Three-band laser antireflection film and preparation method thereof

A three-band, anti-reflection coating technology, applied in optics, optical components, ion implantation plating, etc., can solve problems such as poor adhesion and peeling, and achieve easy control, strong adhesion of the film layer, and excellent optical performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

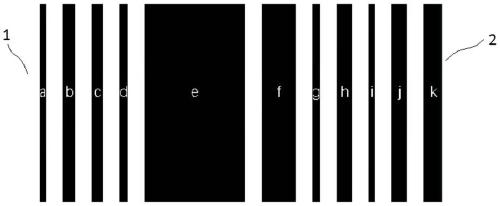

[0036] Such as figure 1 As shown, a three-band laser anti-reflection coating includes a base layer, including a base layer, and the base layer is sequentially deposited with the first YF 3 layer, the first ZnSe layer, the second YF 3 layer, the second ZnSe layer, the third YF 3 layer, the third ZnSe layer, the fourth YF 3 layer, the fourth ZnSe layer, the fifth YF 3 layer, the fifth ZnSe layer and MgF 2 layer; the base layer is a ZnSe base layer.

[0037] The thickness of ZNSE base layer is 2mm, the first YF 3 The thickness of the layer is 204nm, the thickness of the first ZnSe layer is 420nm, the second YF 3 The thickness of the layer is 390nm, the thickness of the second ZnSe layer is 270nm, the third YF 3 The thickness of the layer is 5328nm, the thickness of the third ZnSe layer is 1500nm, the fourth YF 3 The thickness of the layer is 246nm, the thickness of the fourth ZnSe layer is 486nm, the fifth YF 3 The thickness of the layer is 192nm, the thickness of the fi...

Embodiment 2

[0043] A three-band laser anti-reflection coating, including a base layer, including a base layer, the base layer is sequentially deposited with the first YF 3 layer, the first ZnSe layer, the second YF 3 layer, the second ZnSe layer, the third YF 3 layer, the third ZnSe layer, the fourth YF 3 layer, the fourth ZnSe layer, the fifth YF 3 layer, the fifth ZnSe layer and MgF 2 layer; the base layer is a ZnSe base layer.

[0044] The thickness of ZNSE base layer is 2mm, the first YF 3 The thickness of the layer is 206nm, the thickness of the first ZnSe layer is 423nm, the second YF 3 The thickness of the layer is 394nm, the thickness of the second ZnSe layer is 265nm, the third YF 3 The thickness of the layer is 5325nm, the thickness of the third ZnSe layer is 1502nm, the fourth YF 3 The thickness of the layer is 249nm, the thickness of the fourth ZnSe layer is 488nm, the fifth YF 3 The thickness of the layer is 195nm, the thickness of the fifth ZnSe layer is 345nm, the M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com