Retarder for novel water-resistant quick-hardening inorganic cementing material and preparation method thereof

A technology of inorganic gelling materials and retarders, applied in the field of retarders and preparations for repair materials, which can solve problems such as unfavorable engineering applications, loss of excellent performance, and short setting time, so as to protect the environment and improve retarding stability , Prolonging the effect of retarding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

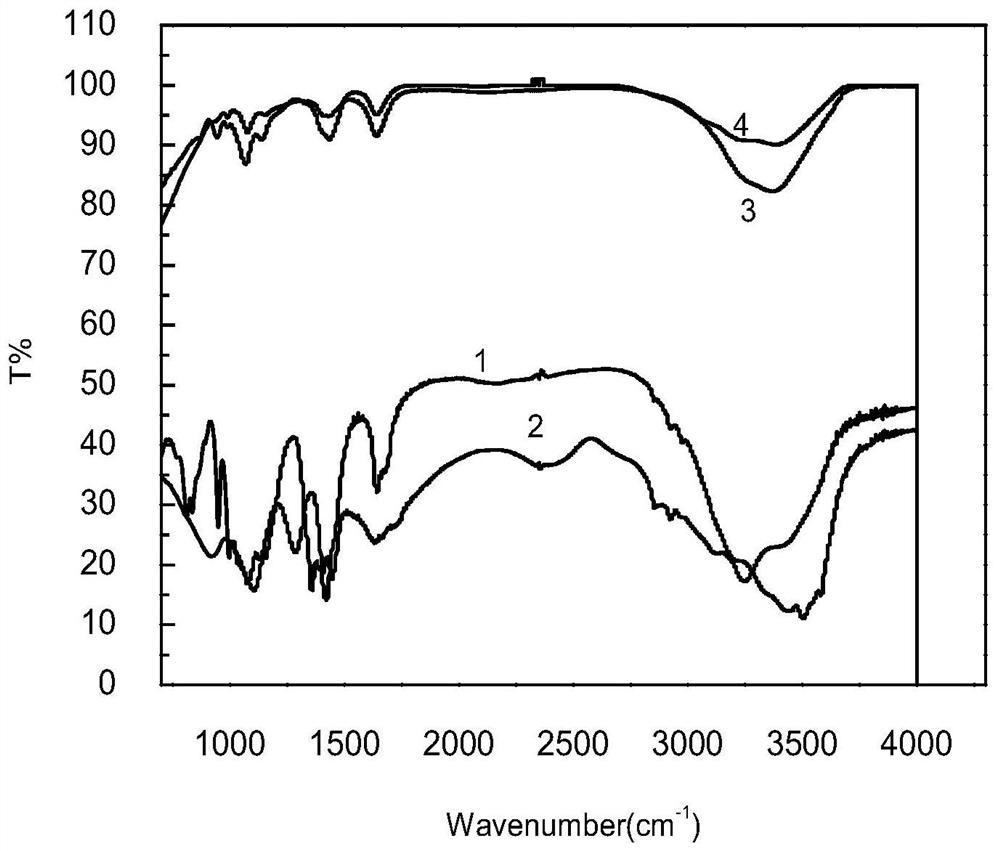

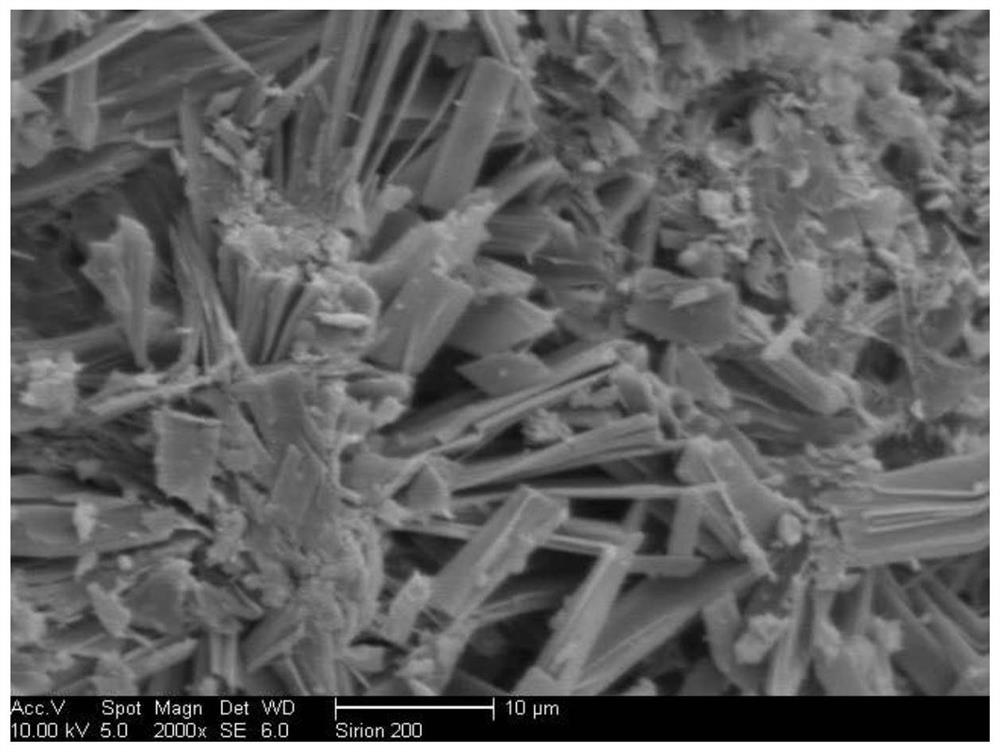

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of a novel water-resistant and fast-hardening inorganic gelling material refers to the Chinese patent document with the authorized announcement number CN104529378B, which specifically includes the following steps:

[0032] S1, weigh 30 parts of magnesium oxide, 50 parts of nano-silicon dioxide, 5 parts of sodium tetraborate powder, 5 parts of composite water reducing agent, 5 parts of potassium dihydrogen phosphate, and 5 parts of chloride-based early strength agent according to parts by weight. Put it into the cement slurry mixer and stir for 4 minutes to mix evenly;

[0033] S2. Add 10 parts of water to the cement slurry mixer and continue stirring for 18 seconds;

[0034] S3. Add 3 parts of polyvinyl alcohol water-based water repellent to the cement slurry mixer, and continue stirring for 22 seconds;

[0035] S4. Pour it into a mold and mold it for 28 minutes, then demould it to obtain a new type of water-resistant and fast-hardening inorganic g...

Embodiment 2

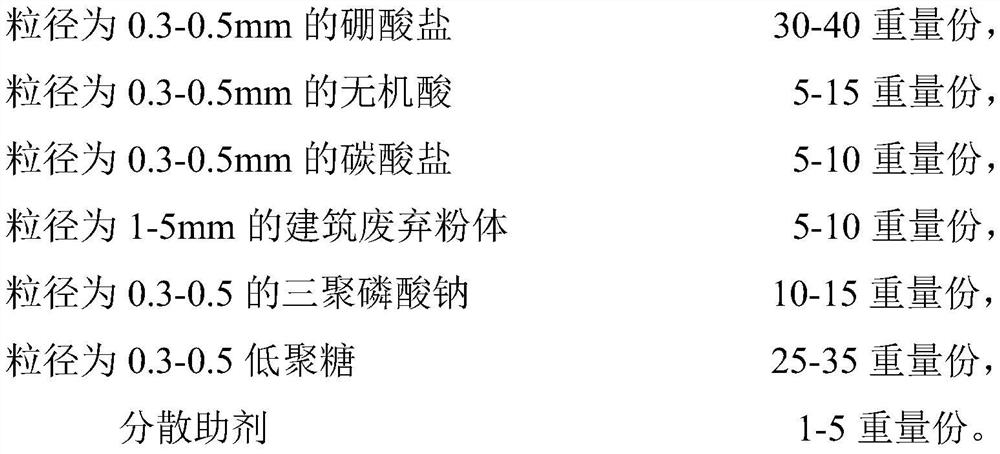

[0037] Step 1: Weigh and mix 30 parts of sodium tetraborate, 5 parts of phosphoric acid, 5 parts of potassium carbonate, and 10 parts of sodium tripolyphosphate according to parts by weight, stir at 100 r / min for 5 minutes and mix evenly to obtain mixture A;

[0038] Step 2, weigh and mix 25 parts of oligosaccharides, 35 parts of water, and 3 parts of dispersing aids according to parts by weight, and stir at 100 r / min for 10 minutes to mix evenly to obtain mixture B;

[0039] The mixture B was subjected to freeze-drying treatment, first dried at minus 45-60°C for 4 hours, and then hollow-dried for 8 hours to obtain oligosaccharide powder B with good dispersion and adsorption properties;

[0040] Step 3, mix the mixture powder A prepared in step 1, the oligosaccharide powder B prepared in step 2, and 5 parts of fly ash, and stir at 60r / min for 10min to mix evenly to obtain a slow Coagulant sample 1.

[0041] The retarder sample 1 that embodiment 2 makes, the novel water-resist...

Embodiment 3

[0043] Step 1: Weigh and mix 30 parts of sodium tetraborate, 5 parts of phosphoric acid, 5 parts of potassium carbonate, and 10 parts of sodium tripolyphosphate according to parts by weight, stir at 100 r / min for 5 minutes and mix evenly to obtain mixture A;

[0044] Step 2, weigh and mix 25 parts of oligosaccharides, 35 parts of water, and 3 parts of dispersing aids according to parts by weight, and stir at 100 r / min for 10 minutes to mix evenly to obtain mixture B;

[0045] The mixture B was subjected to freeze-drying treatment, first dried at minus 45-60°C for 4 hours, and then hollow-dried for 8 hours to obtain oligosaccharide powder B with good dispersion and adsorption properties;

[0046] Step 3, mix the mixture powder A prepared in step 1, the oligosaccharide powder B prepared in step 2, and 5 parts of lignin, and stir at 60 r / min for 10 minutes to mix evenly to obtain a retarder for inorganic repair materials Sample 2.

[0047] The prepared retarder sample 2 was added ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com