A kind of method for preparing superfine calcium carbonate nanopowder

An ultra-fine calcium carbonate, nano powder technology, applied in the direction of calcium carbonate/strontium/barium, nanotechnology, nanotechnology, etc., can solve the problem that it is difficult to obtain nano calcium carbonate, the control of calcium carbonate particle size and pH value is difficult to guarantee and other problems, to achieve the effect of short cycle and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

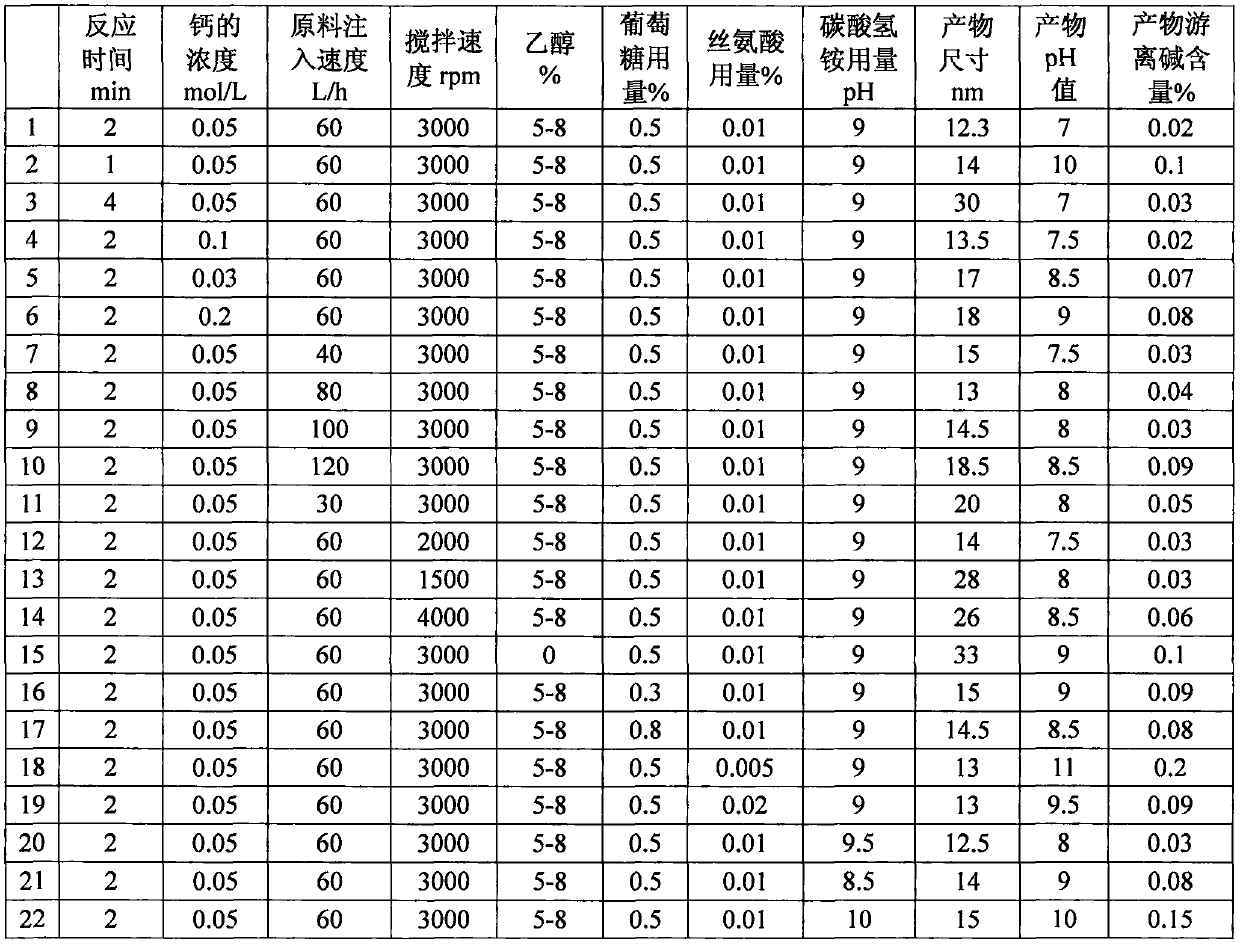

Examples

Embodiment 1

[0024] 1) Limestone is pulverized, sieved, digested by adding deionized water, and aged once to obtain an aged slurry. The concentration of calcium in the aged slurry is 0.05mol / L;

[0025] 2) adding dehydrated ethanol to the ammonium bicarbonate aqueous solution to obtain an ammonium bicarbonate alcohol aqueous solution; wherein, the amount of the dehydrated ethanol is 5-8% of the volume of the ammonium bicarbonate aqueous solution.

[0026] 3) Under the agitation of 3000rpm, at the same speed of 60L / h, the primary aging slurry and the ammonium bicarbonate alcoholic aqueous solution are quickly injected into the reactor to form a white precipitate, and the amount of ammonium bicarbonate added is controlled so that the reaction system when the precipitation reaction is terminated The pH value of the solution is 9, the reaction temperature is 20-30°C, and the reaction is 2 minutes; quickly add a large amount of deionized water to dilute the precipitate, and the slurry is subject...

Embodiment 2

[0031] 1) The limestone is pulverized, sieved, digested by adding deionized water, and subjected to primary aging to obtain a primary aging slurry. The concentration of calcium in the primary aging slurry is 0.05mol / L. ;

[0032] 2) adding dehydrated ethanol to the ammonium bicarbonate aqueous solution to obtain an ammonium bicarbonate alcohol aqueous solution; wherein, the amount of the dehydrated ethanol is 5-8% of the volume of the ammonium bicarbonate aqueous solution.

[0033] 3) Under the agitation of 3000rpm, at the same speed of 60L / h, the primary aging slurry and the ammonium bicarbonate alcoholic aqueous solution are quickly injected into the reactor to form a white precipitate, and the amount of ammonium bicarbonate added is controlled so that the reaction system when the precipitation reaction is terminated The pH value of the solution is 9, the reaction temperature is 20-30°C, and the reaction is 1 minute; quickly add a large amount of deionized water to dilute th...

Embodiment 3

[0038] 1) The limestone is pulverized, sieved, digested by adding deionized water, and subjected to primary aging to obtain a primary aging slurry. The concentration of calcium in the primary aging slurry is 0.05mol / L. ;

[0039] 2) adding dehydrated ethanol to the ammonium bicarbonate aqueous solution to obtain an ammonium bicarbonate alcohol aqueous solution; wherein, the amount of the dehydrated ethanol is 5-8% of the volume of the ammonium bicarbonate aqueous solution.

[0040] 3) Under the agitation of 3000rpm, at the same speed of 60L / h, the primary aging slurry and the ammonium bicarbonate alcoholic aqueous solution are quickly injected into the reactor to form a white precipitate, and the amount of ammonium bicarbonate added is controlled so that the reaction system when the precipitation reaction is terminated The pH value of the solution is 9, the reaction temperature is 20-30°C, and the reaction is 4 minutes; a large amount of deionized water is quickly added to dil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com