Blast hole punching and positioning device and positioning method

A positioning method and hole positioning technology are applied in measuring devices, active optical measuring devices, earthwork drilling and mining, etc., which can solve problems such as manual measurement, large angle errors, and blasting operations that cannot achieve the expected results, and achieve simple structure, Ease of use and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

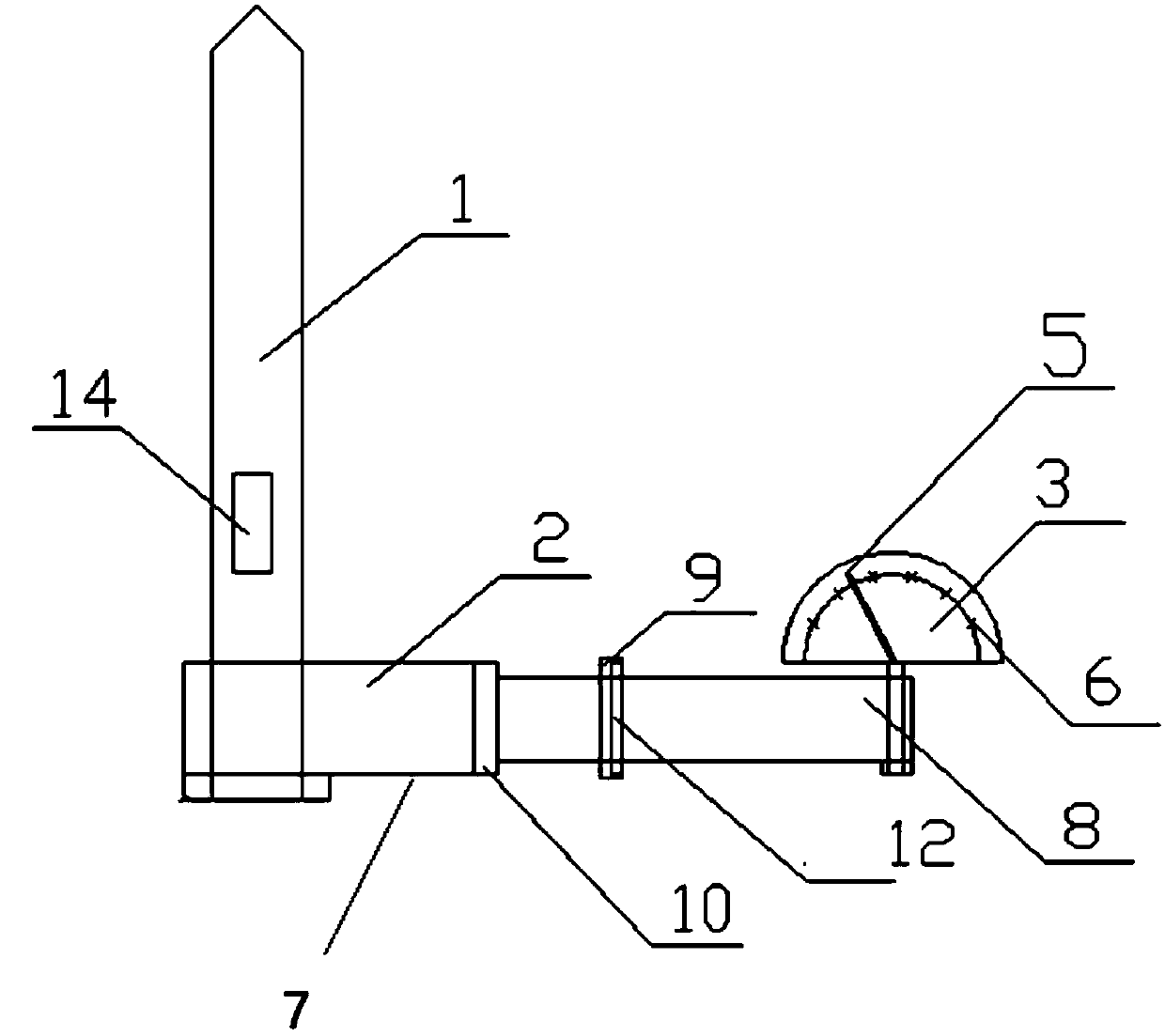

[0027] A blasthole drilling positioning device (see figure 1 ), which includes a positioning rod 1, a telescopic rod 2 is fixed horizontally on the top of the positioning rod 1, and an angle measuring instrument 3 is fixed upward on the top of the telescopic rod 2.

[0028] The positioning rod 1 is provided with a level 14; the level 14 is fixed on the middle and upper part of the positioning rod 1 .

[0029] The telescopic rod 2 includes an outer rod 7 and an inner rod 8, and the inner rod 8 and the outer rod 7 are fixed by a fixing ring 9; a rubber ring is arranged inside the fixing ring 9.

[0030] The angle measuring instrument 3 includes a semicircular dial, the front and back of the semicircular dial are marked with an angle value 6, the center of the semicircular dial is movably connected to a laser emitter 5, and the light-emitting end of the laser emitter 5 points to the angle Value direction; the 0 scale of the semicircular dial is parallel to the telescopic rod 2. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com