Environment-friendly textile fabric surface fluff scraping device

A technology for weaving cloth and scraping device, which is applied in the direction of fabric surface trimming, textile and paper making, etc., can solve problems such as endangering the health of operators, damage to yarn and cloth, waste, etc., and achieve the effect of solving low cleaning efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

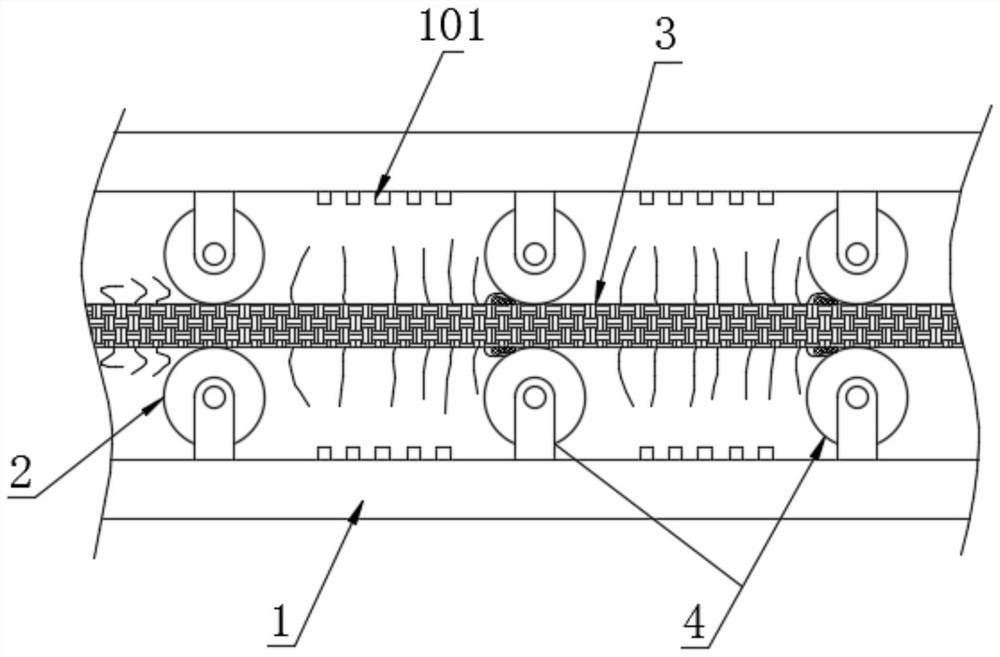

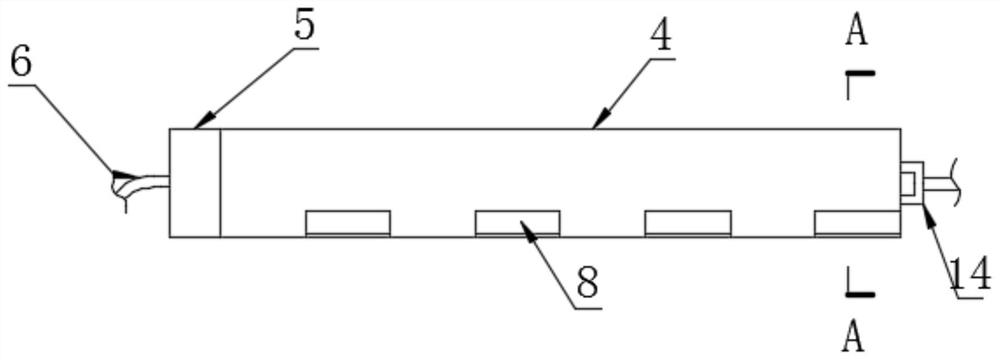

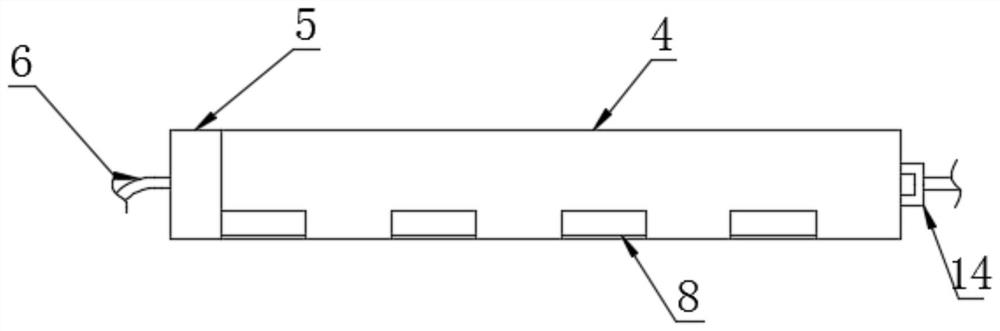

[0026] as attached figure 1 to attach Figure 7 Shown: the present invention provides an environment-friendly textile cloth surface fluff scraping device,

[0027] The specific usage and function of this embodiment:

[0028] In the present invention, an environment-friendly type textile cloth surface fluff scraping device includes a support frame 1, the upper and lower parts of the support frame 1 are provided with suction heads 101, and the inner side of the left part of the support frame 1 is provided with a driving roller 2, A textile cloth 3 is arranged between the driving rollers 2, a shaving support cylinder 4 is arranged on the inside of the right part of the support frame 1, and an air chamber 5 is arranged on the rear side of the shaving support cylinder 4, and the rear side of the air chamber 5 is fixedly connected with a The exhaust pipe 6, the inside of the shaving support cylinder 4 and the support frame 1 are provided with a fixed shaft 7, and the inside of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com