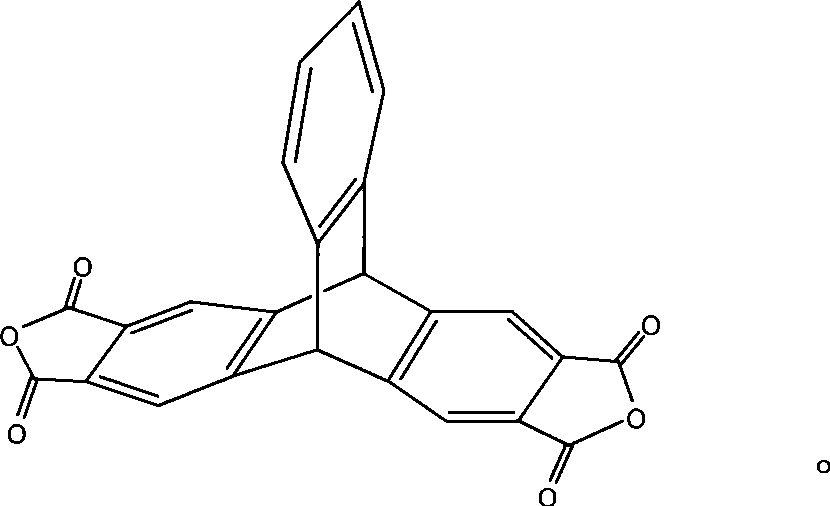

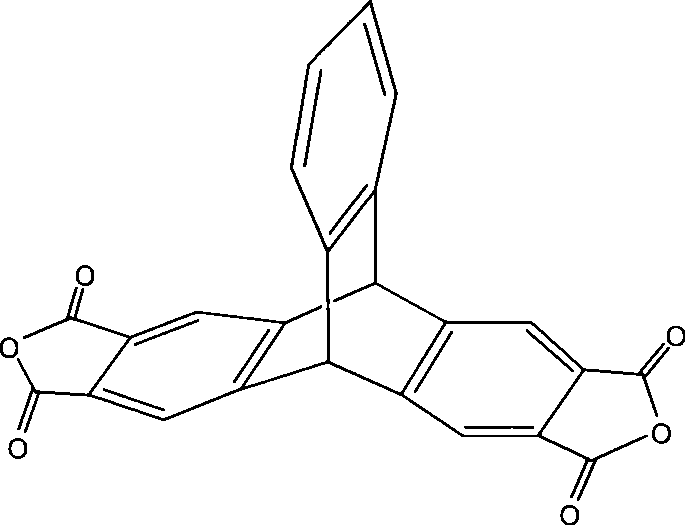

2,3,6,7-tetracarboxylic dianhydride triptycene and method for synthesizing the same

A technology of tetracarboxylic dianhydride triptycene and tetramethyl triptycene, applied in 2 fields, can solve problems such as difficulty in synthesizing polyimide, and achieve the effects of avoiding side reactions, easy production and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following is the best embodiment of the invention

[0026] Under the conditions of ice-salt bath and vigorous stirring, 30g (grams) of aluminum chloride was divided into three additions and added in a 500ml three-necked flask equipped with 65ml (milliliters) of o-xylene and a mechanical stirrer, and then added 15g of phthalic anhydride in three batches, During the feeding process, ensure that the system temperature is lower than -5°C. After the addition, let the system stir at room temperature for 3 hours (hours), and then react in a water bath at 55° C. for 3 hours. Afterwards, slowly disperse the viscous mixed reactant in 500ml of 5% hydrochloric acid ice-water mixed solution. During the pouring process, vigorous stirring is required so that the excess aluminum chloride can be fully hydrolyzed. of white solid. Dissolve this solid in 300ml of 5% sodium hydroxide solution, let it stand for stratification, the upper layer is a small amount of o-xylene, and the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com