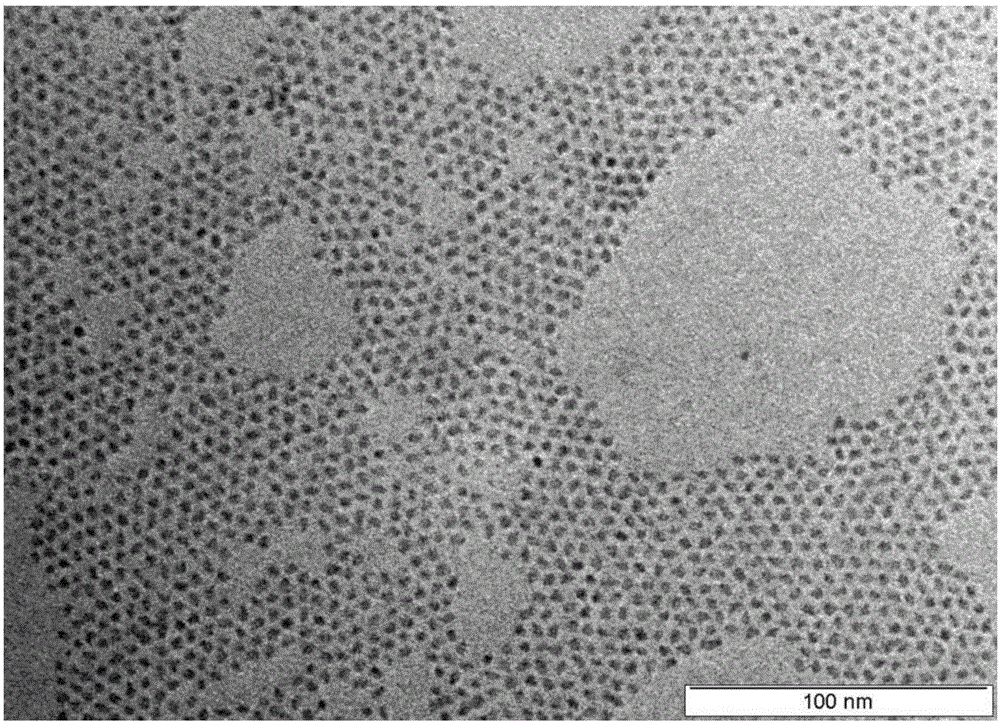

Preparation method of monodisperse PbS quantum dot

A technology of lead sulfide and quantum dots, applied in chemical instruments and methods, luminescent materials, etc., can solve problems such as difficulties in large-scale production, high cost of sulfur sources, and easy volatility, and achieve low cost of equipment and raw materials, low cost, and easy operation. The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation method of monodisperse lead sulfide quantum dots, comprising the steps of:

[0026] S1. Mix 0.834g (0.003mol) of lead chloride with 10mL of oleylamine, heat to 100°C and stir for 30 minutes to obtain a lead precursor. The concentration of lead in the lead precursor is about 0.3mol / L, and then cool down to 20°C ,spare;

[0027] S2. Stir 0.075g (0.001mol) thioacetamide and 2mL oleylamine at 20°C for 20min to form a sulfur precursor, the concentration of sulfur in the sulfur precursor is about 0.5mol / L;

[0028] S3. At a temperature of 20°C, mix the lead precursor in S1 and the sulfur precursor in S2 and stir rapidly (wherein the molar ratio of lead to sulfur is 3:1), the stirring speed can be selected according to experience, for example, it can be selected as 100-500r / min, then heated to 70°C and kept for 15min;

[0029] S4. Cool the solution after the heat preservation in S3 to 20° C., inject 8 mL of oleic acid to remove the residual lead precursor;

[...

Embodiment 2

[0037] A preparation method of monodisperse lead sulfide quantum dots, comprising the steps of:

[0038] S1. Mix 1.391g (0.005mol) of lead chloride with 10mL of oleylamine, heat to 140°C and stir for 40min to obtain a lead precursor, the concentration of lead in the lead precursor is about 0.5mol / L, and then cool down to 28°C ,spare;

[0039] S2. Stir 0.075g (0.001mol) thioacetamide and 20mL oleylamine at 28°C for 20min to form a sulfur precursor, the concentration of sulfur in the sulfur precursor is about 0.05mol / L;

[0040] S3. At a temperature of 28°C, mix the lead precursor in S1 and the sulfur precursor in S2 and stir rapidly (the molar ratio of lead to sulfur is 5:1), then heat to 90°C and keep it warm for 120min;

[0041] S4. Cool the solution after the heat preservation in S3 to 28° C., and inject 25 mL of oleic acid to remove the residual lead precursor;

[0042] S5. Add n-hexane and ethanol and centrifuge to obtain lead sulfide quantum dots coated with oleic acid ...

Embodiment 3

[0045] A preparation method of monodisperse lead sulfide quantum dots, comprising the steps of:

[0046] S1. Mix 0.734g (0.002mol) of lead bromide with 10mL of oleylamine, heat to 190°C and stir for 20min to obtain a lead precursor, the concentration of lead in the lead precursor is about 0.2mol / L, and then cool down to 35°C ,spare;

[0047] S2. Stir 0.075g (0.001mol) thioacetamide and 1mL oleylamine at a temperature of 35°C for 20min to form a sulfur precursor, the concentration of sulfur in the sulfur precursor is about 1mol / L;

[0048] S3. At a temperature of 20°C, mix the lead precursor in S1 and the sulfur precursor in S2 and stir rapidly (the molar ratio of lead to sulfur is 2:1), then heat to 60°C and keep it warm for 25min;

[0049]S4. Cool the solution after the heat preservation in S3 to 35° C., inject 4 mL of oleic acid to remove the residual lead precursor;

[0050] S5. Add n-hexane and ethanol and centrifuge to obtain lead sulfide quantum dots coated with oleic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com