Green preparation of NiCo2S4@ACF electrode material

An electrode and composite material technology, used in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve problems such as difficult to degrade pollutants, and achieve the effect of improving performance and overcoming large energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

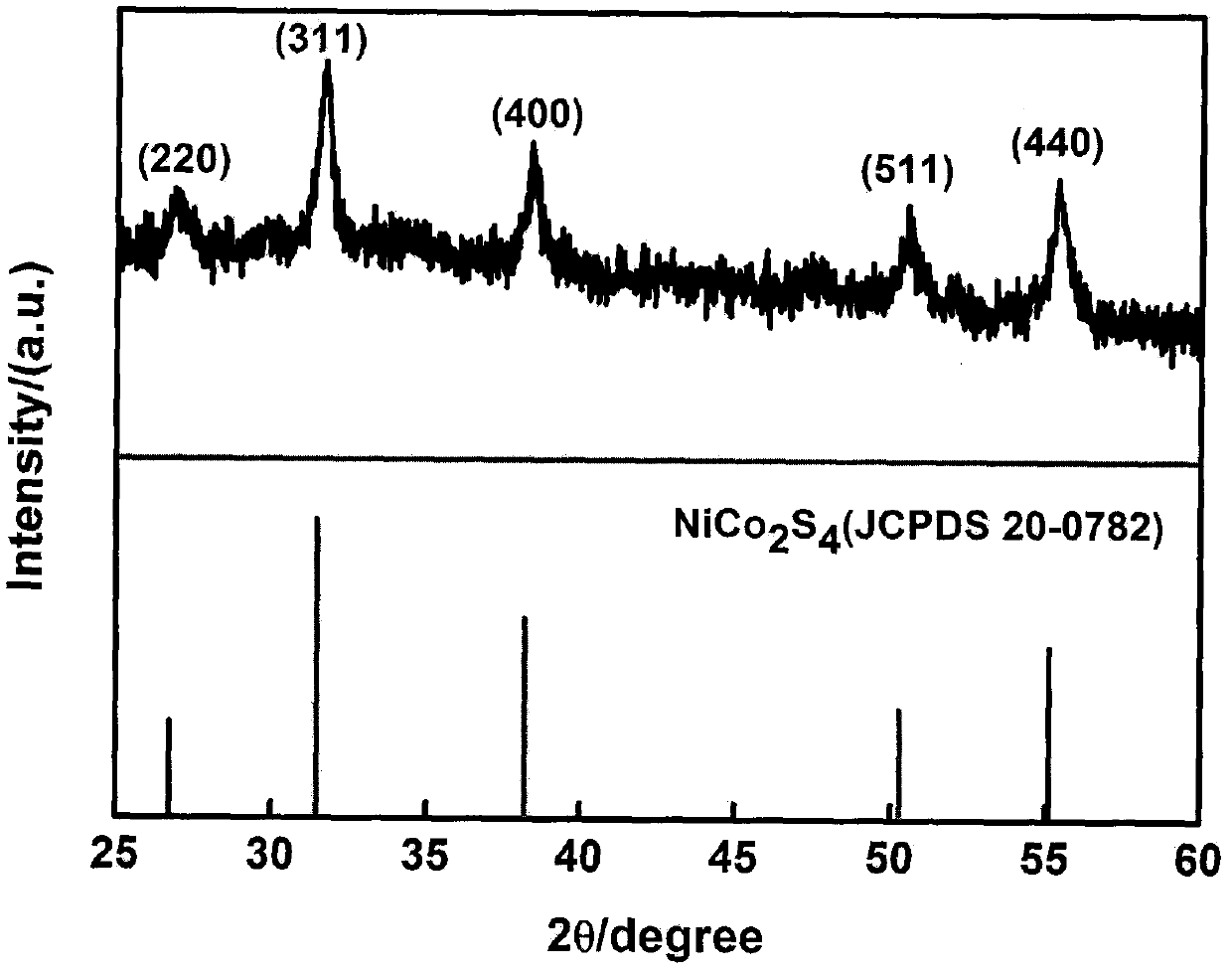

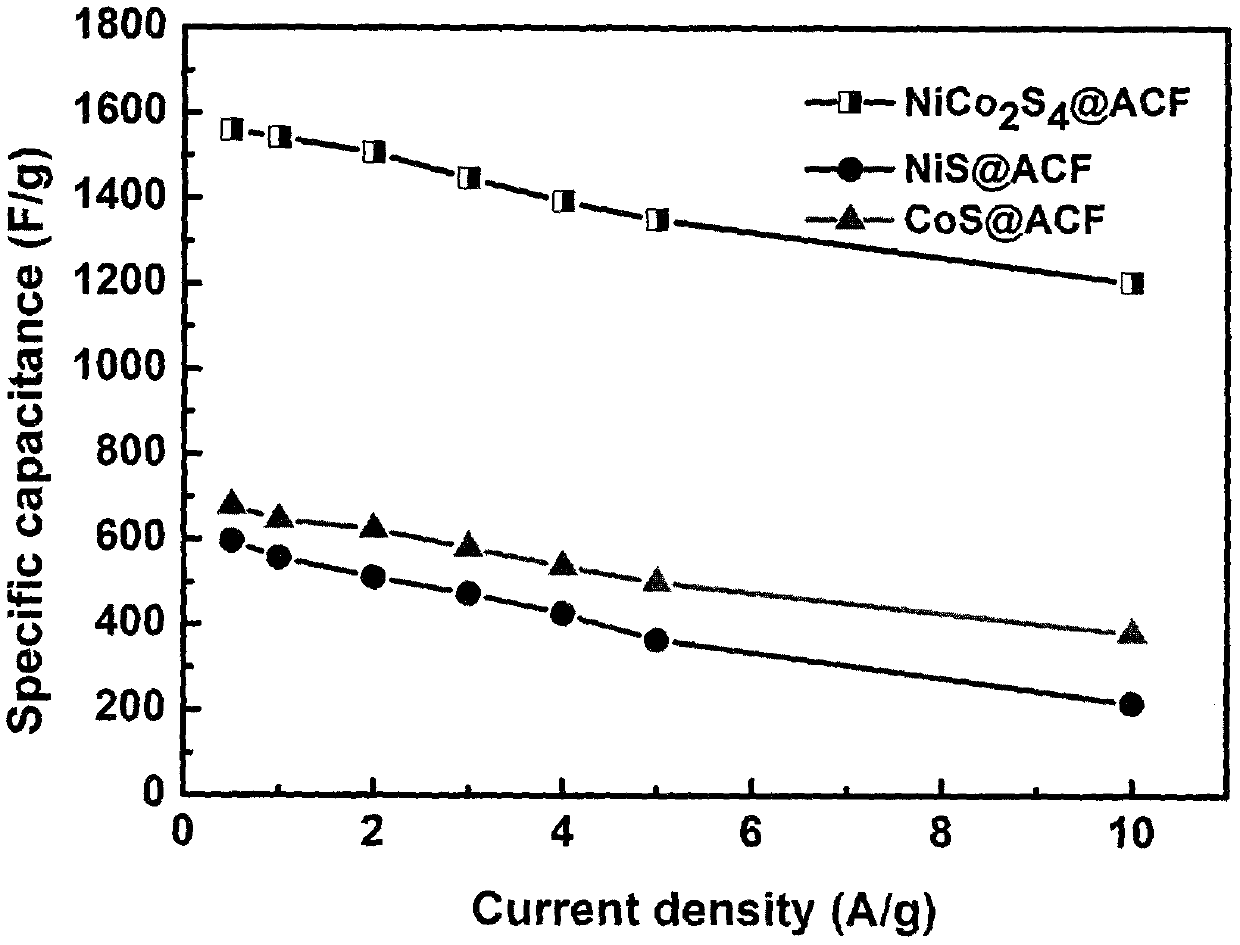

Image

Examples

Embodiment 1

[0017] A kind of NiCo for supercapacitor electrode 2 S 4 The preparation method of @ACF composite material comprises the following steps:

[0018] (1) Evenly distribute the ground ACF, nickel nitrate, and cobalt nitrate in a mixture of absolute ethanol and deionized water, and perform ultrasonic treatment to obtain solution A;

[0019] (2) Dissolving urea in deionized water and stirring for a certain period of time to obtain a homogeneous solution B;

[0020] (3) Slowly add solution A obtained in step (1) to solution B, and continue stirring to obtain a precursor solution;

[0021] (4) Transfer the precursor solution obtained in (3) into a hydrothermal reaction kettle with a suitable volume, heat it in an oven at 100°C, and keep the temperature at a constant temperature for 10 hours. Wash until colorless, and vacuum-dry to obtain a purple-red precursor;

[0022] (5) Put the precursor obtained in (4) in a certain concentration of Na 2 Soak in S solution at room temperature...

Embodiment 2

[0024] A kind of NiCo for supercapacitor electrode 2 S 4 The preparation method of @ACF composite material comprises the following steps:

[0025] (1) Evenly distribute the ground ACF, nickel nitrate, and cobalt nitrate in a mixture of absolute ethanol and deionized water, and perform ultrasonic treatment to obtain solution A;

[0026] (2) Dissolving urea in deionized water and stirring for a certain period of time to obtain a homogeneous solution B;

[0027] (3) Slowly add solution A obtained in step (1) to solution B, and continue stirring to obtain a precursor solution;

[0028] (4) Transfer the precursor liquid obtained in (3) into a hydrothermal reaction kettle with a suitable volume, heat it in an oven at 120°C, and keep the temperature at a constant temperature for 10 hours. Wash until colorless, and vacuum-dry to obtain a purple-red precursor;

[0029] (5) Put the precursor obtained in (4) in a certain concentration of Na 2 Soak in S solution at room temperature f...

Embodiment 3

[0031] A kind of NiCo for supercapacitor electrode 2 S 4 The preparation method of @ACF composite material comprises the following steps:

[0032] (1) Evenly distribute the ground ACF, nickel nitrate, and cobalt nitrate in a mixture of absolute ethanol and deionized water, and perform ultrasonic treatment to obtain solution A;

[0033] (2) Dissolving urea in deionized water and stirring for a certain period of time to obtain a homogeneous solution B;

[0034] (3) Slowly add solution A obtained in step (1) to solution B, and continue stirring to obtain a precursor solution;

[0035] (4) Transfer the precursor solution obtained in (3) into a hydrothermal reaction kettle with a suitable volume, heat it in an oven at 150°C, and keep the temperature constant for 10 hours. Wash until colorless, and vacuum-dry to obtain a purple-red precursor;

[0036] (5) Put the precursor obtained in (4) in a certain concentration of Na 2 In S solution, soak for 12 hours at room temperature, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com