Direct-reverse flotation process for preparing high-purity sulfur concentrate

A forward-reverse flotation, high-purity sulfur technology, applied in flotation, solid separation, etc., can solve problems such as pyrite loss and sulfide concentrate grade reduction, and achieve the effect of reducing emissions, important environmental benefits and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

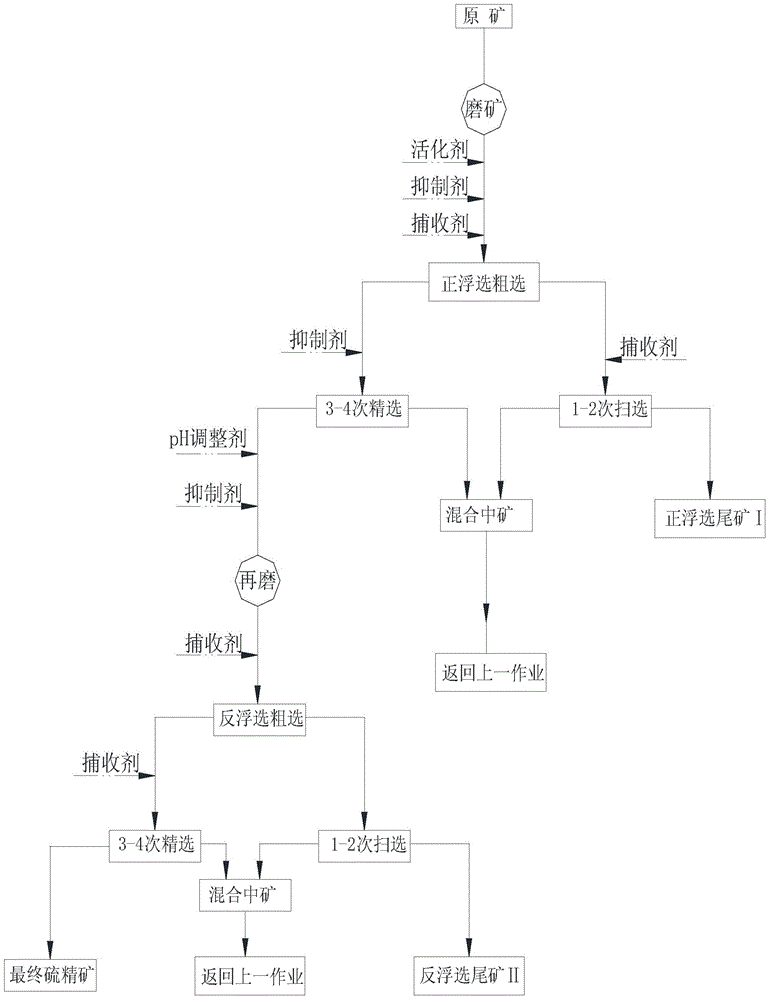

[0026] Embodiment 1, with reference to Fig. 1, a kind of forward and reverse flotation process of preparing high-purity sulfur concentrate, this process comprises the following steps:

[0027] (1) Grinding the pyrite raw ore to the grinding fineness required by the flotation operation;

[0028] (2) Add appropriate amount of activator, inhibitor water glass and xanthate anion collector to the ground pulp to carry out positive flotation of sulfur concentrate;

[0029] (3) The direct flotation operation undergoes one roughing, one to two sweepings, three to five beneficiations to obtain crude sulfur concentrate, and the middle ore from the sweeping and beneficiation operations returns to the previous operation step by step;

[0030] (4) Add appropriate amount of pH adjuster and strong oxidant to the crude sulfur concentrate obtained from the positive flotation operation and feed it into the regrinding operation;

[0031] (5) Add appropriate amount of cationic collector to the gr...

Embodiment 2

[0034] Example 2, in the step (1) of the forward and reverse flotation process for preparing high-purity sulfur concentrate described in Example 1: the grinding fineness is -200 mesh and the content reaches 51%-75%.

Embodiment 3

[0035] Example 3, in the step (1) of the forward and reverse flotation process for preparing high-purity sulfur concentrate described in Example 1: the grinding fineness is -200 mesh and the content reaches 60%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com