Feeder with bionic sharkskin placoid scale structure and manufacturing method of feeder

A manufacturing method and feeder technology, applied in the application field of engineering bionic technology, can solve the problems of wear noise, damage, burning of the conveying motor, etc., and achieve the effects of ensuring health, improving the working environment, and reducing maintenance and repair costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

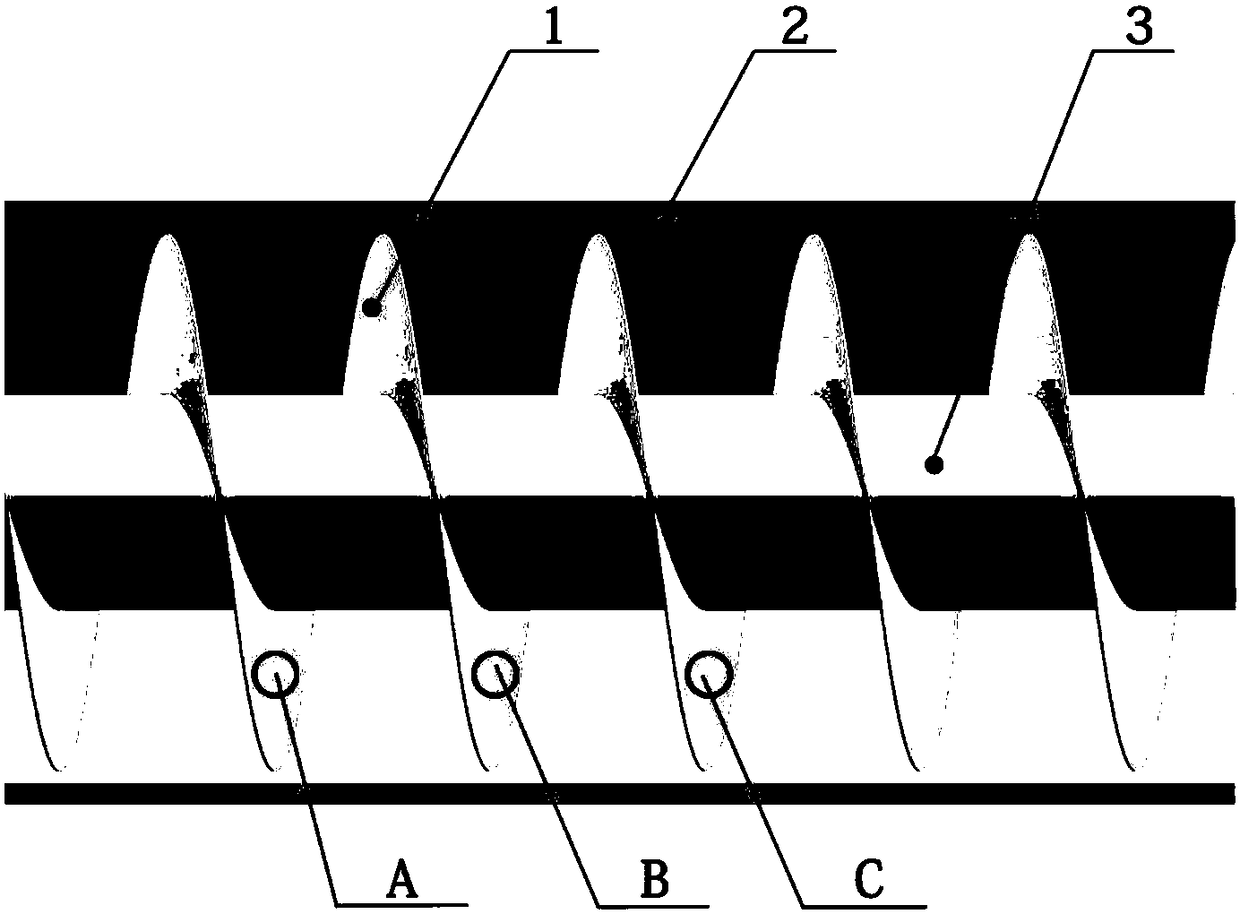

[0046] The present embodiment provides a kind of spiral blade with the processing design method of bionic shark skin shield scale structure, and it comprises the following steps:

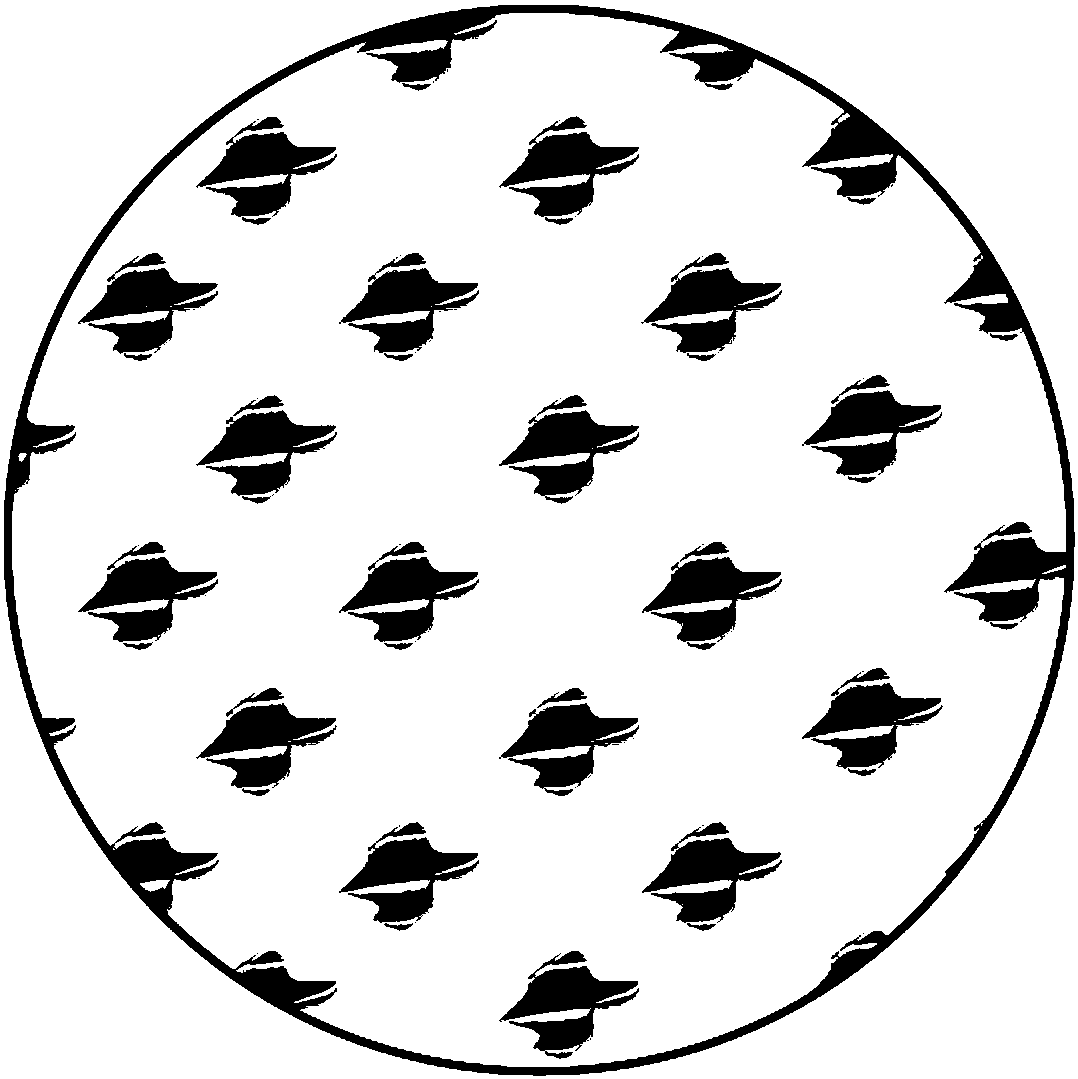

[0047] Step 1, prepare the shark shield phosphorus biological template: cut off the trunk epidermis of blue shark shark skin (fresh shark skin that can be directly purchased from the seafood market) of 50 mm × 50 mm, peel off the subcutaneous tissue of the trunk epidermis, and use a mass concentration of 3 to 6 % phosphate aqueous solution to wash, and peel off the subcutaneous tissue to obtain shark scute tissue; fix the washed shark scute tissue in 25% glutaraldehyde aqueous solution at 5°C for 20-30 hours, and then use the volume fraction Gradient dehydration with gradually increasing ethanol solution; fix the edge of the dehydrated shark scute tissue with tooling to prevent warping during the drying process, and then place the flattened and fixed shark scute tissue in a drying oven at 60°C Under...

Embodiment 2

[0052] In a briquette preparation plant, pulverized coal is used as the material to be conveyed, and a shaft double-tube screw feeder is used for feeding. First prepare the shark shield scale structure template. In a self-made vacuum hot press, use a polymethyl methacrylate (PMMA) plate as a substrate, and lay a 150mm×300mm tiger shark shark skin scale on it with the face down and use the plate to supplement it with air. Flatten the mat; raise the temperature to PMMA glass transition temperature (Tg) 105°C under vacuum and keep it constant for 10 minutes, then apply isostatic pressure on the flat plate and keep it for 30 minutes, the size depends on the area of the fish skin; keep the pressure and cool down at 70°C The lower mold is removed to obtain a replica template printed with the negative mold of the shield scale. The replica is turned over by prepolymer vacuum casting method, and polydimethylsiloxane (PDMS) prepolymer is selected as the casting material to obtain the i...

Embodiment 3

[0055] A food processing factory uses a two-stage screw feeder to transport flour with a certain amount of moisture. The first-stage spiral blade does not use a shark shield scale structure, but is used to control the speed of the screw feeder's flour delivery; the second-stage spiral blade The shark shield scale structure is designed on the top to ensure that the adhesion of flour to the spiral blade is reduced when conveying flour with a certain amount of moisture. After high-precision scanning of the pretreated white shark skin structure, the overall structure of multiple shark shield scales is obtained, and multiple groups of multiple shark shield scale overall structures are pressed on the spiral blades by mechanical pressing method, and multiple shark shields The part of the overall structure of the scales protruding from the helical blade is located on the front of the blade, and the edge of the overall structure of multiple shark shield scales is smoothed so that it can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com