Measuring method of material's dynamic adsorption coefficient in vacuum state

A technology of dynamic adsorption and vacuum state, which is applied in the direction of analyzing materials and instruments, and can solve problems such as the inability to directly measure the dynamic adsorption coefficient of activated carbon

Inactive Publication Date: 2014-12-03

JIANGSU NUCLEAR POWER CORP

View PDF7 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Neither of these two types of instruments can directly measure the dynamic adsorption coefficient of activated carbon for inert gases under negative pressure.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0041] step 1

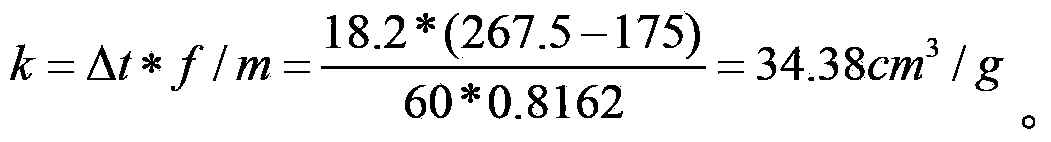

[0042] Mixed carrier gas and gas to be adsorbed Kr, the volume flow f of the mixed gas is 18.2cm 3 / min; adjust the temperature and humidity of the mixed gas.

[0043] Step 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

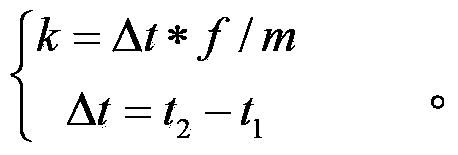

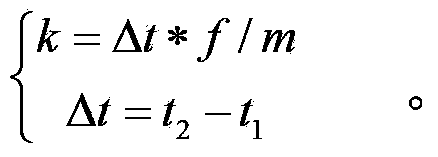

The invention belongs to the technical field of physical and chemical performance measurement of a material and specifically relates to a measuring method of a material's dynamic adsorption coefficient in a vacuum state. The method provided by the invention comprises the following steps: a, a carrier gas and a gas to be adsorbed are mixed, and temperature adjustment and humidity adjustment are carried out; b, the gas mixture which has undergone temperature adjustment and humidification passes through an adsorbing material bed without an adsorbing material and an adsorbing material bed with an adsorbing material respectively, and then the gas mixture undergoes dehumidification; the gas which has undergone dehumidification is processed by a gas chromatography-mass spectrometric method, and the time of concentration of the gas to be adsorbed in the gas mixture reaching the peak is recorded; and c, the dynamic adsorption coefficient is calculated. By the method, the technical problem that it is hard to directly measure inert-gas dynamic adsorption coefficient of activated carbon under the negative pressure condition in the prior art is solved; and by means of vacuum adjustment, temperature and humidity adjustment and the like, the dynamic adsorption coefficient of an adsorbing material under different environmental conditions is measured.

Description

Technical field [0001] The invention belongs to the technical field of material physical and chemical performance measurement, and specifically relates to a method for measuring the dynamic adsorption coefficient of a material in a vacuum state. Background technique [0002] The use of activated carbon to adsorb Ar, Kr, Xe, Rn and other radioactive inert gases is an effective method, especially in nuclear power plants, the use of activated carbon beds to adsorb and retain radioactive inert gases can effectively remove their radioactivity and protect workers. The purpose of physical health and environmental protection from pollution. [0003] The operating state of activated carbon beds in nuclear power plants is mostly negative pressure, so as to prevent the radioactivity in the system from leaking into the external environment due to positive pressure, causing environmental radioactive pollution. At present, there are two types of devices for measuring the adsorption performance ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N7/04

Inventor 魏建军张振中欧阳钦江锋张冰刘熠管玉峰

Owner JIANGSU NUCLEAR POWER CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com