Repair and maintenance type charging method of lead-acid storage battery

A lead-acid battery and battery technology, applied in secondary battery repair/maintenance, secondary battery charging/discharging, etc., can solve the problems of shortening battery life, failing to reach the rated capacity of the battery, and long charging time of lead-acid batteries, etc. problem, achieve the effect of shortening charging or repairing time, eliminating electrochemical polarization, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment one: the repair of lead-acid storage battery

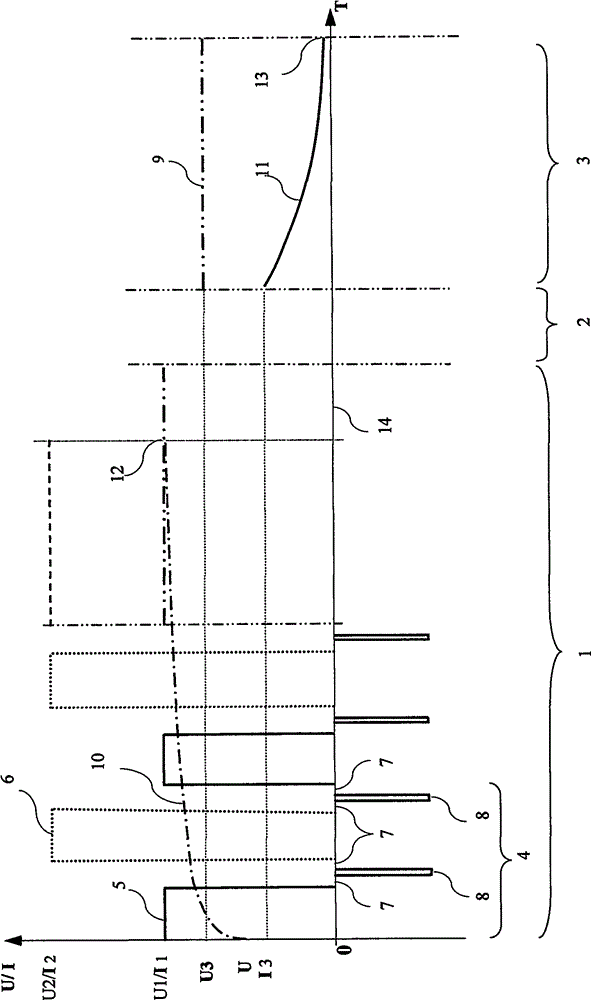

[0034] Such as figure 1 As shown, this example uses a battery repair machine to repair a group of 48V, 400AH 50% new lead-acid batteries that have been used for ten years, and provides a method for repairing lead-acid batteries, including the following steps:

[0035] Step 1, use the battery repair machine to carry out constant current, pause, discharge, pause, frequency sweep pulse, pause, discharge, pause in parallel and repeat the work process of a continuous output as a working cycle for the lead-acid battery; that is, the first Working phase 1 is the working phase of constant current and pressure limitation;

[0036] Step 2, the process of stabilizing the battery at rest; the second working stage 2 in the figure is the stable working stage of the battery;

[0037] Step 3: The repair machine supplements the charging process of the battery until the lead-acid battery obtains the rated capacity of saturation,...

Embodiment 2

[0051] Embodiment 2: maintenance charging of lead-acid battery

[0052] In this example, a group of 48V, 270AH 70% new lead-acid batteries that have been used for five years are discharged for 3.5 hours after being fully charged with the original matching charger. Charge. After maintenance-style charging, use a discharge machine to conduct a discharge test. Set the discharge parameters of the discharge machine as: stop voltage 40.8V, discharge current 54A. The result: the discharge time is 4.7 hours, and the battery capacity saturation this time is 94 %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com