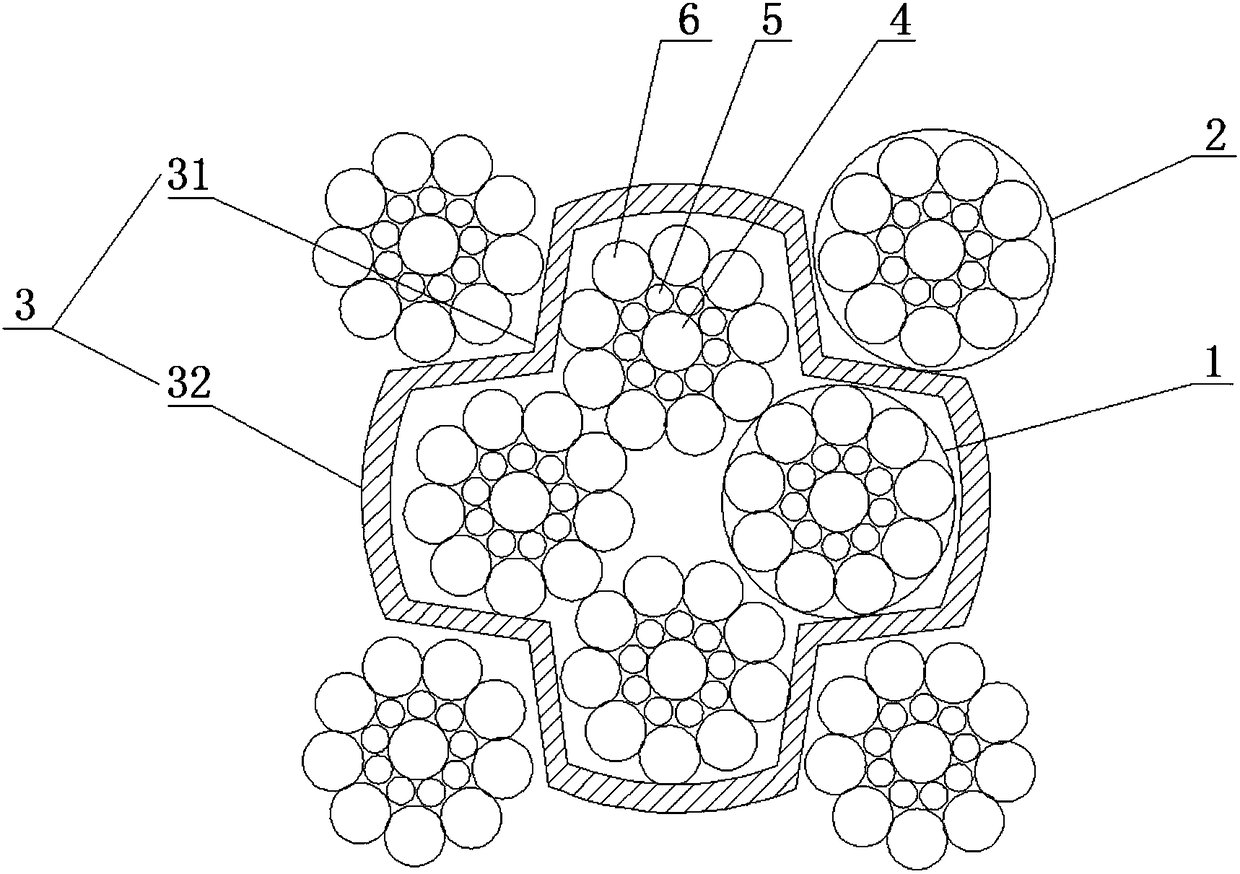

Square eight-strand torsion-resistant steel wire rope

A steel wire rope and eight-strand technology, applied in the field of steel wire rope, can solve the problems of insufficient flexibility, anti-corrosion and anti-rust functions, short service life of anti-twist steel wire rope, no lubrication, anti-corrosion and anti-rust, etc., to increase the sustainable use time and increase the overall strength , the effect of reasonable structure arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific embodiments. This embodiment is implemented on the premise of the technical solution of the present invention. It should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

[0015] like figure 1 As shown, a square eight-strand anti-twist steel wire rope includes six inner layer strands 1 and six outer layer strands 2; the six inner layer strands 1 are arranged in a ring, and the twist direction is left twist; and six A central strand 3 is also arranged in the middle gap of the strands of the inner layer, and the periphery of the central strand 3 is also provided with six cotton and linen braided strips 4 soaked in oil, and the cotton and linen braided strips 4 are located at Between the inner layer strands 1 and the center strands 3, the inner layer strands...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com