Flotation method for sulfur in associated pyrites

A pyrite and flotation cell technology, which is applied in the field of beneficiation process and comprehensive utilization of resources, can solve the problems of low sulfur grade and recovery rate of sulfur concentrate, can not affect the recovery of main element iron, and lack of comprehensive recovery technology, etc., to achieve easy Industrial application, significant economic and social benefits, simple effect of process deconstruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

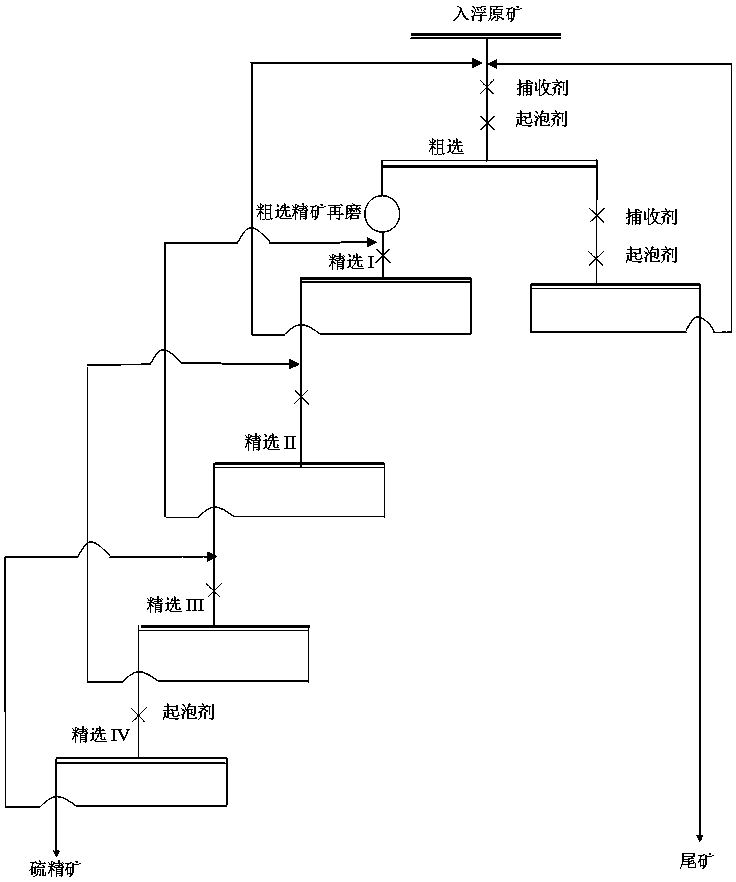

[0025] according to figure 1 As shown in the process flow, the overflow that has undergone secondary grinding and secondary classification is introduced into the stirring tank through the pipeline, water is added to adjust the pulp concentration to 33%, and isoamyl sodium xanthate is added to the stirring tank at a dosage of 250g / t, stirred for 5 minutes, then added MIBC to the stirred tank, the dosage was 90g / t, stirred for 5 minutes, and the pulp in the stirred tank was introduced into the rougher flotation tank through the pipeline for rougher selection; The dosage of medicine is 60g / t, the dosage of MIBC is 25g / t, and the supplementary dosage of MIBC for the fourth selection is 13g / t. Under the condition of not adding regulator, the first coarse, one sweep, and coarse concentrate are used for regrinding , Four times of beneficiation process, coarse concentrate regrinding concentration is 60%, grinding fineness is -0.043mm content is 88%, total sulfur grade can be obtained...

Embodiment 2

[0027] according to figure 1 As shown in the process flow, the overflow that has undergone secondary grinding and secondary classification is introduced into the stirring tank through the pipeline, water is added to adjust the pulp concentration to 20%, and isoamyl sodium xanthate is added to the stirring tank at a dosage of 250g / t, stirred for 5 minutes, then added MIBC to the stirred tank, the dosage was 90g / t, stirred for 5 minutes, and the pulp in the stirred tank was introduced into the rougher flotation tank through the pipeline for rougher selection; The dosage of medicine is 60g / t, the dosage of MIBC is 25g / t, and the supplementary dosage of MIBC for the fourth selection is 13g / t. Under the condition of not adding regulator, the first coarse, one sweep, and coarse concentrate are used for regrinding , Four times of beneficiation process, coarse concentrate regrinding concentration is 60%, grinding fineness is -0.043mm content is 88.16%, total sulfur grade can be obtai...

Embodiment 3

[0029] according to figure 1 As shown in the process flow, the overflow after the second-stage grinding-secondary classification is introduced into the stirring tank through the pipeline, water is added to adjust the pulp concentration to 33%, and isoamyl sodium xanthate is added to the stirring tank at a dosage of 200g / t, stirred for 5 minutes, then added MIBC into the stirred tank, the dosage was 120g / t, stirred for 5 minutes, and the pulp in the stirred tank was introduced into the rougher flotation tank through the pipeline for rough selection; The dosage of medicine is 50g / t, the dosage of MIBC is 30g / t, and the supplementary dosage of MIBC for the fourth selection is 13g / t. Under the condition of not adding regulator, the first coarse, one sweep, and coarse concentrate are used for regrinding , Four times of beneficiation process, coarse concentrate regrinding concentration is 66%, grinding fineness is -0.043mm content is 88%, total sulfur grade can be obtained is 42.34...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com