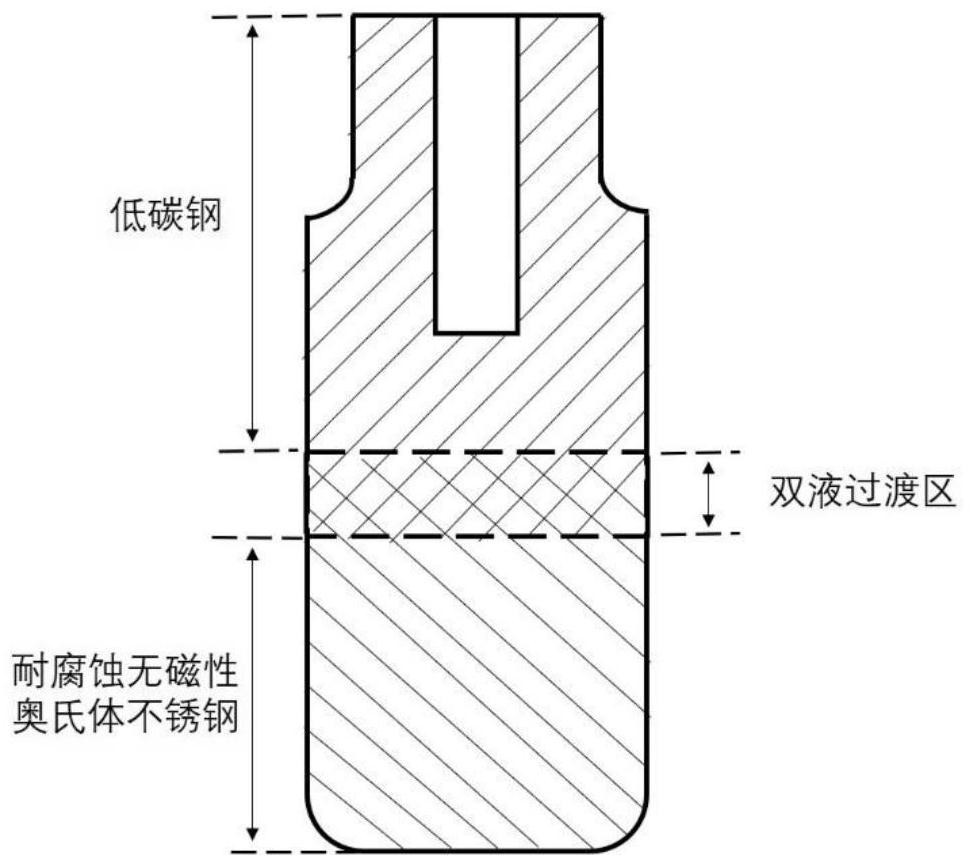

Preparation method of single-phase non-magnetic corrosion-resistant electrolytic aluminum crust breaking hammer and product thereof

A technology of shelling hammer and electrolytic aluminum, applied in the field of material forming, can solve the problems of high cost and poor pertinence of hammer loss, and achieve the effects of low production cost, ensuring the purity of primary aluminum, and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) The lost foam casting method is used to make the lost model cavity according to the standard size of the hammer head (the raw materials are expandable polystyrene resin beads EPS, expandable methyl methacrylate and styrene copolymer resin beads The combination of STMMA and expandable polymethyl methacrylate resin beads EPMMA, the mass ratio is 1:1:1), the upper hollow structure of the vanishing model cavity accounts for 45% of the total volume of the upper part, and it is carried out under an argon atmosphere Carbonization treatment, the temperature is 1300°C, and the time is 2 hours; accurately weigh the mass of the disappearing model cavity, weigh its mass after carbonization treatment, and calculate the amount of residual carbon;

[0041] (2) The composition of austenitic stainless steel is calculated according to the mass fraction: C: 0.08% (the amount of C added needs to subtract the residual carbon in the disappearing model cavity), Si: 0.08%, Cr: 19.00%, Mn: 1...

Embodiment 2

[0044] (1) Using the method of lost foam casting, according to the standard size of the hammer head, make the lost model cavity (the raw material is expandable polystyrene resin beads EPS), and the upper hollow structure of the lost model cavity accounts for 42% of the total volume of the upper part. %, carry out carbonization treatment under an argon atmosphere, the temperature is 1200 ° C, and the time is 3 hours; accurately weigh the mass of the disappearing model cavity, weigh its mass after carbonization treatment, and calculate the amount of residual carbon;

[0045] (2) The composition of austenitic stainless steel is calculated according to the mass fraction: C: 0.05% (the amount of C added needs to subtract the residual carbon in the disappearing model cavity), Si: 0.07%, Cr: 18.50%, Mn: 1.58% , Ni: 8.76%, P: 0.04%, S: 0.02%, and the remaining content is pure iron powder; the austenitic stainless steel components are melted and mixed to obtain austenitic stainless stee...

Embodiment 3

[0048] (1) The lost foam casting method is used to make the lost model cavity according to the standard size of the hammer head (the raw materials are expandable methyl methacrylate and styrene copolymer resin beads STMMA and expandable polymethyl methacrylate Resin beads EPMMA, the mass ratio is 1:1), the upper hollow structure of the disappearance model cavity accounts for 47% of the total volume of the upper part, carbonization treatment is carried out under an argon atmosphere, the temperature is 1450 ° C, and the time is 1 h; accurate weighing The mass of the disappearing model cavity is weighed after carbonization treatment, and the residual carbon amount is calculated;

[0049] (2) The composition of austenitic stainless steel is calculated according to the mass fraction: C: 0.06% (the amount of C added needs to subtract the residual carbon in the disappearing model cavity), Si: 0.50%, Cr: 19.50%, Mn: 1.56% , Ni: 10.00%, P: 0.03%, S: 0.03%, and the remaining content is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com