Cyanide-free and chromium-free copper lead flotation separation method

A separation method, copper and lead separation technology, applied in the field of smelting, can solve the problems of dichromate ions are difficult to handle, cyanide is highly toxic, environmental pollution, etc., to improve the degree of monomer dissociation, clean the surface, and good separation environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

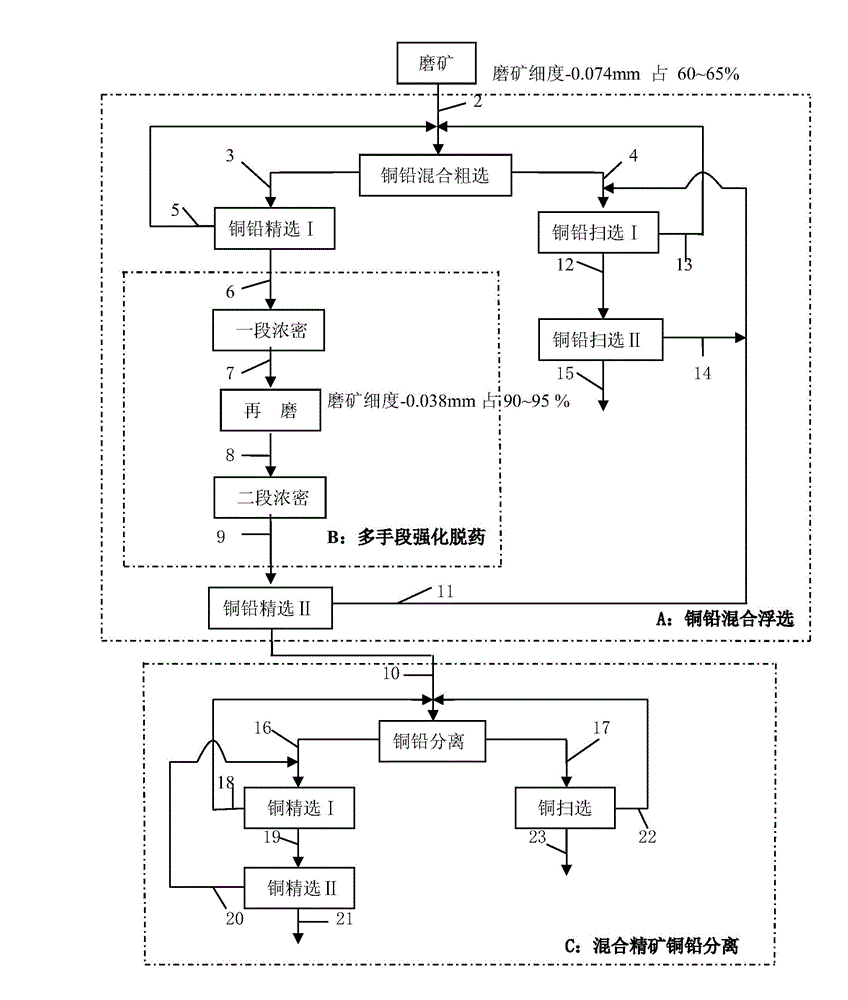

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0015] The detailed technological process of the present invention is: firstly, the crushed raw ore (1) and water are added into a ball mill at a ratio of 1:1 for grinding, until the grinding fineness of the ball mill discharge reaches -0.074mm, accounting for 60-65% . Ball mill discharge (2) Add lime in an amount of 1000-1500g / t (based on the weight of raw ore dry ore, the same below), adjust the pH value of the ore slurry to 9-10, and then add collectors in an amount of 80-100g / t , the dosage of Z-200 is 20-30g / t and the dosage of foaming agent terpineol oil is 5-10g / t for copper-lead mixed roughing; Roughing tailings (4) add collector 20-30g / t and Z-200 10-15g / t to carry out copper-lead scavenging I; copper-lead concentration I tailings (5) return to copper Lead mixed roughing, copper and lead concentration I concentrate (6) is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com