Efficient colored heat-insulating and cooling coating as well as preparation method and application thereof

A thermal insulation cooling and color technology, applied in coatings, polyester coatings, polyamide coatings, etc., can solve the problems of insufficient heat insulation and cooling effects, limited sunlight reflection ability, poor stain resistance, etc., and achieve heat insulation and cooling effect, avoiding the increase of surface density, and the effect of excellent cooling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

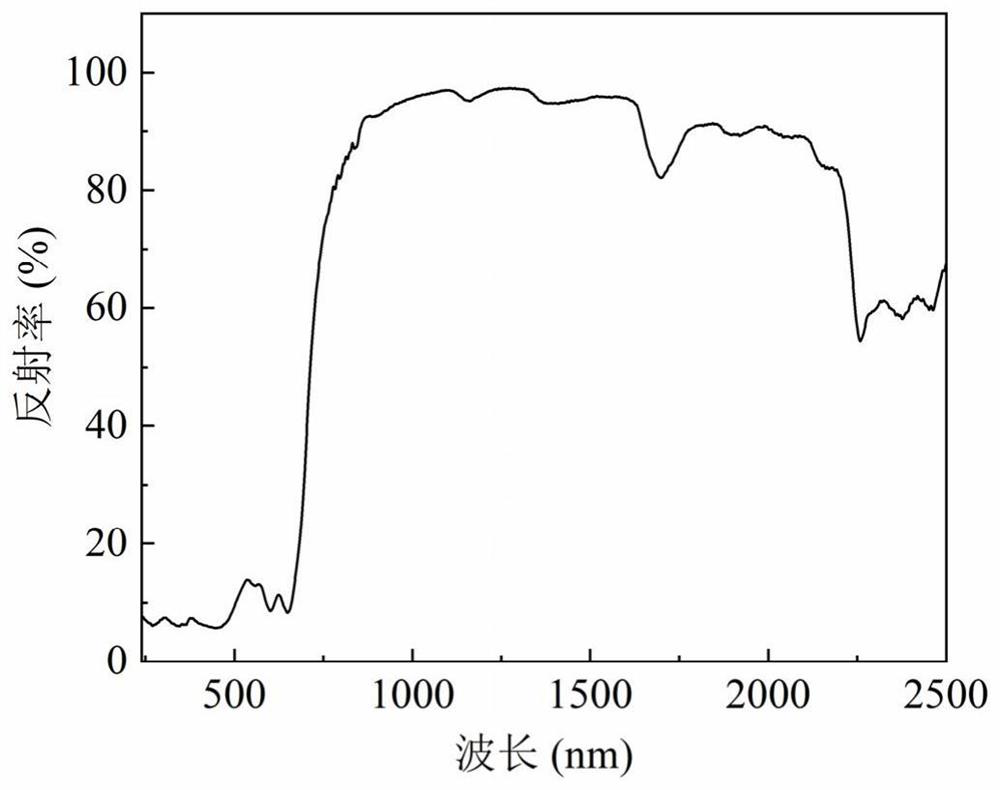

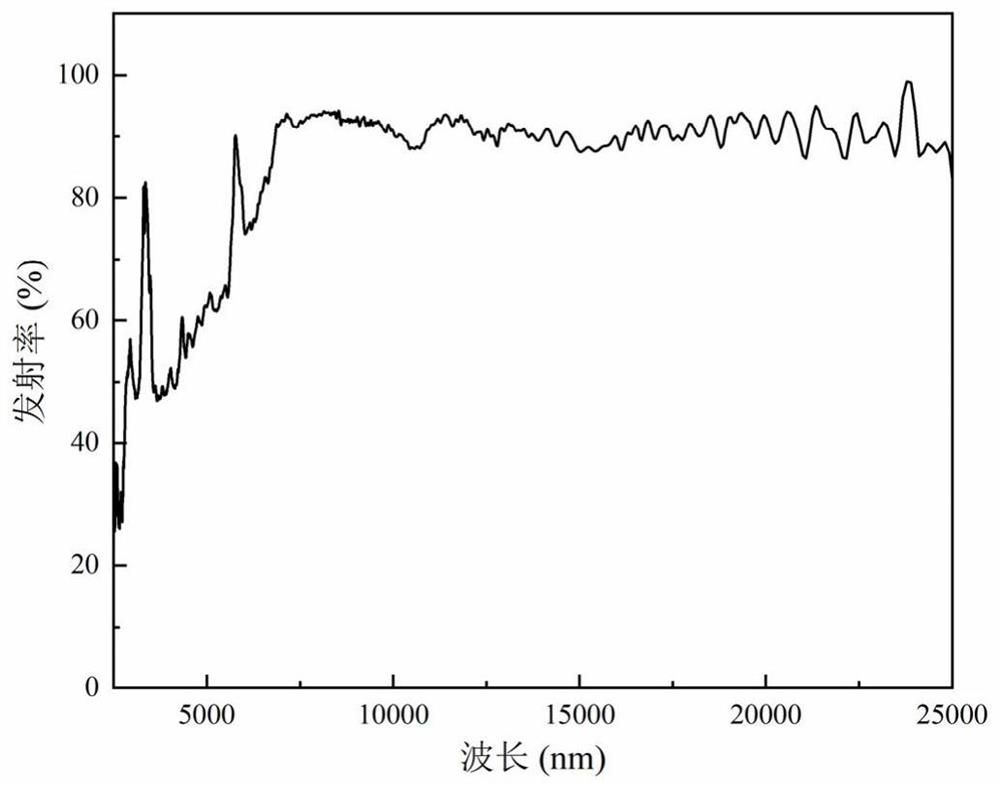

[0056] The utility model relates to a high-efficiency color heat-insulating and cooling coating, which uses a spectrally selective porous film as a bottom layer, an infrared transparent color film is arranged on the spectrally selective porous film, and the spectrally selective porous film is a polymer porous film.

[0057] In this embodiment, the thickness of the infrared transparent color film is 30 μm, and the color of the infrared transparent color film is medium green MG1151, which is an infrared transparent medium green film. It is prepared after curing. Specifically, the yellow dye in the solvent, the solvent scarlet dye, the solvent emerald green dye, and the solvent black dye are prepared into dye liquors of different colors, and then the above dye liquors are mixed and tinted to meet the requirements of the Lab value. Transparent dye liquor and acrylic resin BS-963 are prepared after curing.

[0058]In this embodiment, the spectrally selective porous film is formed b...

Embodiment 2

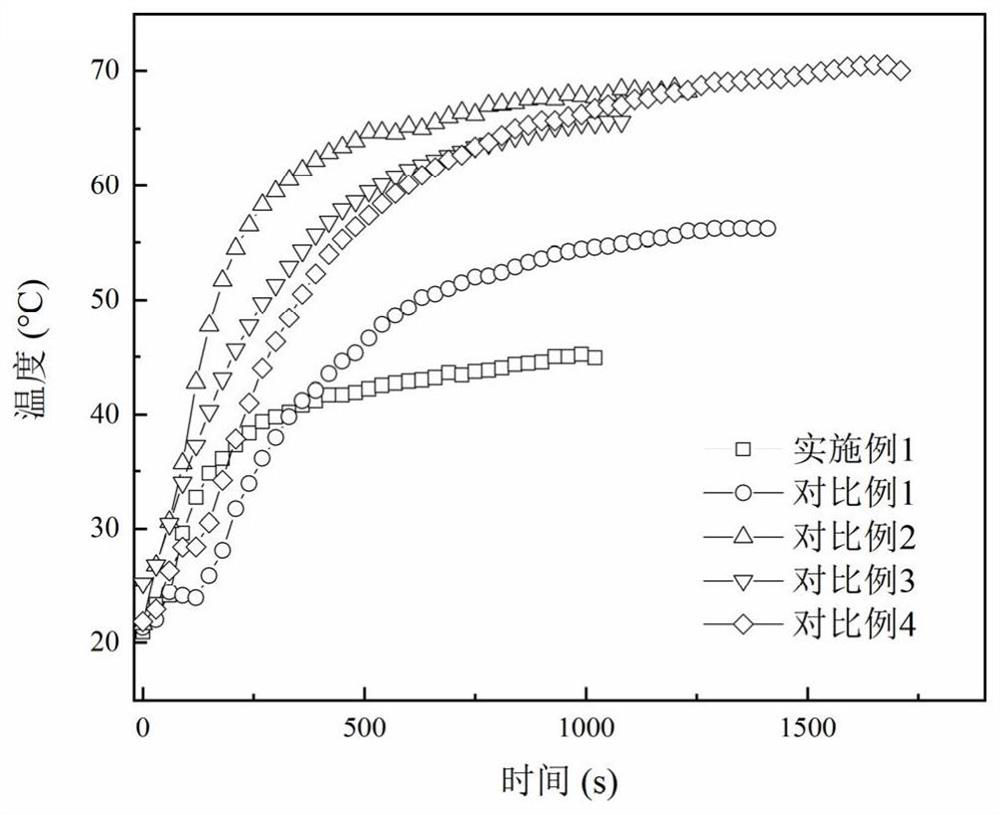

[0072] A preparation method of a high-efficiency color thermal insulation and cooling coating, the steps are basically the same as those in Example 1, the difference is only that: in step (2), the thickness of the spectrally selective porous film is 420 μm.

[0073] After testing, the solar reflectance of the high-efficiency color thermal insulation and cooling coating is 40.32%, the maximum temperature of the backside of the coating material is 57.2°C, the reflectance is significantly lower than that of Example 1, and the temperature of the backside is significantly higher than that of Example 1, because The role of the spectrally selective porous film is to reflect sunlight, and its reflectivity is heavily dependent on the thickness of the film. Reducing the film thickness will lead to a significant decrease in the overall sunlight reflectivity and thermal insulation performance of the composite coating.

Embodiment 3

[0075] A preparation method of a high-efficiency color thermal insulation and cooling coating, the steps are basically the same as those in Example 1, the only difference is: in step (2), the thickness of the spectrally selective porous film is 1200 μm.

[0076] After testing, the solar reflectance of the high-efficiency color thermal insulation and cooling coating is 54.05%, the maximum temperature of the back of the coating material is 44.0°C, the reflectivity is slightly higher than that of Example 1, and the temperature of the backside is slightly lower than that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com