Efficient concrete mixing device

A mixing device and concrete technology, which is applied in the direction of cement mixing device, clay preparation device, unloading device, etc., can solve the problems of small extrusion force of extrusion support, low discharge efficiency, low mixing efficiency, etc., to improve work efficiency , Extrusion force is large, the effect of fast discharge speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

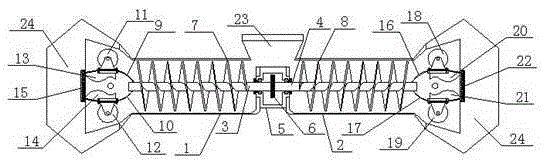

[0014] Such as figure 1 The high-efficiency concrete mixing device shown includes a shell a1, a shell b2, a stirring shaft a7 and a stirring shaft b8, and one end of the shell a1 and the shell b2 is respectively connected to the power shaft a3 and the power shaft b4 through a bearing and a sealing ring One end of the power shaft a3, b4 is connected to the power equipment 6 arranged in the body 5, the other end of the power shaft a3, b4 is respectively connected to the stirring shaft a7 and the stirring shaft b8, and the stirring shaft a7 is connected to a set of symmetrical brackets a9 and The bracket b10, the bracket a9 is provided with the active extrusion wheel a11, the bracket b10 is provided with the driven extrusion wheel a12, the active extrusion wheel a11 and the driven extrusion wheel a12 are respectively connected to the extrusion block a13 and the extrusion block b14, The extruding blocks a13 and b14 are both connected to the discharge plate a15 arranged at the othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com