Corrosion inhibitor for circulating cooling water with high chlorine ion content of 3000mg/L-100000mg/L

A technology of circulating cooling water and corrosion and scale inhibitors, which is applied in the field of corrosion and scale inhibitors, can solve problems such as no specific guidance plan, and achieve significant economic and social benefits, stable operation, and economical feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

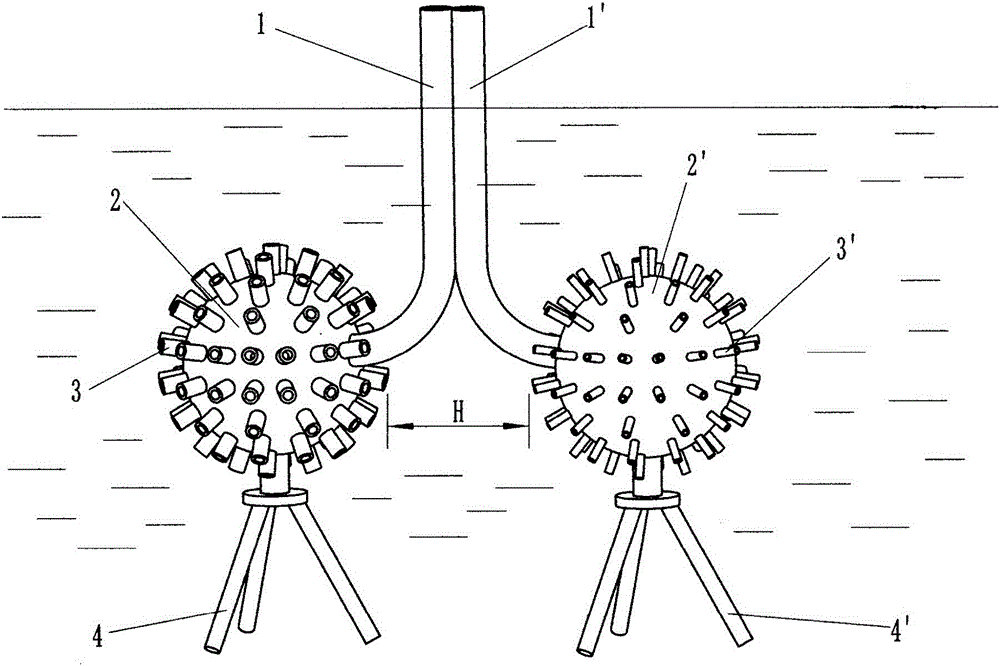

Image

Examples

Embodiment 1

[0022] Embodiment 1: the corrosion and scale inhibitor for circulating cooling water with high chloride ion content of the present invention comprises a liquid part and a solid part, wherein: based on the liquid part gross weight 100%, the weight percent of each component of the liquid part is: Hydroxyethylidene diphosphonic acid 18%, 2-phosphonic acid butane-1,2,4-tricarboxylic acid (PBTCA) 12%, N-containing polycarboxylic acid NDA (polyacrylamide) 10%, polycyclic Sodium oxysuccinate (PESA) 16%, the balance is water. Based on 100% of the total weight of the solid part, the weight percentages of the components of the solid part are: 22% of tannin extract, 21% of fulvic acid, 2% of sodium hydroxide, and the balance is sodium salt; the sodium salt is sodium carbonate Combination with trisodium phosphate, the weight ratio of sodium carbonate and trisodium phosphate is 1:0.5.

[0023] The preparation method of the above-mentioned liquid part (composite preparation) is that water,...

Embodiment 2

[0026] Embodiment 2: the corrosion and scale inhibitor for circulating cooling water with high chloride ion content of the present invention includes a liquid part and a solid part, wherein: based on the total weight of the liquid part 100%, the weight percentage of each component of the liquid part is: Diethylenetriaminepentamethylenephosphonic acid (DTMPPA) 20%, N-containing polycarboxylic acid (NDA) 25%, phosphinesulfonic acid 18%, the balance is water; based on the total weight of the solid part 100%, the solid The percentages by weight of some components are: 15% of tannin extract, 26% of fulvic acid, 1% of sodium hydroxide, and the balance is sodium salt; the sodium salt is a combination of sodium tripolyphosphate and sodium nitrite, sodium tripolyphosphate The weight ratio with sodium nitrite is 1:0.5.

[0027] The preparation method of above-mentioned liquid part (composite preparation) is, water, diethylene triamine pentamethylene phosphonic acid, polycarboxylic acid ...

Embodiment 3

[0030] Embodiment 3: The corrosion and scale inhibitor for circulating cooling water with high chloride ion content of the present invention includes a liquid part and a solid part, wherein: based on the total weight of the liquid part 100%, the weight percentage of each component of the liquid part is: Polyaminopolyether-based methylene phosphonic acid (PAPEMP) 10%, organic carboxylic acid 20%, polyepoxysodium sodium (PESA) 15%, the balance is water; organic carboxylic acid is phosphinohydrolyzed polymaleic anhydride (PPMA) and N-containing polycarboxylic acid (NDA), the weight ratio of phosphine-based hydrolyzed polymaleic anhydride (PPMA) and N-containing polycarboxylic acid (NDA) is 1:0.5; Based on 100% of the total weight, the weight percentages of the components in the solid part are: 15% of tannin extract, 25% of fulvic acid, 0.5% of sodium hydroxide, and the balance is sodium salt; the sodium salt is sodium carbonate, triphosphate The combination of sodium, the weight ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com