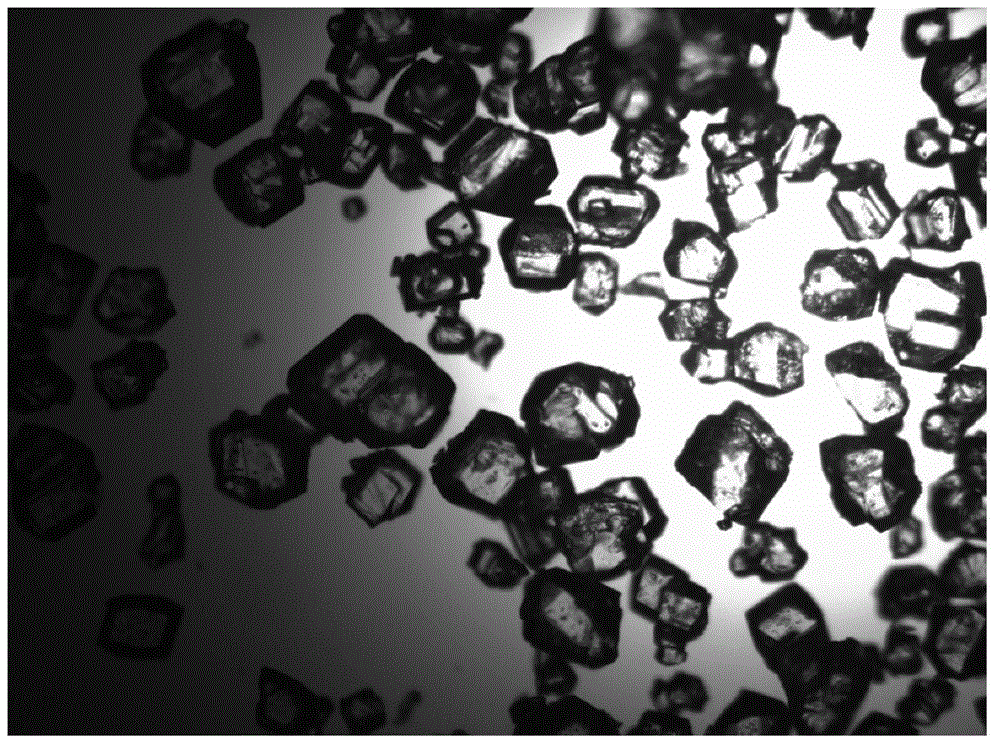

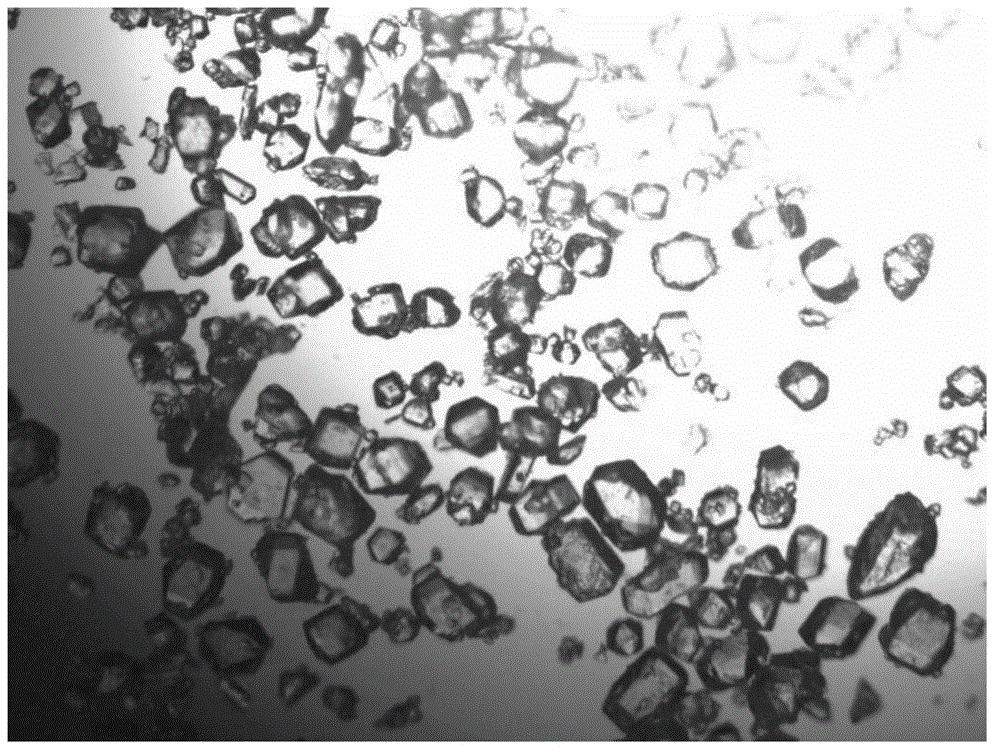

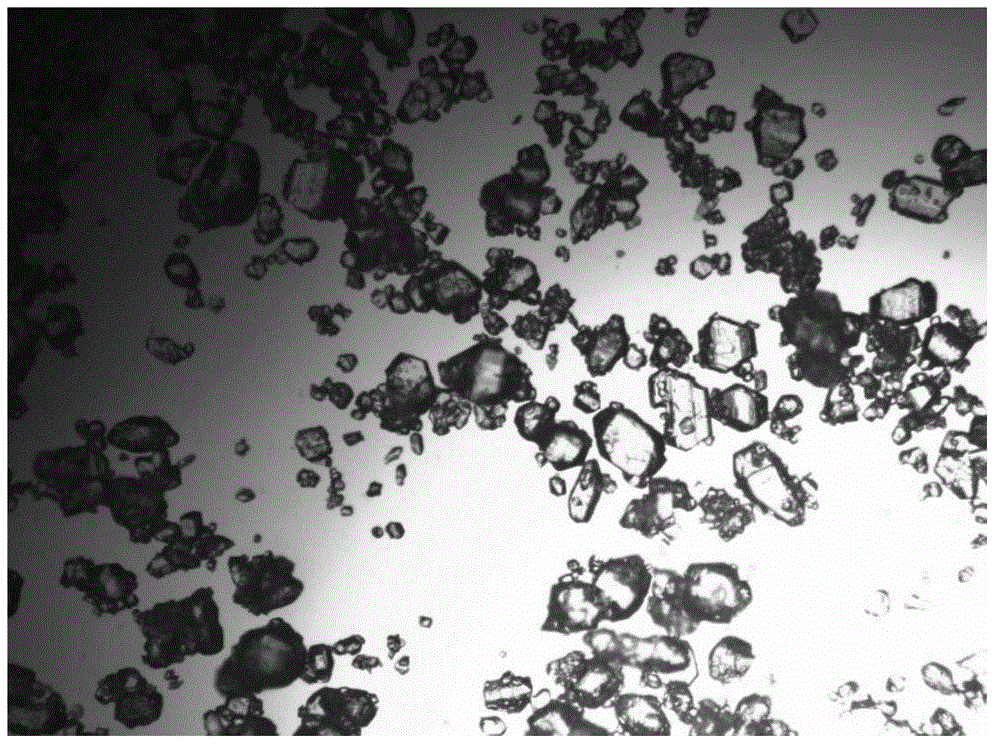

Citric acid crystal and production method thereof

A production method and technology of citric acid, applied in the separation/purification of carboxylic acid compounds, organic chemistry and other directions, can solve the problems of high energy consumption, polycrystalline citric acid crystals, uneven particle size and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Concentrate and crystallize multiple batches of citric acid feed liquid in 4 sequentially arranged crystallizers (1#, 2#, 3# and 4#), and put each batch of crystal slurry liquid obtained by concentrated crystallization into the same solid-liquid separation system solid-liquid separation in sequence;

[0053] Among them, the latter crystallizer of 4# crystallizer is the 1# crystallizer, and the time when the latter crystallizer starts to concentrate and crystallize among the two adjacent crystallizers is controlled, so that the time when the latter crystallizer ends the concentrated crystallization and the solid-liquid separation system The time difference between the end of the crystal slurry liquid obtained in the previous crystallizer is not more than 3min (the time required for the concentration and crystallization of each batch of citric acid feed liquid is 6h, and the time required for the liquid-solid-liquid separation of each batch of crystal slurry is 2h. When t...

Embodiment 2

[0056] Concentrate and crystallize multiple batches of citric acid feed liquid in 4 sequentially arranged crystallizers (1#, 2#, 3# and 4#), and put each batch of crystal slurry liquid obtained by concentrated crystallization into the same solid-liquid separation system solid-liquid separation in sequence;

[0057] Among them, the latter crystallizer of 4# crystallizer is the 1# crystallizer, and the time when the latter crystallizer starts to concentrate and crystallize among the two adjacent crystallizers is controlled, so that the time when the latter crystallizer ends the concentrated crystallization and the solid-liquid separation system The time difference between the end of the crystal slurry liquid obtained in the previous crystallizer is not more than 3min (the time required for the concentration and crystallization of each batch of citric acid feed liquid is 6h, and the time required for the liquid-solid-liquid separation of each batch of crystal slurry is 2h. When t...

Embodiment 3

[0060] Concentrate and crystallize multiple batches of citric acid feed liquid in 4 sequentially arranged crystallizers (1#, 2#, 3# and 4#), and put each batch of crystal slurry liquid obtained by concentrated crystallization into the same solid-liquid separation system solid-liquid separation in sequence;

[0061] Among them, the latter crystallizer of 4# crystallizer is the 1# crystallizer, and the time when the latter crystallizer starts to concentrate and crystallize among the two adjacent crystallizers is controlled, so that the time when the latter crystallizer ends the concentrated crystallization and the solid-liquid separation system The time difference between the end of the crystal slurry liquid obtained in the previous crystallizer is not more than 3min (the time required for the concentration and crystallization of each batch of citric acid feed liquid is 6h, and the time required for the liquid-solid-liquid separation of each batch of crystal slurry is 2h. When t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com