Chemical reaction kettle with automatic cleaning function

A chemical reaction, automatic cleaning technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of human harm, difficult to mechanically clean, easy to residual toxic and harmful gases and liquids, etc. Effect of high pressure and contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

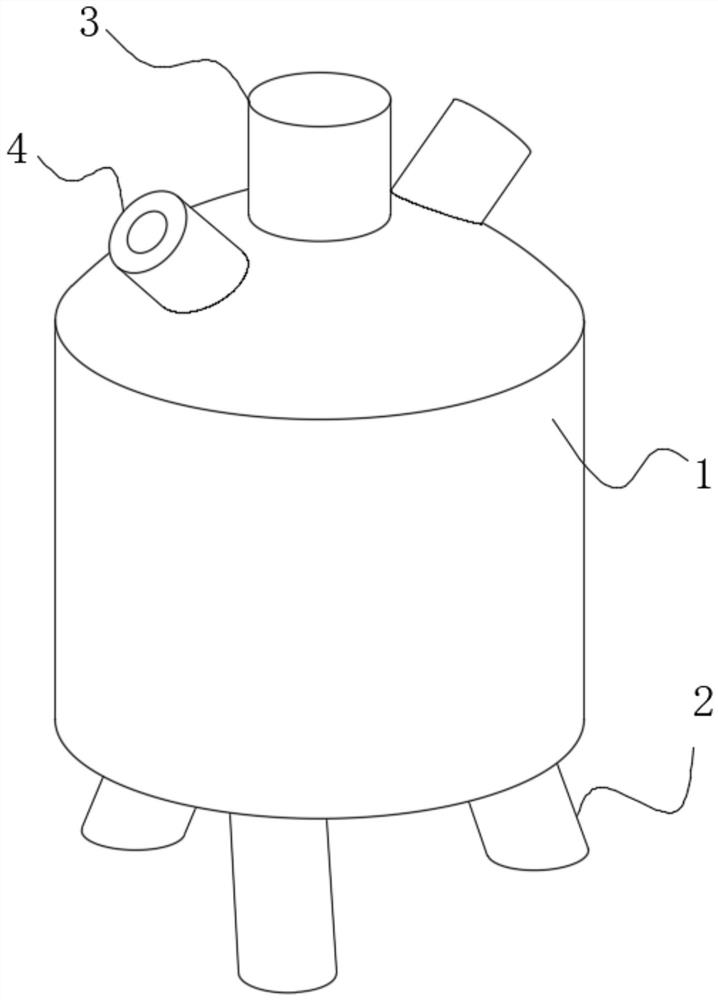

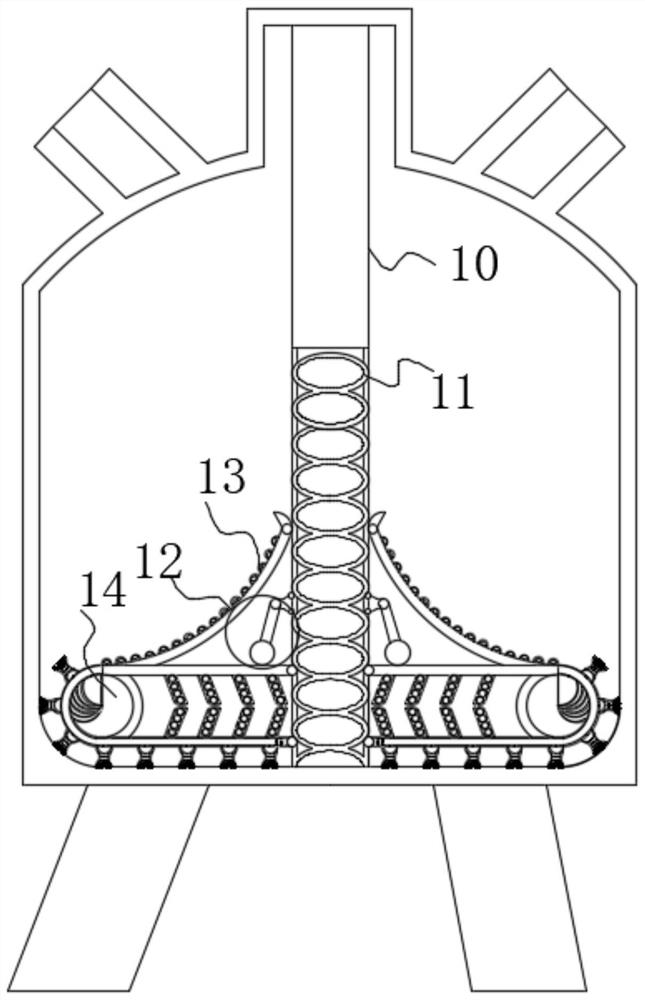

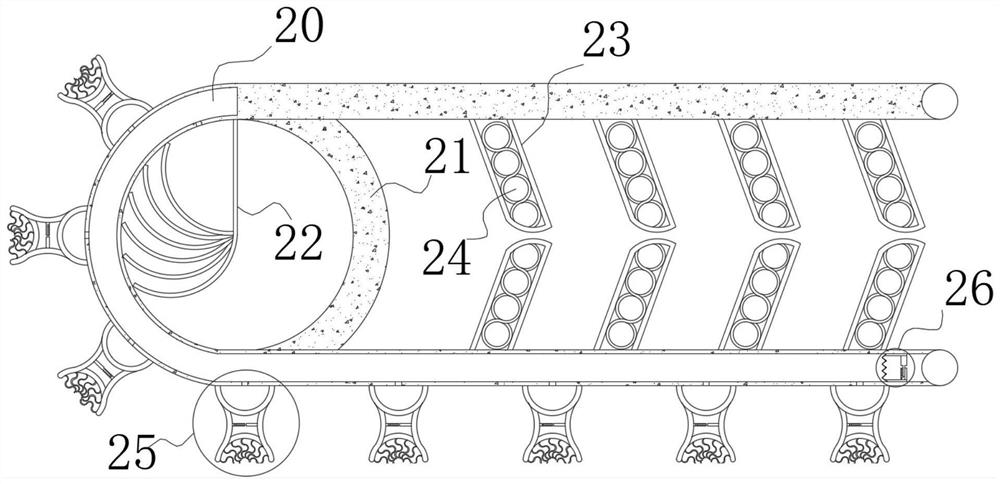

[0023] use Figure 1-Figure 7 A chemical reaction kettle with automatic cleaning function according to an embodiment of the present invention is described as follows.

[0024] Such as Figure 1-Figure 7 As shown, a kind of chemical reaction kettle with automatic cleaning function of the present invention comprises kettle body 1, and the lower surface of kettle body 1 is fixedly connected with bracket 2, and the upper surface of kettle body 1 is fixedly connected with protective cover 3, and the protective cover 3 Both sides are fixedly connected with feeding pipe 4, the bottom end of feeding pipe 4 communicates with the inside of kettle body 1, and the inside of kettle body 1 is provided with transmission shaft 10, and the top of transmission shaft 10 is connected with the inner surface of protective cover 3 in rotation , the bottom end of the transmission shaft 10 is rotationally connected with the inner surface of the top of the kettle body 1, the outer surface of the trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com