Production technology for as-cast spheroidal graphite iron casting QT600-7

A nodular cast iron, production process technology, applied in the field of casting, can solve the problems of material performance degradation, loose structure, unstable production, etc., and achieve the effect of reducing production costs and stabilizing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

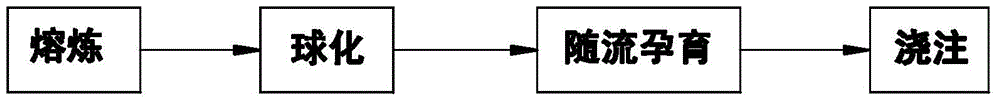

Method used

Image

Examples

Embodiment 1

[0027] (1) Smelting: Select Q10 pig iron with a weight percentage content of 20%, Q235 steel scrap with a weight percentage content of 10% and recycled material with a weight percentage content of 70%, and put them into an intermediate frequency induction furnace to melt into molten iron;

[0028] (2) Spheroidization: 0.3% by weight of Cu, 0.1% by weight of Ni, 0.8% by weight of RE-Mg spheroidizer and 0.5% by weight of 10mm particle size The SiBaCa inoculant is placed at the bottom of a 1T ladle. Preferably, the weight percentages of RE and Mg in the RE-Mg nodulizer are RE3 and Mg8 respectively. The molten iron after smelting is heated up to 1500°C, and then poured into Spheroidizing in the ladle;

[0029] (3) Flowing inoculation: when the spheroidized molten iron is subcontracted, a powdered SiBaCa inoculant with a weight percentage content of 0.2% is added with the flow;

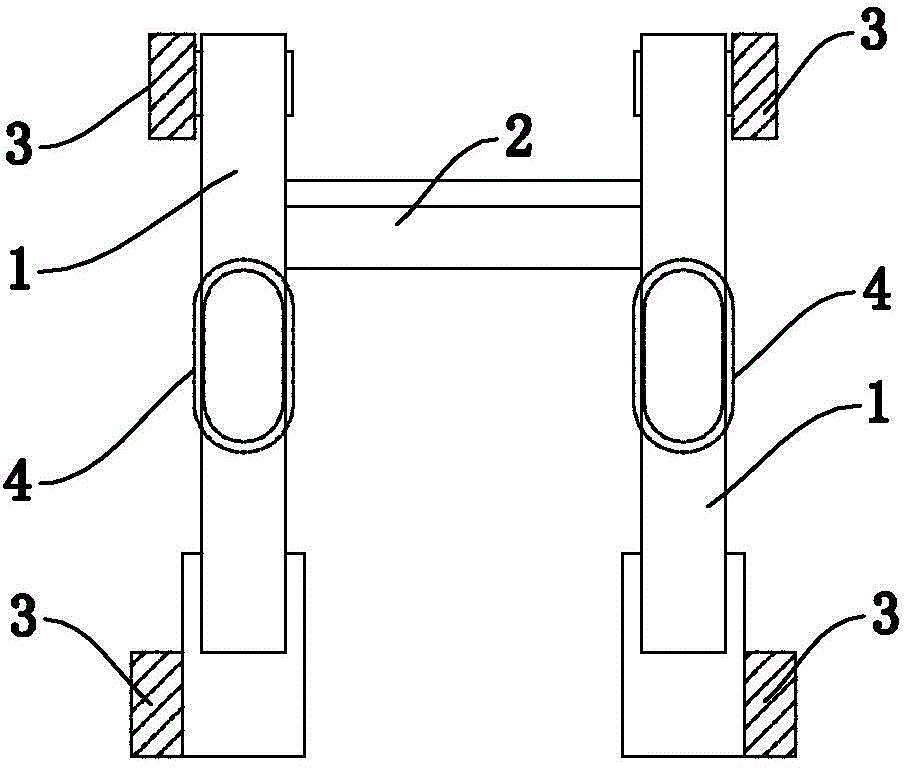

[0030] (4) Pouring: pour the molten iron into the mold after inoculation with the flow, set the chill ...

Embodiment 2

[0032] (1) Smelting: select Q10 pig iron with a weight percentage content of 50%, Q235 steel scrap with a weight percentage content of 30% and returned materials with a weight percentage content of 20%, and put them into an intermediate frequency induction furnace to melt into molten iron;

[0033] (2) Spheroidization: 1.2% by weight of Cu, 0.6% by weight of Ni, 1.5% by weight of RE-Mg spheroidizer and 1.5% by weight of 10mm particle size The SiBaCa inoculant is placed at the bottom of a 1T ladle. Preferably, the weight percentages of RE and Mg in the RE-Mg nodulizer are RE3 and Mg8 respectively. The molten iron after smelting is heated up to 1600°C, and then poured into Spheroidizing in the ladle;

[0034] (3) Flowing inoculation: when the spheroidized molten iron is subcontracted, a powdered SiBaCa inoculant with a weight percentage content of 0.4% is added with the flow;

[0035] (4) Pouring: pour the molten iron into the mold after inoculation with the flow, set the chill...

Embodiment 3

[0037] (1) Smelting: select Q10 pig iron with a weight percentage content of 30%, Q235 steel scrap with a weight percentage content of 20% and recycled materials with a weight percentage content of 50%, and put them into an intermediate frequency induction furnace to melt into molten iron;

[0038](2) Spheroidization: 0.7% by weight of Cu, 0.4% by weight of Ni, 1.1% by weight of RE-Mg spheroidizer and 1% by weight of 10mm particle size The SiBaCa inoculant is placed at the bottom of a 1T ladle. Preferably, the weight percentages of RE and Mg in the RE-Mg nodulizer are RE3 and Mg8 respectively. The molten iron after smelting is heated up to 1560°C, and then poured into Spheroidizing in the ladle;

[0039] (3) Flow inoculation: when the spheroidized molten iron is subcontracted, a powdered SiBaCa inoculant with a weight percentage content of 0.3% is added with the flow;

[0040] (4) Pouring: pour the molten iron into the mold after inoculation with the flow, set the chill iron ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Material strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com