Sludge dewatering equipment

A sludge dewatering and equipment technology, applied in water/sludge/sewage treatment, sludge treatment, dehydration/drying/concentrated sludge treatment, etc. material box and other problems to achieve the effect of complete dehydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

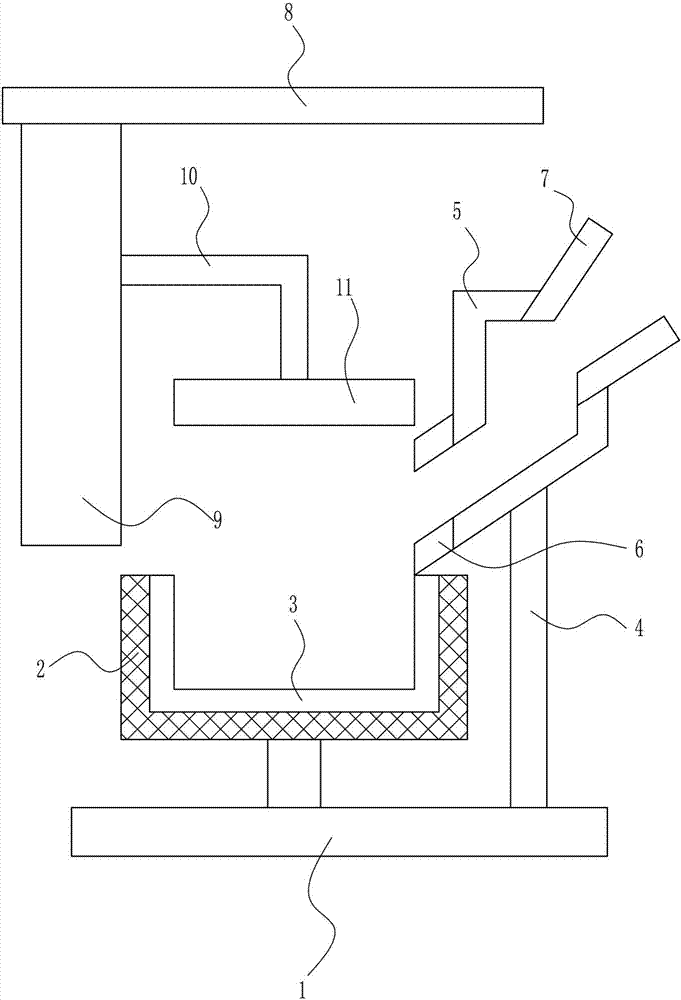

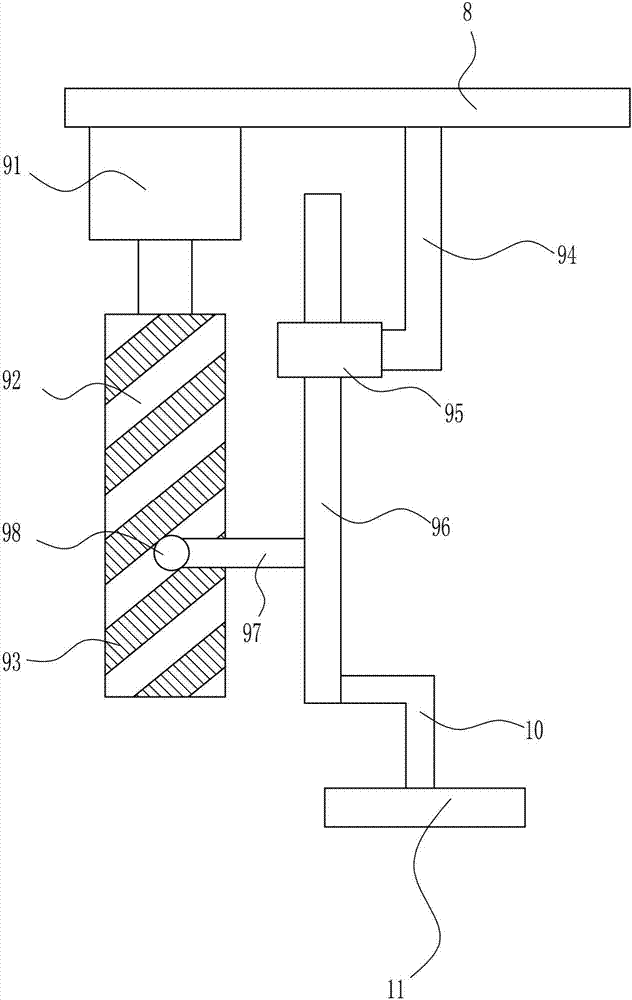

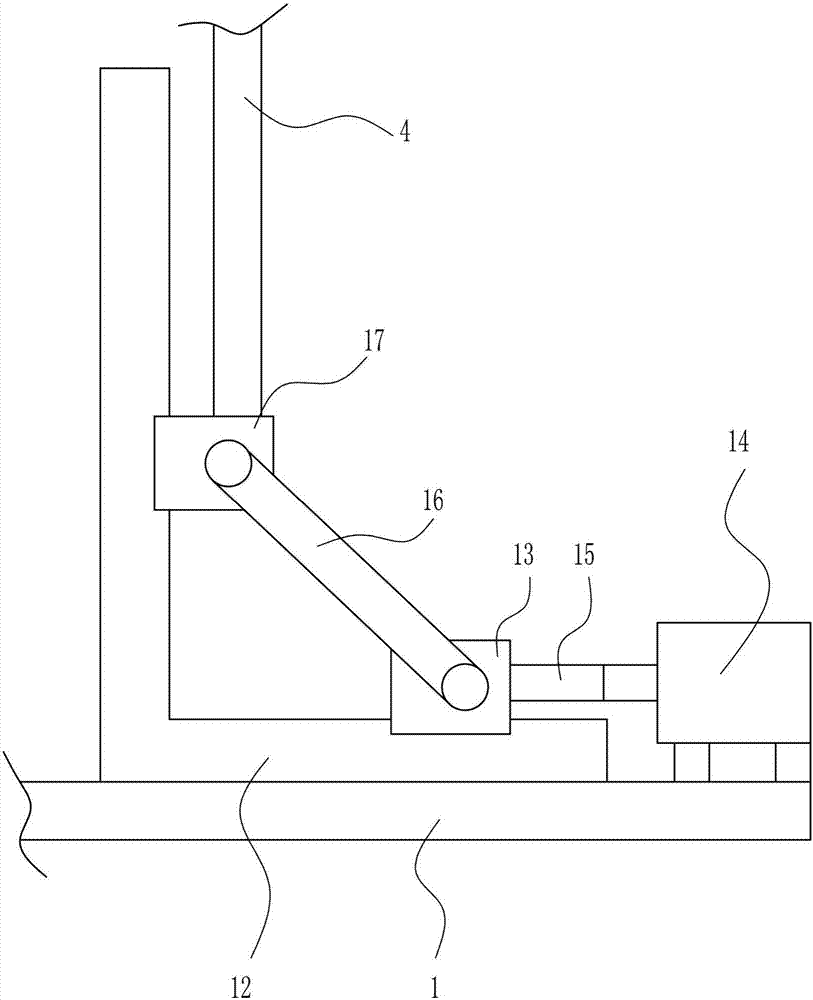

[0040] A kind of sludge dewatering equipment, such as Figure 1-7 As shown, it includes a bottom plate 1, a filter frame 2, a filter membrane 3, a support 4, a feed box 5, a first feed hopper 6, a second feed hopper 7, a top plate 8, a lifting mechanism 9, and a first connecting rod 10 And pressing plate 11, bottom plate 1 top left side is connected with filter frame 2, filter frame 2 is provided with filter membrane 3, bottom plate 1 top right side is connected with support 4, support 4 top is connected with feed box 5, feed box 5 bottom The left side is connected with the first feed hopper 6, the first feed hopper 6 is located above the right side of the filter frame 2, the top right side of the feed box 5 is connected with the second feed hopper 7, and the bottom left side of the top plate 8 is connected with a lifting mechanism 9. The right side of the lifting mechanism 9 is provided with a first connecting rod 10 , the bottom of the first connecting rod 10 is connected wi...

Embodiment 2

[0042] A kind of sludge dewatering equipment, such as Figure 1-7 As shown, it includes a bottom plate 1, a filter frame 2, a filter membrane 3, a support 4, a feed box 5, a first feed hopper 6, a second feed hopper 7, a top plate 8, a lifting mechanism 9, and a first connecting rod 10 And pressing plate 11, bottom plate 1 top left side is connected with filter frame 2, filter frame 2 is provided with filter membrane 3, bottom plate 1 top right side is connected with support 4, support 4 top is connected with feed box 5, feed box 5 bottom The left side is connected with the first feed hopper 6, the first feed hopper 6 is located above the right side of the filter frame 2, the top right side of the feed box 5 is connected with the second feed hopper 7, and the bottom left side of the top plate 8 is connected with a lifting mechanism 9. The right side of the lifting mechanism 9 is provided with a first connecting rod 10 , the bottom of the first connecting rod 10 is connected wi...

Embodiment 3

[0045] A kind of sludge dewatering equipment, such as Figure 1-7 As shown, it includes a bottom plate 1, a filter frame 2, a filter membrane 3, a support 4, a feed box 5, a first feed hopper 6, a second feed hopper 7, a top plate 8, a lifting mechanism 9, and a first connecting rod 10 And pressing plate 11, bottom plate 1 top left side is connected with filter frame 2, filter frame 2 is provided with filter membrane 3, bottom plate 1 top right side is connected with support 4, support 4 top is connected with feed box 5, feed box 5 bottom The left side is connected with the first feed hopper 6, the first feed hopper 6 is located above the right side of the filter frame 2, the top right side of the feed box 5 is connected with the second feed hopper 7, and the bottom left side of the top plate 8 is connected with a lifting mechanism 9. The right side of the lifting mechanism 9 is provided with a first connecting rod 10 , the bottom of the first connecting rod 10 is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com