Quick-change sealed vacuum suction head structure design

A technology of structural design and vacuum suction head, which is applied in the direction of labeling, packaging, labeling machines, etc., can solve the problems of complicated suction head replacement operation and reduced air tightness, and achieve easy operation, improved replacement time, and increased extrusion The effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

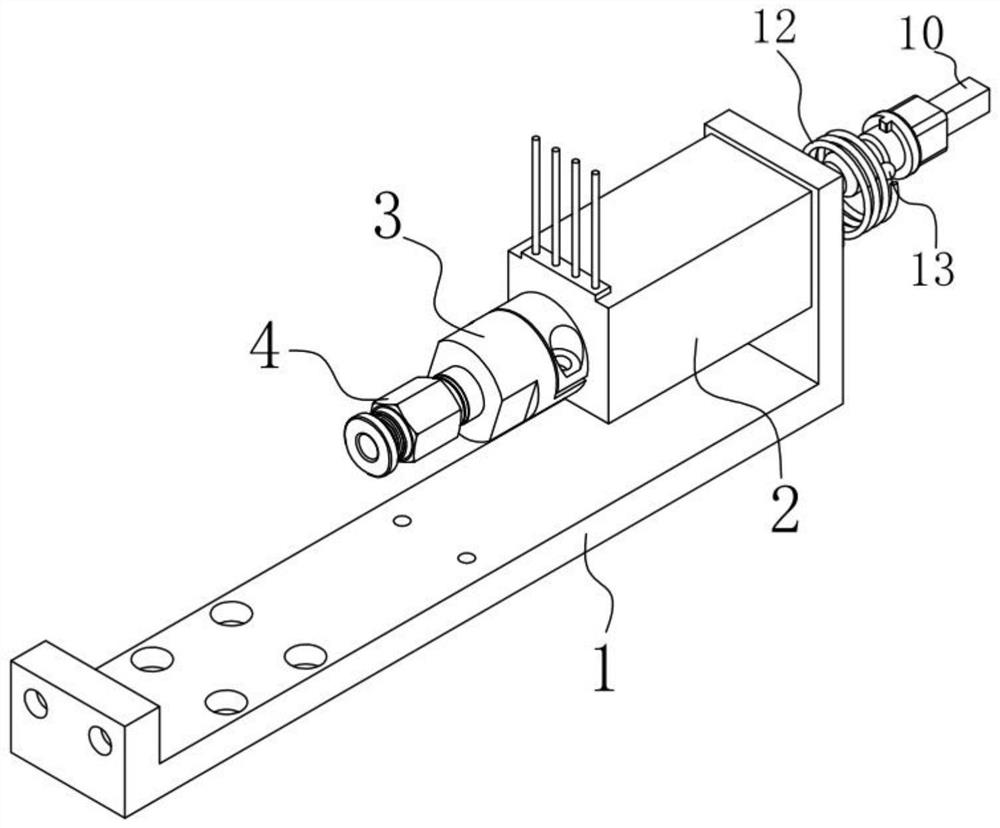

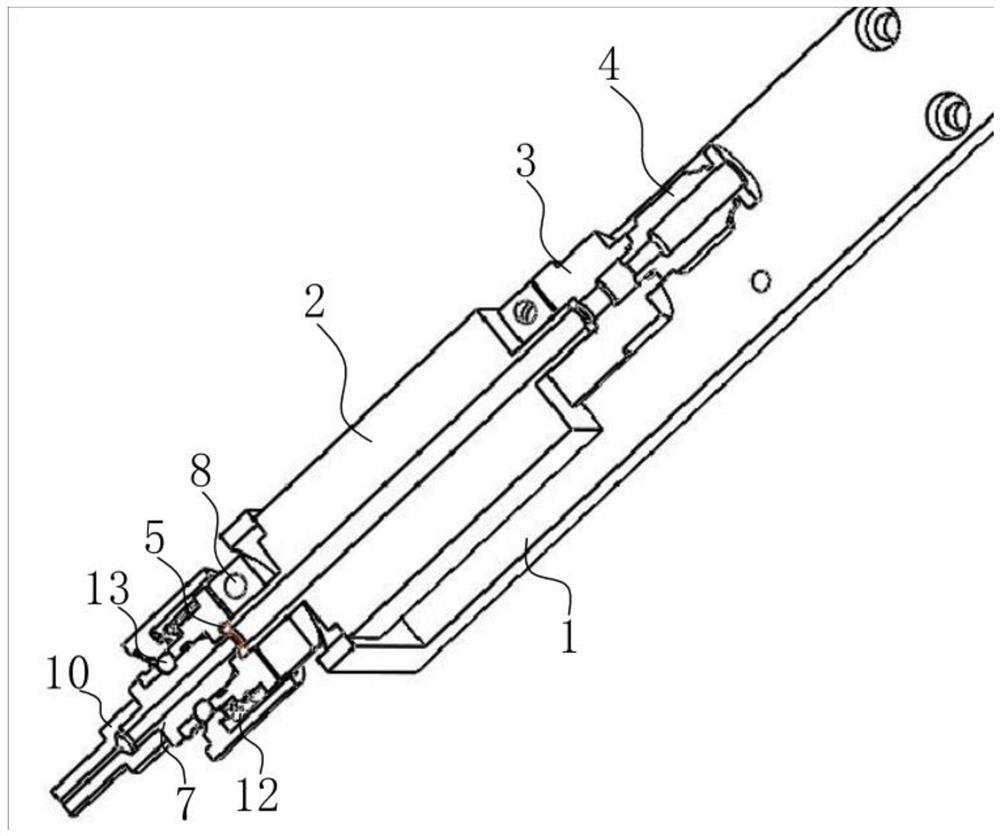

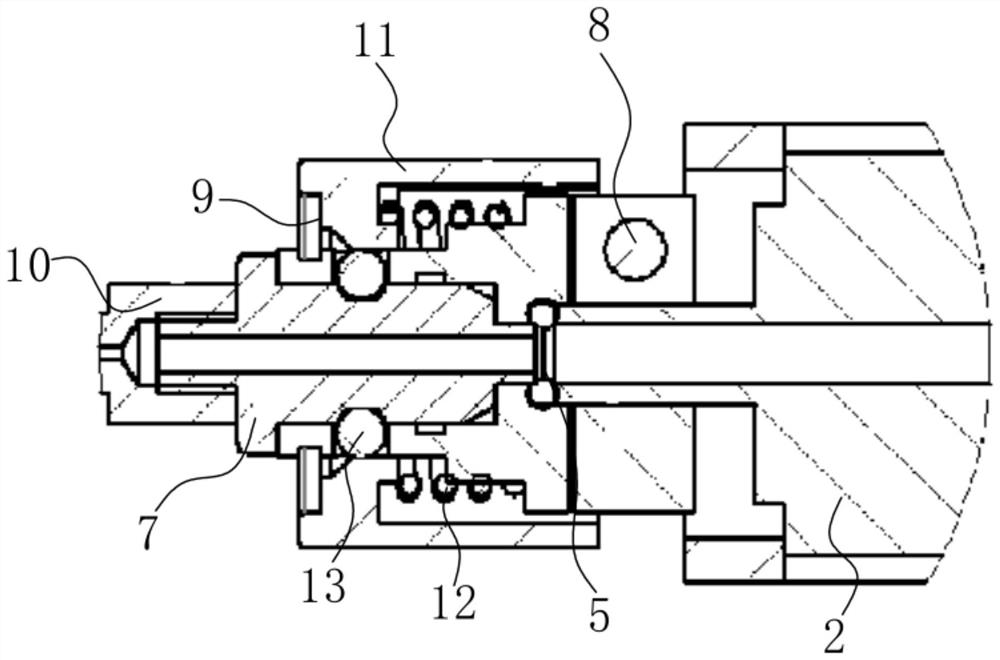

[0040] Please refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 ,in, figure 1 A structural schematic diagram of the first embodiment of the structural design of a quick-change sealed vacuum suction head provided by the present invention; figure 2 for figure 1 A sectional view of the whole of the device shown; image 3 for figure 2 The partial structural schematic diagram of the whole device shown in Fig. 4 is figure 1 A schematic diagram of the overall three-dimensional structure of the device shown; Figure 5 for figure 1 The schematic diagram of the structure of the lower motor connection sleeve shown; Figure 6 for figure 1 Overall side view of the device shown. A structural design of a quick-change sealed vacuum suction head, comprising: a mounting bracket 1;

[0041] A rotating electrical machine 2, the rotating electrical machine 2 is fixedly installed on one side of the mounting bracket 1;

[0042] A universal quick-change ...

no. 2 example

[0058] Please refer to Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 and Figure 12 , based on the structural design of the quick-change sealing vacuum suction head provided in the first embodiment of the present application, the second embodiment of the present application proposes another structural design of the quick-change sealing vacuum suction head. The second embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

[0059] Specifically, the structural design of a quick-change sealed vacuum suction head provided by the second embodiment of the present application is different in that, in a structural design of a quick-change sealed vacuum suction head, the surface of the lower motor connection sleeve 6 is provided with The connection assembly 14 , the connection assembly 14 includes a rotating seat 141 , and a fixed sleeve 142 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com