Preparation method of EVA/lead sulfide quantum dot composite packaging adhesive film material with light converting function

A technology for encapsulating film and quantum dots, which is applied in the field of photofunctional materials for solar cells, can solve the problems of short lifespan of rare earth organic complexes, and achieve excellent light conversion and long lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In parts by weight, 5 parts of lead sulfide quantum dots and 0.05 part of silane coupling agent were added to 100 parts of acetone, and ultrasonicated for 10 minutes, as the lead sulfide quantum dot suspension A for later use.

[0030] 100 parts of EVA (VA content of 24%wt), 0.2 parts of dioxane peroxide, 0.3 parts of 2,4-dihydroxybenzophenone, 1 part of N, N'-bis[3-(3,5-bis tert-butyl-4-hydroxyphenyl)propionyl]hydrazine, 2 parts of dilauryl thiodipropionate, 0.1 part of white wax oil and 20 parts of the above suspension A, put into a high-speed mixer and mix evenly, and then mix at 80°C Mix evenly in an open mill to obtain an EVA / lead sulfide quantum dot composite packaging film material with light conversion function, the light transmittance in the visible light range is ≥ 70%, and the light conversion range is 400-600nm.

Embodiment 2

[0032]In 100 parts of tetrahydrofuran, add 20 parts of lead sulfide quantum dots, 2 parts of titanate coupling agent, ultrasonic for 120 minutes, as lead sulfide quantum dot suspension A for later use.

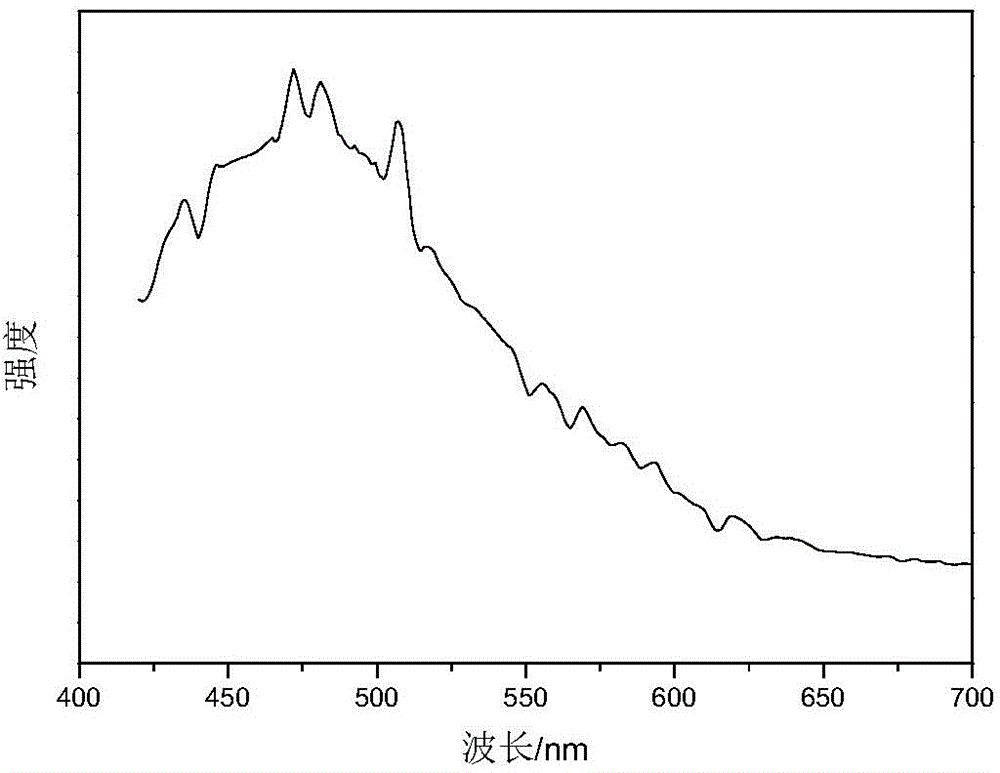

[0033] 100 parts of EVA (VA content is 28%wt), 0.5 parts of benzoyl peroxide, 2 parts of isooctyl peroxide tert-butyl ester, 0.3 parts of bis(2,2,6,6-tetramethyl-4- Piperidyl) sebacate, 2.5 parts of 2-phenylbenzimidazole-5-sulfonic acid, 1 part of pentaerythritol bisphosphite (2,4-di-tert-butylphenyl) ester, 0.5 parts of 2,2 '-Methylenebis(4-methyl-6-tert-butylphenol), 10 parts of citric acid ester and 10 parts of the above suspension A, put into a high-speed mixer and mix evenly, and then mix evenly in a 100°C internal mixer , that is, an EVA / lead sulfide quantum dot composite packaging film material with the function of light conversion is obtained, and the light transmittance in the visible light range is ≥73%; figure 1 It is the emission spectrum of the EVA / lead sulfide q...

Embodiment 3

[0035] In 100 parts of cyclohexane, add 10 parts of lead sulfide quantum dots, 0.5 parts of aluminate coupling agent, ultrasonic for 180 minutes, and use it as lead sulfide quantum dot suspension A for later use.

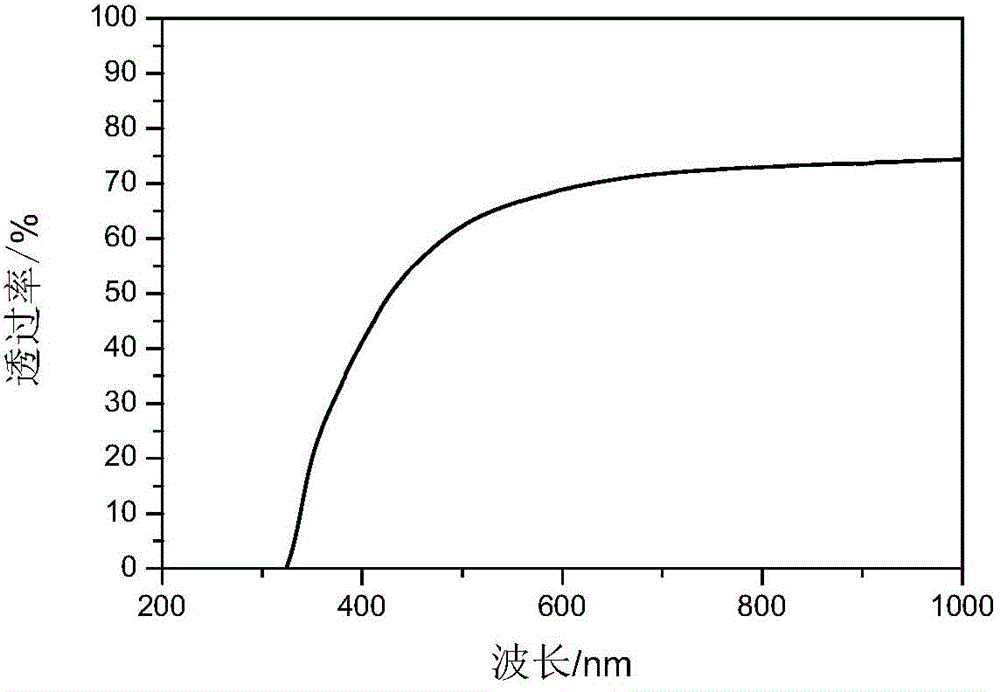

[0036] 100 parts of EVA (VA content is 40%), 5 parts of dicumyl peroxide, 5 parts of 2-(2'-hydroxy-3', 5'-dipentylphenyl) benzotriazole, 0.1 parts Put 2,6-di-tert-butyl-4-methylphenol, 15 parts of stearic acid and 1 part of the above suspension A into a high-speed mixer and mix them uniformly, and then mix them uniformly in an extruder at 130°C to obtain a EVA / lead sulfide quantum dot composite packaging film material with light conversion function, the light conversion range is 400-600nm; figure 2 It is the ultraviolet-visible spectrogram of the EVA / lead sulfide quantum dot composite encapsulation adhesive film material with the light conversion function of embodiment 3, by figure 2 It can be seen that the light transmittance of the packaging film in visible lig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com