Beneficiation method for arsenic-containing lead sulfide ore

A mineral processing method and lead sulfide technology, applied in flotation, solid separation, etc., can solve problems such as the dissociation of galena and arsenopyrite, the quality of lead concentrate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

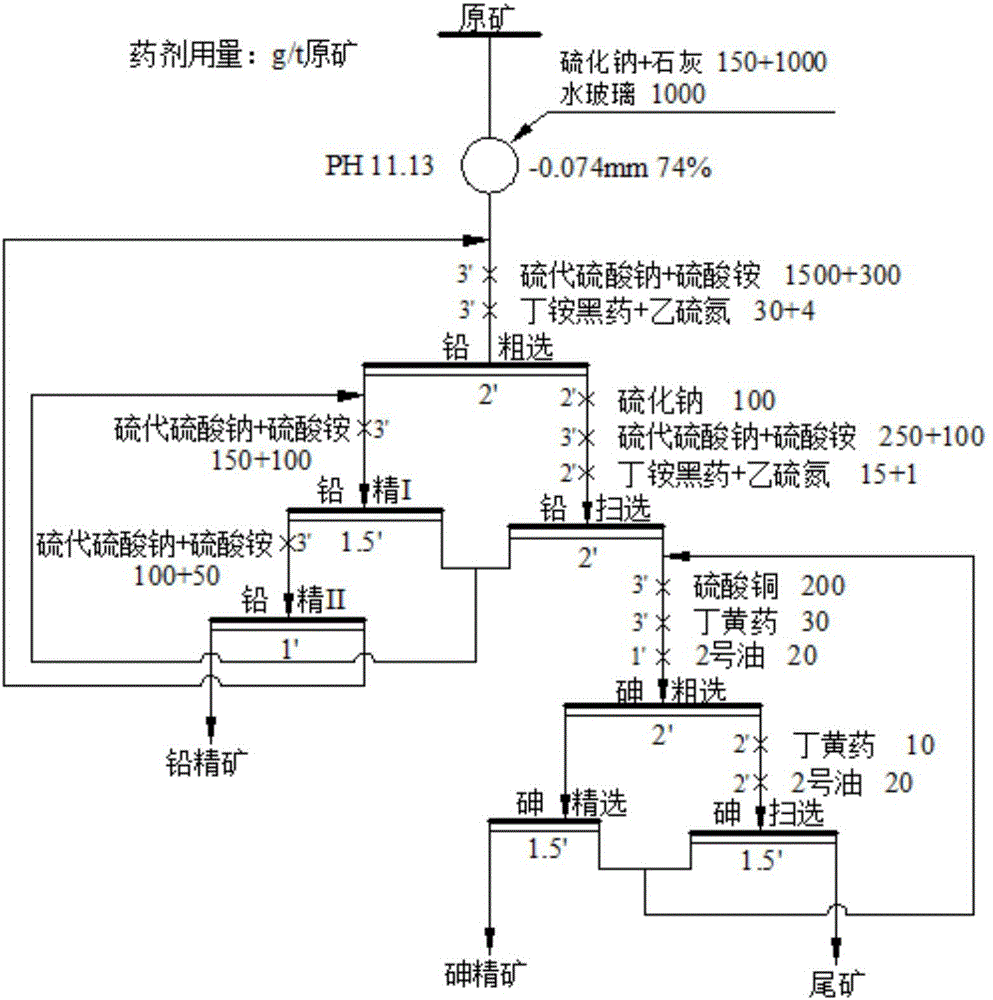

[0021] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

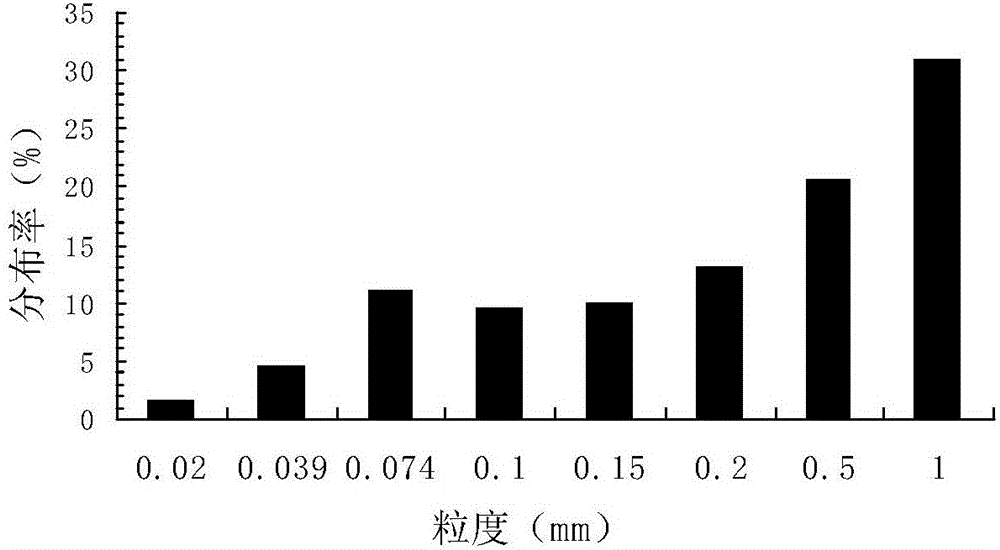

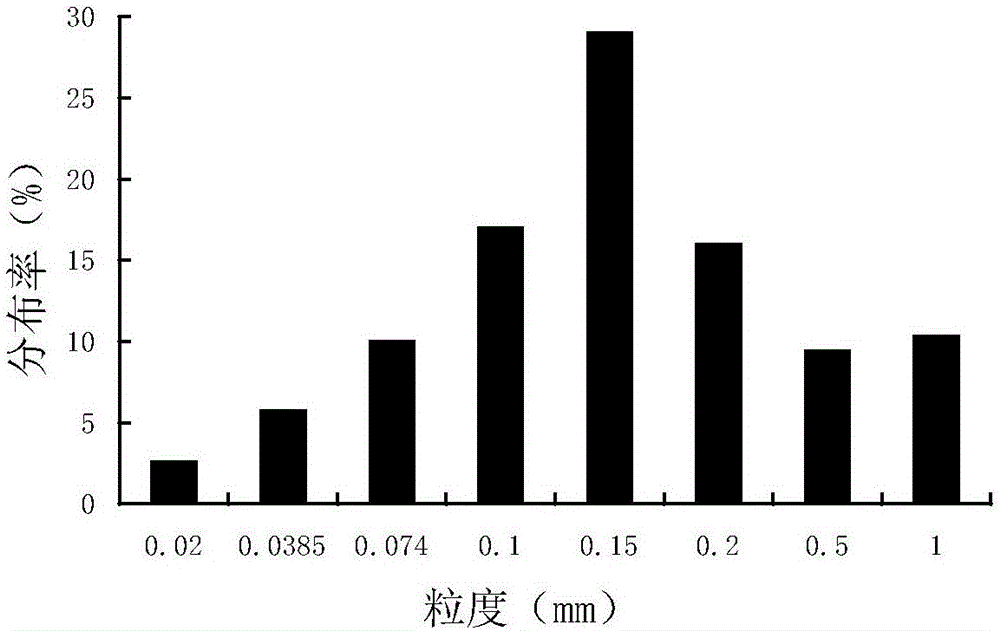

[0022] After the raw ore sample is obtained, the ore material composition analysis is carried out, including the following contents:

[0023] 1. Chemical analysis of raw ore

[0024] The chemical analysis results of raw ore are shown in Table 1

[0025] Table 1 Chemical analysis results of raw ore

[0026] element Pb Zn S As Sb Bi Cu TC content / % 2.52 0.12 1.25 0.38 0.0050 0.0025 0.065 0.11 element K 2 o

Na 2 o

CaO MgO Al 2 o 3

SiO 2

P CaF 2

content / % 3.82 0.21 0.93 0.21 12.46 65.50 0.021 0.11 element Hg Mo co WO 3

Ni sn Cd Ga content / % 0.0082 0.0023 0.0009 0.0016 0.0007 0.0024 element Te Se Th U In Tl Au*10 -6

Ag*10 -6

Content / 10 -6

0.18 43.0

[0027] The che...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com