Two-stage acidification and flotation process of nickel-copper sulfide ore

A nickel sulfide and flotation technology, which is applied in flotation, solid separation, grain processing, etc., can solve the problems of affecting chemicals, reducing the buoyancy of minerals, and restricting the recovery rate of beneficiation, so as to improve the grade of concentrate and reduce the floatability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

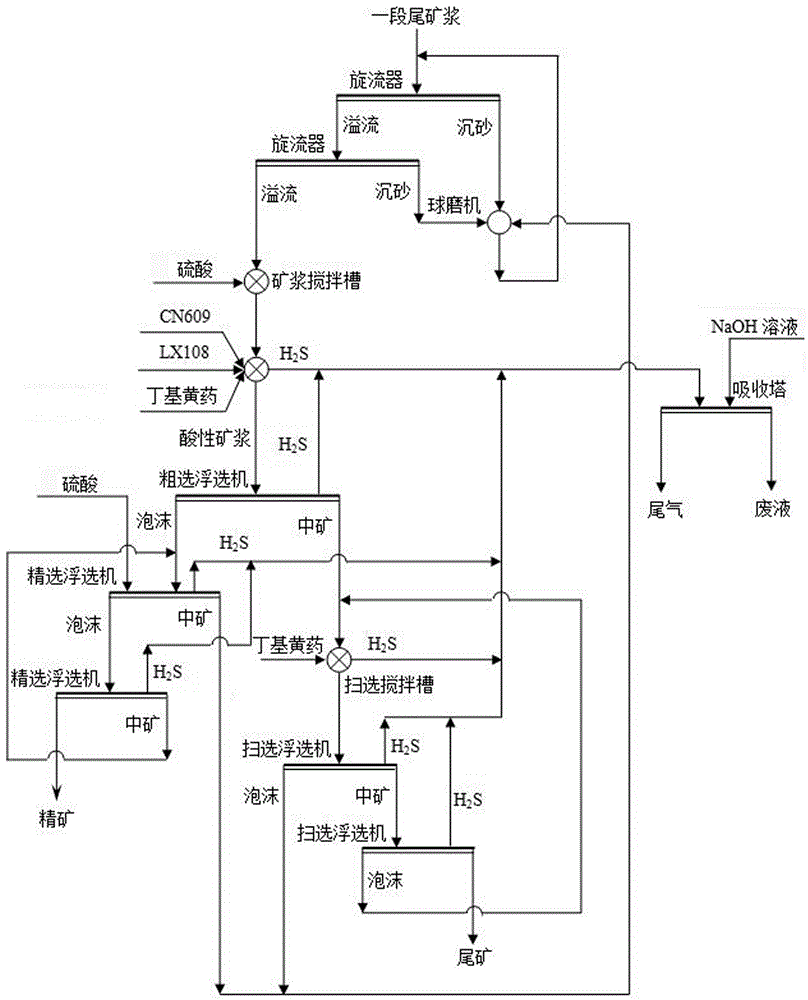

[0021] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0022] The second-stage acid-added flotation process includes: raw ore preparation stage, acid-added pulping stage, flotation stage and waste gas treatment stage;

[0023] The preparation stage of raw ore includes grinding and grading process to provide pulp with required fineness and concentration for the flotation machine;

[0024] The stage of adding acid and sizing includes the process of adding acid to the pulp and adding the flotation agent, so that the pH value of the pulp meets the requirements of acid flotation, and at the same time, the flotation agent added to the pulp is stirred evenly;

[0025] The flotation stage includes one roughing, two beneficiation, two sweeps, acid addition of concentrate and chemical addition of sweep, so as to obtain the final concentrate product and tailings waste;

[0026] The waste gas treatment stage is to absorb the hydroge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com