type rolling machine

A type rolling machine and frame technology, applied in the field of type rolling machines, can solve problems such as position deviation of rolling wheels, troublesome adjustment process, inability to roll type on bottle caps of different specifications, etc., and achieve the effect of eliminating misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

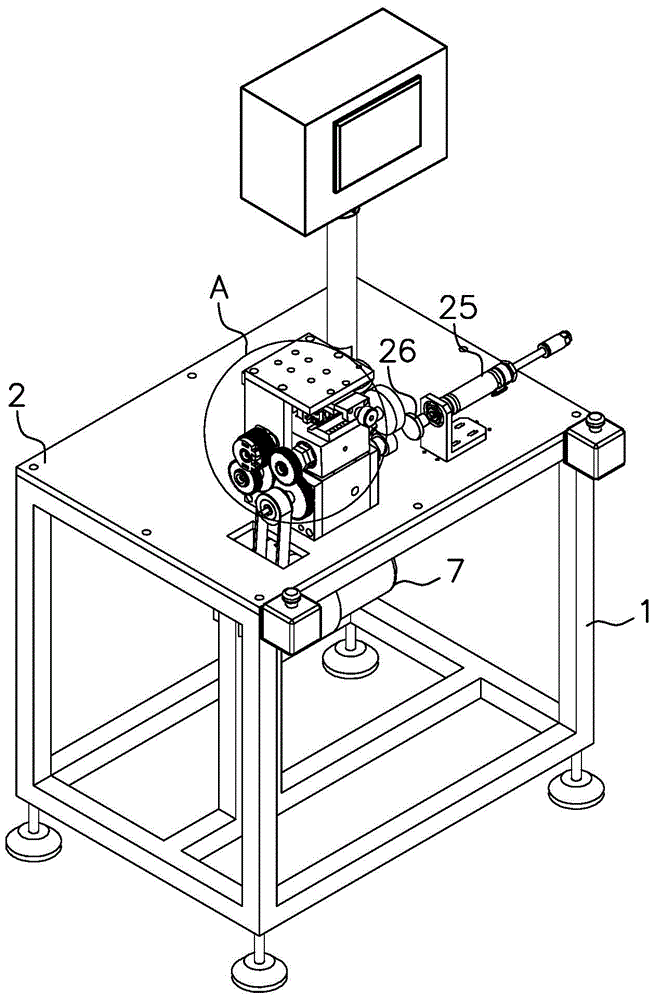

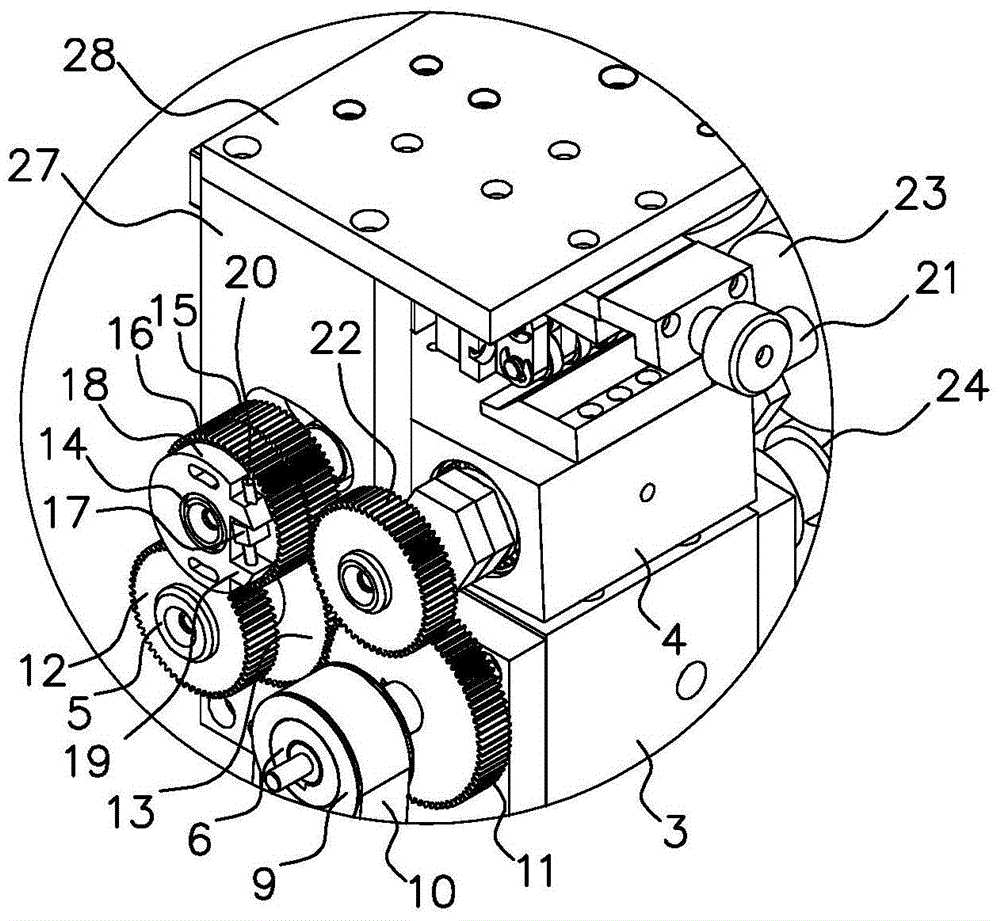

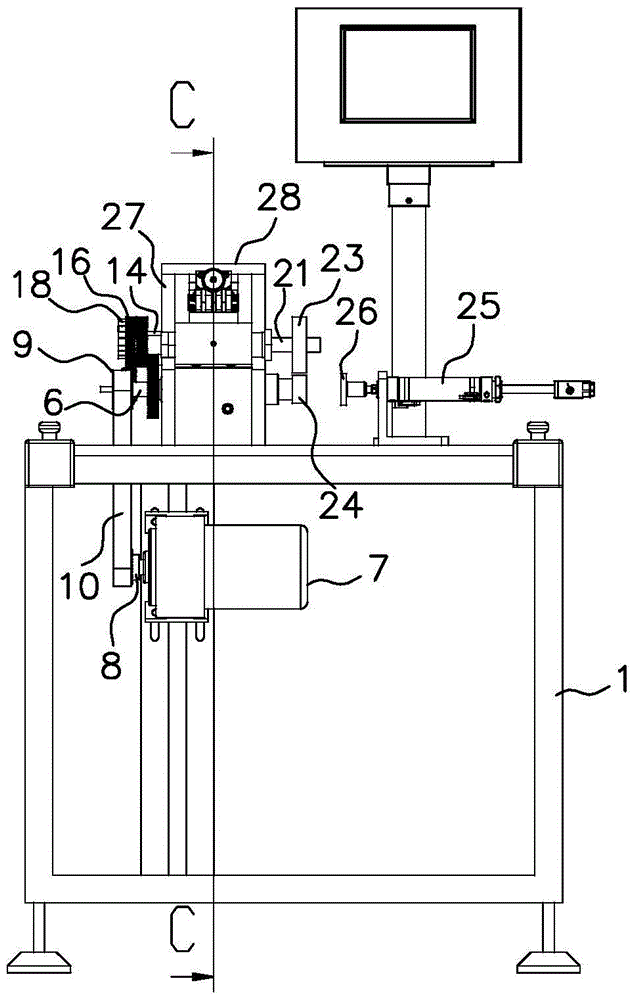

[0039] like figure 1 , figure 2 , Image 6 As shown, the present embodiment is a character rolling machine, comprising a frame 1, a panel 2 installed on the top surface of the frame 1, a fixed platform 3 is installed on the panel 2, and a turning mechanism is hinged on the fixed platform 3 through the first transition shaft 5. Taiwan 4. Wherein, the fixed table 3 is rotated with a first rotating shaft 6, and the turning table 4 is rotated with a second rotating shaft 21. The first rotating shaft 6 is equipped with support wheels 24 for suiting workpieces. The rolling wheel 23 of pressing workpiece.

[0040] Depend on image 3 Visible, also be equipped with left top cylinder 25 on the panel 2, the output shaft of left top cylinder 25 is equipped with left jack 26, is used for workpiece is fixed on the supporting wheel 24 in rolli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com