An auxiliary adjustment area array, linear array detector installation device and installation method

A linear array detector and installation device technology, applied in the field of optical instruments, can solve problems such as deviation between optical paths, affecting signal sensitivity, signal strength, signal integrity, poor detector positioning accuracy, etc., to improve the fixing effect, Improve the sensitivity and increase the effect of squeezing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

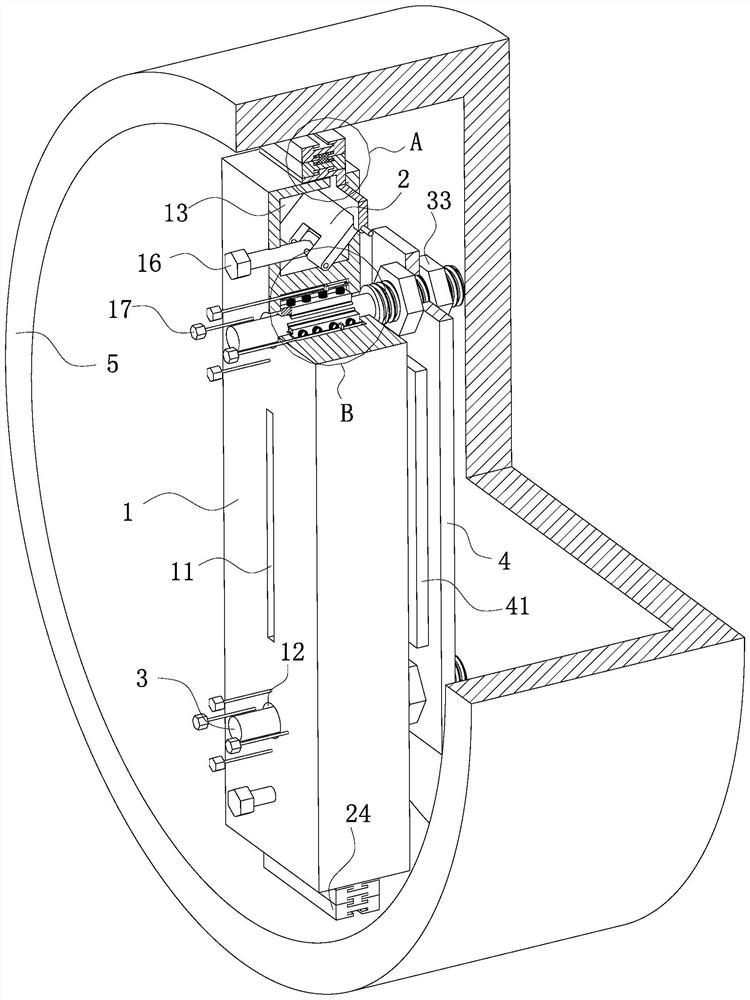

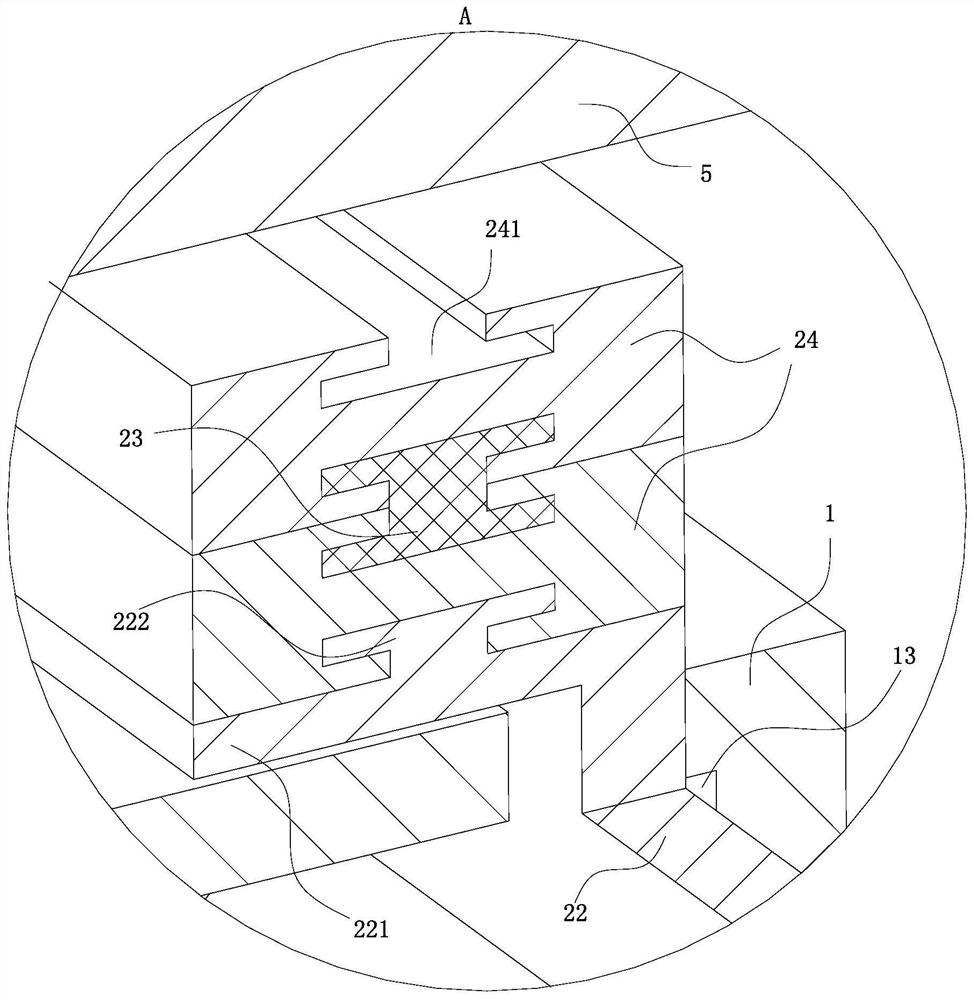

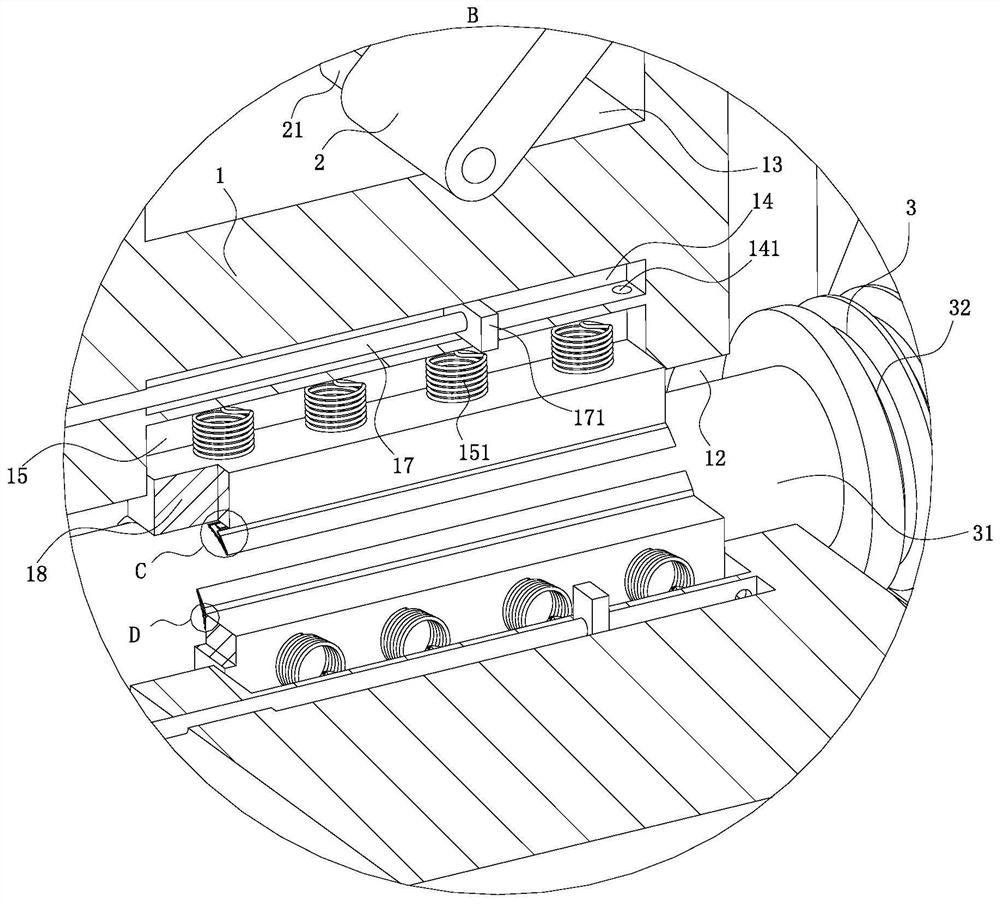

[0039]As an embodiment of the present invention, the first cavity 13 is opened in the auxiliary mounting plate 1; the distance between the first cavity 13 and the upper end face of the auxiliary mounting plate 1 in the length direction is smaller than that between the second cavity 14 and the second cavity. The distance between the upper end faces of the auxiliary mounting plate 1 in the length direction; the end face of the auxiliary mounting plate 1 is provided with a through hole; a telescopic plate 22 is slidably installed in the through hole; one end of the telescopic plate 22 is located Outside the cavity one 13, the other end stretches into the inside of the cavity one 13; on the end of the telescopic plate 22 outside the cavity one 13, a transverse plate 221 is fixedly installed; the transverse plate 221 and the auxiliary mounting plate 1 The end faces are parallel; the end of the telescopic plate 22 located in the cavity one 13 is hinged with a hinged plate 2; the end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com