Novel device and method for moulding pipe

A pouring method and technology for pipe fittings, which are applied to the pouring device of pipe fittings and the field of pouring pipe fittings, can solve the problems of many waste products, insufficient pouring and deformation of poured pipe fittings, and achieve the effects of being conducive to stability, smooth surface and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In the following, referring to the drawings, through the description of the embodiments, the specific embodiments of the present invention such as the shape and structure of the various components involved, the mutual position and connection relationship between the various parts, the function and working principle of each part, etc. Detailed description:

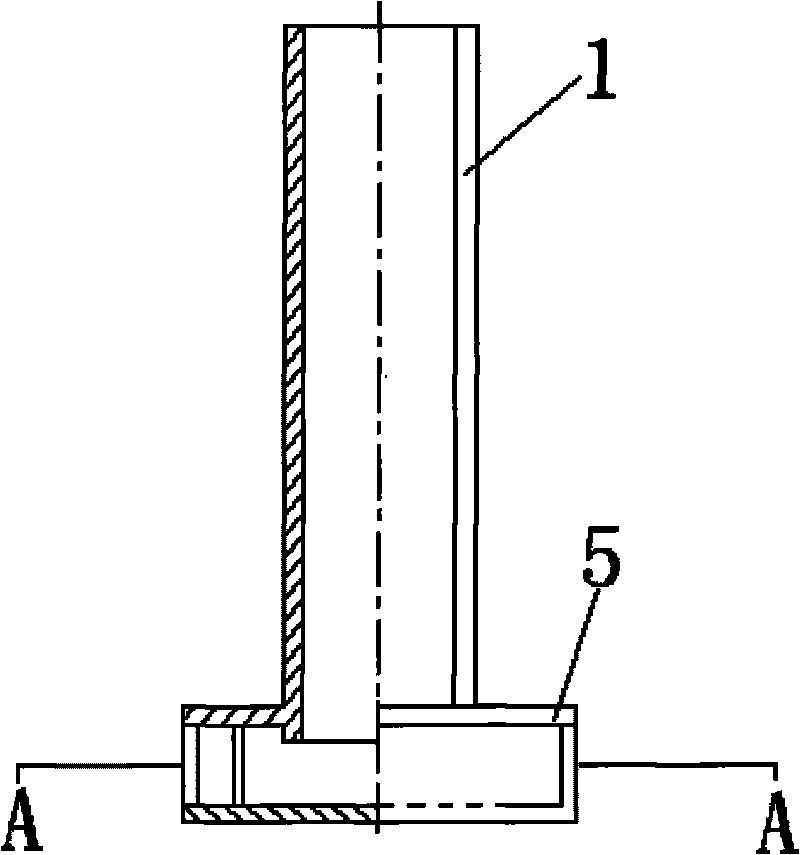

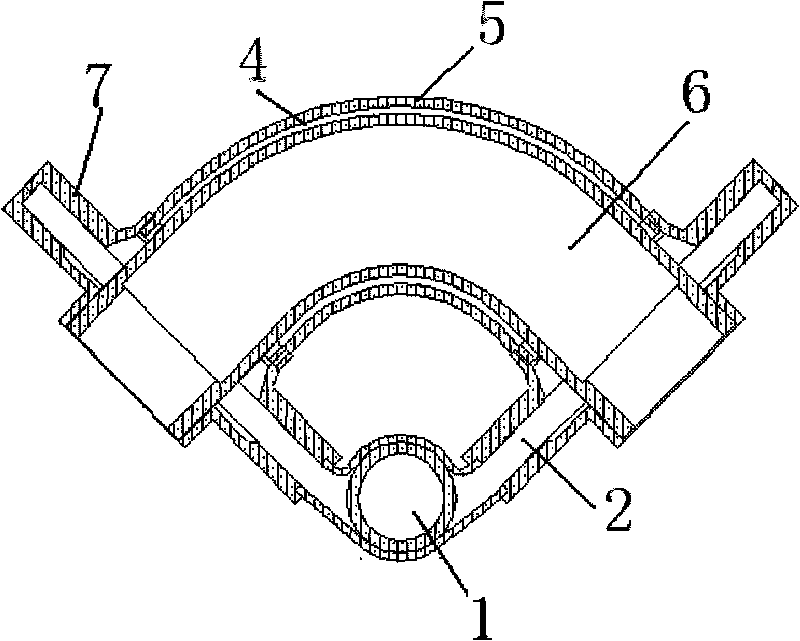

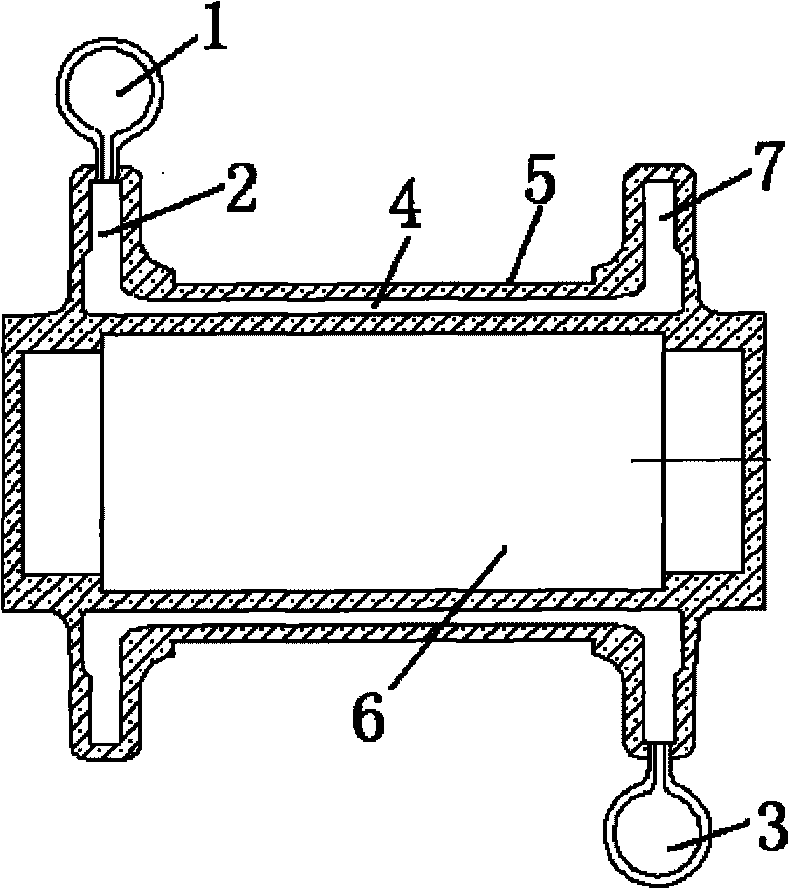

[0033] As attached Figure 1-4 As shown, the present invention is a new type of pipe casting device, including sprue 1, inner runner 2, and riser 3. The new type of pipe casting device also includes pipe fitting sand mold 4, the one or more The sprue 1 is in communication with one or more inner runners 2, and the inner runner 2 is in communication with a pipe fitting sand mold 4 with a gap structure formed by a double cen material, and the pipe fitting sand mold 4 is in communication with one or more risers 3.

[0034] The sprue 1 is arranged as a hollow tubular structure, the sprue 1 is arranged as a vertically arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com