Flotation enriching method for willemite

A zinc silicate and flotation technology, which is applied in flotation, solid separation, etc., can solve the problems of low flotation index, complex process structure, high production cost, etc., and achieve low chemical consumption, simple process structure, and low energy consumption. little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The first example of the flotation enrichment method of zinc silicate ore of the present invention comprises the steps:

[0020] 1. Mineral raw materials:

[0021] The zinc content in the ore used is 8.78%, and the silicon content is 15.61%. Phase analysis shows that zinc mainly exists in the form of zinc silicate ore, and gangue minerals mainly exist in the form of carbonate and silica minerals.

[0022] 2. Flotation agents and operating conditions:

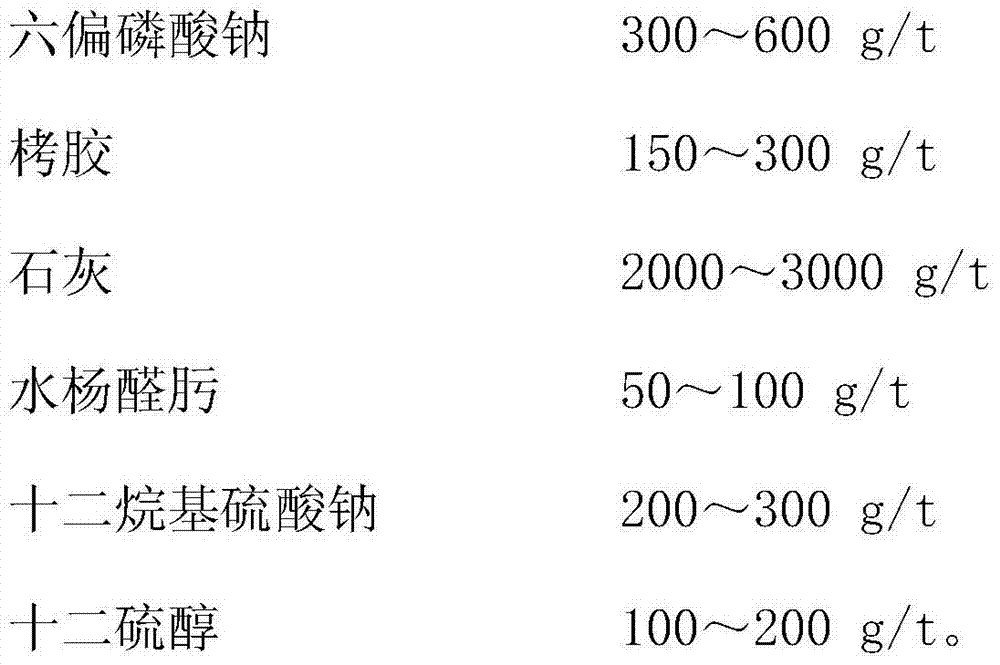

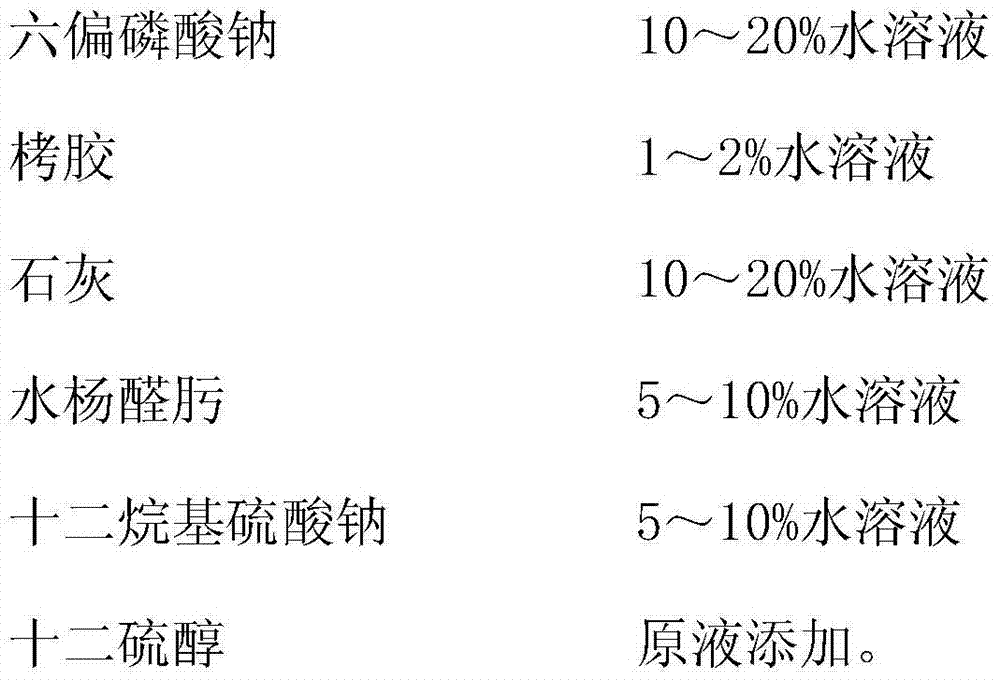

[0023]

[0024] During the flotation process, add sodium hexametaphosphate and tannin extract to the ore mill to grind the ore until the mineral monomers are dissociated, then use sodium hydroxide to adjust the pH value of the pulp to 10-11, and then add lauryl sulfuric acid Sodium and dodecylmercaptan are used for flotation, and the flotation foam is zinc silicate concentrate. According to the above medicament parameters, one roughing, four times sweeping and three times beneficiation were used to carry out the test...

Embodiment 2

[0026] The second example of the flotation enrichment method of zinc silicate ore of the present invention comprises the steps:

[0027] 1. Mineral raw materials:

[0028] The zinc content in the ore used is 11.23%, and the silicon content is 18.90%. Phase analysis shows that zinc mainly exists in the form of zinc silicate ore, and gangue minerals mainly exist in the form of carbonate and silica minerals.

[0029] 2. Flotation agents and operating conditions:

[0030]

[0031] During the flotation process, add sodium hexametaphosphate and tannin extract to the ore mill to grind the ore until the mineral monomers are dissociated, then use sodium hydroxide to adjust the pH value of the pulp to 10-11, and then add lauryl sulfuric acid Sodium and dodecylmercaptan are used for flotation, and the flotation foam is zinc silicate concentrate. According to the above medicament parameters, one roughing, four times sweeping and three times beneficiation were used to carry out the te...

Embodiment 3

[0033] The third example of the flotation enrichment method of zinc silicate ore of the present invention comprises the steps:

[0034] 1. Mineral raw materials:

[0035] The zinc content in the ore used is 15.66%, and the silicon content is 25.95%. Phase analysis shows that zinc mainly exists in the form of zinc silicate ore, and gangue minerals mainly exist in the form of carbonate and silica minerals.

[0036] 2. Flotation agents and operating conditions:

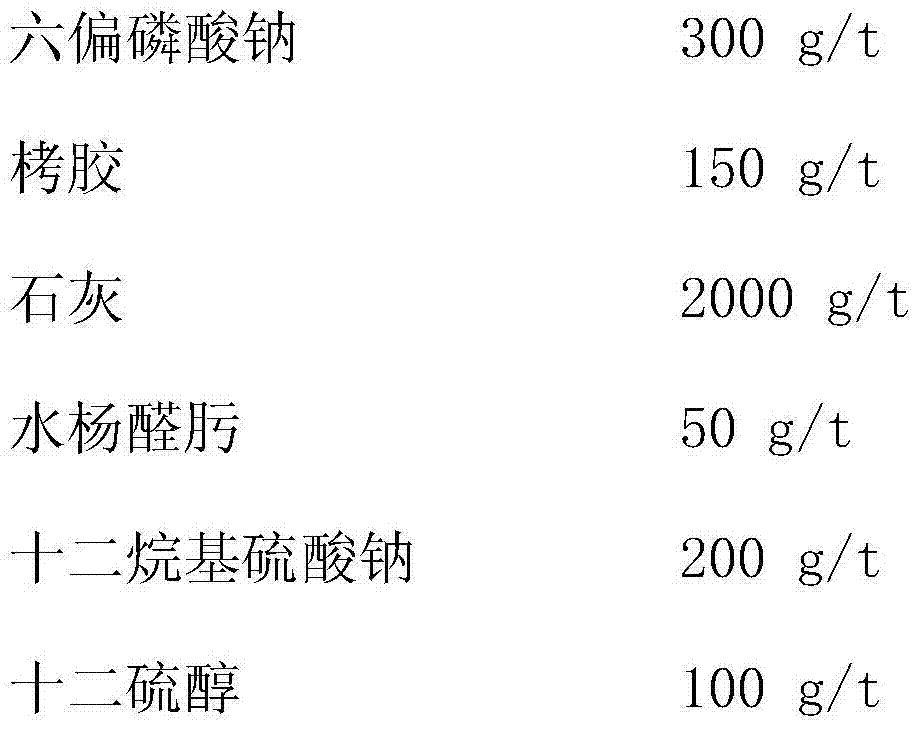

[0037]

[0038]

[0039] During the flotation process, add sodium hexametaphosphate and tannin extract to the ore mill to grind the ore until the mineral monomers are dissociated, then use sodium hydroxide to adjust the pH value of the pulp to 10-11, and then add lauryl sulfuric acid Sodium and dodecylmercaptan are used for flotation, and the flotation foam is zinc silicate concentrate. According to the above medicament parameters, one roughing, four times sweeping and three times beneficiation were used to test ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com