Preparation method of titanium dioxide based graphene /La3+ carbon fibers

A technology of titanium dioxide and graphene, applied in the field of functional fibers, can solve the problems of low utilization rate of visible light and low photon quantum yield, and achieve good antibacterial effect, simple equipment and simple production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Material preparation: Weigh 2g of polyacrylonitrile (PAN), 25ml of DMF, 2ml of glacial acetic acid and 2.5ml of tetra-n-butyl titanate (Ti(OC 4 h 9 ) 4 )mixture.

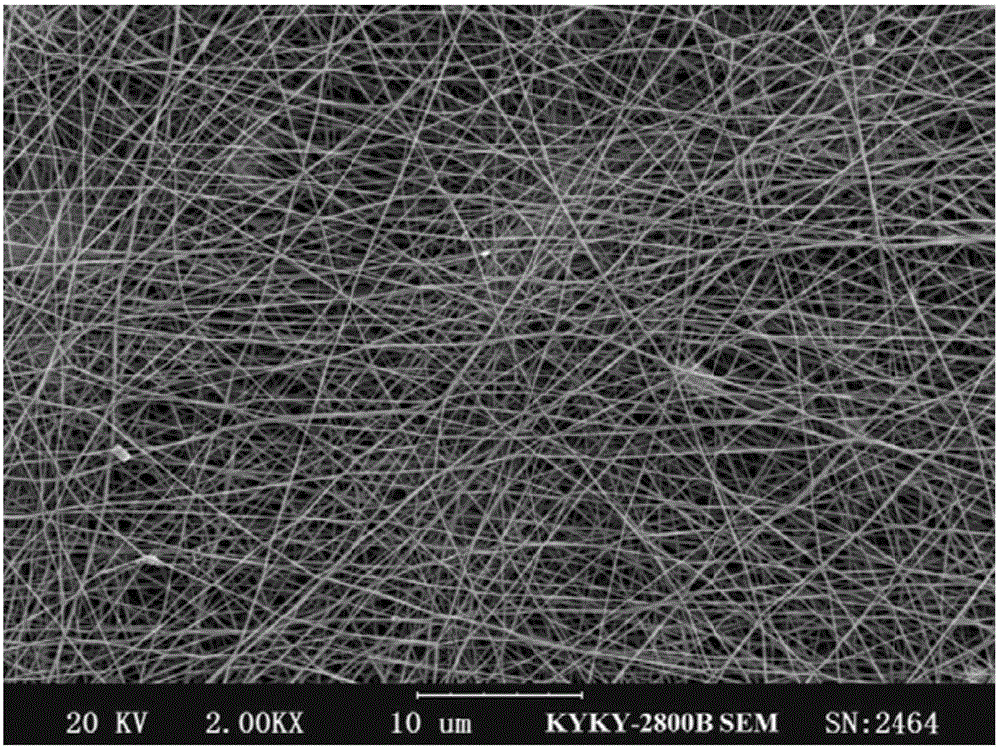

[0031] 2. Adopt: Hummers method to prepare graphene, and carry out ultrasonic treatment under the condition of room temperature 25 ℃. The mass ratio of graphene (GO) doping amount to Ti is 0.05.

[0032] 3. Gradually add GO / DMF mixed solution into PAN / DMF, stir in vacuum, and sonicate for 10 hours, and finally get 25ml GO / PAN spinning solution; the volume ratio of GO / DMF to DMF in PAN / DMF is 1:1.

[0033] 4. Then add 0.031g of lanthanum nitrate to the mixture containing 2ml of glacial acetic acid and 2.5ml of tetra-n-butyl titanate (Ti(OC 4 h 9 ) 4 ) in the mixed solution, forming La 3+ Doped TiO(OAc) 2 The solution was then slowly added to the above GO / PAN mixed solution under magnetic stirring. After the dropwise addition, magnetic stirring was continued for 10 h to finally obtain a spinning solu...

Embodiment 2

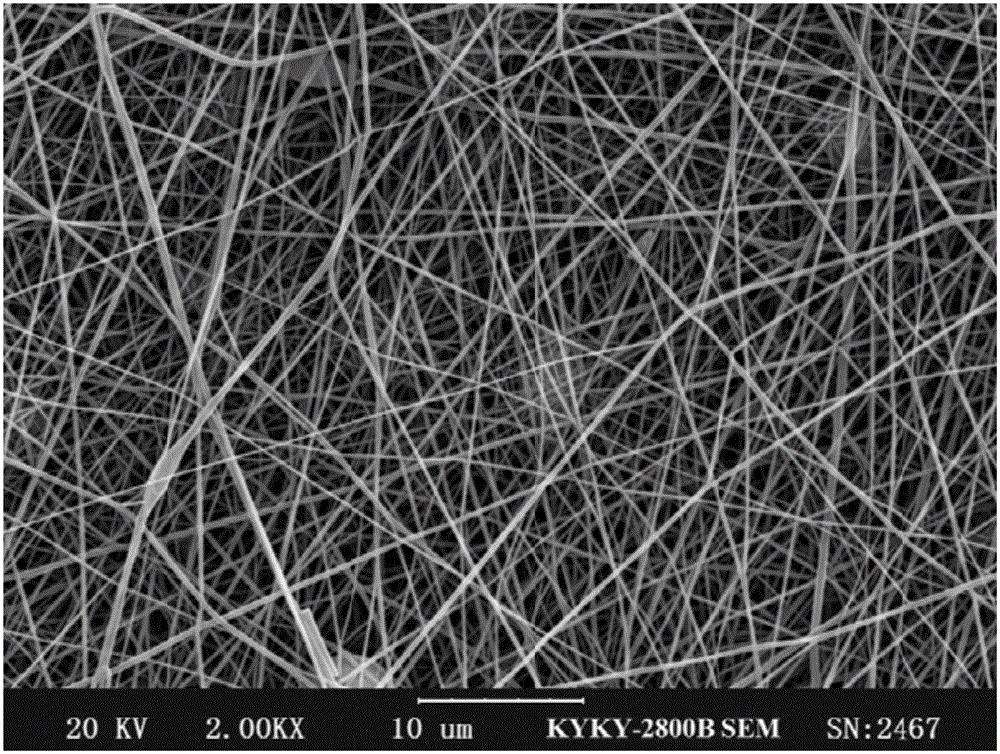

[0039] 1. Material preparation: Weigh 2g of polyacrylonitrile (PAN), 25ml of DMF, 2ml of glacial acetic acid and 2.5ml of tetra-n-butyl titanate (Ti(OC 4 h 9 ) 4 ) mixed solution, the mass ratio of GO doping amount to Ti is 0.10.

[0040] 2. Steps 2, 3, 4, and 5 are repeated in Example 1.

[0041] 3. Antibacterial test: as in Example 1

[0042] By comparing the size of the antibacterial zone diameter to compare the strength of the sample's bactericidal performance, the antibacterial diameter is 19mm, GO / La3+ co-doped TiO 2 (GLCT) nanofibers have a better antibacterial effect on Escherichia coli.

Embodiment 3

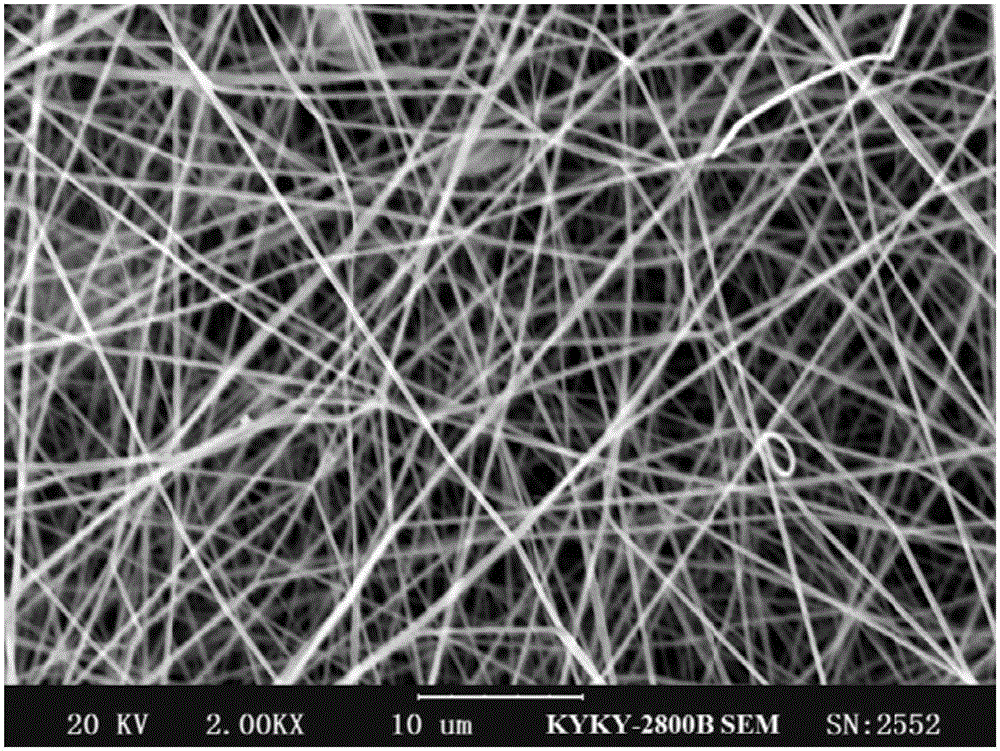

[0044] 1. Material preparation: weigh 2g polyacrylonitrile (PAN), measure 25ml DMF, 2ml glacial acetic acid and 2.5ml tetra-n-butyl titanate (Ti(OC4H9)4) mixed solution, GO doping amount and Ti mass The ratio is 0.2.

[0045] 2. Steps 2, 3, 4, and 5 are repeated in Example 1.

[0046] By comparing the size of the diameter of the inhibition zone to compare the strength of the bactericidal performance of the sample, the antibacterial diameter is 22mm, GO / La 3+ co-doped TiO 2 (GLCT) nanofibers have good antibacterial effect on Escherichia coli.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com