Multi-point injected ammonia water atomization reduction method for reducing NOx discharge of gas-fired boiler

A gas-fired boiler and ammonia water technology, which is applied in the field of gas-fired boiler NOx reduction, multi-point injection ammonia water atomization reduction to reduce nitrogen oxide emission, can solve the problems of short residence time, ammonia water escape, and ammonia water temperature being too targeted. The effect of reducing NOx generation and NOx emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

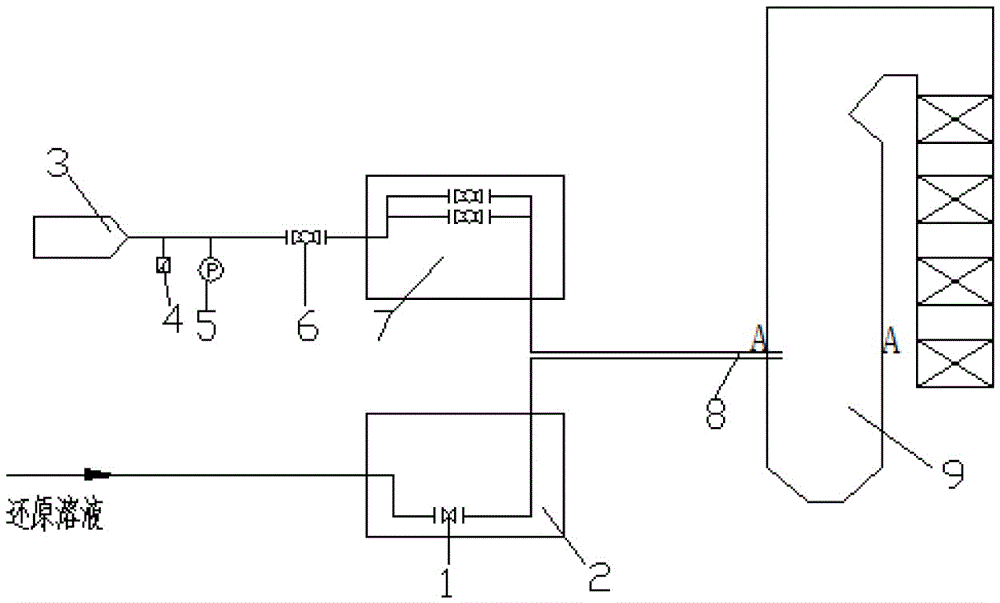

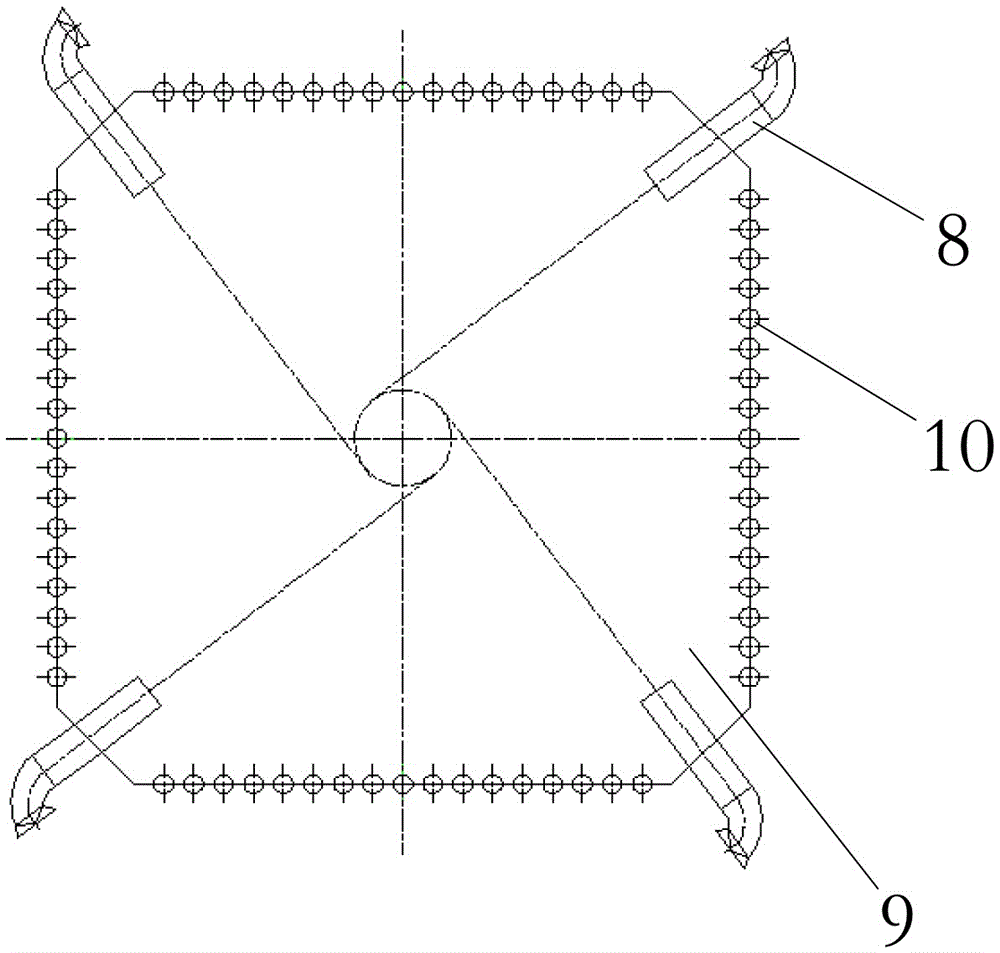

[0012] figure 1 It is a schematic structural diagram of the ammonia reduction system; figure 2 Schematic diagram of the structure of the multi-point injection system.

[0013] Such as figure 1 , shown in 2, a gas-fired boiler for reducing nitrogen oxide emissions by atomizing reduction of multi-point injection ammonia water, including compressed air system, ammonia water supply system and multi-point injection system, is characterized in that:

[0014] The compressed air system includes an air storage tank 3 , a flow control valve 4 , a pressure regulating valve 5 , an air solenoid valve 6 and a compressed air distribution chamber 7 connected successively by pipelines.

[0015] The ammonia water supply system is pipe-connected with the ammonia solution distribution chamber 2 by controlling the regulating valve 1;

[0016] The multi-point injection system includes a plurality of spray guns 8 symmetrically and evenly distributed around the inner water wall 10 of the furnace ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com