Manufacturing process for granulator material barrel

A manufacturing process and technology of a granulator, which is applied in the field of manufacturing process of a granulator barrel, can solve the problems of poor wear resistance and wear on the inner wall of the barrel, and achieve enhanced wear resistance, long service life, and novel structural design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

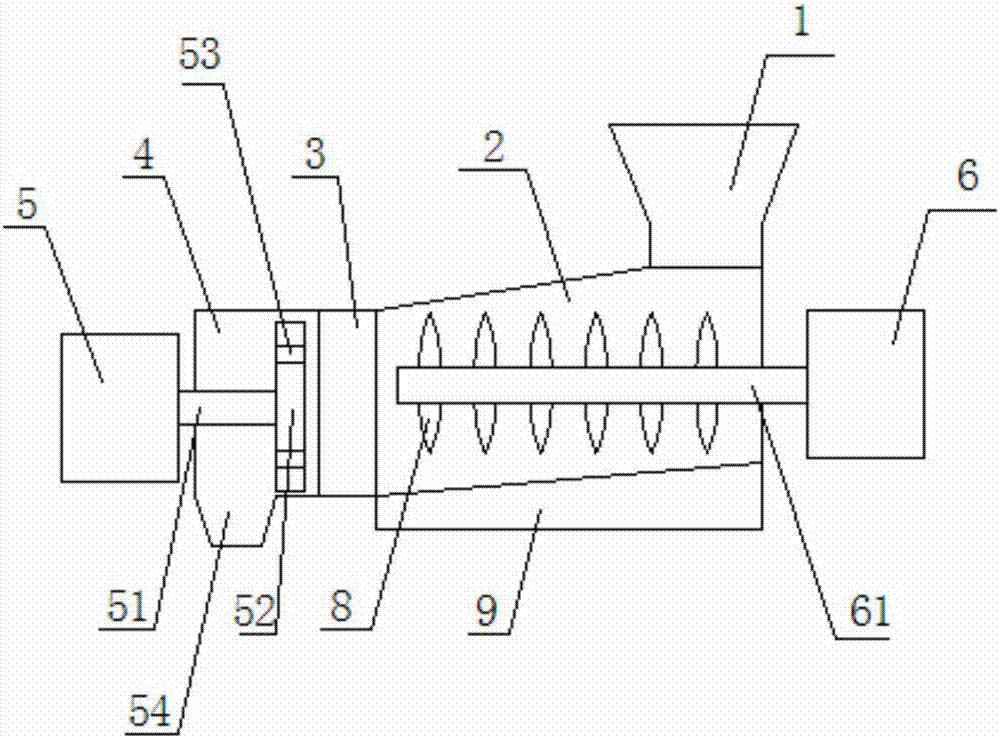

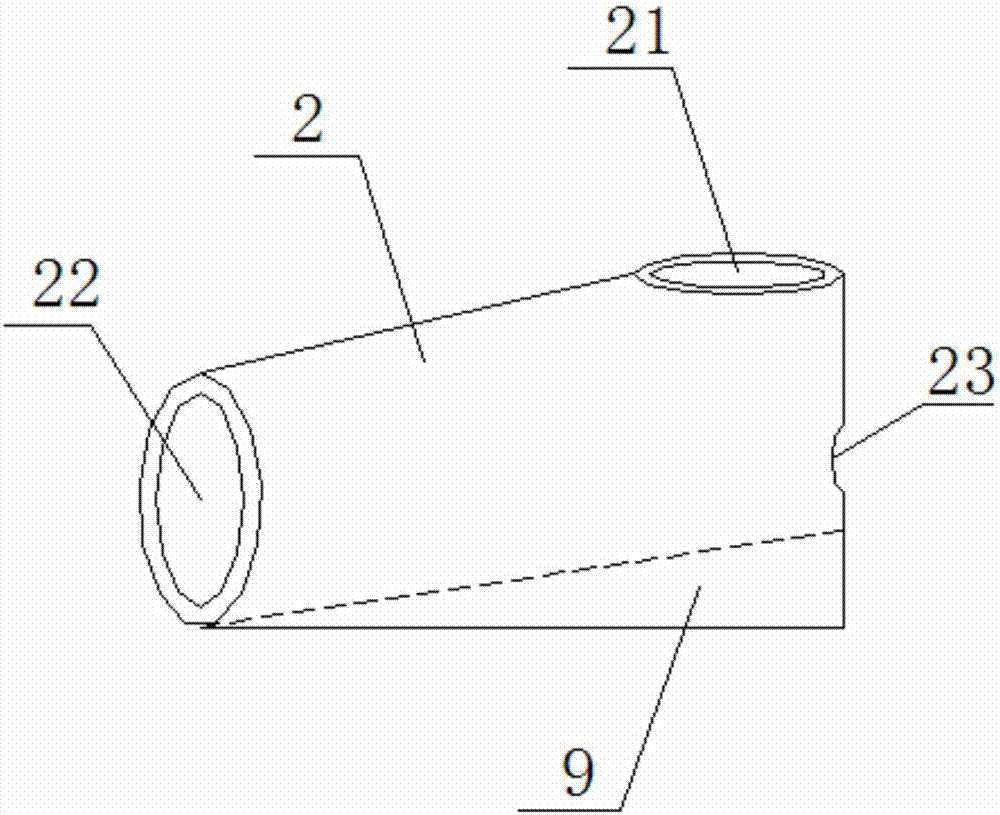

[0026] Such as Figure 1 to Figure 2 As shown, the present invention provides a granulator, comprising: a feed hopper 1, a barrel 2 communicated with the feed hopper 1, a buffer chamber 3 communicated with the feed barrel 2, and a granulation chamber 4 communicated with the buffer chamber 3 . The raw material enters the barrel 2 from the feed hopper 1, and is transported to the buffer chamber 3 after being heated in the barrel 2. After being squeezed in the buffer chamber 3, it enters the granulation chamber 4 for granulation.

[0027] One side of the barrel 2 is provided with a first motor 6 . The first motor 6 is connected to the first rotating shaft 61 . The first rotating shaft 61 extends into the inside of the barrel 2 . The helical blade 8 is arranged on the first rotating shaft 61 . The first motor 6 drives the first rotating shaft 61 to rotate, and transmits the raw material to the buffer chamber 3 through the helical blade 8 .

[0028] A second motor 5 is provide...

Embodiment 2

[0033] A manufacturing process of a granulator barrel, the steps are as follows:

[0034] ① Roll forming of barrel

[0035] Ductile cast iron is used as raw material, and the barrel is made by roll forming technology. One end of the barrel has a vertical opening, and the other end has a horizontal opening;

[0036] ②, Spraying treatment on the inner wall of the barrel

[0037] Use electrostatic spraying technology to spray the inner wall of the barrel, and leave it for 10 days naturally after spraying;

[0038] The preparation method of the spraying liquid is: 25 parts of epoxy resin, 5 parts of titanium dioxide, 10 parts of methylolated phenol, 5 parts of leveling agent, 15 parts of solvent, 5 parts of 5,7-dihydroxyflavone and trifluoropropanesulfone Put 5 parts of Long in a mixing container, stir and mix evenly;

[0039] ③, heat treatment

[0040] Place the barrel in a heat treatment furnace for heat treatment at 200°C for 0.5h, then let it cool naturally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com