A kind of ultraviolet curing adhesive with light conversion function and preparation method thereof

A technology of ultraviolet light and curing glue, which is applied in the direction of non-polymer organic compound adhesives, adhesives, adhesive additives, etc., and can solve problems such as many operating steps, environmental pollution, and complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

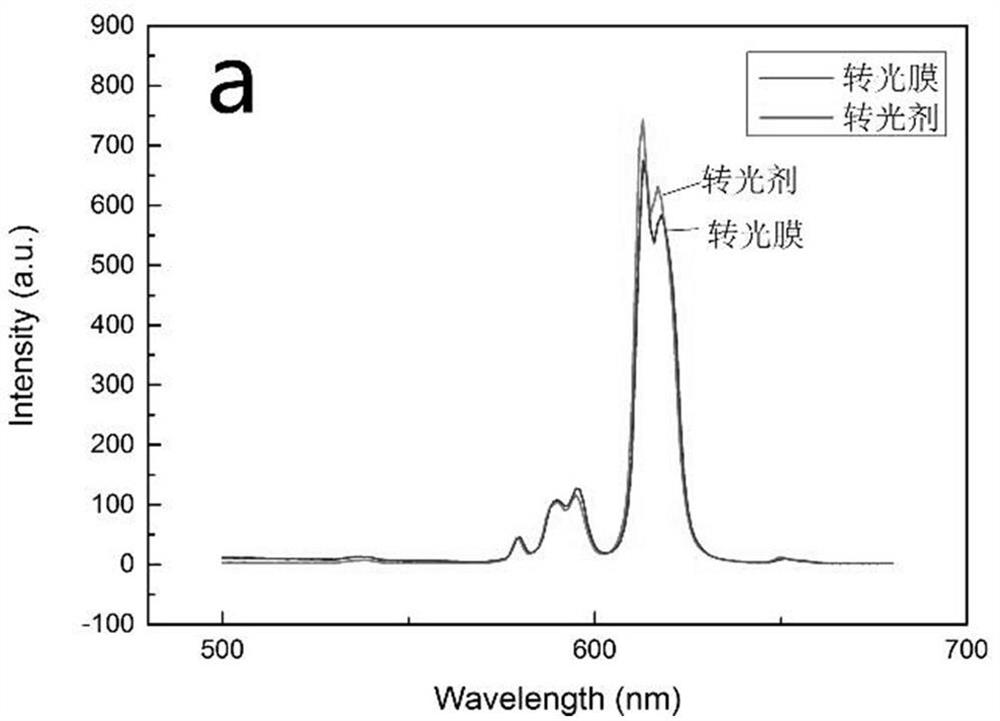

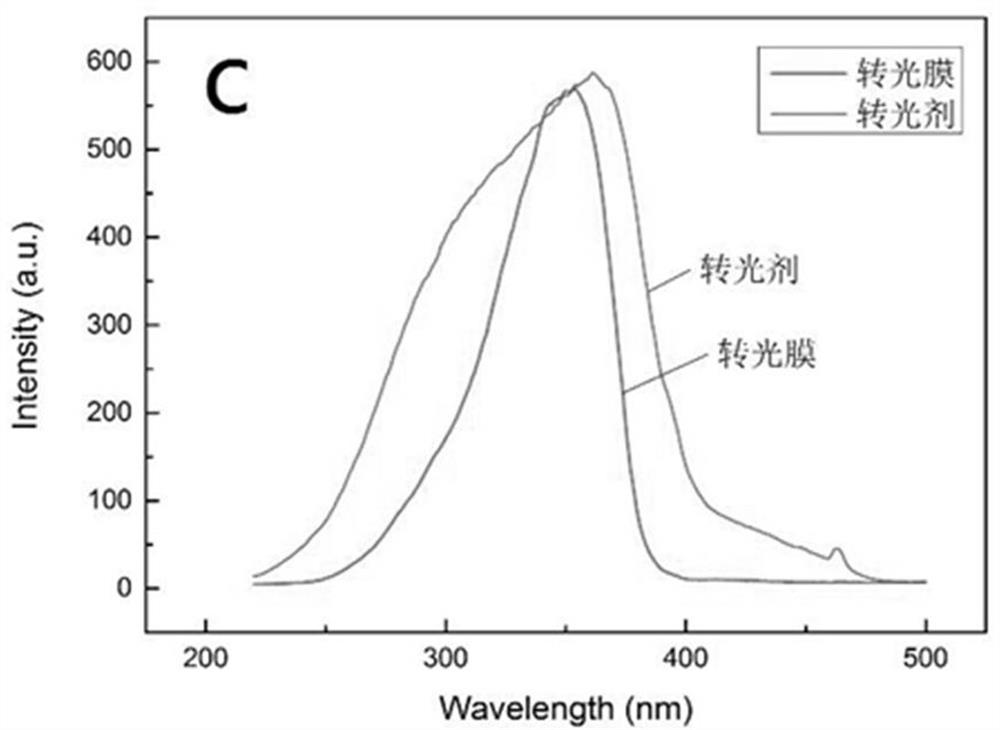

Image

Examples

Embodiment 1

[0039] A method for preparing a light-converting thin film, comprising the following steps:

[0040](1) Weigh 6.95 g of trimethylolpropane (monomer A) and 13.9 g of trimethylolpropane triacrylate (monomer B) into a 100 ml container, and then add 0.125 g of 2 μm light conversion agent CaMoO 4 : Eu 3+ , disperse intermittently on a high-speed disperser for 60 s to crush and disperse the light transfer agent evenly to obtain a suspension;

[0041] (2) Add 0.125 g photoinitiator TPO, 3.75 g diluent isobornyl acrylate, 0.05 g defoamer JY-821 and 0.10 g antioxidant 1726 to the above suspension in sequence, and use magnetic stirring under light-shielding conditions Stirring on the mixer for 20 minutes to obtain UV curable adhesive A with light conversion function.

[0042] (3) Spray the UV-curable adhesive A sample on the PVC sheet with a sprayer to form a light-transfer coating about 100 μm thick;

[0043] (4) Expose the light-converting coating prepared in step (3) to an ultra...

Embodiment 2

[0046] A method for preparing a light-converting thin film, comprising the following steps:

[0047] (1) Weigh 6.95g of pentaerythritol tetrakis(3-mercaptopropionate) (monomer A) and 13.9g of 1,3,5-tri-2-propenyl-1,3,5-triazine-2, 4, 6(1H, 3H, 5H)-triketone (monomer B), put it into a 100ml container, and then add 0.125g of Y with an average particle size of about 2μm 2 o 3 : 0.1Eu 2+ The light-changing agent is intermittently dispersed on a high-speed disperser for 60 s, so that the light-changing agent is crushed and dispersed evenly to obtain a suspension;

[0048] (2) Add 0.125 g photoinitiator TPO, 3.75 g diluent butyl acrylate, 0.05 g defoamer JY-821 and 0.10 g antioxidant 1726 to the above suspension in sequence, and use a magnetic stirrer under shading conditions Stir for 20 min to obtain UV-curable adhesive B with light conversion function.

[0049] (3) Spray the UV-curable adhesive B sample on the PP sheet with a sprayer to form a light-transfer coating about 100 ...

Embodiment 3

[0055] A method for preparing a light-converting thin film, comprising the following steps:

[0056] (1) Weigh 4.17 g of pentaerythritol tetrakis (3-mercaptopropionate) ester (monomer A) and 16.68 g of allyl vinyl ester (monomer B) respectively, put them into a 100ml container, and then add 0.125g of average particle size About 2μm CaS: 0.01Eu 2+ , 0.01Cu + The light-changing agent is intermittently dispersed on a high-speed disperser for 60 s, so that the light-changing agent is crushed and dispersed evenly to obtain a suspension;

[0057] (2) Add 0.125 g photoinitiator 184, 3.75 g diluent isooctyl acrylate, 0.05 g defoamer JY-821 and 0.10 g antioxidant 1010 to the above suspension in sequence, and use magnetic stirring under light-shielding conditions Stirring on the mixer for 20 min, the UV curable adhesive C with light conversion function was obtained.

[0058] (3) Coat the sample of UV-curable adhesive C on the PE film using a coating machine to form a light-converting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com