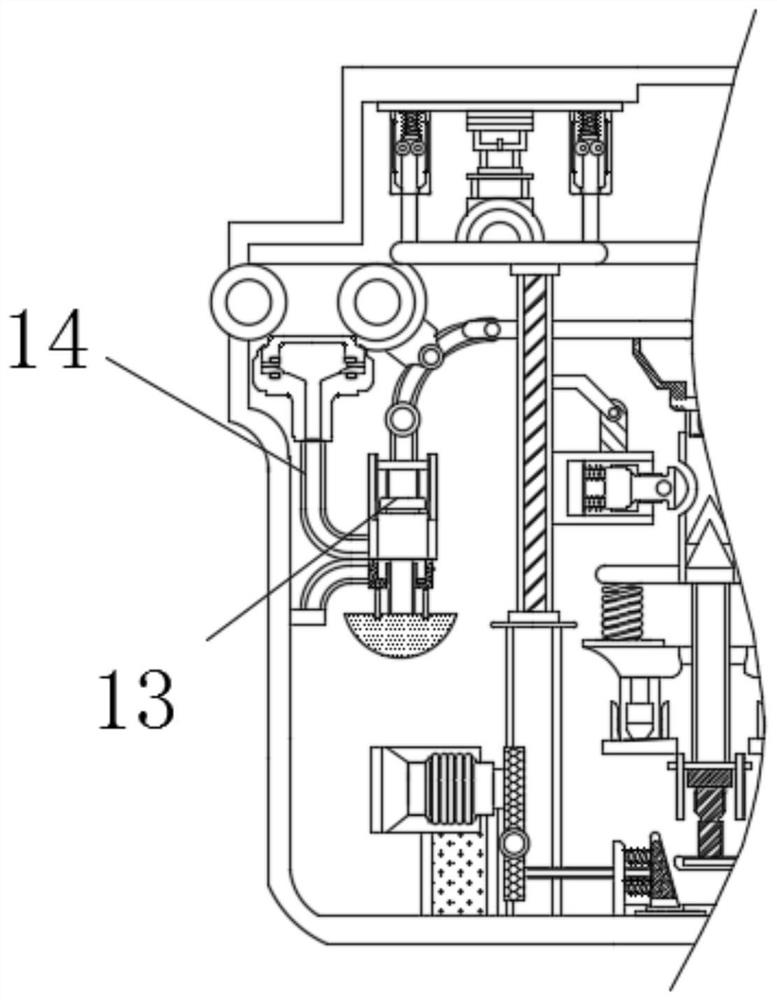

An auxiliary adjustment area array, linear array detector installation device and installation method

ActiveCN112683317BAccurate irradiationHigh sensitivityMeasurement apparatus componentsNutsEngineeringOptical instrument

The invention belongs to the technical field of optical instruments, and specifically relates to an installation device and installation method for auxiliary adjustment of area array and line array detectors, including the following steps: S1: Fixing the PCB board (41) to the fixing frame (4) by glue ); S2: Fix the screw rod (3) on the fixed bracket (4) in the S1 step; S3: Insert the screw rod (3) into the perforation (12) on the basis of the S2 step, and pass the movable block (18 ) preliminarily fix the screw rod (3); S4: on the basis of step S3, place the auxiliary mounting plate (1) in the casing (5), rotate the fixing rod one (16), and squeeze the heightening block (24) to On the inner wall of the housing (5); S5: Based on the steps in S4, slowly rotate the fixing rod 2 (17) around the hole (12) on the auxiliary mounting plate (1), and adjust the position of the screw (3) accurately; S6: Complete After the fine adjustment of the fixing frame (4) in the step S5, the start-up test of the detector is carried out; the present invention has simple structure, is convenient to use, can reduce the difficulty of installing the detector and improve the installation accuracy.

Owner:浙江澍源智能技术有限公司 +1

Paint spraying auxiliary mechanism capable of keeping paint spraying distance and avoiding sagging for hardware

InactiveCN113399179AAvoid drippingSqueeze hardCleaning using gasesSpray boothsEngineeringSpray painting

The invention relates to the technical field of hardware processing, and provides a paint spraying auxiliary mechanism capable of keeping a paint spraying distance and avoiding sagging for hardware. The paint spraying auxiliary mechanism comprises a machine body, wherein a telescopic rod is movably connected to the interior of the machine body, a pressing plate is movably connected to the bottom of the telescopic rod, and a retractable rod is fixedly connected to the bottom of the pressing plate. According to the paint spraying auxiliary mechanism capable of keeping the paint spraying distance and avoiding the sagging for the hardware, a pressing block makes contact with a hardware iron workpiece, a compression spring is continuously compressed along with movement of the pressing plate, and when the compression spring is compressed to 5 cm, the elasticity of the compression spring enables a clamping plate to get rid of the limitation and move upwards; the compression spring is compressed to 5 cm so as to control a distance between a spray head and a surface to be sprayed to be within a set range and avoid the sagging, the clamping plate drives a curved bar to rotate, the curved bar extrudes paint through a piston, the piston extrudes the paint out of the interior of a paint box, and due to the fact that the clamping plate instantly gets rid of the limitation by the compression spring, the extrusion force of the clamping plate is large, and paint dripping caused by the too small spraying pressure is avoided.

Owner:佛山市桂宜科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com